Desulphurization method for acid gas

An acid gas and air technology, applied in the field of acid gas desulfurization process, can solve the problems of inappropriate addition of ammonia recovery devices, increase the burden of water treatment and operating costs, and achieve the effects of saving investment and operating costs, short process flow and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

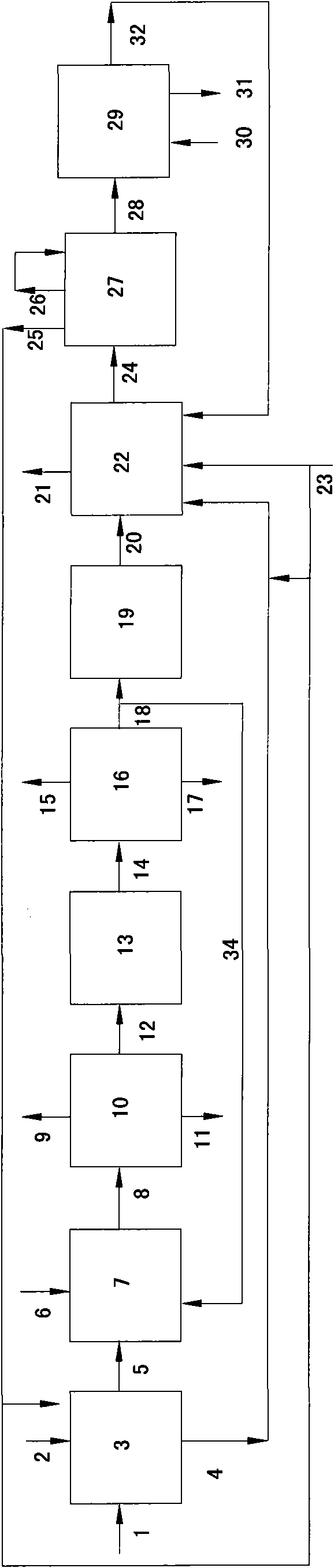

[0058] figure 1 It is a schematic flow chart of the acid gas desulfurization process described in the present invention. Such as figure 1 Shown, acid gas 1 and scrubbing liquid 2 from pipeline enter ammonia scrubbing device 3 and the ammonia in acid gas is washed off, and the scrubbing rate to ammonia (the weight percent of the ammonia in the washed ammonia and acid gas) can be 1-99%, if the acid gas does not contain ammonia, the ammonia washing device 3 can be canceled, and in this case the ammonia required in the inventive process can be purchased or come from other devices in the factory. The washing liquid 2 can be demineralized water. The liquid part of the ammonia washing device 3 is the waste water 4 containing ammonia and a small amount of hydrogen sulfide, which goes to the absorbing device 22 for washing sulfur dioxide for sulfur dioxide absorption and washing. The gas 5 from the ammonia washing device 3 enters the acid gas combustion device 7 . Ammonia, hydrogen...

Embodiment 2

[0075] The process is the same as in Example 1, except that the acid gas in the pipeline does not contain ammonia, and the ammonia washing device 3 is omitted.

