Patents

Literature

69results about How to "Automatic unloading" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

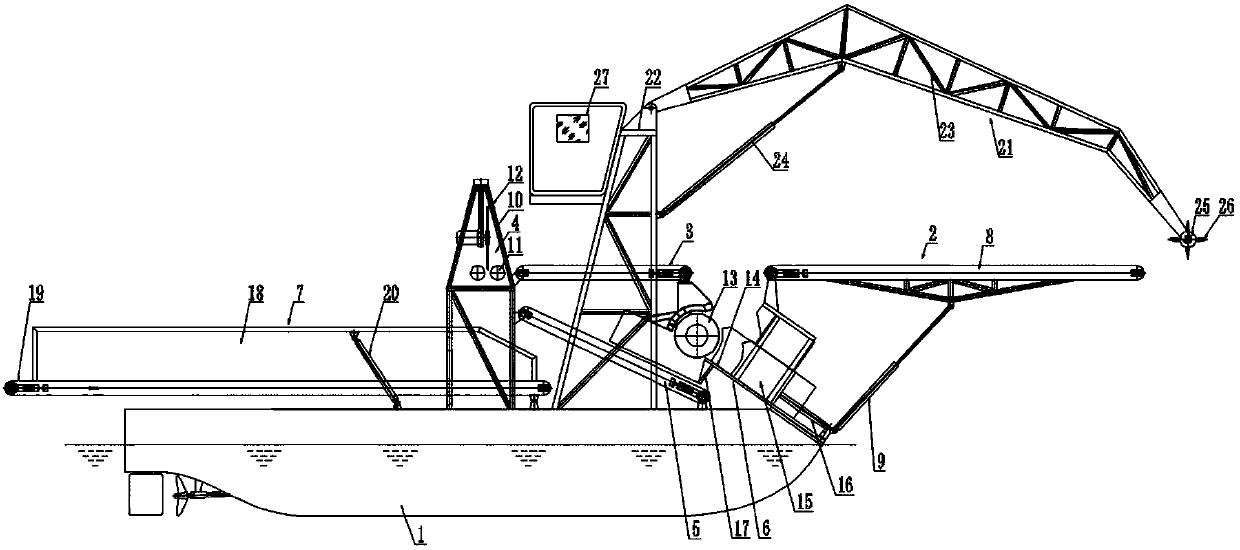

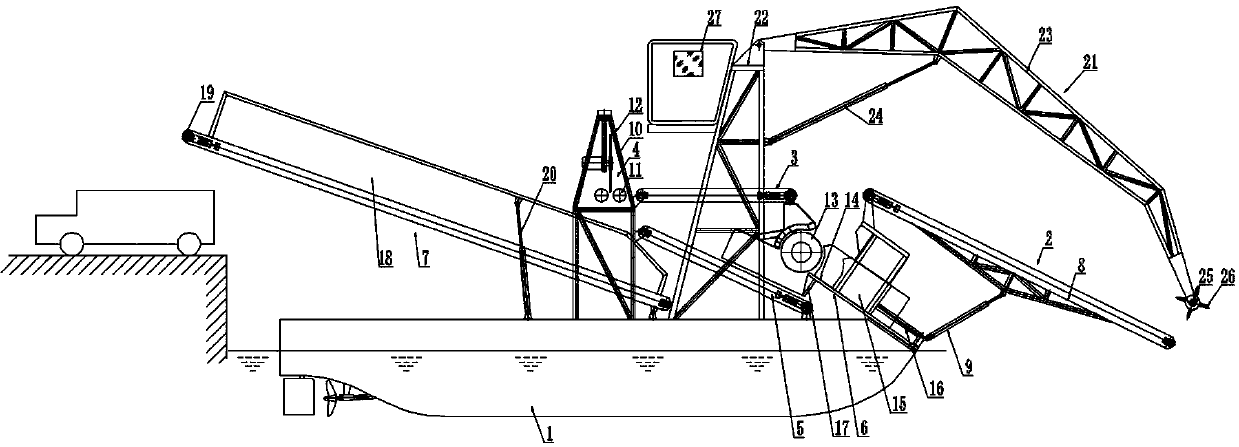

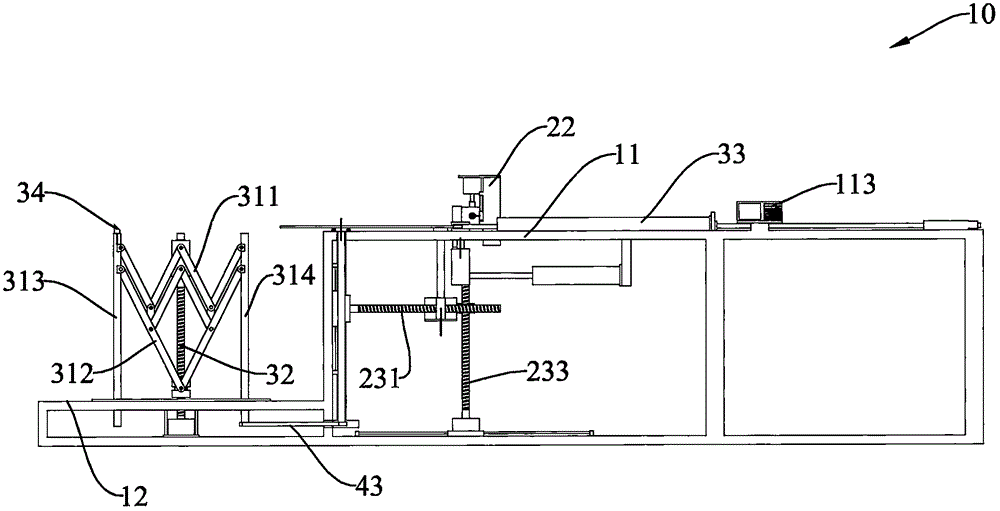

Automatic water surface floating object cleaning boat

PendingCN109653180AImprove cleaning efficiencyReduce manual labor intensityWater cleaningGrain treatmentsEngineeringMechanical engineering

The invention discloses an automatic water surface floating object cleaning boat which comprises a boat body, a fishing device, a horizontal conveying device, a saw cutting device, a broken material conveying device, a breaking device and a storing and discharging device. The fishing device is arranged on the head of the boat body is used for fishing floating objects, the storing and discharging device is arranged at the tail of the boat body is used for storing and discharging of materials, the saw cutting device is fixed above the storing and discharging device, the horizontal conveying device is horizontally fixed between the fishing device and the saw cutting device, the breaking device is fixed on the lower portion of the discharging end of the fishing device, the broken material conveying device is obliquely fixed onto the lower portion of the horizontal conveying device, the lower end of the broken material conveying device is positioned below the breaking device, and the high end of the broken material conveying device is positioned above the storing and discharging device. The boat can directly fish floating objects in different directions on the water surface.

Owner:SICHUAN ORIENT HYDROELECTRIC ENG

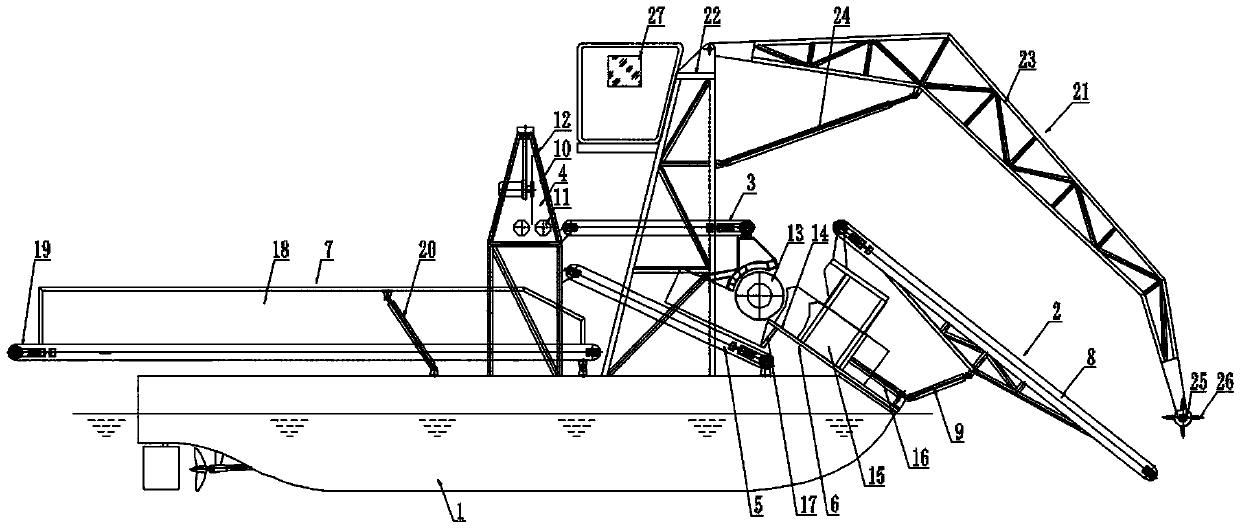

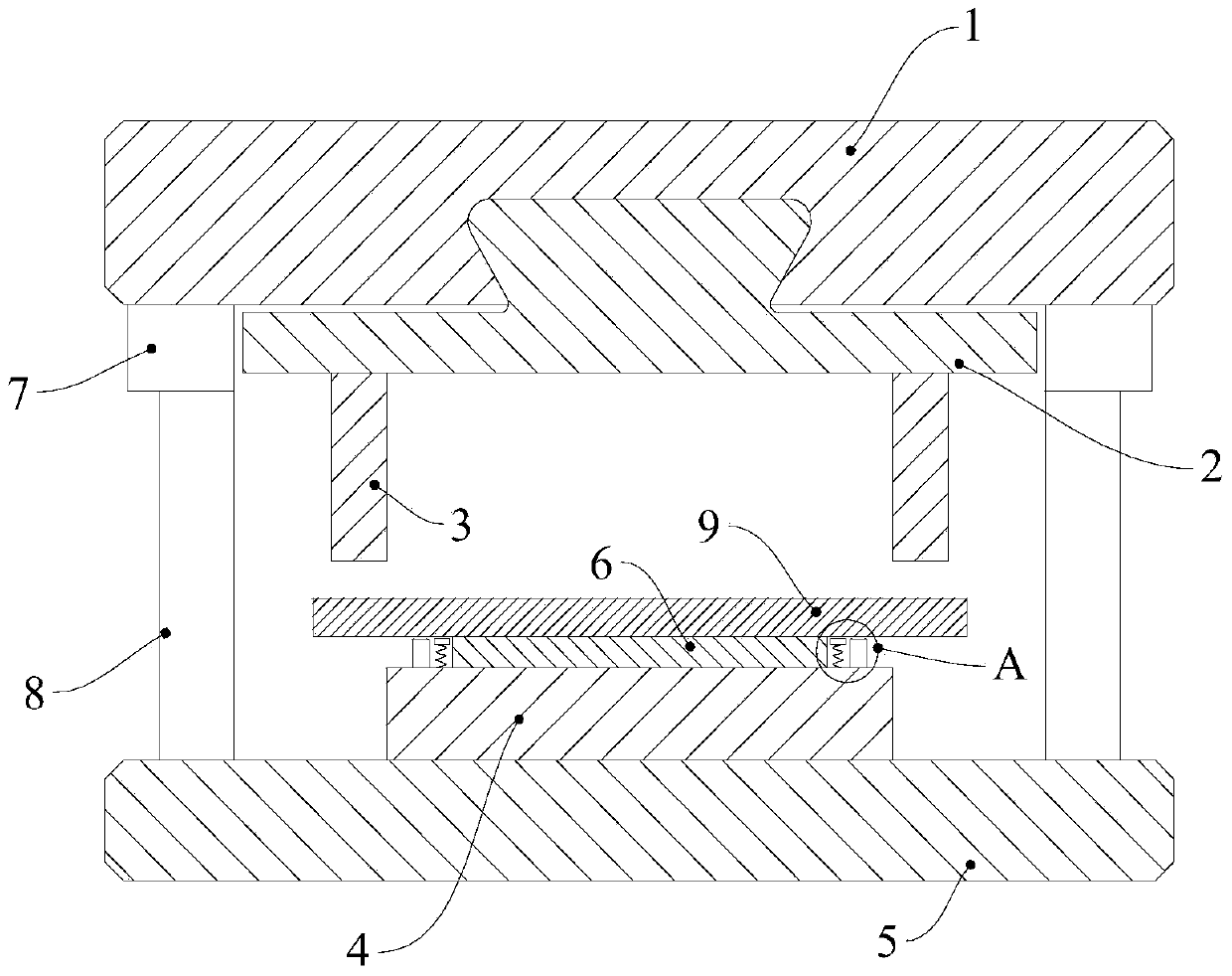

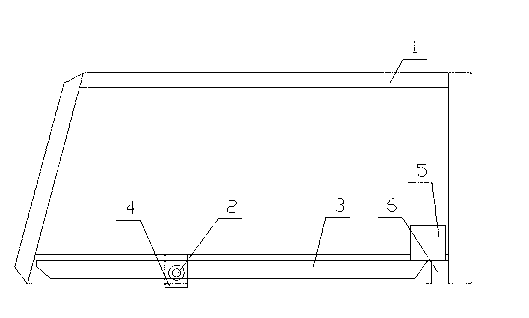

Edge folding die for U-shaped steel plate

InactiveCN103990711AAutomatic unloadingShaping toolsEjection devicesEngineeringMechanical engineering

The invention discloses an edge folding die for a U-shaped steel plate. According to the edge folding die, an edge folding male die is arranged on an upper die plate, a stamping table, a spring and an ejecting block are arranged on a lower die fixing plate, the stamping table is used for containing the steel plate, the ejecting block is connected with the spring, and an electromagnet is arranged inside the stamping table. The steel plate with the edge to be folded is placed on the stamping table, the electromagnet is powered on to generate magnetic force, the steel plate is attacked and attached to the stamping table, the edge folding lower die moves downwards to stamp the workpiece to complete edge folding, and the spring is in the compression state at the moment; when folding of the edge of the steel plate is completed and the edge folding male die moves upwards, an electromagnet unit is powered off, the magnetic force disappears, the steel plate is jacked away from the stamping table by the ejecting block driven by the spring, and discharging is completed automatically.

Owner:昆山电子羽电业制品有限公司

Coal residue collecting equipment

The invention discloses coal residue collecting equipment which comprises an equipment body and a feeding pipe. The feeding pipe is movably arranged on the top side of the equipment body, and the feeding pipe is communicated with the interior of the equipment body. A mounting box fixedly installed on the top side of the equipment body is arranged on one side of the feeding pipe, a sliding hole isformed in the inner wall of the side, close to the feeding pipe, of the mounting box in the horizontal direction, a fixing rod is arranged in the sliding hole in a sliding mode, and the two ends of the fixing rod extend out of the sliding hole. The end, far away from the feeding pipe, of the fixing rod extends into the mounting box and is fixedly provided with a sliding block. The feeding pipe iscontinuously knocked so that the feeding pipe cannot be blocked during discharging, a cover plate can be automatically opened when a collecting box is full of coal residues, then automatic dischargingis carried out, and time and labor are saved; the coal residue collecting equipment is more convenient to use, and the requirements of people are met.

