Method for extracting iodine from dehydrate wet method diluted phosphoric acid reaction iodic waste gas

A method of phosphoric acid and iodine extraction technology, applied in the field of phosphoric acid to achieve the effects of improving atmospheric environment, good environmental protection effect and large benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

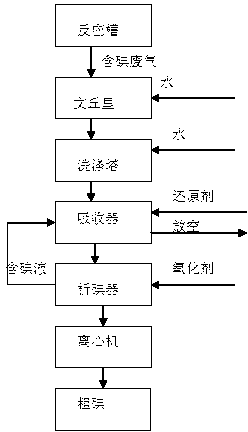

Method used

Image

Examples

Embodiment 1

[0021] A factory adopts the technology of the present invention to extract iodine from the iodine-containing waste gas of dihydrate wet-process phosphoric acid reaction, and the specific scheme is as follows:

[0022] ① Collect the mass fraction of iodine in the reaction waste gas of dihydrate wet-process phosphoric acid to be 3×10 -6 ~10×10 -6 For the iodine-containing gas, the fluorine in the reaction exhaust gas is first washed with Venturi scrubber and scrubber with water;

[0023] ② The iodine-containing waste gas enters the packed iodine absorption tower after removing fluorine, fills the sealing tank of the iodine absorption tower with 10000 kg of water, and continuously feeds the absorbent SO into the sealing tank of the iodine absorption tower 2 ; The amount of absorbent added is 1kg / h;

[0024] ③ Use a perfluorinated washing circulation pump to pump the liquid in the sealing tank into the iodine absorption tower for spraying and circulating washing;

[0025] ④ The...

Embodiment 2

[0029] A factory adopts the technology of the present invention to extract iodine from the iodine-containing waste gas of dihydrate wet-process phosphoric acid reaction, and the specific scheme is as follows:

[0030] ① Collect the mass fraction of iodine in the reaction waste gas of dihydrate wet-process phosphoric acid to be 3×10 -6 ~10×10 -6 For the iodine-containing gas, the fluorine in the reaction exhaust gas is first washed with Venturi scrubber and scrubber with water;

[0031] ② The iodine-containing waste gas enters the packed iodine absorption tower after removing fluorine, fills the sealing tank of the iodine absorption tower with 10000 kg of water, and continuously feeds the absorbent SO into the sealing tank of the iodine absorption tower 2 ; The amount of absorbent added is 5kg / h;

[0032] ③ Use a perfluorinated washing circulation pump to pump the liquid in the sealing tank into the iodine absorption tower for spraying and circulating washing;

[0033] ④ The...

Embodiment 3

[0037] A factory adopts the technology of the present invention to extract iodine from the iodine-containing waste gas of dihydrate wet-process phosphoric acid reaction, and the specific scheme is as follows:

[0038] ① Collect the mass fraction of iodine in the reaction waste gas of dihydrate wet-process phosphoric acid to be 3×10 -6 ~10×10 -6 For the iodine-containing gas, the fluorine in the reaction exhaust gas is first washed with Venturi scrubber and scrubber with water;

[0039] ② The iodine-containing waste gas enters the packed iodine absorption tower after removing fluorine, fills the sealing tank of the iodine absorption tower with 10,000 kg of water, and continuously adds sulfur into the sealing tank of the iodine absorption tower; the amount of absorbent added is 3kg / h;

[0040] ③ Use a perfluorinated washing circulation pump to pump the liquid in the sealing tank into the iodine absorption tower for spraying and circulating washing;

[0041] ④ The exhaust gas i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com