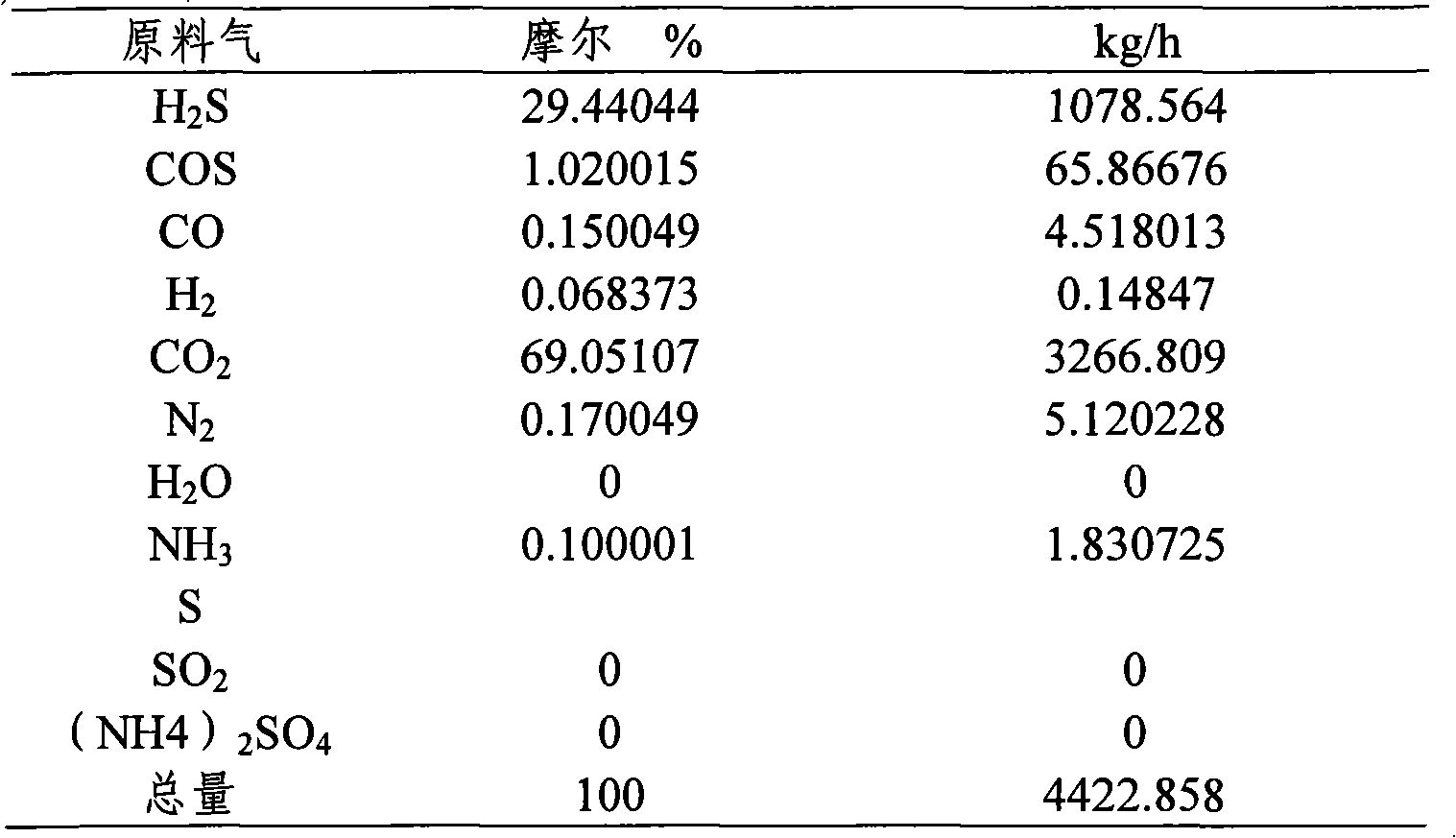

[0076] The composition of the acid gas in the pipeline is as follows:

[0077]

[0078]

[0079] The acid gas enters the combustion device, the acid gas entering the main burner is 5%, the combustion temperature is 500°C, the acid gas entering the main combustion chamber is 95%, the combustion temperature is 950°C, and the required catalyst amount is: 3.9M 3 , the catalytic reduction temperature is 210°C, and the incineration temperature is 1200°C. After combustion and catalytic reaction, 506.4kg / h of sulfur is obtained, including 1084kg / h of SO 2 Absorbed by ammonia, the concentration of purchased ammonia water is 20%, the temperature for eluting sulfur dioxide is 50°C, the spray pressure is 0.8MPa, the vacuum degree used by the falling film evaporator is 0.06MPa, and finally ammonium sulfate is generated at 22...

Embodiment 3

[0082] The process is the same as in Example 1, except that the acid gas in the pipeline does not contain ammonia, and the ammonia washing device 3 is omitted.