Owner:安徽中乾能源有限公司

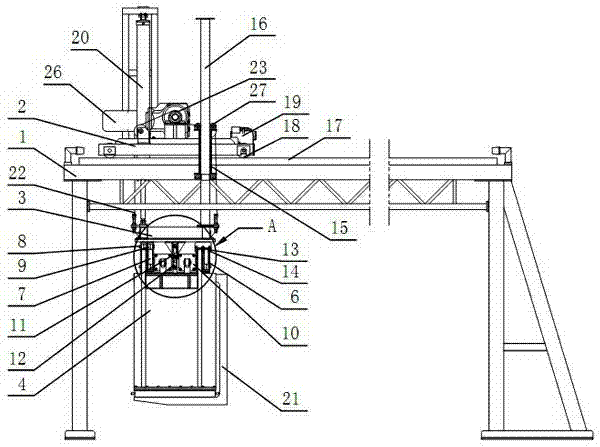

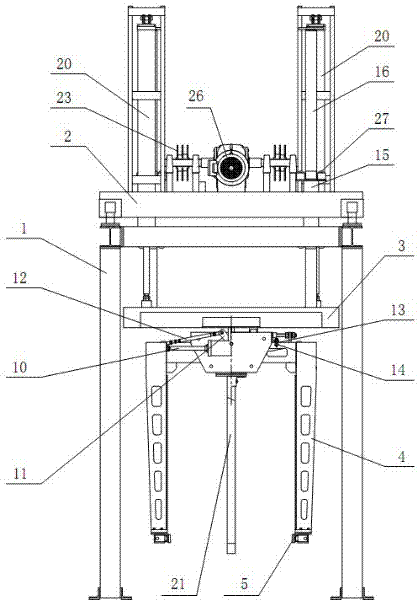

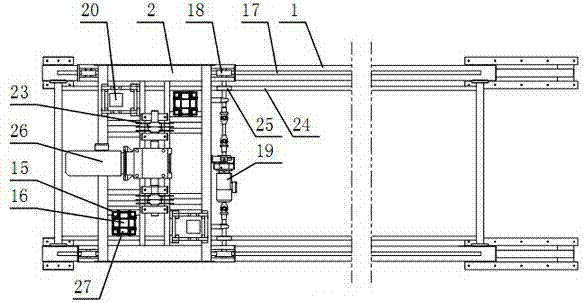

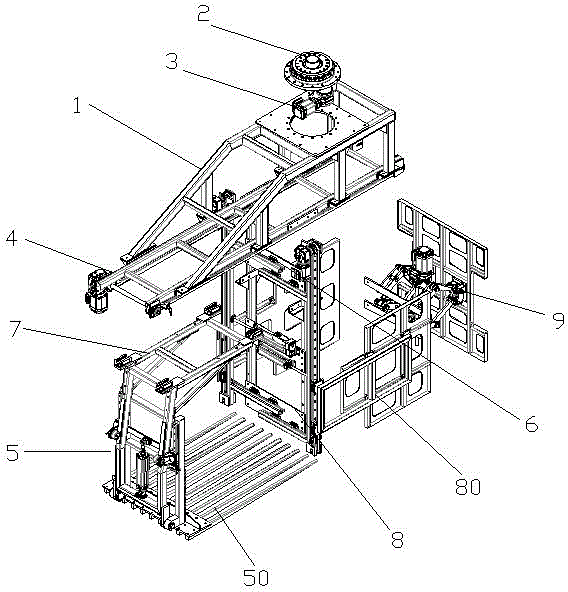

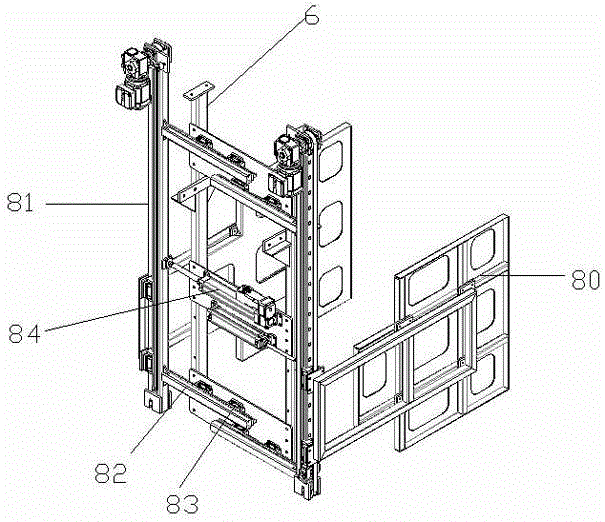

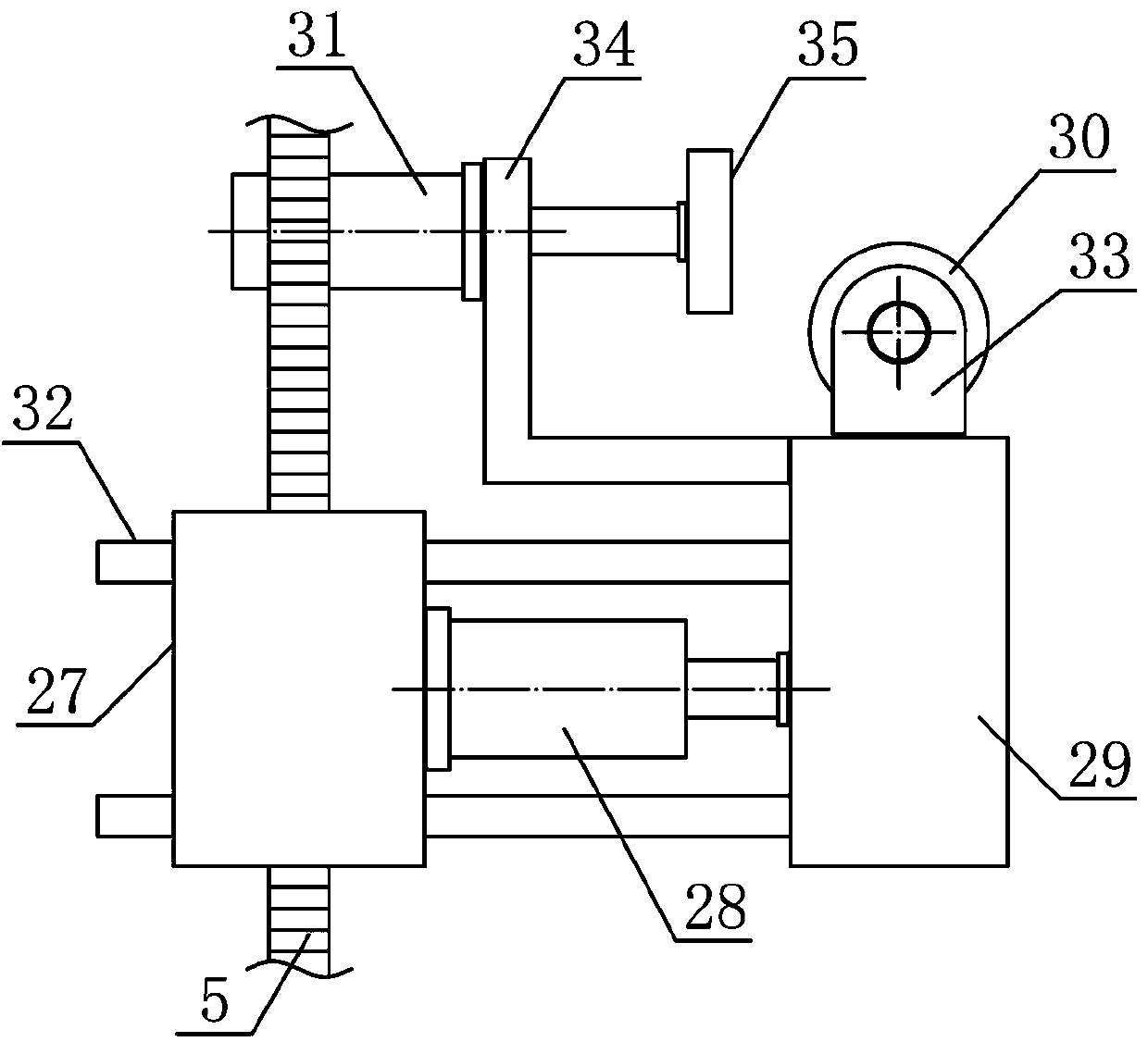

Single-chuck destacking machine

InactiveCN102408015APromise to leaveReduce labor intensityStacking articlesDe-stacking articlesBrickEngineering

The invention discloses a single-chuck destacking machine, which comprises a rack, wherein a travelling trolley is connected with the rack in a sliding way and is driven by a travelling power device; a lifting frame is connected with the travelling trolley in a sliding way; a lift and pull device is also arranged on the travelling trolley and is used for driving the lifting frame to lift; two clamping plates are horizontally arranged under the lifting frame opposite to each other; limiting grooves are horizontally formed at the bottom of the lifting frame; sliding plates which are connected with the interior of the limiting groove in a sliding way are respectively and fixedly arranged at the tops of the two clamping plates; clamping blocks are respectively and fixedly arranged at the bottoms of the two clamping plates; and a clamping drive device which drives the clamping plates to move in an opposite direction is connected between the tops of the two clamping plates. The single-chuck destacking machine is simple in structure, and can automatically unload brick stacks, and manual brick unloading is not required; therefore, the labor efficiency of workers is high, and the labor intensity is low.

Owner:山东矿机迈科建材机械有限公司

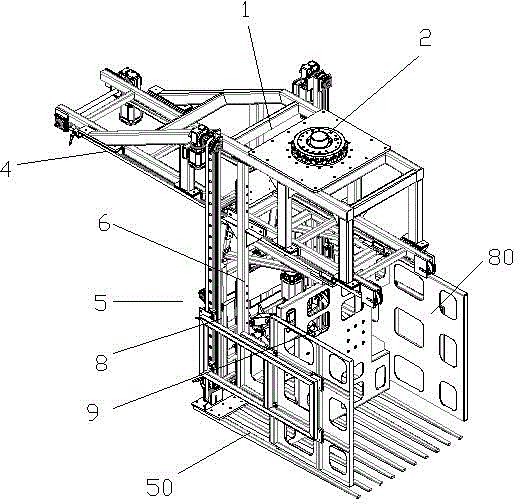

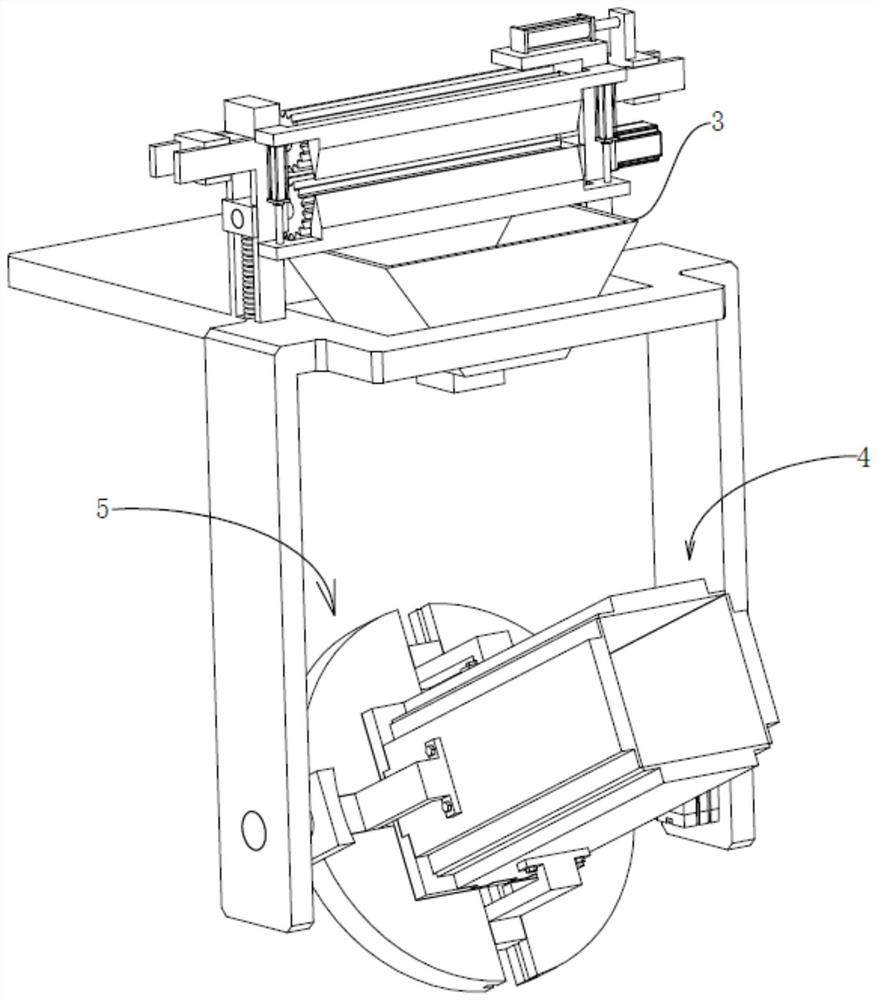

Inserting and taking type grabber capable of automatically unloading goods

ActiveCN104444964AAutomatic unloadingLifting devicesLoad-engaging elementsElectrical and Electronics engineering

The invention relates to the technical field of stacking and conveying, and discloses an inserting and taking type grabber capable of automatically unloading goods. The inserting and taking type grabber capable of automatically unloading goods comprises a machine frame and a rotary connecting seat arranged on the machine frame, wherein two parallel horizontal electric cylinders are arranged on the lower side of the machine frame, an inserting and taking mechanism and a vertical limiting supporting frame are arranged under the machine frame, the upper end of the inserting and taking mechanism is connected with the horizontal electric cylinders in a sliding mode through a sliding connecting frame, a row of inserting rods used for inserting and taking stacks are arranged at the lower end of the inserting and taking mechanism, a lateral plate adjustment mechanism is arranged on the limiting supporting frame, two parallel lateral plates are arranged on two sides of the lateral plate adjustment mechanism respectively, and the lateral plate adjustment mechanism can control the two lateral plates to ascend and descend synchronously, and draw close and get away synchronously. The inserting and taking type grabber capable of automatically unloading goods has the advantages of being capable of conveying whole stacks of goods, separating goods from trays in the conveying process and being capable of automatically unloading goods.

