Method for preparing potassium iodide by using micro-channel reactor

A micro-channel reactor, potassium iodide technology, applied in the direction of alkali metal iodide, etc., can solve the problems of narrow product application field, harsh production conditions, and many three wastes, etc., achieves simple and easy preparation method, widened application field, Overcome unsafe effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

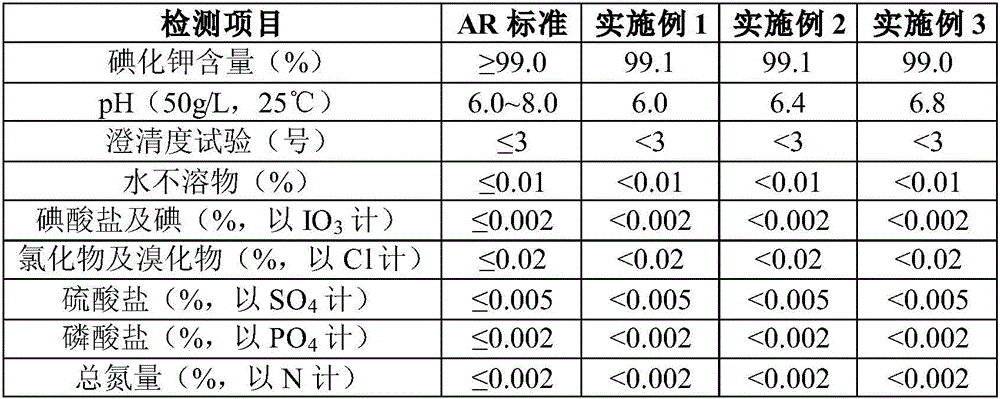

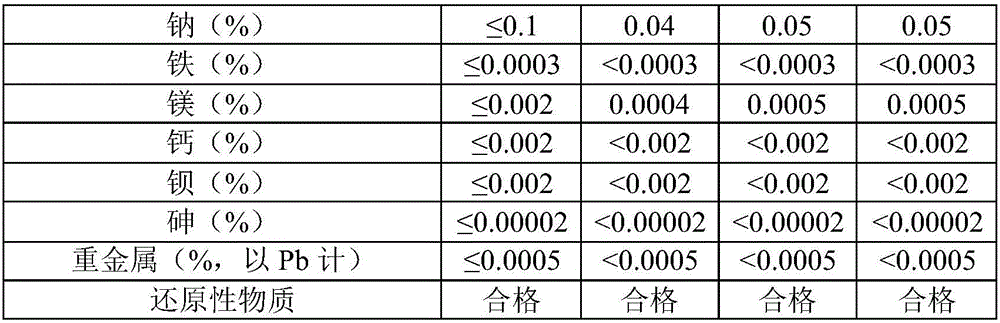

Examples

Embodiment 1

[0033] Embodiment 1: utilize microchannel reactor to prepare potassium iodide.

[0034] (1) At room temperature, weigh 1422g of hydroiodic acid (wherein the content of hydrogen iodide is 57wt%) and 4.4g of formic acid, and mix them uniformly to obtain solution A.

[0035] (2) At room temperature, weigh 326g of potassium hydroxide and 414g of deionized water respectively, and mix them uniformly to obtain solution B (wherein the content of potassium hydroxide is 40wt%).

[0036] (3) Utilize feed pump to pump above-mentioned solution A and solution B respectively in the reactant storage tank A and the reactant storage tank B of liquid-liquid phase microchannel reactor, under 70 ℃ of reaction temperature, by controlling solution A and The respective flow velocity of solution B continuously makes the two mix according to the hydrogen iodide in solution A: the weight ratio of potassium hydroxide=2.16:1 in solution B in the reaction pipeline of liquid-liquid phase microchannel reacto...

Embodiment 2

[0038] Embodiment 2: utilize microchannel reactor to prepare potassium iodide.

[0039] (1) At room temperature, weigh 1400g of hydroiodic acid (wherein the content of hydrogen iodide is 58wt%) and 5.6g of formic acid, and mix the two uniformly to obtain solution A.

[0040] (2) At room temperature, weigh 380g of potassium hydroxide and 620g of distilled water respectively, and mix them uniformly to obtain solution B (wherein the content of potassium hydroxide is 38wt%).

[0041] (3) Utilize feed pump to pump above-mentioned solution A and solution B respectively in the reactant storage tank A and the reactant storage tank B of liquid-liquid phase microchannel reactor, under 95 ℃ of reaction conditions, by controlling solution A and The respective flow velocity of solution B continuously makes the two mix according to the hydrogen iodide in solution A: the weight ratio of potassium hydroxide=2.3:1 in solution B in the reaction pipeline of liquid-liquid phase microchannel react...

Embodiment 3

[0043] Embodiment 3: utilize microchannel reactor to prepare potassium iodide.

[0044] (1) At room temperature, weigh 1540g of hydroiodic acid (wherein the content of hydrogen iodide is 56wt%) and 3.9g of formic acid, and mix the two uniformly to obtain solution A.

[0045] (2) At room temperature, weigh 450g of potassium hydroxide and 550g of deionized water respectively, and mix them uniformly to obtain solution B (wherein the content of potassium hydroxide is 45wt%).

[0046] (3) Utilize feed pump to pump above-mentioned solution A and solution B respectively in the reactant storage tank A and the reactant storage tank B of the liquid-liquid phase microchannel reactor, under 85 ℃ of reaction conditions, by controlling solution A and The respective flow velocity of solution B continuously makes the two mix according to the hydrogen iodide in solution A: the weight ratio of potassium hydroxide=2.2:1 in solution B in the reaction pipeline of liquid-liquid phase microchannel r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com