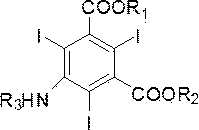

Method for recycling iodine from production waste liquid of X-CT series contrast agents

A technology of X-CT and recovery method, applied in the direction of iodine, iodine/hydrogen iodide, etc., can solve the problems of large consumption of oxidant, affecting normal production, and high production cost, achieving low production cost, wide range of use, and low equipment requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Take 500 ml of iohexol production waste liquid in the X-CT series of contrast media (with I + Calculate, containing iodine 15.2 g / L) In the normal pressure reflux device, add NaOH to adjust the pH to 12, and add 0.3 g of zinc powder, heat to boil and reflux for 0.5 hours, and then concentrate to 2 / 3 of the original volume. Cool to room temperature, by adding H 2 SO 4 Adjust the pH to 1.0-3.0, slowly add 10 ml 30% H 2 O 2 , And keep stirring. Allow the reaction for 20 minutes, cool and stand for 20 minutes, filter, and collect 4.8 g of crude iodine. Return the filtrate to the reactor, and slowly add 2 mL saturated FeCl under stirring 3 For the solution, determine the end point of the oxidation reaction by the potential monitoring method, stand for 20 minutes, filter, and collect 2.4 g crude iodine. Then, dichloroethane is used as the extractant to continuously extract the remaining elemental iodine in the waste liquid in multiple stages until the color of the extract liqu...

Embodiment 2

[0033] Take 3 L of iohexol production waste liquid in the X-CT series of contrast media (with I + Calculate, containing 14.6 g / L of iodine) In an atmospheric reactor with reflux device, add NaOH to adjust the pH to 14, and add 3.0 g of zinc powder, heat to boil and reflux for 0.5 hours, and then concentrate to 2 / 3 of the original volume. Cool to room temperature, by adding H 2 SO 4 Adjust the pH to 1.0-3.0, slowly add 25 ml 30% H 2 O 2 , And keep stirring. Allow to react for 30 minutes, cool and stand for 40 minutes, filter, and collect 31.7 g of crude iodine. Return the filtrate to the reactor, and slowly add 10 mL saturated FeCl under stirring 3 Determine the end point of the oxidation reaction of the solution by potential monitoring, let it stand for 20 minutes, filter, and collect 13.9 g of crude iodine. Then, dichloroethane is used as the extractant to continuously extract the remaining elemental iodine in the waste liquid in multiple stages until the color of the extract ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com