Owner:HANGZHOU WAHAHA TECH

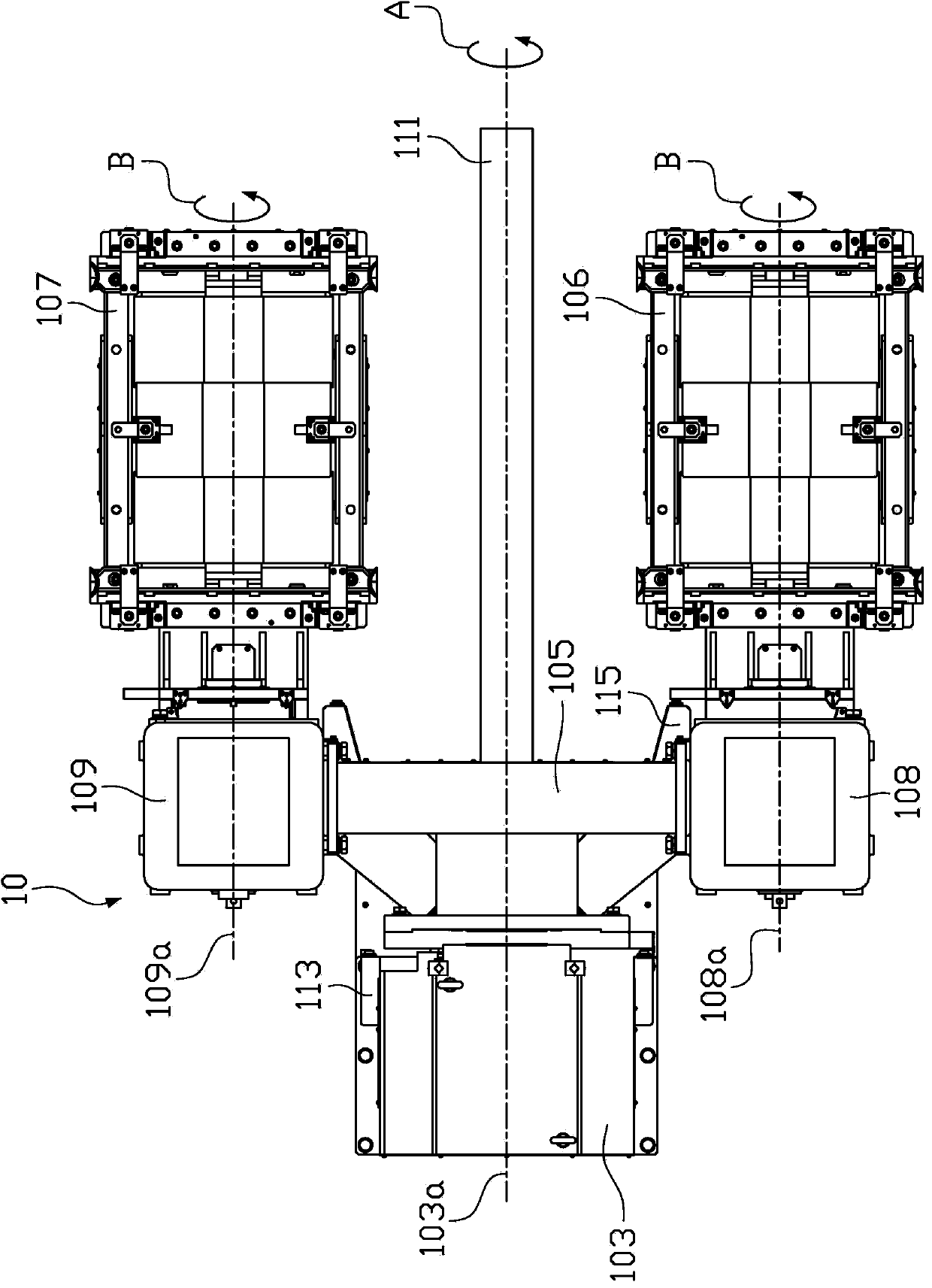

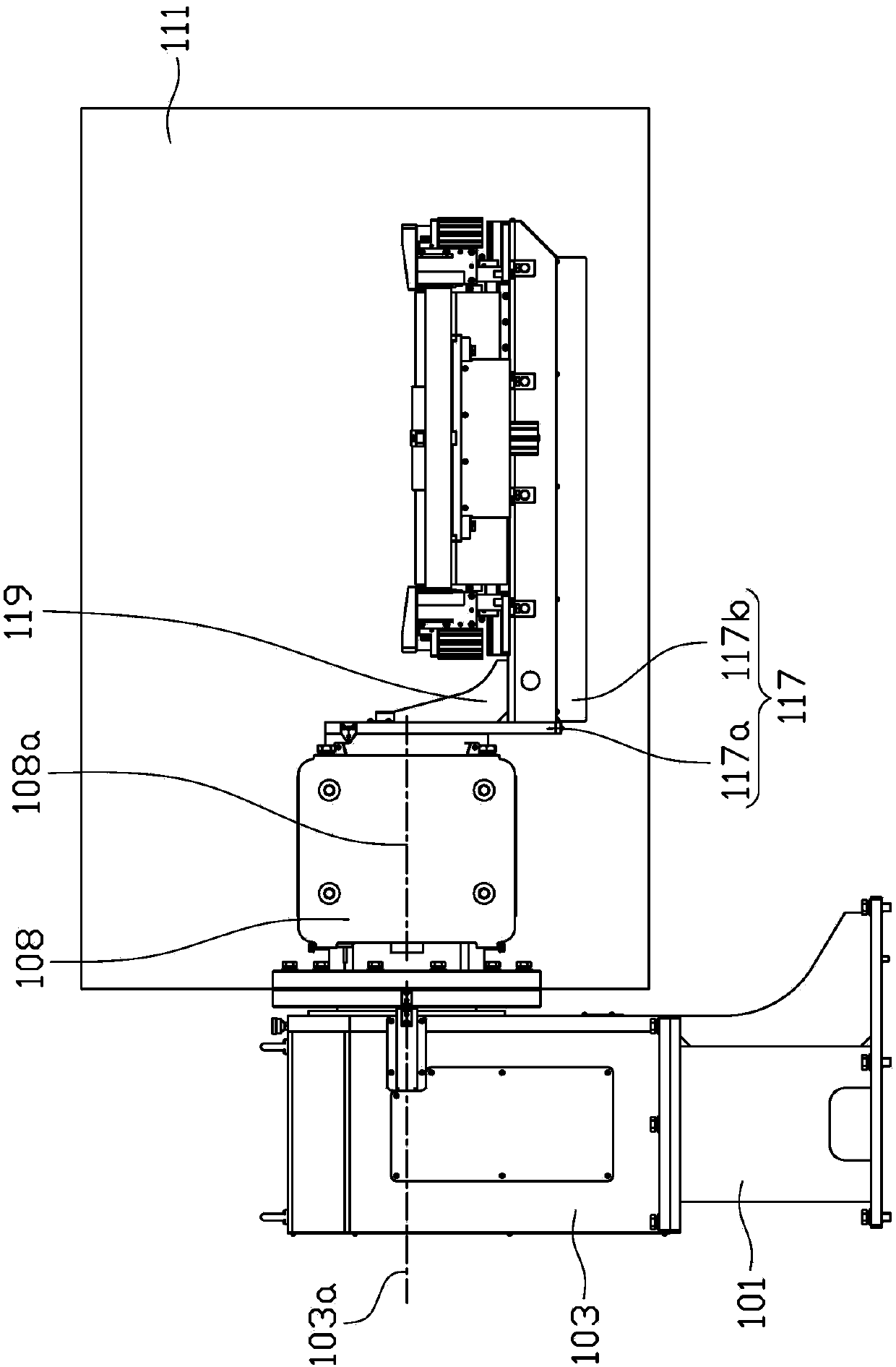

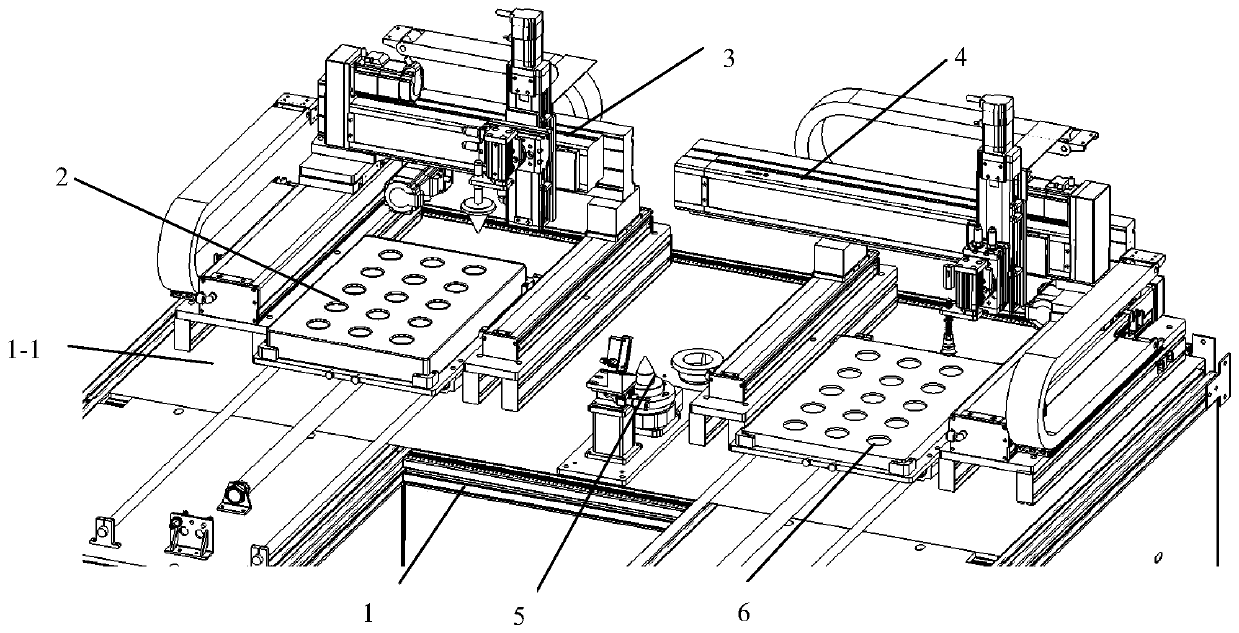

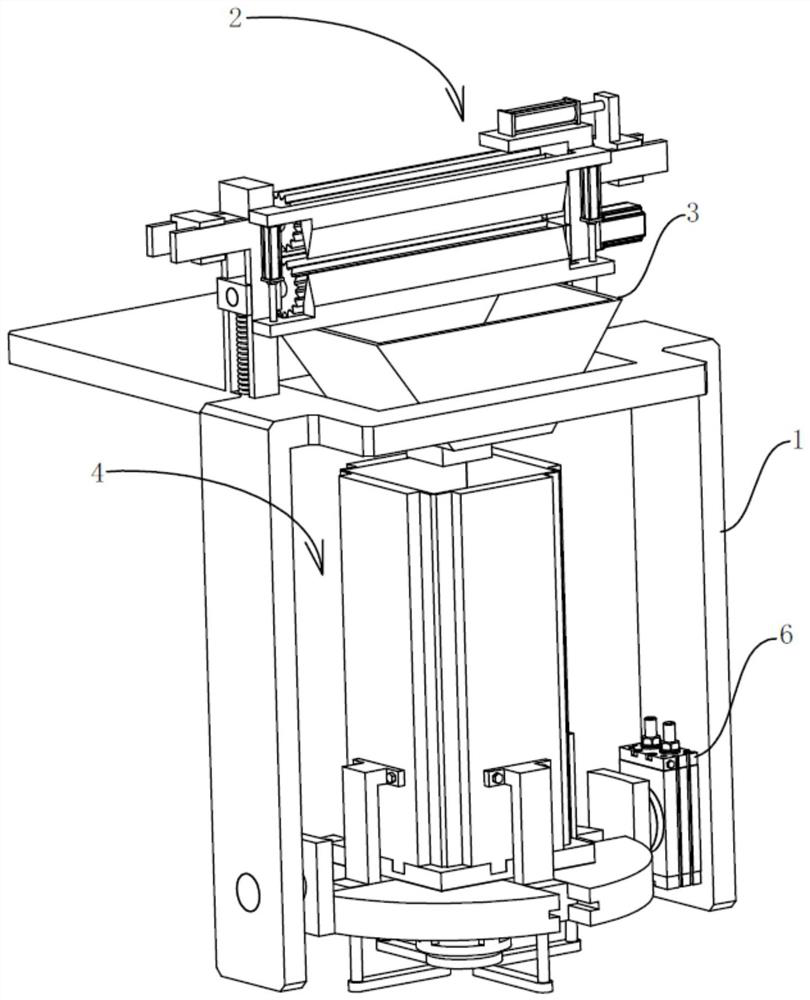

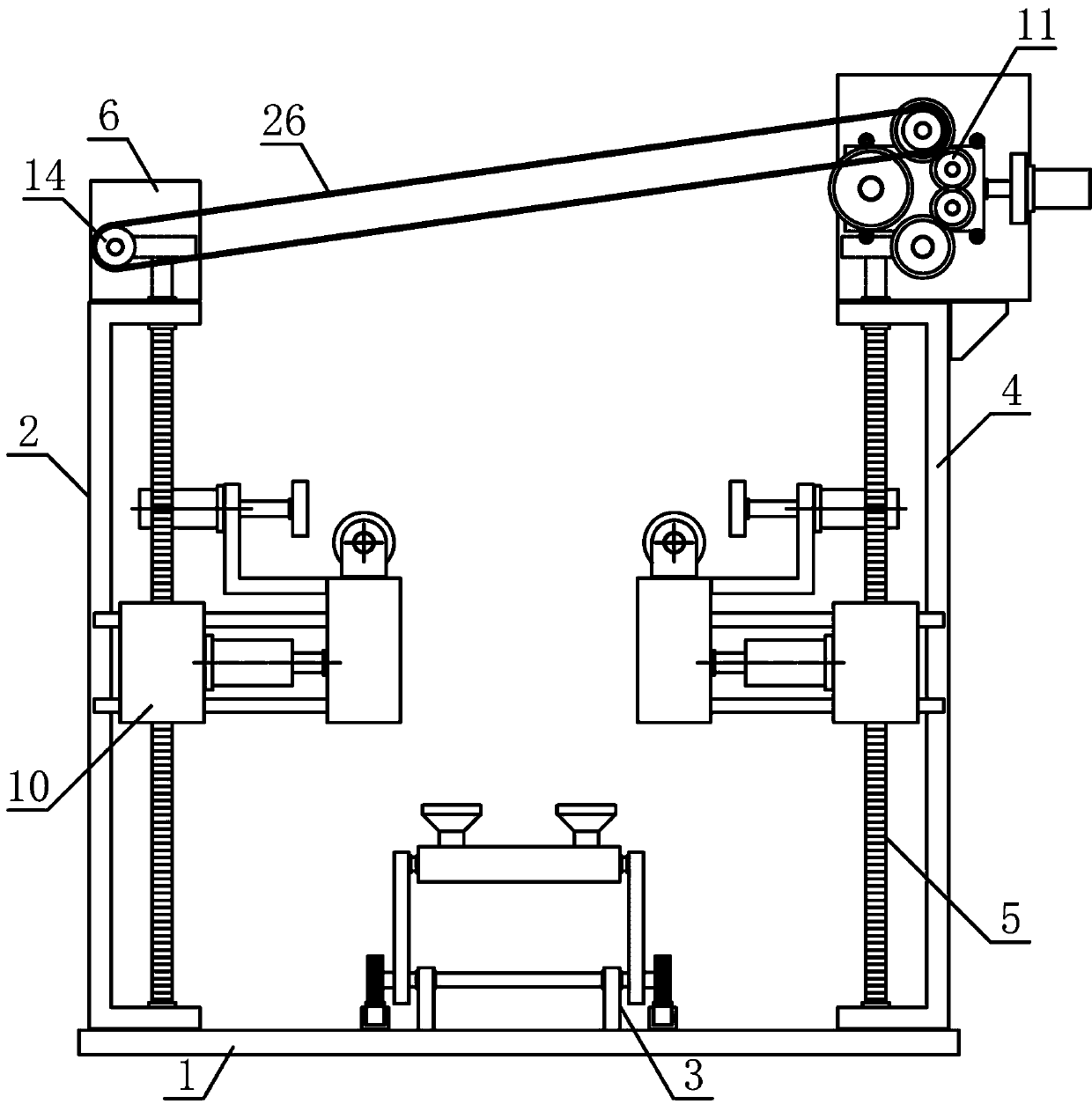

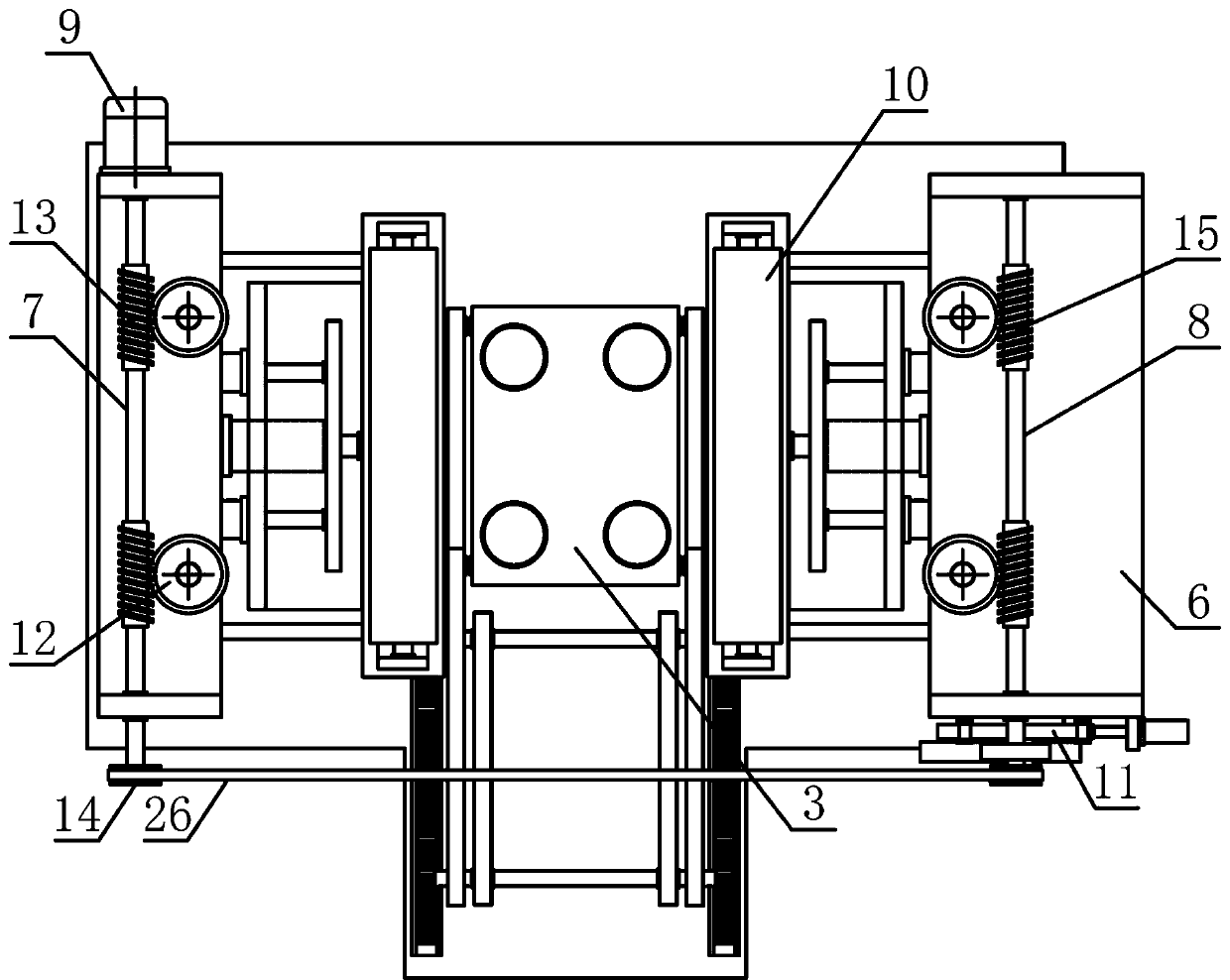

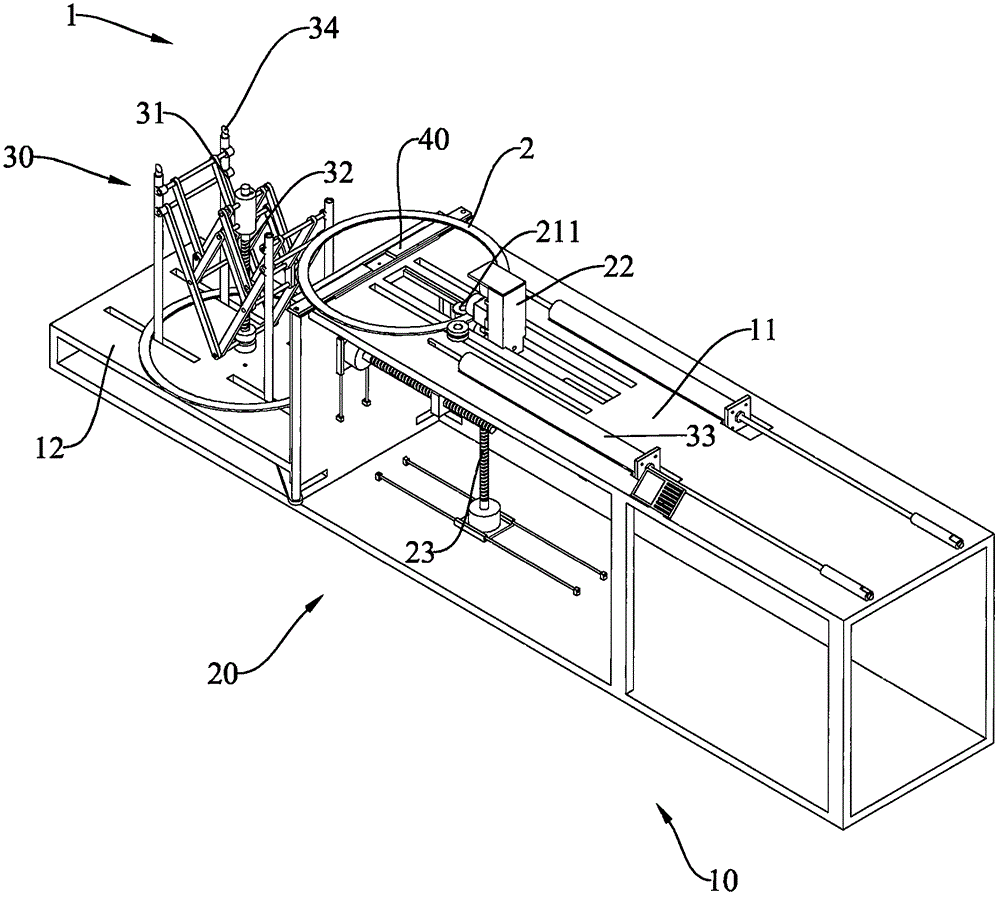

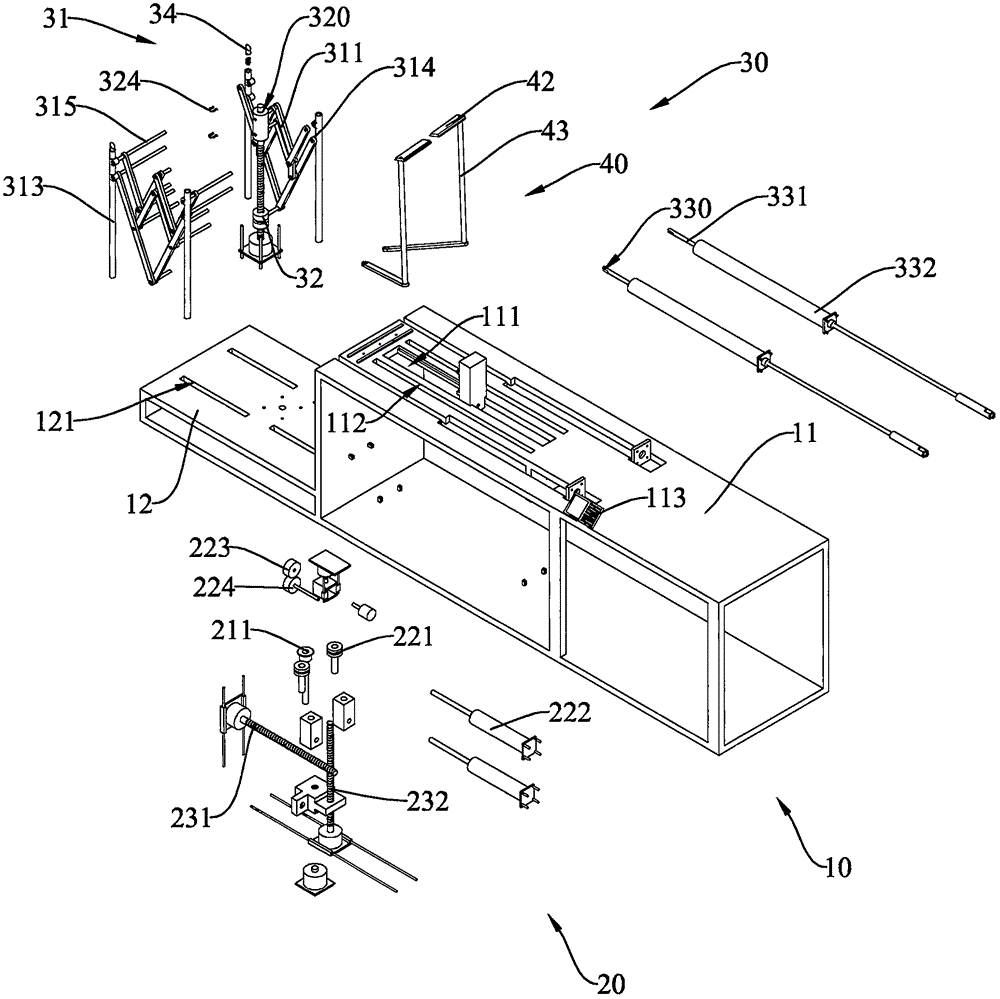

Welding tool of standard knot square frame of construction lift and welding method thereof

ActiveCN103551788AIncrease productivityAutomated weldingWelding/cutting auxillary devicesAuxillary welding devicesBuilding constructionWelding

The invention provides a welding tool of a standard knot square frame of a construction lift. The welding tool comprises a turning component, a revolving arm, two clamping devices and two position changing mechanisms, wherein the turning mechanism is provided with a rotating shaft; the revolving arm is connected to the rotating shaft of the turning component; the two position changing mechanisms are arranged at the two ends of the revolving arm respectively and are provided with a rotating shaft respectively; the two clamping devices are connected to the rotating shafts of the two position changing mechanisms respectively; the rotating shaft of the turning component drives the revolving arm, the two clamping devices and the two position changing mechanisms to turn together during rotation; the rotating shafts of the two position changing mechanisms drives the two clamping devices to rotate respectively during rotation. The welding tool can realize simultaneous manual feeding and automatic welding; an operator can operate the operations of two stations by standing at the same position, so that the labor intensity is reduced. The invention also provides a welding method using the welding tool.

