Horizontal double temperature zone I-131 destructive distillation device

A dual temperature zone, dry distillation technology, applied in the directions of alkali metal iodide, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of iodine-131 vapor leakage, unfavorable safety production, shortening the service life of production equipment, etc. Absorption efficiency, increased contact area, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

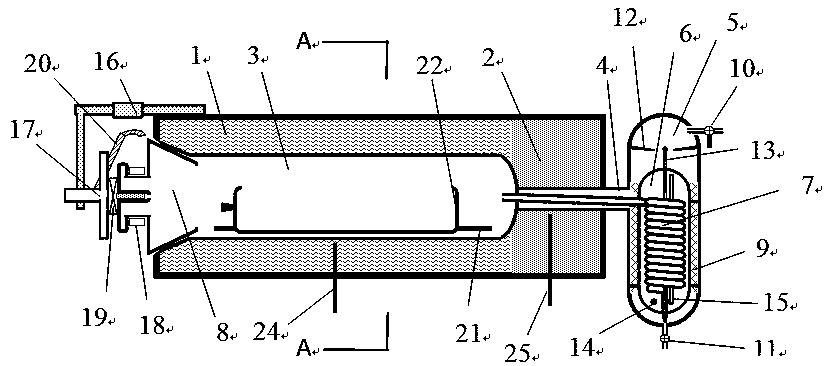

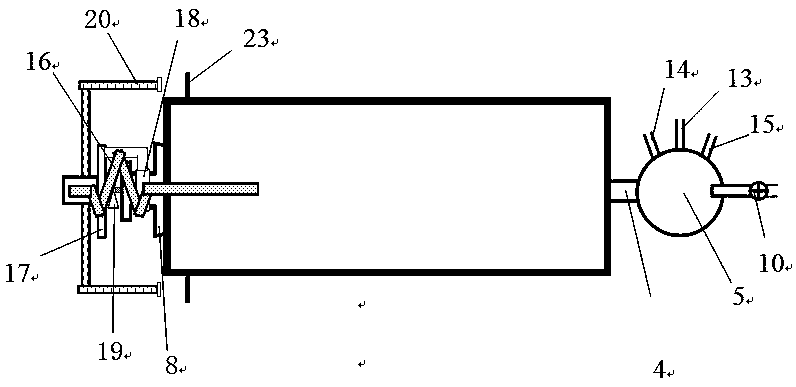

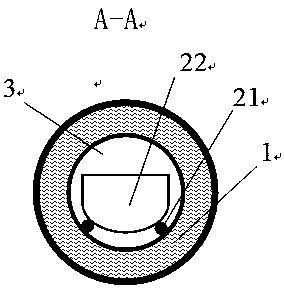

[0022] figure 1 It is a schematic diagram of the overall structure of a horizontal double temperature zone I-131 retort device of the present invention, figure 2 It is a top view structure schematic diagram of a horizontal double temperature zone I-131 retort device of the present invention image 3 yes image 3 A-A cutaway view. exist Figure 1~Figure 3Among them, the horizontal dual-temperature zone I-131 retort device of the present invention includes a heating furnace with a horizontal tube furnace structure, a furnace cover, a distillation absorber, and a telescopic frame 16; the connection relationship of the above-mentioned retort production device is as follows: The distillation absorber part is placed in the heating furnace cavity, the furnace cover and the telescopic frame 16 are arranged at the same end of the heating furnace, one end of the telescopic frame 16 is fixed horizontally on the top center of the heating furnace, and the other end of the telescopic fr...

Embodiment 2

[0029] The structure of this embodiment is the same as that of Embodiment 1, except that the angle between the upper pipe of the coiled pipe 7 and the horizontal line is 10°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com