Method for refining industrial coarse iodine

An industrial and iodine quantity technology, applied in the directions of iodine, iodine/hydrogen iodide, etc., can solve the problems of high impurity content in iodine products, difficult to industrialize production, outdated and outdated processes, etc., to improve product added value, easy industrialization, and appearance regular effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

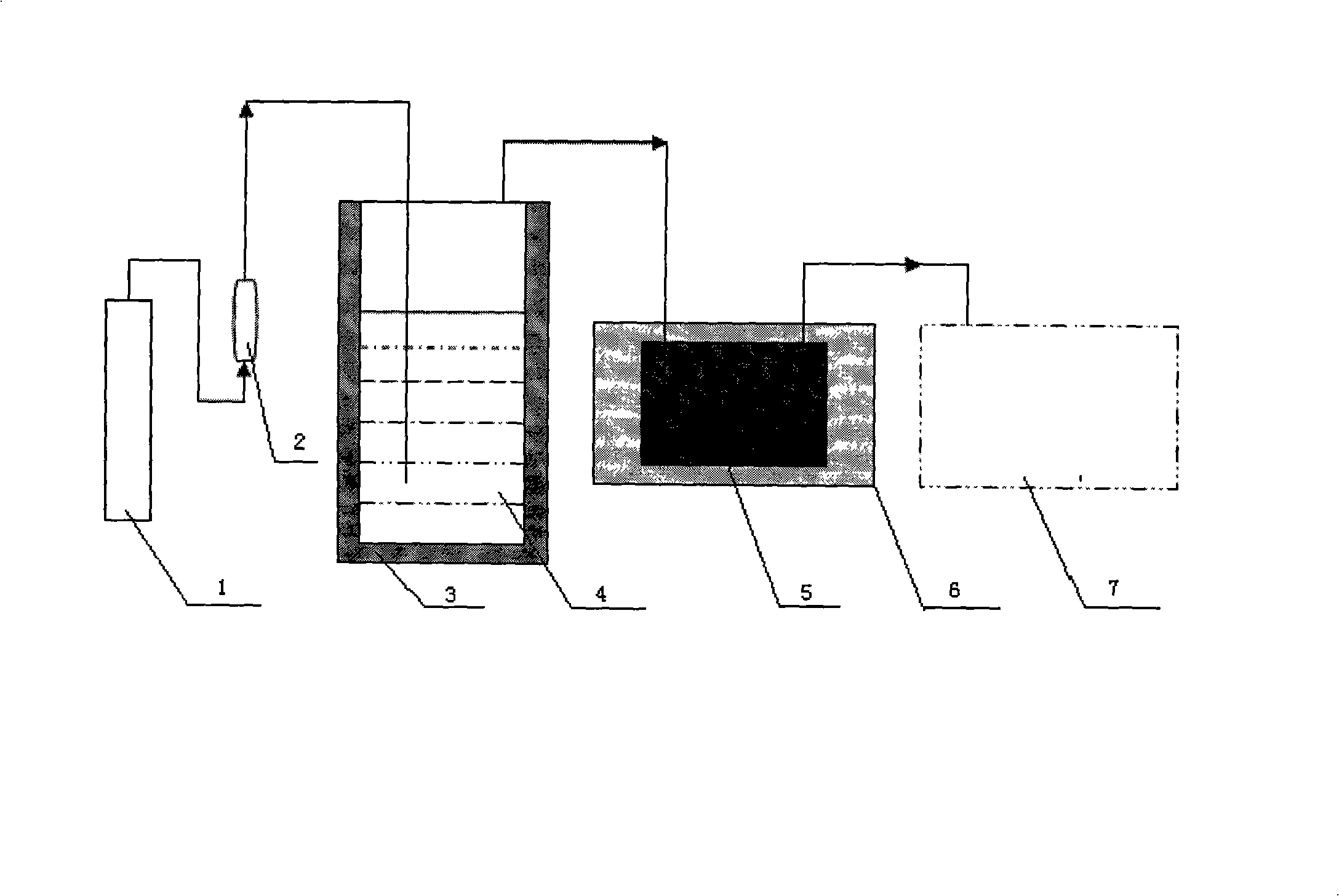

Image

Examples

Embodiment 1

[0013] Take 300.21 kg of crude iodine with an iodine content of 70.18% and add it to the jacketed sublimator of concentrated sulfuric acid with 50L98% of gas blowing device installed, adjust the ambient temperature of the crystallization device to 20°C, turn on the circulation heating system switch, and Circulate heating glycerin to heat the sublimator to 60°C, adjust the gas flow meter, and pass 8.00L / min dry air through the gas distributor at the bottom of the sublimator to start sublimation of iodine into the crystallizer and keep it for 60min. Adjust the circulation heating system, raise the temperature to 160°C, adjust the gas flow meter, so that the gas flow rate is 1.20L / min into the sublimator, keep for 40min to collect the remaining iodine, then close the gas switch and the valve of the circulation heating system. Gained smart iodine in the crystallizer is 204.08kg.

[0014] After testing, the content of elemental iodine in refined iodine is 99.98%. The recovery rate...

Embodiment 2

[0016] Take 250.19 kg of crude iodine with an iodine content of 95.28% and add it to a jacketed sublimator equipped with a gas blowing device and added 50L of 98% concentrated sulfuric acid, adjust the ambient temperature of the crystallization device to 20°C, and turn on the circulation heating system switch , put in circulation to heat glycerin to heat the sublimator to 90°C, adjust the gas flow meter, and pass 10.00L / min dry N2 through the gas distributor at the bottom of the sublimator, so that iodine starts to sublimate and enter the crystallizer, keep it for 40min, and adjust the cycle Heating the system, raising the temperature to 200°C, adjusting the gas flow meter so that the gas flow rate is 1.10L / min into the sublimator, keeping for 50 minutes to collect the remaining iodine, closing the gas switch and the valve of the circulating heating system. Gained smart iodine in the crystallizer is 235.52kg.

[0017] After testing, the content of elemental iodine in refined i...

Embodiment 3

[0019] Get the crude iodine 200.38kg that iodine content is 82.41% and join in the jacket type sublimator that gas blowing device is housed and the concentrated sulfuric acid of 50L98% has been added, adjust crystallization device ambient temperature to 20 ℃, turn on the circulation heating system switch, pass Circulate heating glycerin to heat the sublimator to 100°C, adjust the gas flow meter, and pass 14.00L / min dry air through the gas distributor at the bottom of the sublimator to start sublimation of iodine into the crystallizer and keep it for 80 minutes. Adjust the circulation heating system, raise the temperature to 190°C, adjust the gas flow meter, so that the gas flow rate is 1.00L / min into the sublimator, keep for 60 minutes to collect the remaining iodine, and close the gas switch and the valve of the circulation heating system. Gained smart iodine in the crystallizer is 163.94kg.

[0020] After testing, the content of elemental iodine in refined iodine is 99.99%. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com