Owner:ZOOMLION HEAVY IND CO LTD

Mowing equipment with adjusting function for landscape gardening

The invention relates to mowing equipment with an adjusting function for landscape gardening. The mowing equipment comprises a main body, a handle and two moving devices, and further comprises a collecting mechanism and an adjusting mechanism. The adjusting mechanism comprises a connecting rod, a lifting rod, a moving plate, a mowing assembly and two adjusting assemblies. The mowing assembly comprises a first motor and a plurality of blades, and each adjusting assembly comprises a second motor, a gear, a rotating shaft and a rack; the collecting mechanism comprises a supporting shaft, a collecting box, a swinging assembly and a collecting assembly; and each collecting assembly comprises a suction pump, a hose, a fixing box, a communication pipe and two suction nozzles. According to the mowing equipment with the adjusting function for landscape gardening, through the adjusting mechanism, the heights of the blades can be adjusted to meet different trimming requirements, and therefore, the trimmed length of a lawn can be adjusted through the collecting mechanism. Through the collecting mechanism, the trimmed turfgrass clippings can be collected, and do not need to be cleaned manually,and the workload of a user is reduced.

Owner:GUANGZHOU DANJUE COMM TECH CO LTD

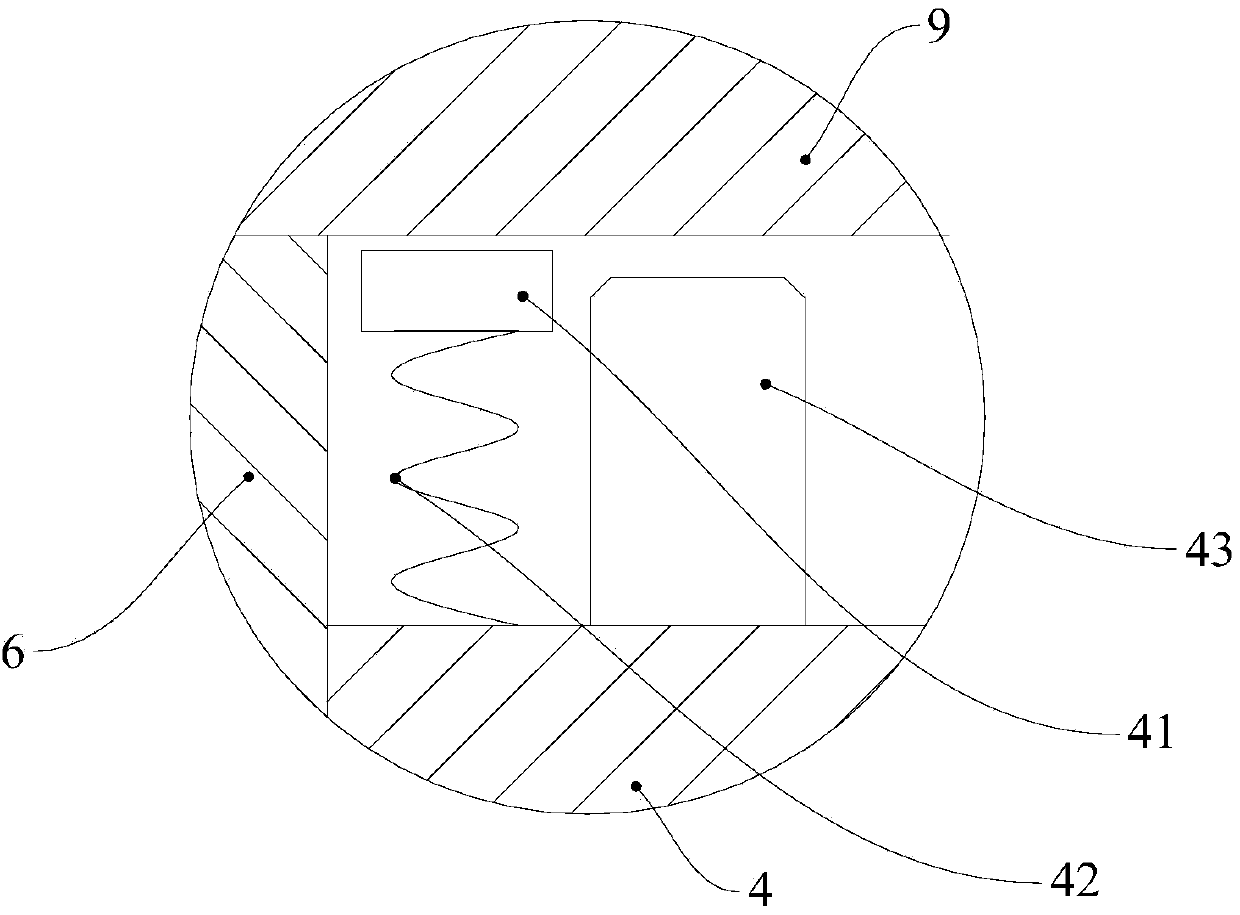

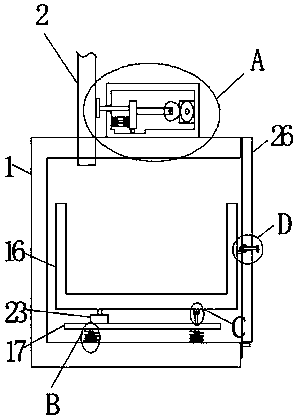

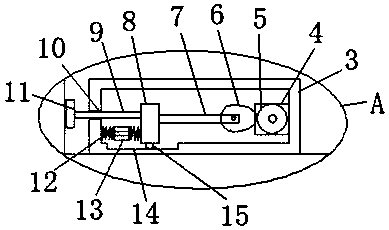

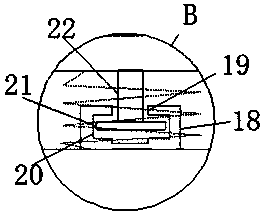

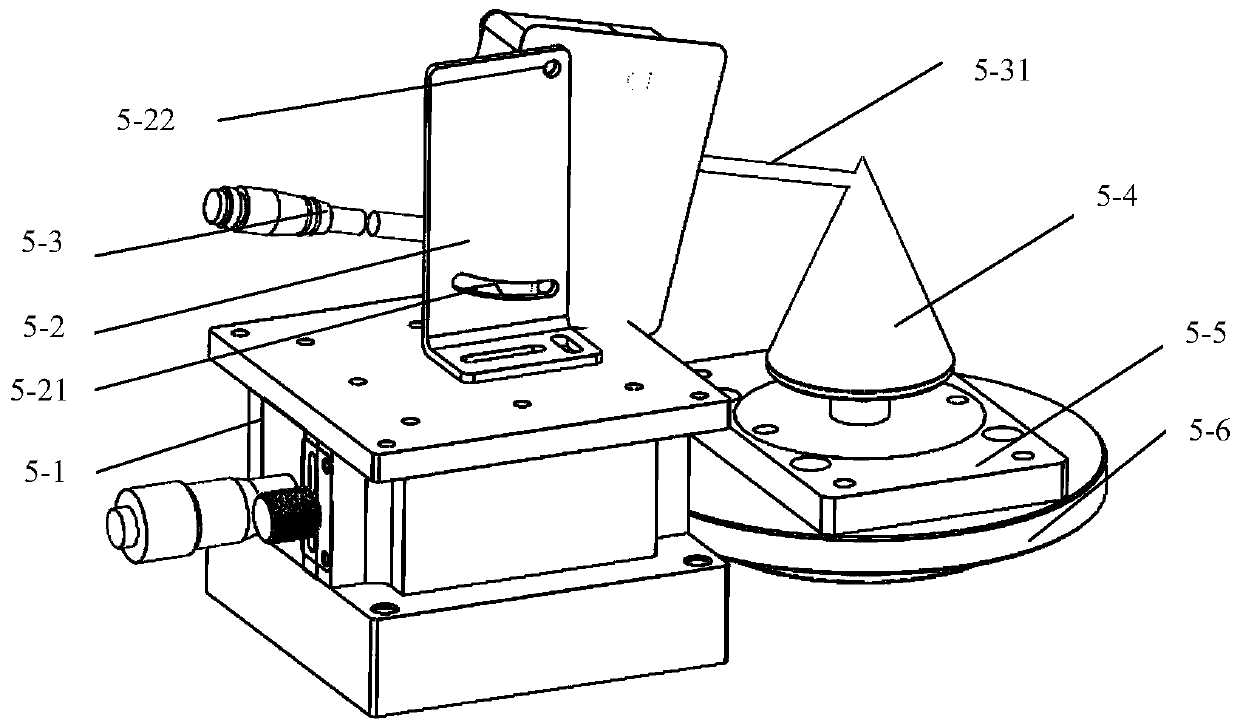

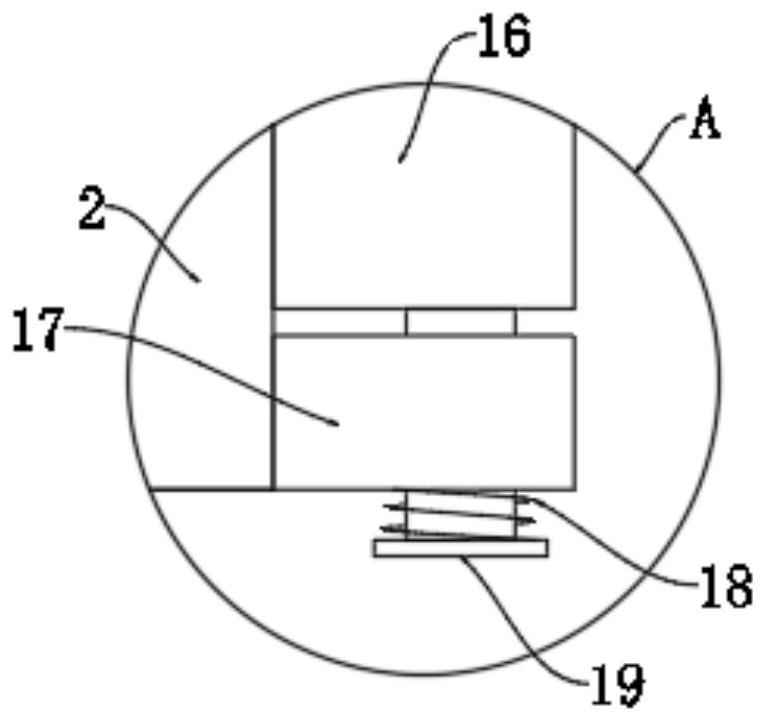

Device for detecting liner thickness and wall thickness difference

ActiveCN110823108AReduce scratchesReduce the impactDirt cleaningUsing optical meansLaser rangingEngineering

