Process and device for purifying sulfuric acid phase in iodine and sulfur cycle under low pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

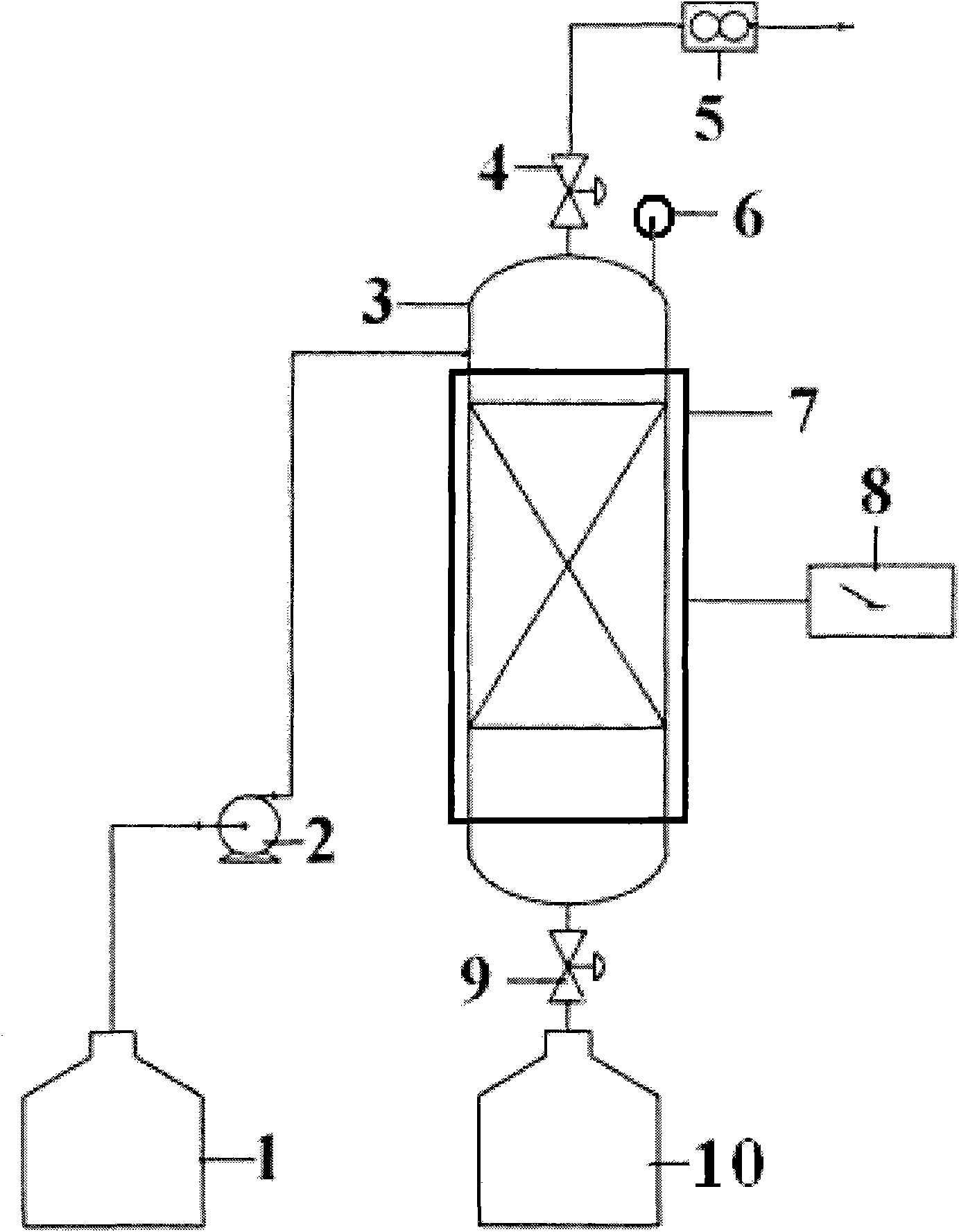

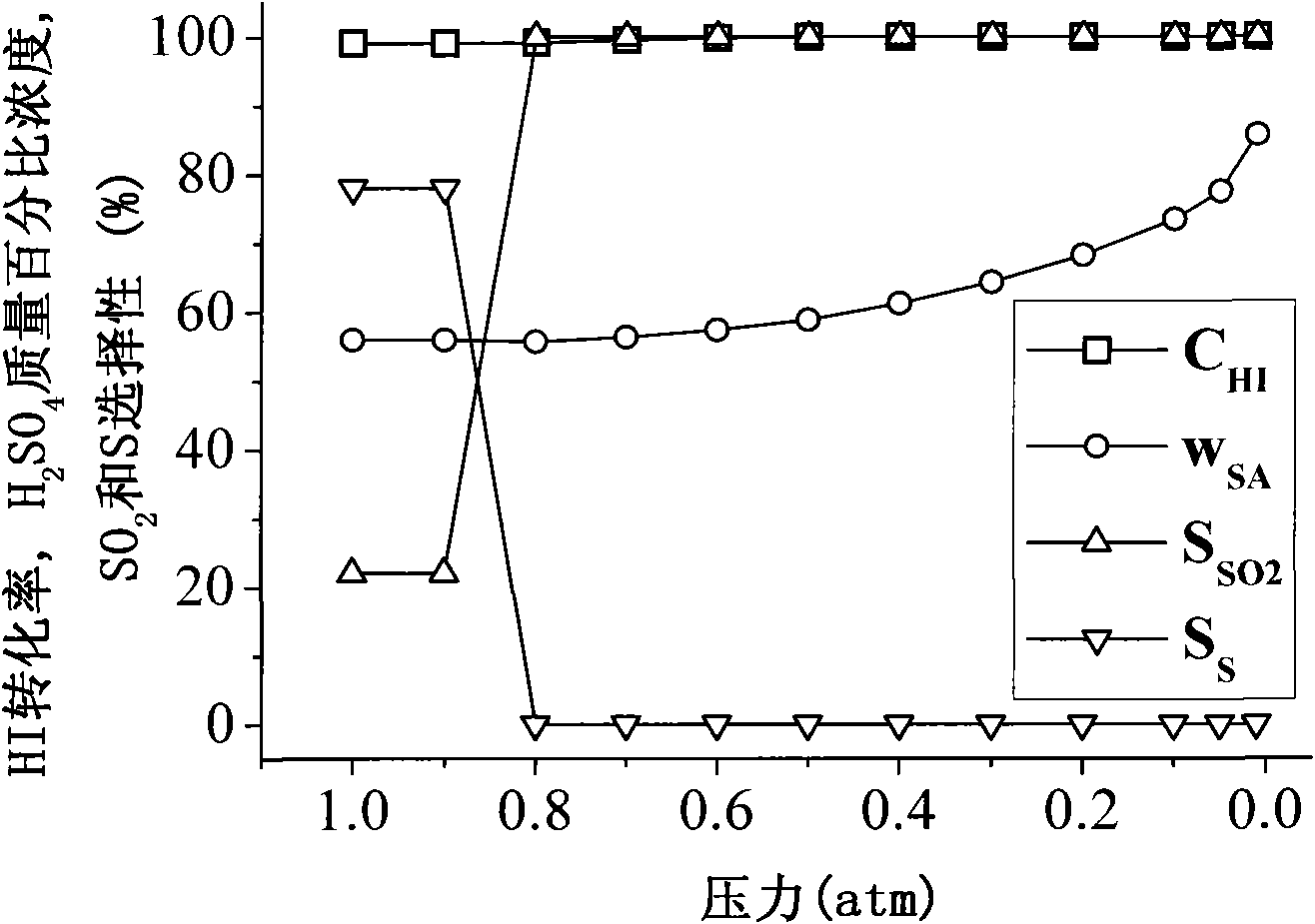

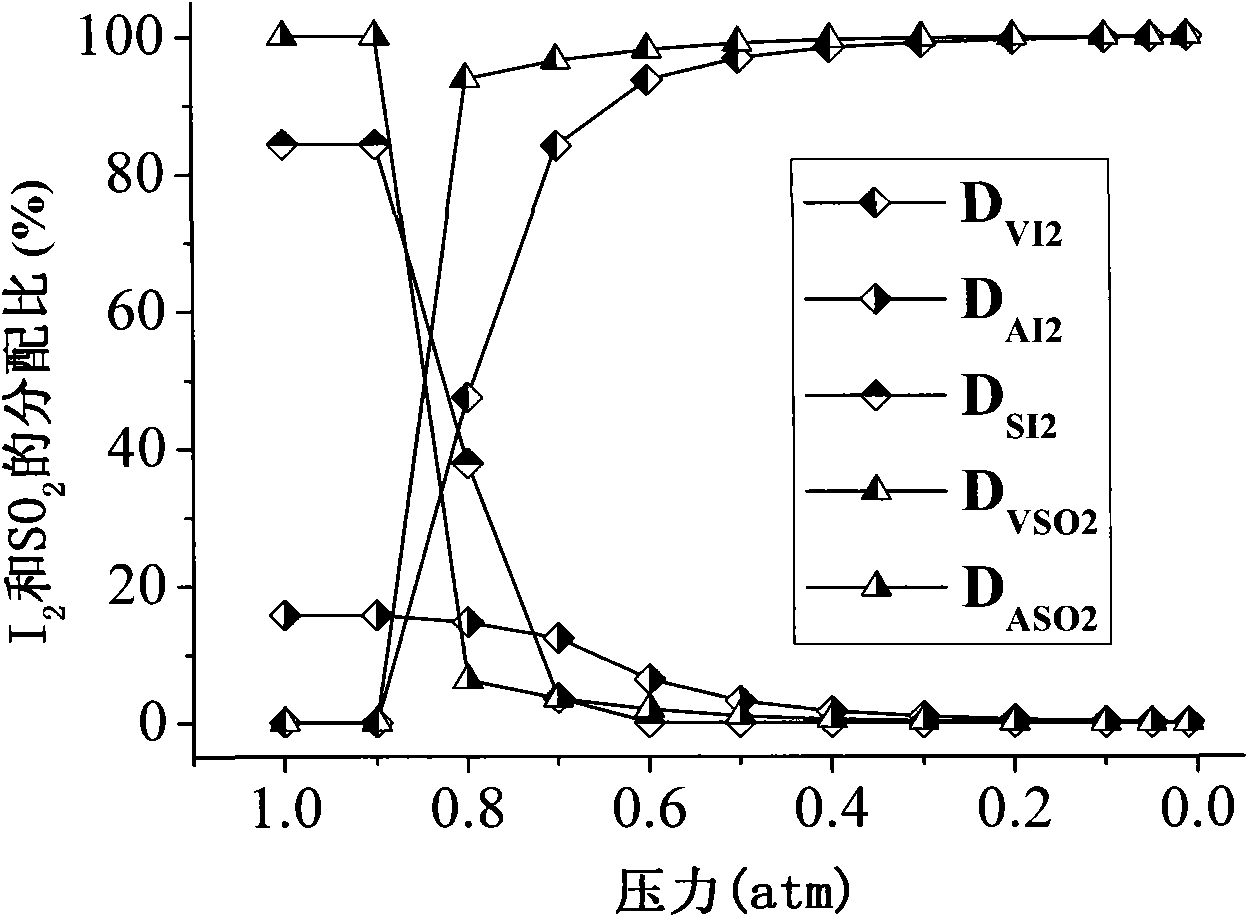

[0033] First, the purification and concentration tower (such as figure 1 Shown) heating up to 110°C, using a vacuum control pump to control the pressure P of the purification and concentration tower to 1atm (as a comparison), 0.9atm, 0.8atm, 0.7atm, 0.6atm, 0.5atm, 0.4atm, 0.3atm, 0.2 atm, 0.1atm, 0.05atm, 0.01atm, through the liquid flow control pump will be composed into H 2 SO 4 +0.1HI+4H 2 O (ie molar ratio H 2 SO 4 :HI:H 2 (0=1: 0.1: 4) sulfuric acid phase, input from the upper feed port of the purification and concentration tower, the liquid flow rate of the control sulfuric acid phase is 183g / h, and the sulfuric acid phase flows through the purification and concentration tower of temperature control temperature and low pressure, a small amount of in the sulfuric acid phase The reverse reaction of Benson's reaction between hydroiodic acid and partial sulfuric acid: H 2 SO 4 +2HI=SO 2 +I 2 +2H 2 O, the SO obtained from the purification reaction 2 , I 2 and H ...

