Apparatus for recycling iodine from diluted phosphoric acid for phosphoric acid manufacture with wet-process

A technology of wet-process phosphoric acid and dilute phosphoric acid, applied in the directions of iodine, iodine/hydrogen iodide, etc., can solve the problems of high iodine content requirements of raw materials, high production costs, and high production and operation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

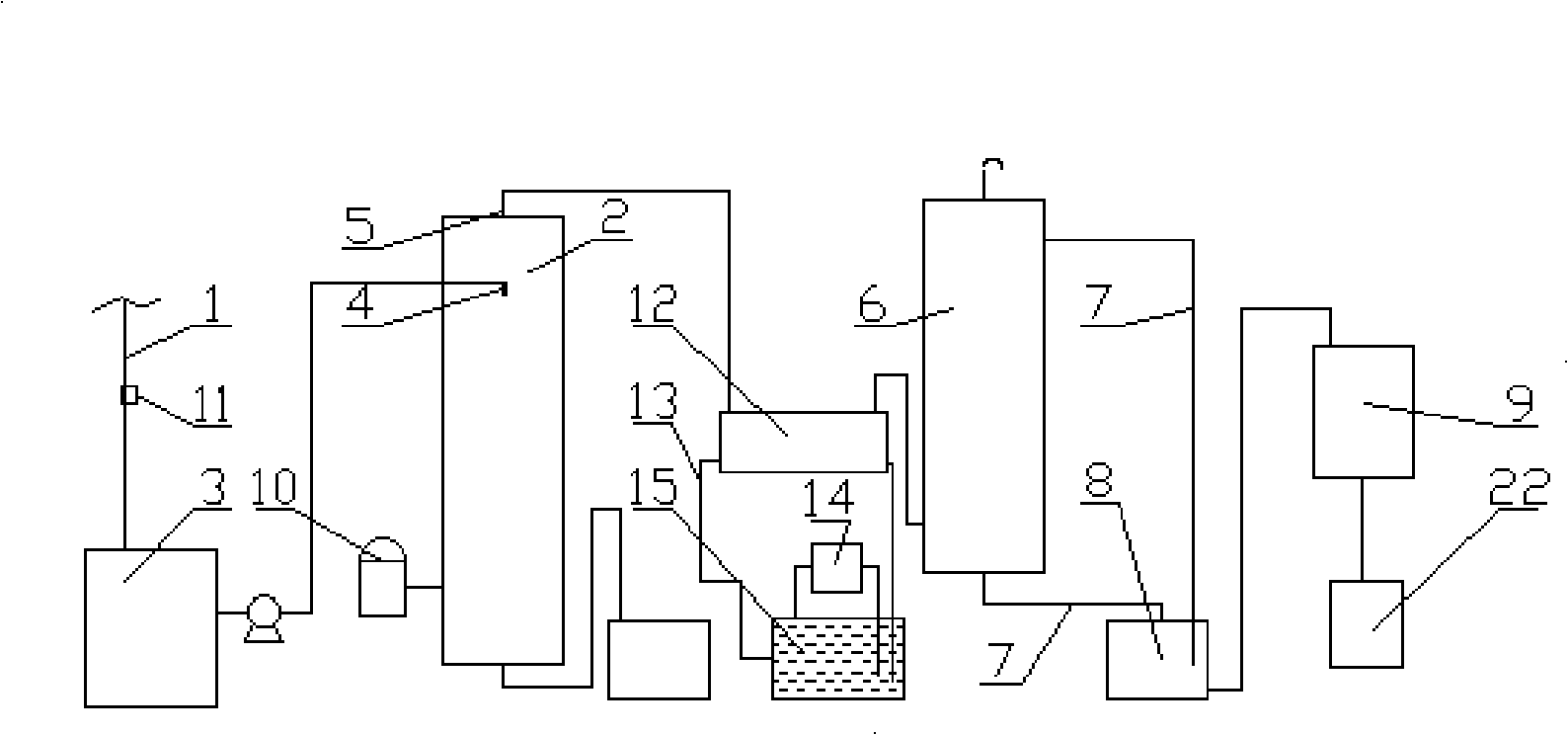

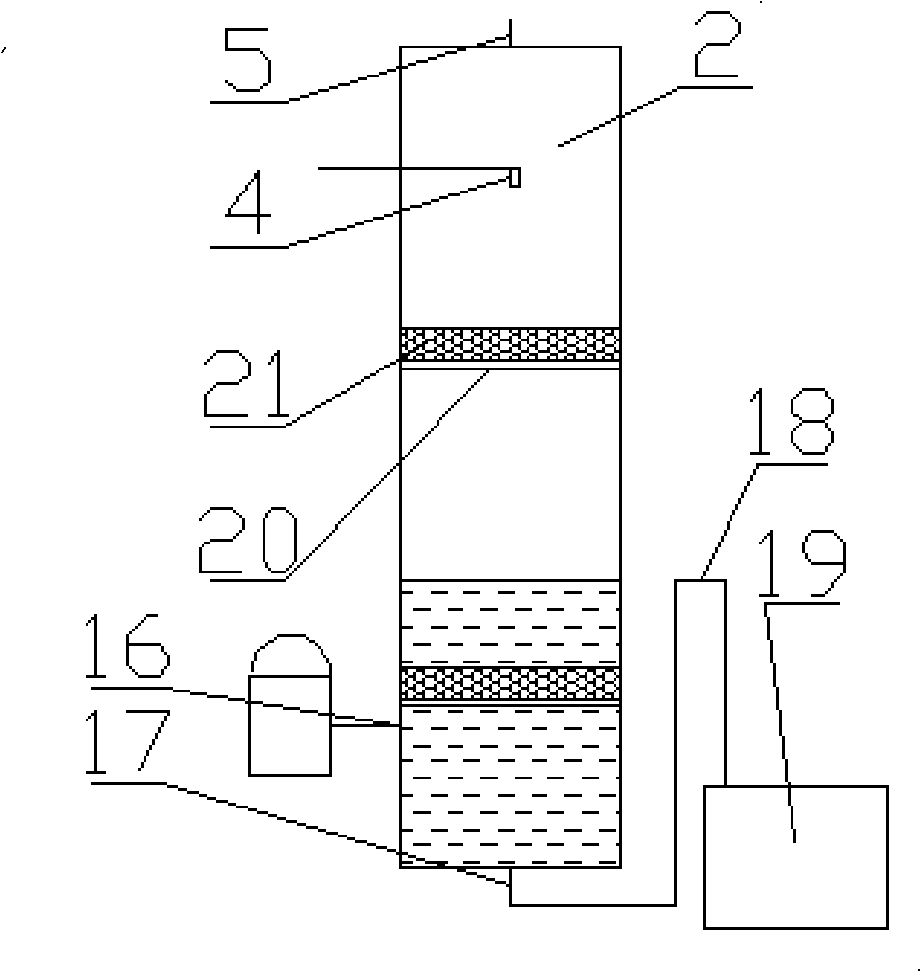

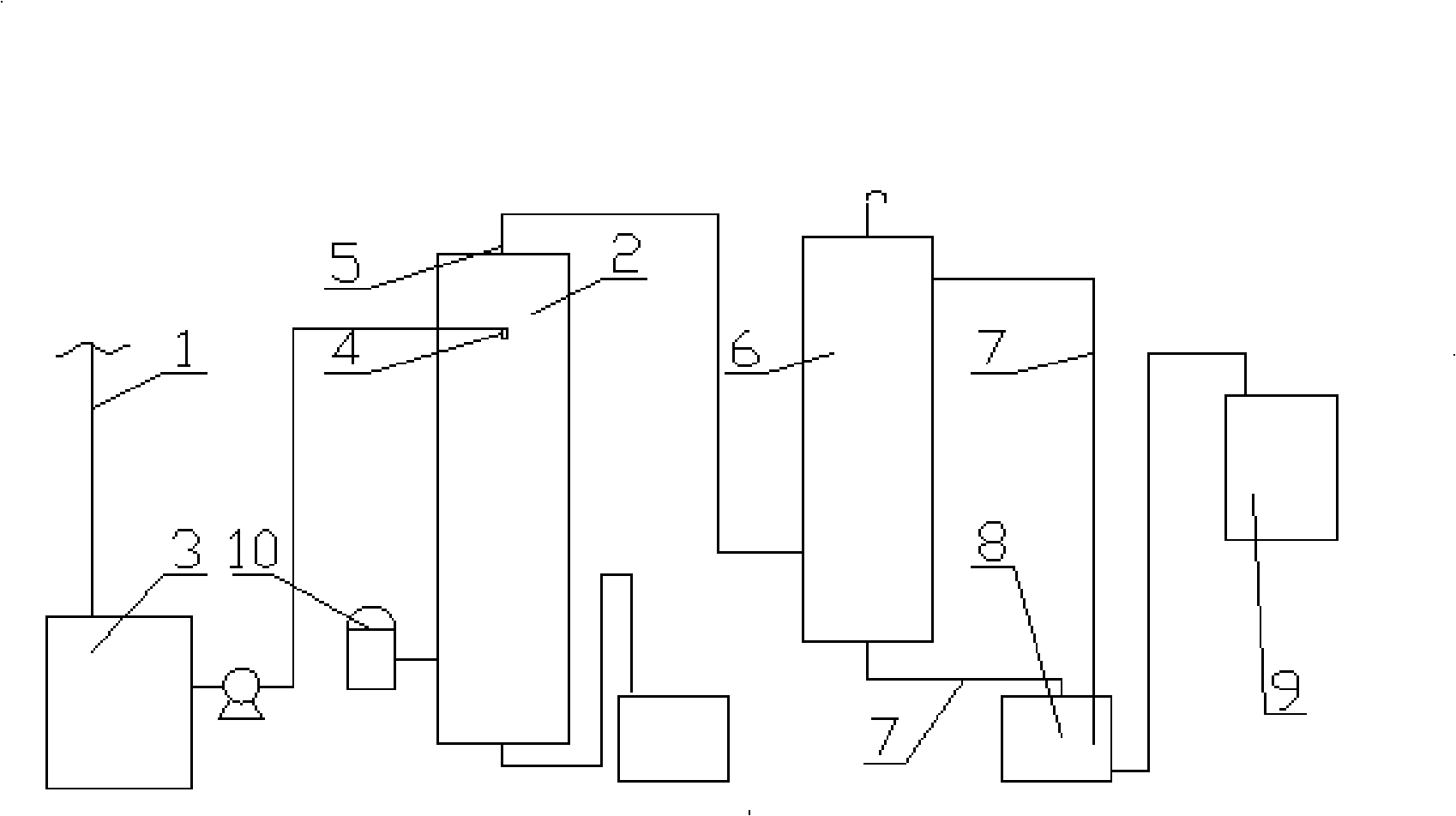

[0019] Embodiment 1 of the present invention: Connect pipeline 1 from the existing phosphate rock production flow device, introduce dilute phosphoric acid, pipeline 1 is connected to oxidation tank 3, and oxidation tank 3 is connected to spray pipe 4 above extraction tower 2 by pipeline , is connected with