The invention discloses a device for detecting liner thickness and a wall thickness difference, and relates to the technical field of wall thickness detection. The device for detecting the liner thickness and the wall thickness difference comprises an adjusting base and a turntable, wherein a vertical mounting plate is arranged on the adjusting base, and an angle-adjustable laser range finder is arranged on the vertical mounting plate; and the turntable is arranged on a light receiving side of the adjusting base, a magnetic base is arranged at the upper end of the turntable, and a liner mold is arranged on the magnetic base. According to the device for detecting the liner thickness and the wall thickness difference, the laser emitted by the laser range finder is used for measuring the liner thickness and the wall thickness difference, a non-contact measurement mode is adopted, the detection precision is improved, the scratch on the surface of a liner is reduced, and the magnetic base is used for achieving rapid replacement of the liner mold.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Energy-saving hot pressing device improving specification of formed workpiece

InactiveCN107838514AIncrease pressure areaEven by forceMetal working apparatusSoldering auxillary devicesEngineeringSteel frame

The invention discloses an energy-saving hot pressing device for improving the specification of a molded workpiece, which comprises a hot press body and a feeding conveyor belt. A bottom fixing plate is welded on the top of one end of the hot pressing machine body, and four corners of the bottom fixing plate are welded There are four support rods, and the tops of the four support rods are screw-fixed with a telescopic cylinder through a fixed frame. The bottom of the telescopic cylinder is connected to the round stand through a telescopic rod, and the upper and lower walls of the round stand are welded with supporting steel. frame, the bottom of the round frame is welded with a sliding frame, and the four corners of the sliding frame are slidably socketed with four support rods through sleeves. In the present invention, first, by providing a round stand, the pressure area of the telescopic rod acting on the sliding frame is increased, and the force on the sliding frame is more uniform, so that the sliding frame is more stable when sliding down, and the accuracy of the specification of the hot-pressed workpiece is improved. The texture of the produced workpiece is more uniform, thereby improving the quality of the energy-saving hot pressing equipment that improves the specifications of the formed workpiece.

Owner:成都君华睿道科技有限公司

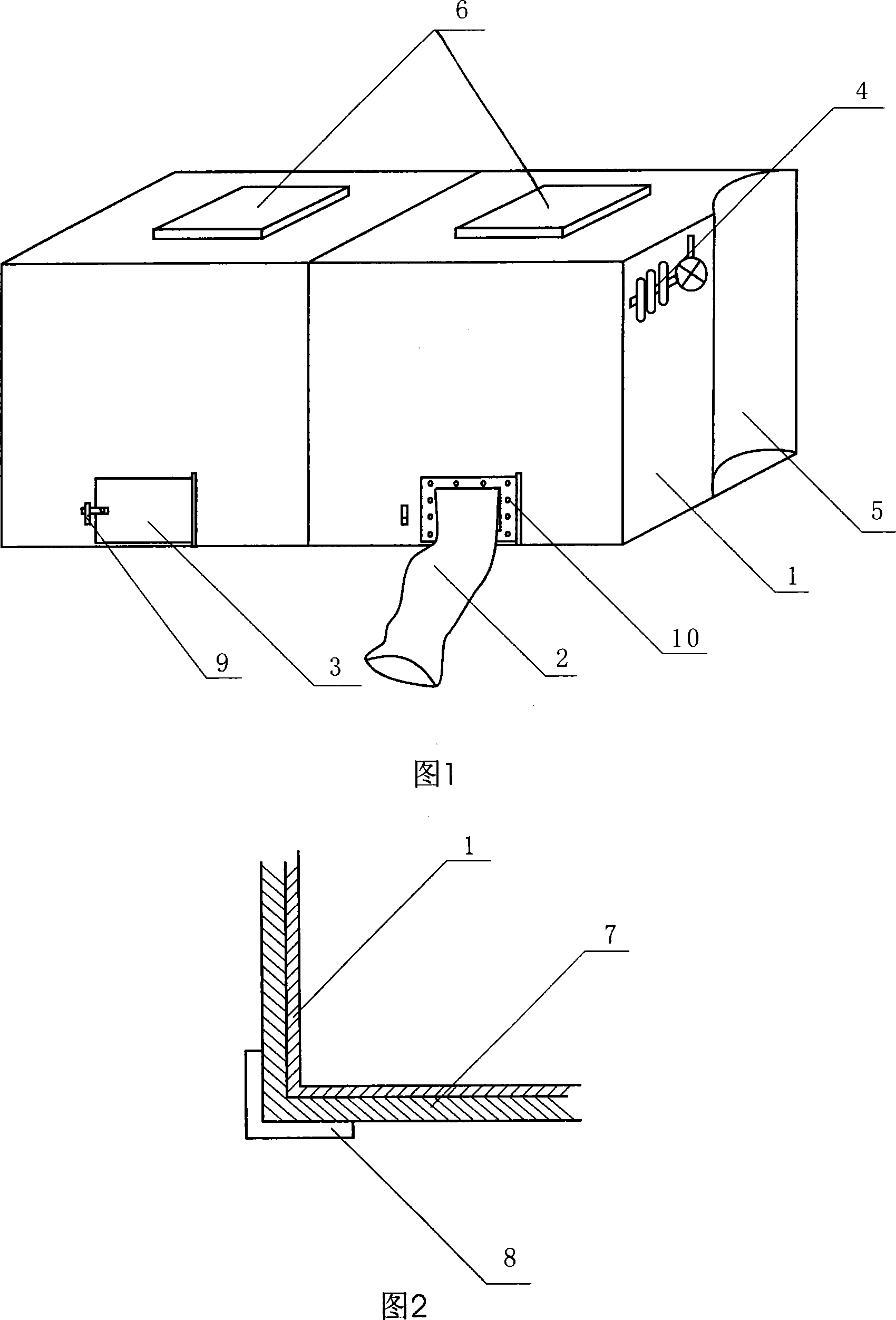

Fish canister for transport

InactiveCN101081012AEnsure safetyAutomatic unloadingPisciculture and aquariaEngineeringOxygen cylinder

The fish transporting cage as one kind of aquatic product storing and transporting facilities includes one cage body with cover, fish loading port and fish discharging port and made of welded stainless steel sheets; one oxygen cylinder on one end of the cage body; and one support made of welded angle irons. The fish discharging port includes one door, one bolt and one rubber coating. The fish transporting cage can ensure the safety of live fishes during transportation and fast fish discharging.

Owner:天津正跃水产储养有限公司

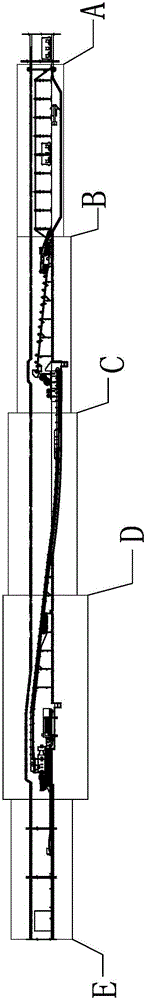

System and method for rapidly conveying and processing matched gangue at rear part of coal mine rock tunnel integrated excavator

ActiveCN105697016AQuick unloadingFast pickupSlitting machinesMaterial fill-upMining engineeringRock tunnel

The invention relates to a system and method for rapidly conveying and processing matched gangue at the rear part of a coal mine rock tunnel integrated excavator. The system comprises a plurality of side dumping mine cars, wherein the side dumping mine cars are located at the tail of a tunneling machine, are led by a storage battery vehicle and form a train, a car detaching device is arranged at one side of the train, a ground groove type gangue storing bin is executed below the car detaching device, a scraper box loading machine is arranged at one end of the gangue storing bin and is connected with a grinding machine through a blocked gangue rubber belt conveyor, the grinding machine is connected with a stirring machine through a ground gangue rubber belt conveyor, and a concrete conveying pump is further connected to the stirring machine and is communicated with a coal roadway for filling by virtue of a filling pipeline. The system and the method have the beneficial effects that the loading is convenient, the car detaching speed is high, the turnaround speed of the train is high, and the tunneling speed is high.

Owner:哈尔滨艾可马恩矿业科技开发有限公司

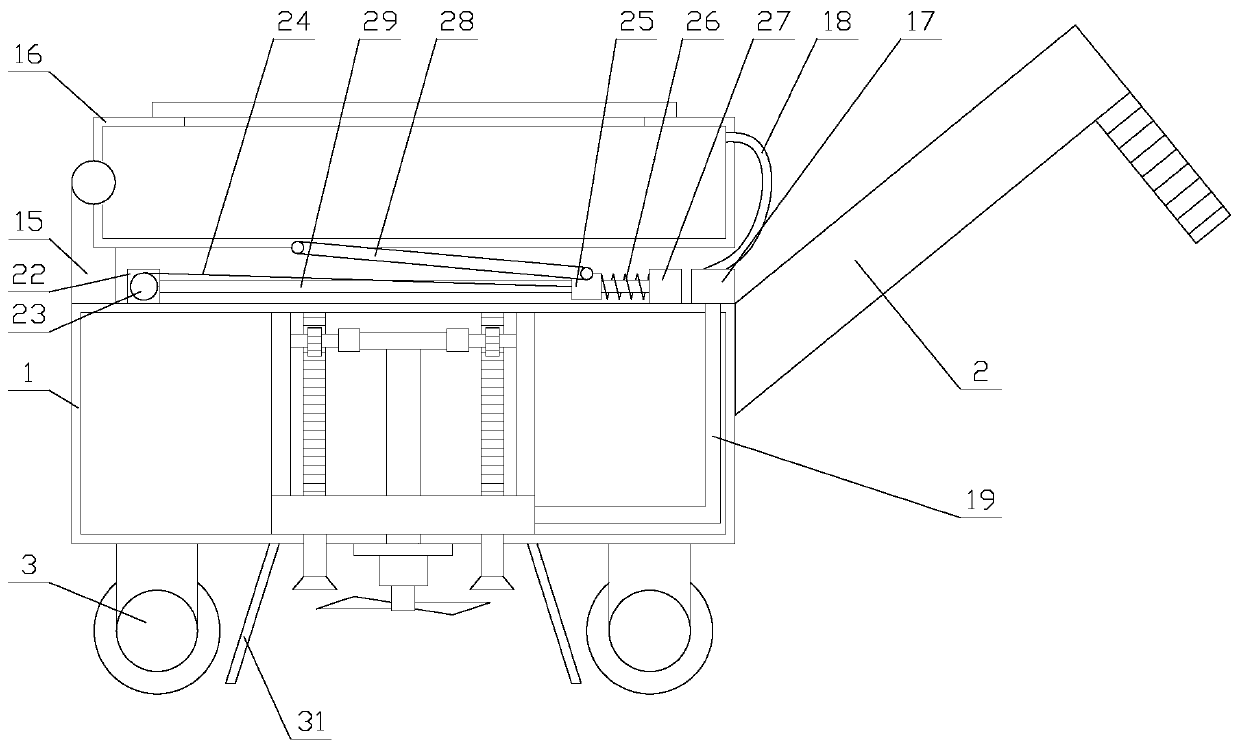

Device for preparing silage from corn straw

InactiveCN112075223AEasy to eatAutomatic unloadingBalingCuttersAgricultural scienceAgricultural engineering

The invention provides a device for preparing silage from corn straw. The device comprises a rack, a crushing mechanism, a hopper, a bundling assembly, a driving assembly and a rotating cylinder, oneof two crushing rollers in the crushing mechanism can move along the vertical direction, and the other crushing roller in the crushing mechanism can move along the horizontal direction; and two cutters can cut up the straw treated by the crushing rollers, the bundling assembly is composed of four extrusion plates and elastic blocking pieces arranged at the two sides of the extrusion plates, and the driving assembly can drive the four extrusion plates to move. Straw parts of the straw are rubbed through the crushing rollers moving in the horizontal direction, so that the situation that the roots of the cut straw are still in a straw shape is avoided, the straw is convenient for animals to eat, the cut straw is bundled through the bundling assembly, subsequent packaging and transportation are facilitated, and the bundling mechanism can automatically unload materials, so that manual intervention is avoided.

