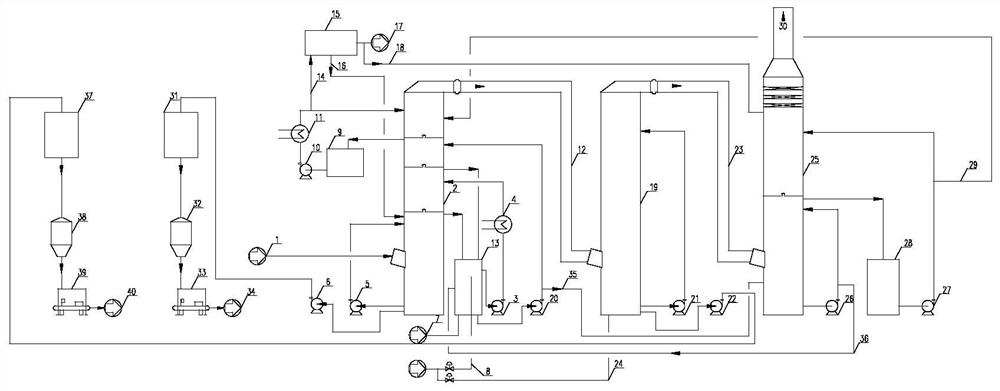

Ammonia-process desulfurization and decarbonization integrated device and method

An ammonia desulfurization and decarbonization technology, applied in chemical instruments and methods, ammonia compounds, fertilization devices, etc., can solve the problem of high investment and operating costs, increased investment and operating costs, and inability to crystallize ammonium sulfate, a by-product of desulfurization, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0055] Sulfurized oxidation, CO 2 Coal Boiler Flue Gas (Work Art Gas) Enter the above desulfurization deproprocarbon integrated device, desulfurization decarburization is 20% ammonia water, and the process gas (boiler flue gas) parameter is shown in the table:

[0056] Serial number project Numerical value 1 Volume, nm 3 / h

560000 2 Temperature, ° C 160 3 SO 2 Content, mg / nm 3

4500 4 CO 2 Content, V%

12 5 Hide 2 O content, V%

5.48 6 O 2 Content, V%

8.65

[0057] The main parameters treated by the desulfurization system are shown in the table:

[0058] Serial number project Numerical value 1 Destination Tower Export Quality, NM 3 / h

528326 2 Debulfur outlet temperature, ° C 18 3 Destination Tower Export SO 2 Content, PPM

<5 4 Destination Tower Export CO 2 Content, V%

12.7 5 Debulfur Tower Export H 2 O content, V%

2.0 6 Branch amounts of ammonium sulfate, t / h 5....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com