blower 10 below extraction tower 2, provides the air that extracts, and the air outlet 5 on extraction tower 2 top is connected packing absorption tower 6 by pipeline, and the iodine extracted from air is carried out circulation absorption by absorption liquid, and packing absorption tower The absorption liquid pipeline 7 of 6 connects collection tank 8, and collection tank 8 connects iodine analysis tank 9 behind, after the iodine in the absorption liquid absorbs saturation, then by analysis iodine tank 9, iodine crystallization is separated out.

[0020] In the present invention, an oxidizing agent can be added into the oxidation tank, and the oxidation reaction of the iodi...

Embodiment 2

[0026] Embodiment 2 of the present invention: Connect pipeline 1 from the existing phosphate rock production process device, introduce dilute phosphoric acid, pipeline 1 is connected to oxidation tank 3, oxidant is added in oxidation tank 3, oxidation tank 3 is connected to extraction tower through pipeline The spray pipe 4 above the 2 is connected with a blower 10 below the extraction tower 2 to provide air for extraction, and the air outlet 5 above the extraction tower 2 is connected to the packed absorption tower 6 through a pipeline, and the iodine extracted from the air by the absorption liquid Carry out cyclic absorption, the absorption liquid pipeline 7 of packing absorption tower 6 connects collection tank 8, and the back of collection tank 8 connects analysis iodine tank 9, after the iodine absorption in the absorption liquid is saturated, then by analysis iodine tank 9, iodine crystallization is separated out.

[0027] Working process: Phosphoric acid is produced from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com