Owner:安徽鑫牛农业科技有限公司

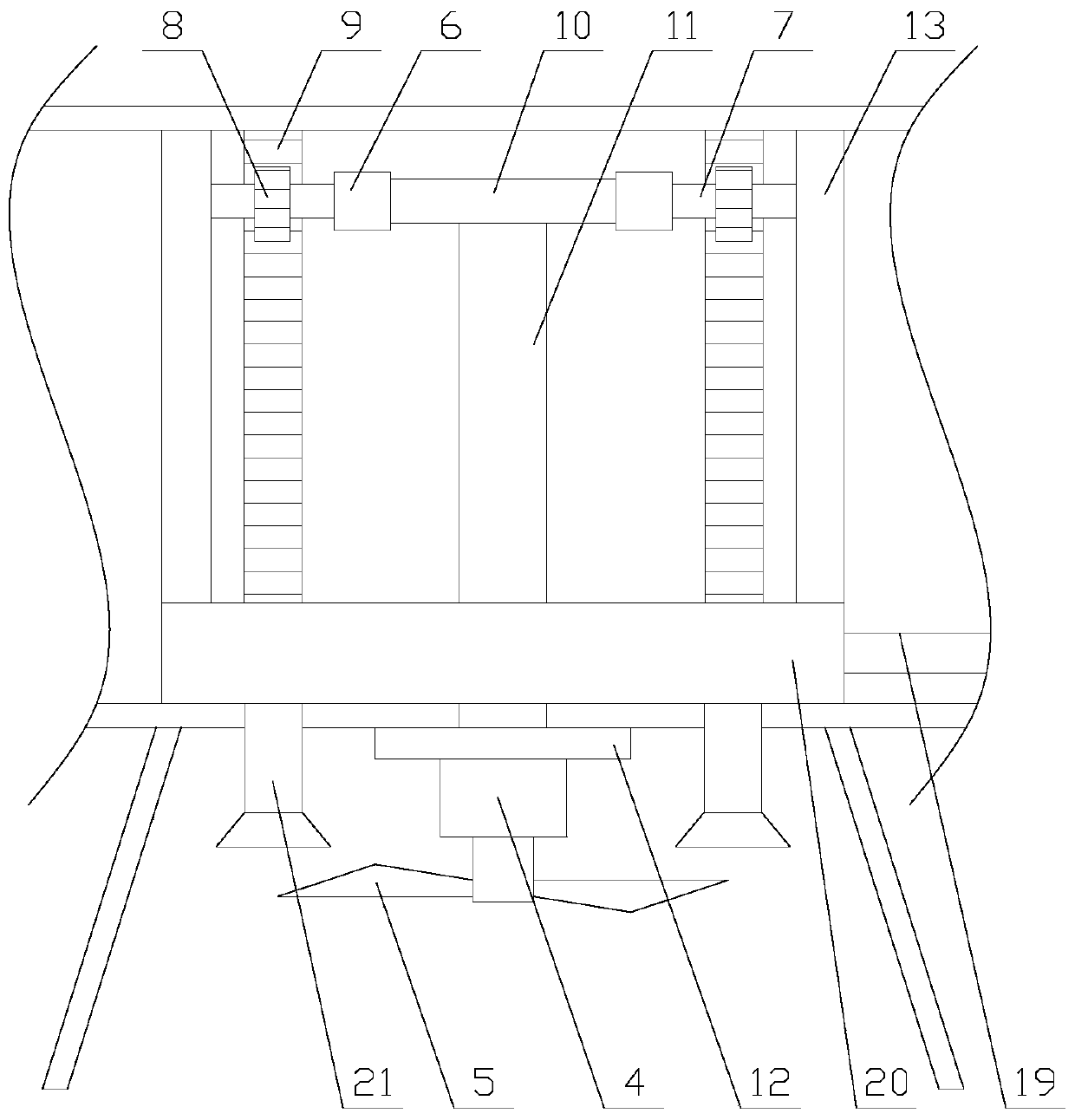

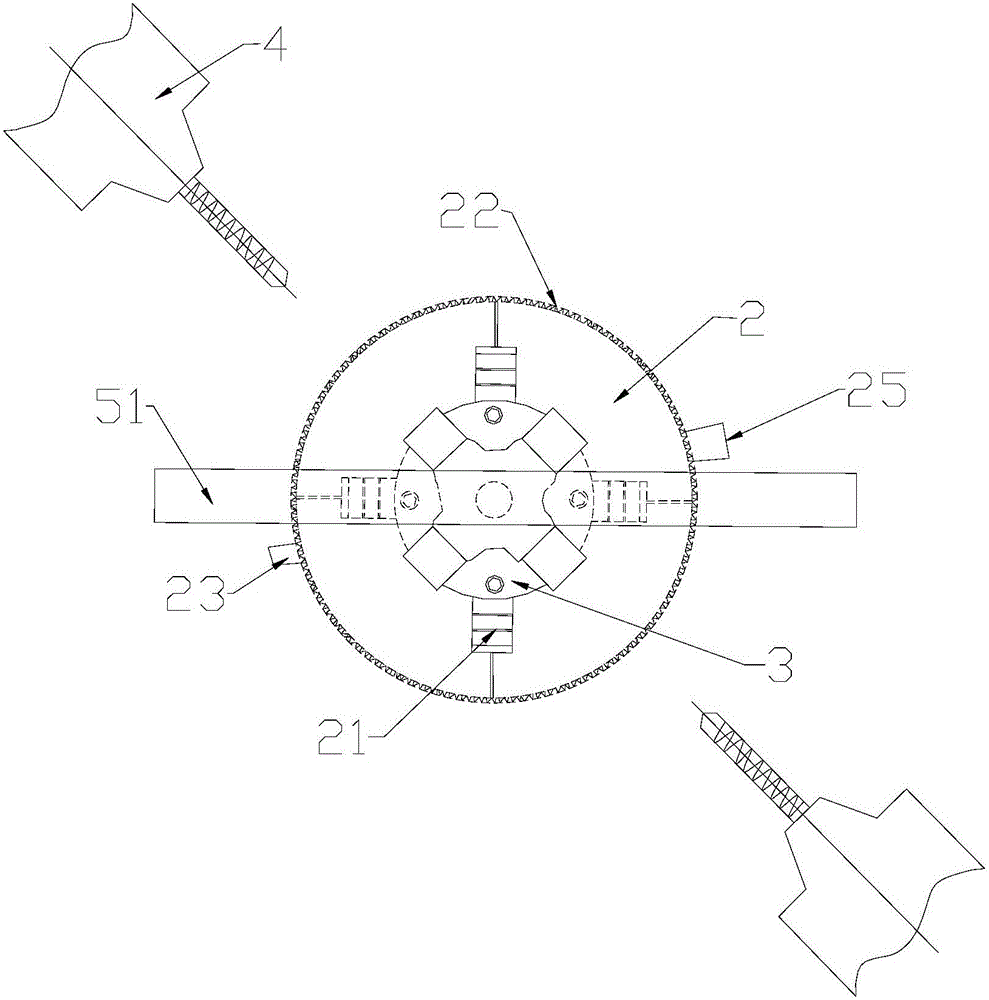

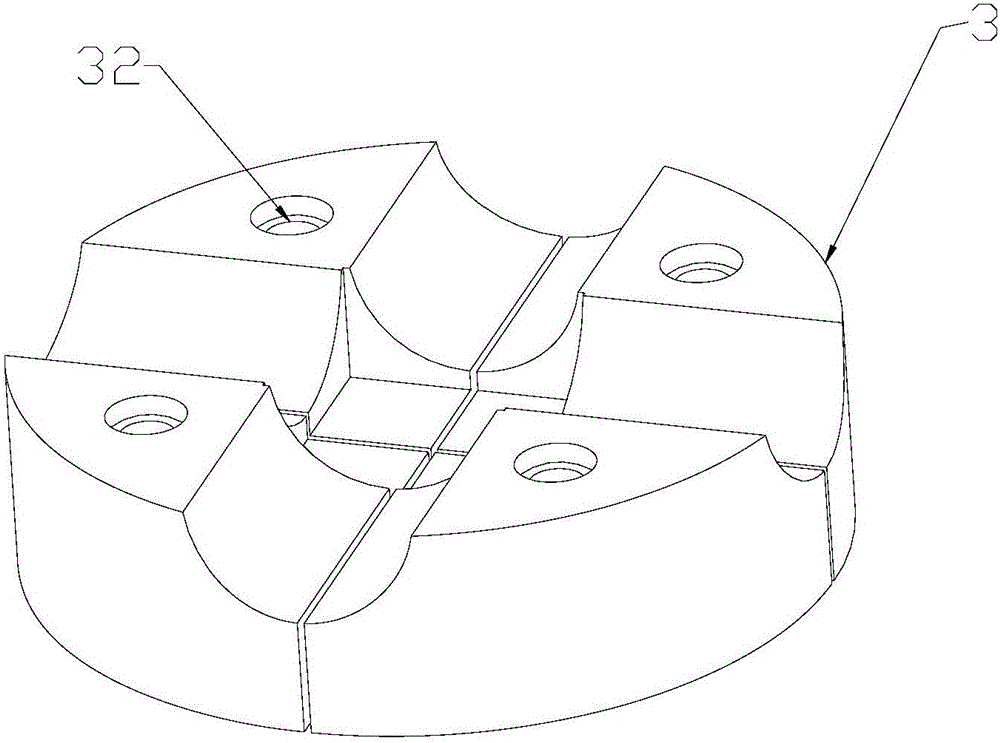

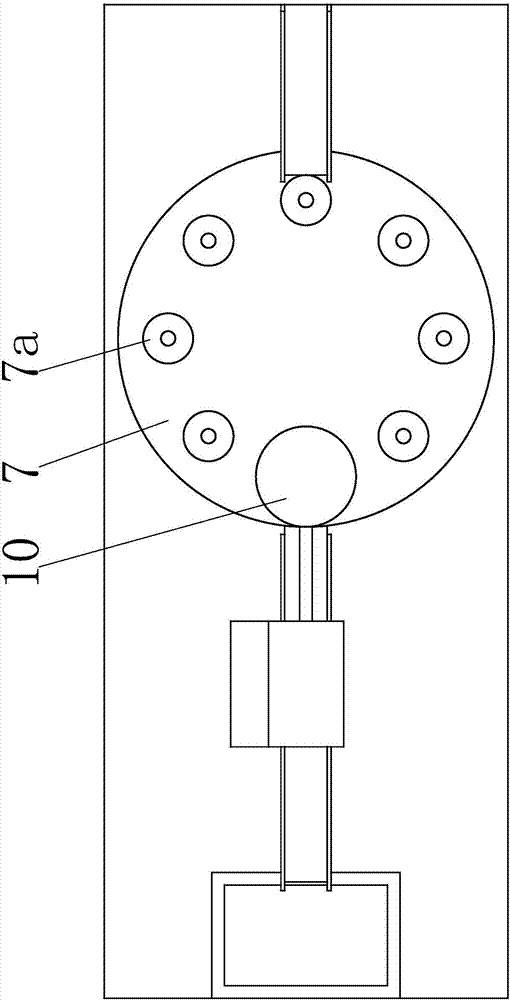

Cross-shaped axle type automatic universal drilling device

ActiveCN105772783AIncrease productivityAutomatic unloadingWork clamping meansChucksDrill bitEngineering

The invention discloses a cross-shaped axle type automatic universal drilling device. The cross-shaped axle type automatic universal drilling device comprises a processing tabletop, a four-jaw chuck which is detachably connected with the processing tabletop, a plurality main motors and a plurality of drill bits connected with the main motors. The cross axle type automatic universal drilling device is characterized in that a support is also arranged on the processing tabletop; a hydraulic cylinder is arranged at the central position of a support cross bar; the lower part of the hydraulic cylinder is connected to a pressure head; the four-jaw chuck is arranged under the pressure head; four jaws on the four-jaw chuck are separately connected with corresponding limiting blocks; straight teeth are arranged on the circumferential surface of the four-jaw chuck and are connected with a gear driving mechanism; a square hole is formed in the circumference of the four-jaw chuck; an auxiliary motor is connected onto the square hole; a through hole penetrates through a center position of the four-jaw chuck and a corresponding position of the processing tabletop; and a material receiving box is arranged under the through hole. According to the cross-shaped axle type automatic universal drilling device disclosed by the invention, two drill bits are arranged for simultaneously processing, so that the production efficiency is improved; and by adopting an improving structure, the device can automatically discharge after the processing is finished.

Owner:诸暨市富邦环保机械有限公司

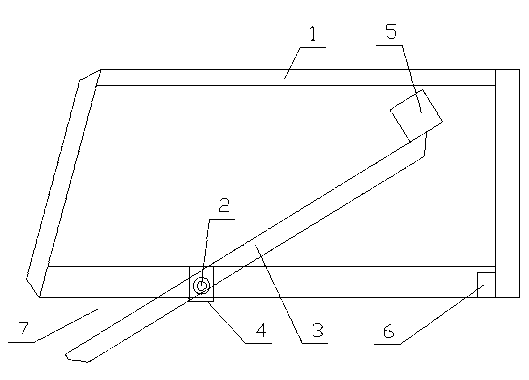

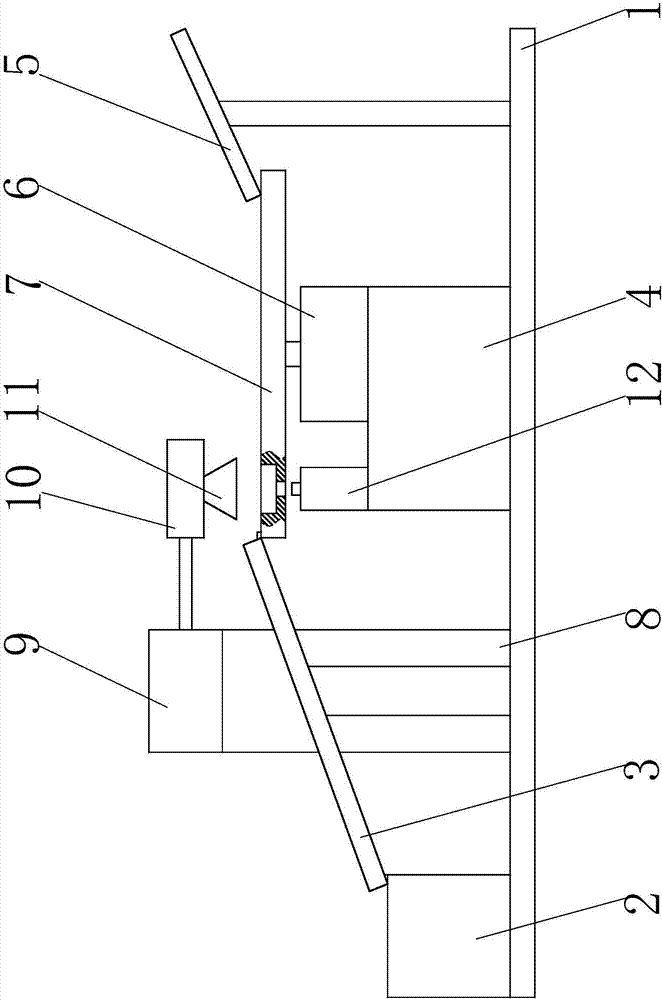

Automatic board station adjusting mechanism

The invention discloses an automatic board station adjusting mechanism and belongs to the field of board machining auxiliary mechanical equipment. The two sides of lifting supports on two sides of theupper portion of a fixed base are vertically and rotationally connected with lifting lead screws; lifting worm wheels are horizontally and fixedly arranged at the upper ends of the lifting lead screws; a rotary rod support is horizontally and fixedly arranged on the upper sides of the lifting supports; the two sides of a main reciprocating rotary rod are horizontally, coaxially and fixedly provided with main lifting worms matched with the lifting worm wheels separately; the two sides of an auxiliary reciprocating rotary rod are horizontally, coaxially and fixedly provided with auxiliary lifting worms matched with the lifting worm wheels separately; an adjusting mechanism is vertically arranged at the positions, on one side of the auxiliary reciprocating rotary rod, of the rotary rod support; and a board bearing mechanism is horizontally arranged on one side of the lifting supports. The automatic board station adjusting mechanism is reasonable in structural design, boards can be stablylifted and adjusted to the inclined station in a swing mode according to the machining demands, automatic transferring, feeding and blanking of boards can be achieved, the automation degree of machining of the boards is improved, and the machining and use requirements are met.

Owner:桐乡市川泰纺织科技有限公司

Wire rope winding equipment capable of removing burrs

The invention discloses wire rope winding equipment capable of removing burrs. The wire rope winding equipment comprises a device box body; sliding spaces with openings facing upwards are formed in the top wall of the device box body in bilateral symmetry; sliding bases are slidably mounted in the sliding spaces; and support bases are fixedly mounted on the sliding bases on the left side and the right side. When wire ropes are wound, a first motor is started, the first motor drives a gear to rotate, the gear drives a first belt pulley to rotate while rotating, and the first belt pulley can enable a roller between tops to rotate and wind the wire ropes while rotating, a wire rope winding device can be wound, and transportation of the wire ropes is facilitated. During winding, the burrs generated on the wire ropes can be removed, the wire ropes can be prevented from being scratched, other equipment is not needed for assistance, that is, the wire rope winding equipment can automatically discharge the wire ropes, and application is convenient.