Embodiment 2

[0036] First, the purification and concentration tower (such as figure 1 Shown) heating up to 60°C, using a vacuum control pump to control the pressure P of the purification and concentration tower to 0.1atm, 0.09atm, 0.08atm, 0.07atm, 0.06atm, 0.05atm, 0.04atm, 0.03atm, 0.02atm, 0.01 atm, by liquid flow control pump will be composed into H 2 SO 4 +0.1HI+4H 2 O (ie molar ratio H 2 SO 4 :HI:H 2 (0=1: 0.1: 4) sulfuric acid phase, input from the upper feed port of the purification and concentration tower, the liquid flow rate of the control sulfuric acid phase is 183g / h, and the sulfuric acid phase flows through the purification and concentration tower of temperature control temperature and low pressure, a small amount of in the sulfuric acid phase The reverse reaction of Benson's reaction between hydroiodic acid and partial sulfuric acid: H 2 SO 4 +2HI=SO 2 +I 2 +2H 2 O, the SO obtained from the purification reaction 2 , I 2 and H 2 O is extracted from the exhaust p...

Embodiment 3

[0039] First, the purification and concentration tower (such as figure 1 Shown) heating up to 60°C, 80°C, 100°C, 120°C, 140°C, 160°C, 180°C, 200°C respectively, using the vacuum control pump to control the pressure P of the purification and concentration tower to 0.06atm, and control the The pump will consist of H 2 SO 4 +0.1HI+4H 2 O (ie molar ratio H 2 SO 4 :HI:H 2 (0=1: 0.1: 4) sulfuric acid phase, input from the upper feed port of the purification and concentration tower, the liquid flow rate of the control sulfuric acid phase is 183g / h, and the sulfuric acid phase flows through the purification and concentration tower of temperature control temperature and low pressure, a small amount of in the sulfuric acid phase The reverse reaction of Benson's reaction between hydroiodic acid and partial sulfuric acid: H 2 SO 4 +2HI=SO 2 +I 2 +2H 2 O, the SO obtained from the purification reaction 2 , I 2 and H 2 O is extracted from the exhaust port at the upper end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com