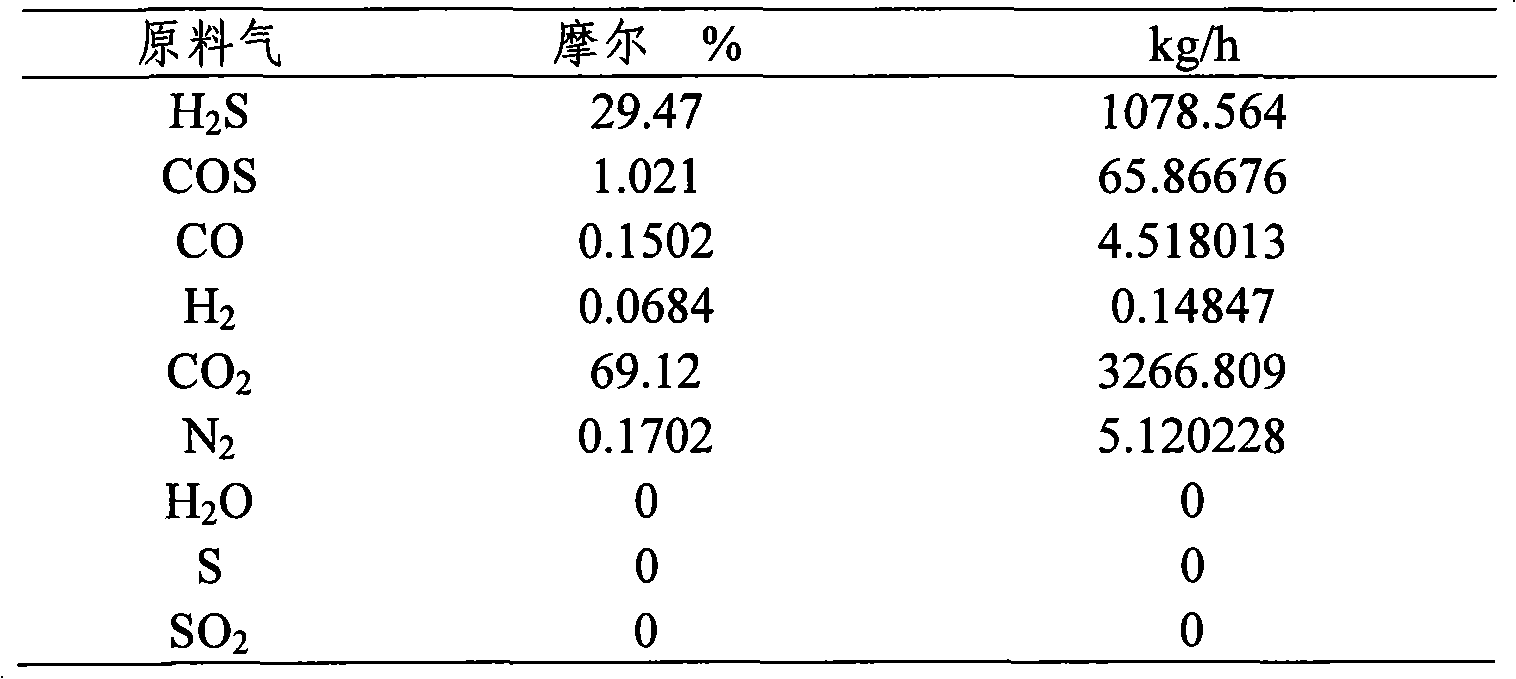

[0083] The composition of the acid gas in the pipeline is as follows:

[0084]

[0085] The acid gas enters the combustion device, the acid gas entering the main burner is 90%, the combustion temperature is 980°C, the acid gas entering the main combustion chamber is 10%, the combustion temperature is 750°C, and the required catalyst amount is: 2.8M 3 , the catalytic reduction temperature is 230°C, and the incineration temperature is 800°C. After combustion and catalytic reaction, 572.6kg / h of sulfur is obtained, including 2745kg / h of SO 2 Absorbed by ammonia, the concentration of purchased ammonia water is 20%, the temperature when eluting sulfur dioxide is 10°C, the spray pressure is 1.5MPa, the vacuum degree used by the falling film evaporator is 0.01MPa, and finally produces ammonium sulfate 5661.8kg / h .

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com