Owner:天长市润源金属制品有限公司

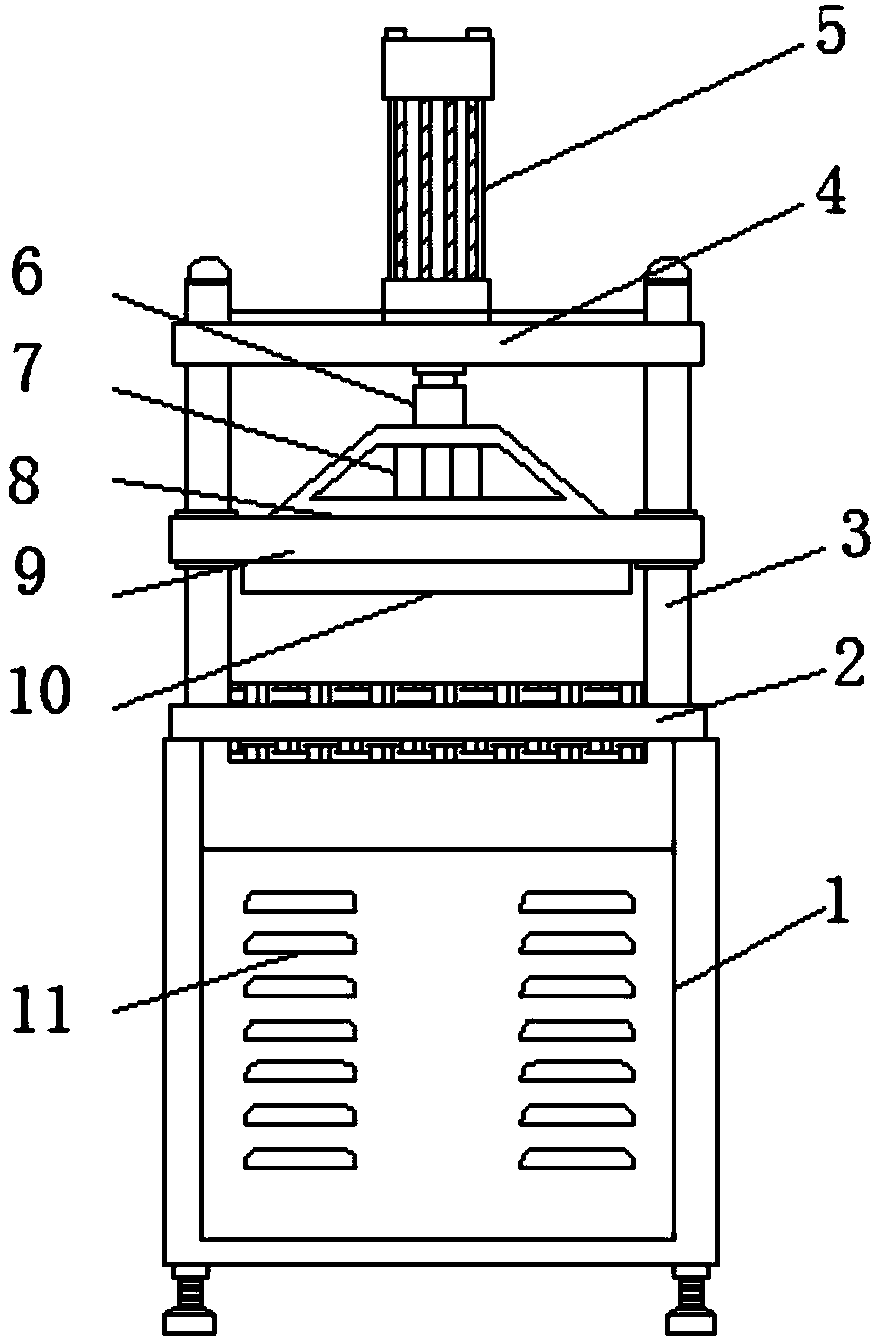

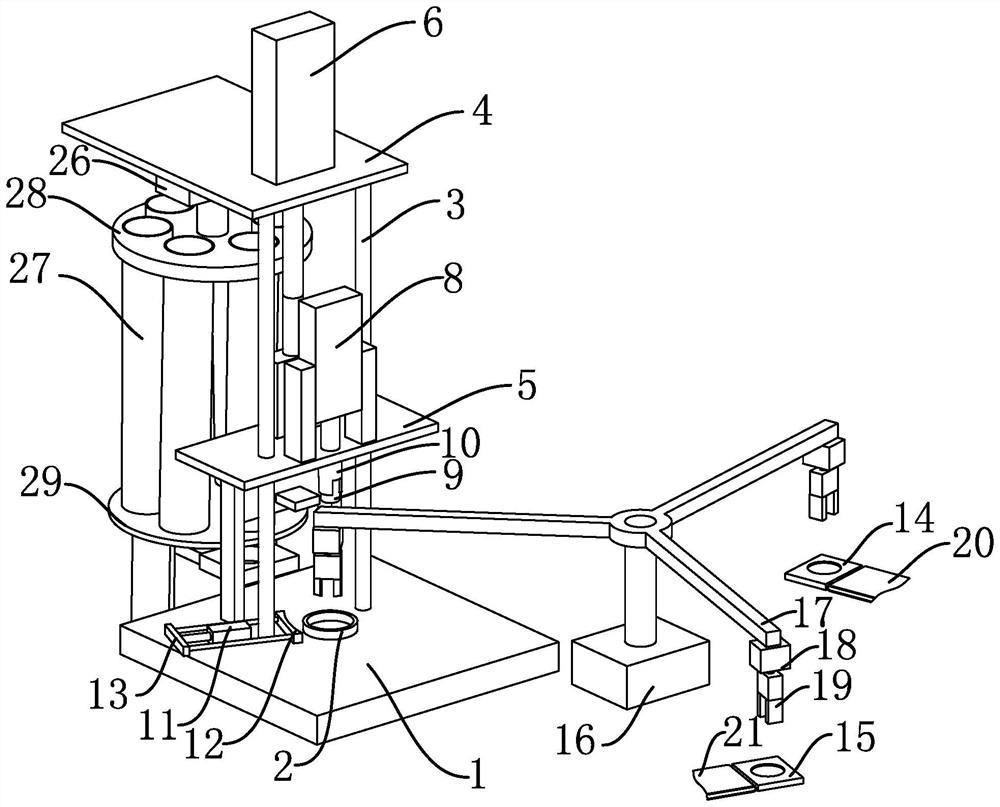

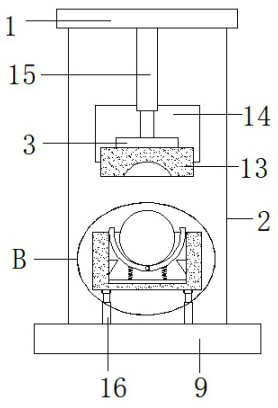

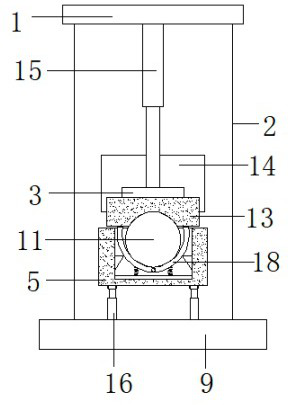

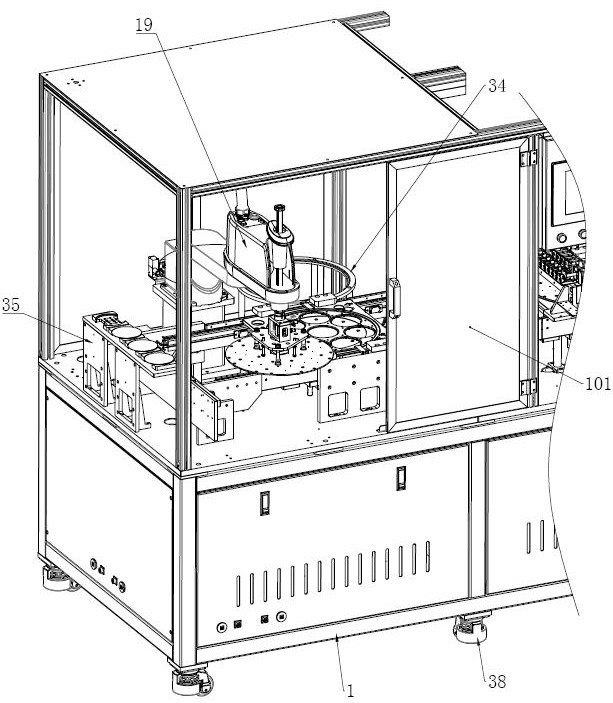

Full-automatic water pump stator mounting equipment

ActiveCN112171238AAutomatic feedingAutomatic unloadingMetal working apparatusControl engineeringControl theory

The invention provides full-automatic water pump stator mounting equipment, and belongs to the technical field of machinery. The problem that in the prior art, the machining efficiency is low is solved. The full-automatic water pump stator mounting equipment comprises a base, and is characterized in that a mounting seat is fixed to the base, and two mounting columns are fixed to the upper portionof the mounting seat; a top plate is fixed at the top ends of the two mounting columns, and a sliding block is slidably arranged on the mounting columns; an air cylinder I is fixed to the top plate, and a piston rod of the air cylinder I penetrates through the top plate; a first air cylinder with an upward piston rod is fixed to the sliding block, the piston rod of the first air cylinder is coaxially fixed with the piston rod of the air cylinder I, an air cylinder II is fixed to the sliding block, and a piston rod of the air cylinder II is downward and penetrates through the sliding block. Thefull-automatic water pump stator mounting equipment has the advantage of improving the machining efficiency.

Owner:兆隆科技(嘉兴)有限公司

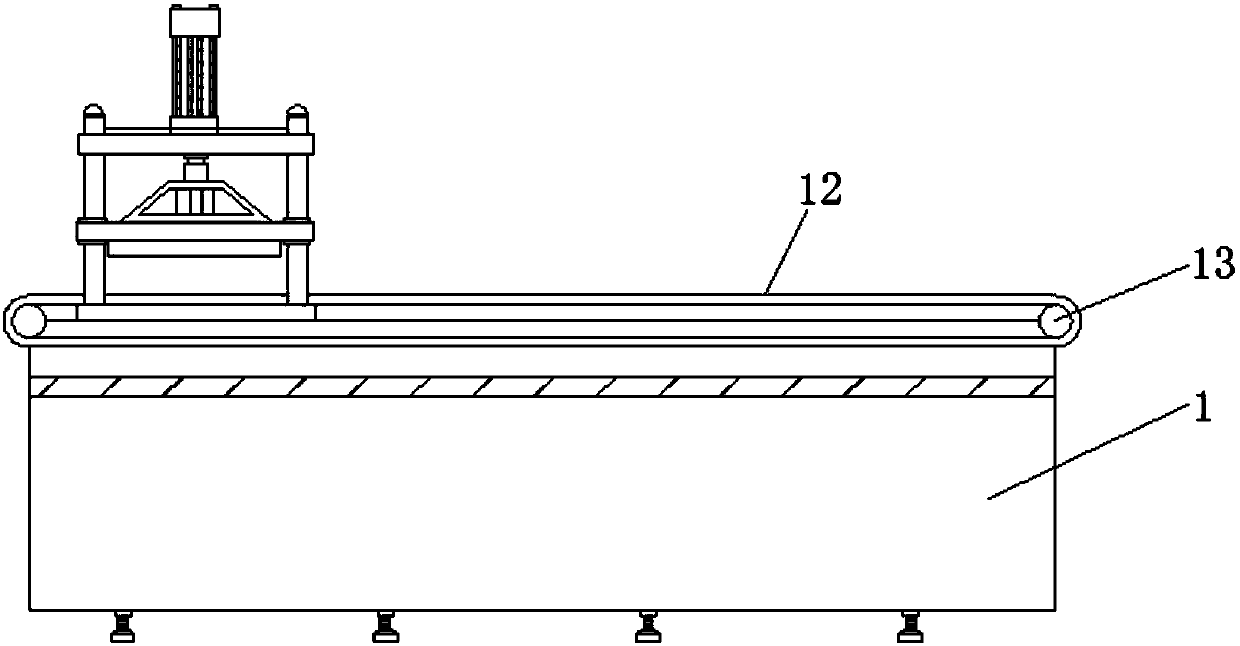

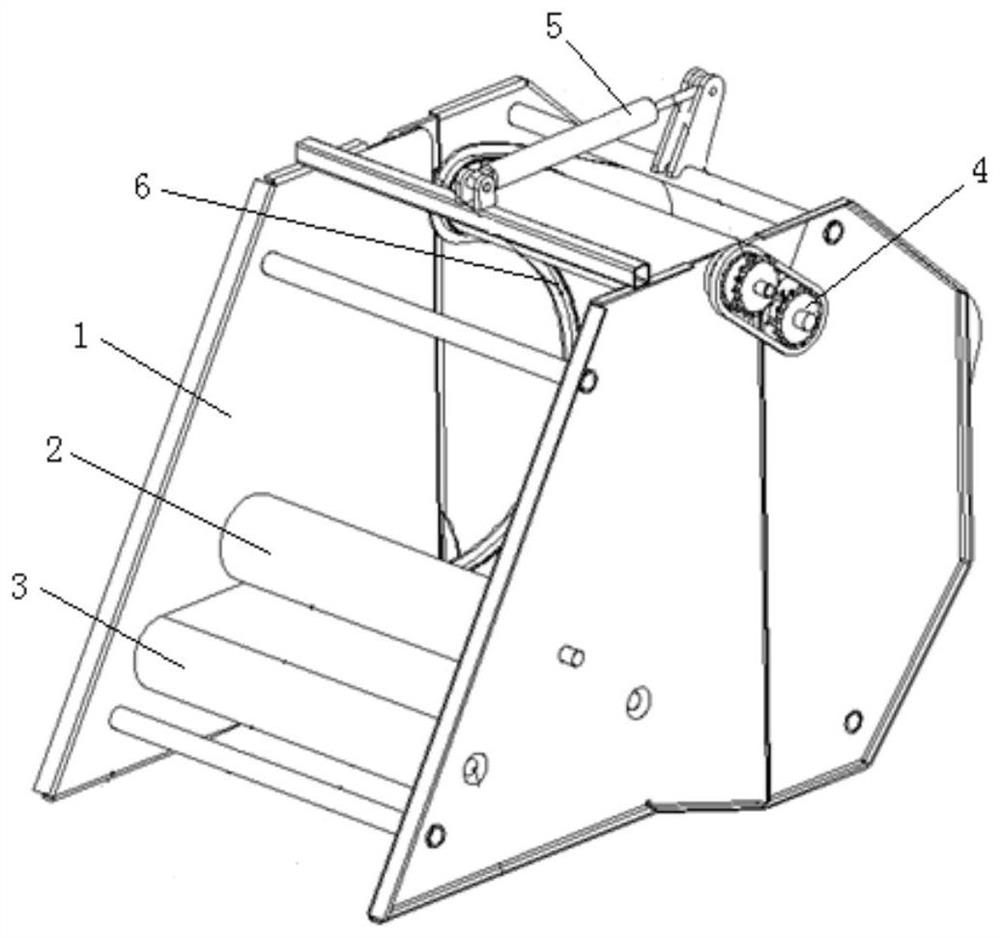

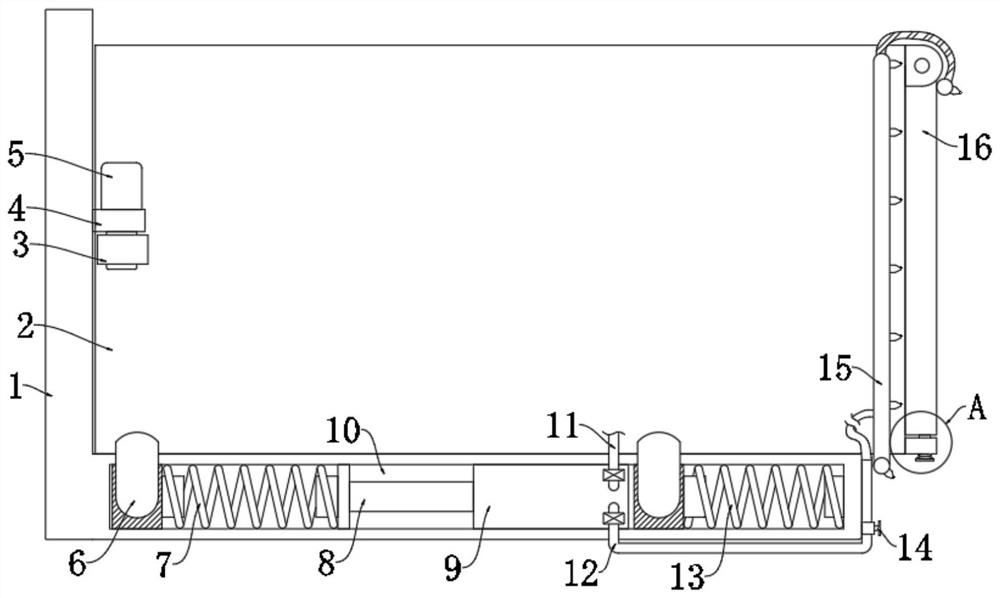

Residual film recycling, rolling and packaging mechanism

PendingCN112027254AAutomatic unloadingPlay a role in assisting membrane releasePackagingGatherer machinesMechanical engineeringElectrical and Electronics engineering

The invention discloses a residual film recycling, rolling and packaging mechanism which comprises a packaging rack, a film pressing roller, a conveying belt, a transmission mechanism, a hydraulic oilcylinder and a residual film packaging belt device. The packaging rack comprises a fixed front portion and a rotatable rear portion hinged to the fixed front portion, the conveying belt is installedbelow the fixed front portion of the packaging rack through a rotating shaft, the film pressing roller is installed above the conveying belt through another rotating shaft, the residual film packagingbelt device is installed on the rotatable rear portion of the packaging rack, the transmission mechanism is used for transmitting the conveying belt and the residual film packaging belt device, and the hydraulic oil cylinder is installed at the top of the packaging rack. The residual film recycling, rolling and packaging mechanism can complete multiple kinds of work through one-time operation, improves the operation efficiency, has the advantages of being simple in structure and low in manufacturing cost, and can meet the agronomic requirements of mechanical film collecting and packaging. Inaddition, the structure design is reasonable and compact, the use is convenient, and a solution is provided for secondary pollution easily caused by farmland residual film stacking.

Owner:SHIHEZI UNIVERSITY

Rapid locating mechanism for stainless steel pipe production

InactiveCN112975493ARapid positioningEasy to processPositioning apparatusMetal working apparatusSS - Stainless steelPipe

The invention discloses a rapid locating mechanism for stainless steel pipe production, relates to the technical field of stainless steel pipe production and processing. In order to solve the problems that rapid location and automatic discharging cannot be achieved in the production and processing process of stainless steel pipes, the following scheme is proposed, and the rapid locating mechanism comprises a base, and two supporting arms are fixedly connected to the top of the base; the tops of the two supporting arms are fixedly connected with a cross beam, and the bottom of the cross beam is fixedly connected with a locating structure; and a discharging device fixedly connected to the top of the base is arranged below the locating structure, and a clamping structure is arranged in a feeding device. According to the rapid locating mechanism, not only can the steel pipe be quickly located and clamped by means of the locating structure and the clamping structure, thereby facilitating machining operation of the steel pipe, but also the steel pipe can be automatically pushed out of the device through control over the discharging device, the labor force is reduced, and the overall working efficiency is improved.

Owner:天长市康弘精特管材有限公司

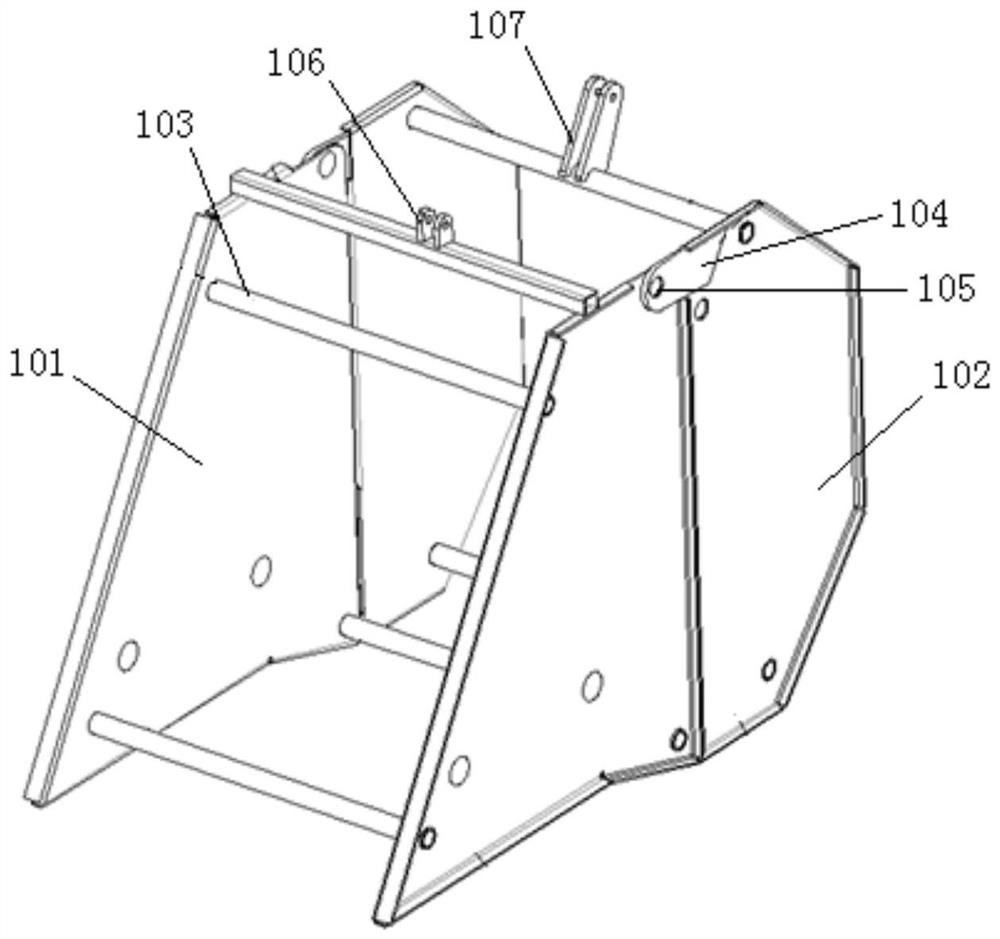

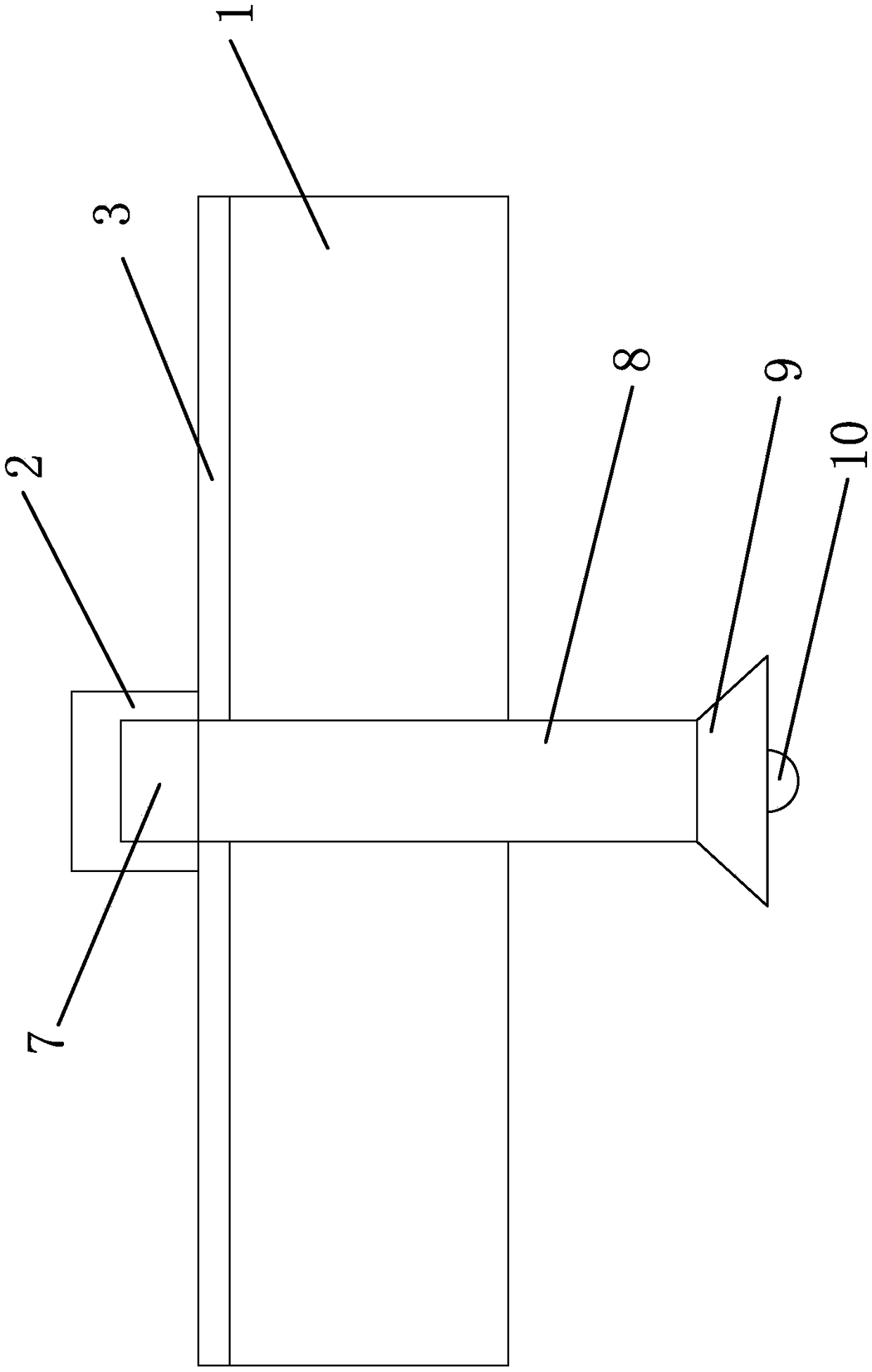

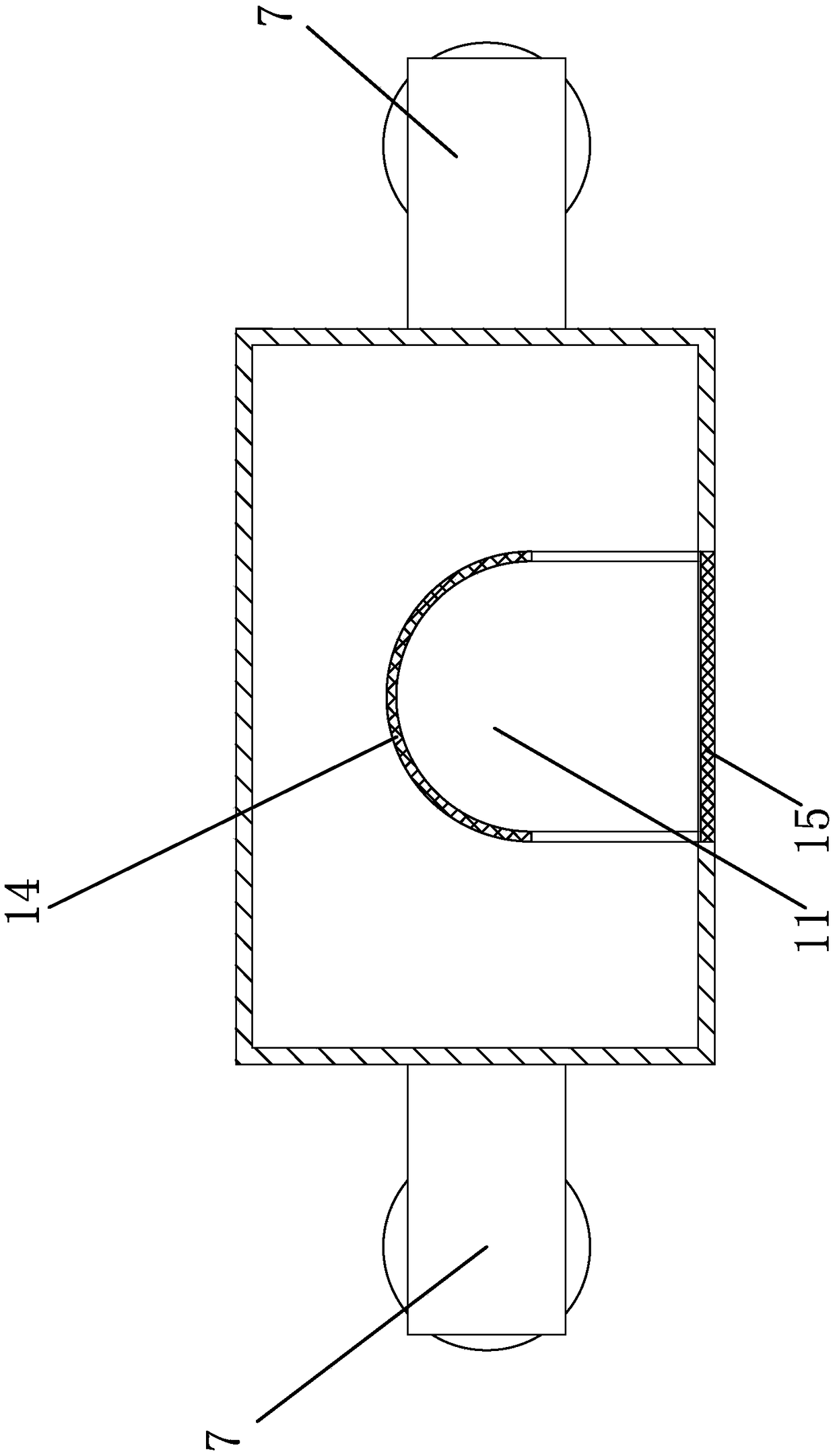

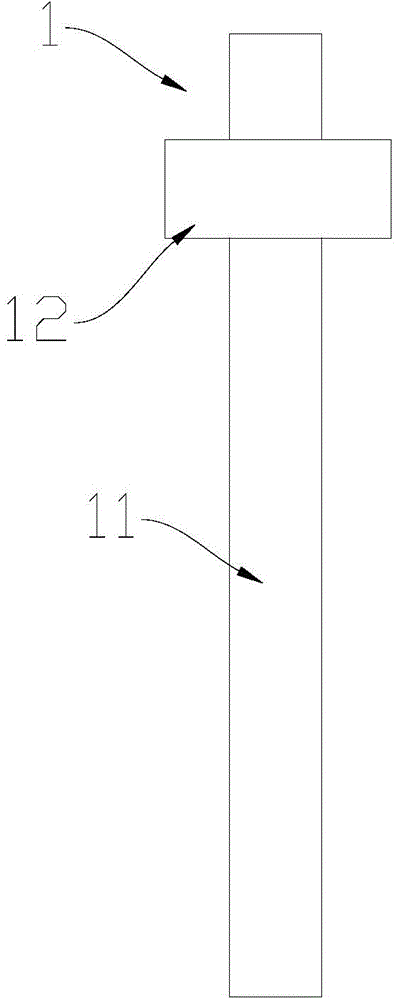

Automatic unloading workpiece basket

InactiveCN103264851ASimple structureAutomatic unloadingLarge containersDischarging meansEngineeringAutomation

The invention discloses an automatic unloading workpiece basket which is convenient to unload. The automatic unloading workpiece basket comprises a basket body, wherein the upper end of the basket body is provided with a feed port; the lower end of the basket body is provided with a rotating shaft and a movable bottom plate which is connected with the rotating shaft; the two ends of the rotating shaft are connected with the lower end of the basket body through mounting seats; the arrangement position of the rotating shaft is away from the middle part of the movable bottom plate; the movable bottom plate is divided into two parts, i.e., a shorter end and a longer end; the basket body close to the shorter end of the movable bottom plate is slantwise arranged; the basket body close to the longer end of the movable bottom plate is vertically arranged; the longer end of the movable bottom plate is provided with a balance weight; and the lower end of the basket body close to the longer end of the movable bottom plate is provided with a supporting block. The automatic unloading workpiece basket has the advantages of simple structure, capability of realizing automatic unloading, high degree of automation, convenience in operation and capabilities of reducing the labor intensity and lowering the production cost.

Owner:JIANGSU ZIQIANG COATING MACHINERY

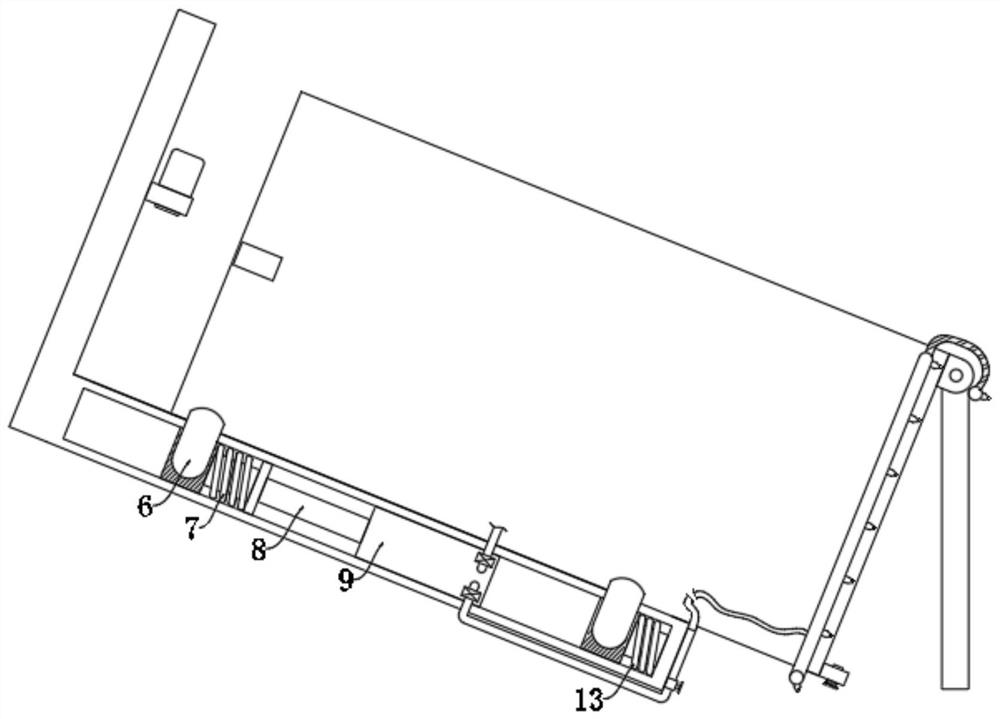

Novel building dump truck hopper capable of reducing dust

InactiveCN112498209ALower hitReduce flyingUsing liquid separation agentVehicle with tipping movementWater storageVehicle frame

The invention provides a novel building dump truck hopper capable of reducing dust. The novel building dump truck hopper comprises an L-shaped truck frame and a truck hopper body arranged on the truckframe, a fixing mechanism used for fixing the truck hopper body is arranged on the truck frame, a sliding groove is formed in the side face of the horizontal portion of the truck frame, the two sidesof the truck hopper body are each fixedly connected with two connecting sliding blocks, the connecting sliding blocks are slidably connected into the sliding groove, a water storage piston barrel located between the two connecting sliding blocks is fixed into the sliding groove, a water inlet pipe and a water outlet pipe are connected with the water storage piston barrel, a valve is arranged on the water outlet pipe, a piston rod is arranged at the end, close to the front side, of the water storage piston barrel, the connecting sliding block on the front side is connected with a first spring,and the other end of the first spring is connected with the piston rod. Spraying can be carried out while discharging is carried out, so that striking and flying of dust are effectively reduced, dustgenerated by discharging is effectively controlled, and the effects of dust reducing and environmental protection are achieved.

Owner:陈健平

Spirally wound gasket outer ring groove milling equipment and use method thereof

ActiveCN106270683AHelps to fall off automaticallyRealize automatic unloadingMilling equipment detailsMetal working apparatusDrive wheelMilling cutter

The invention provides spirally wound gasket outer ring groove milling equipment which comprises a working table, a milling device and a discharging device, wherein the working table comprises a groove milling table and a discharging table; a milling groove is formed in the groove milling table; the milling device is mounted in the milling groove, and comprises a milling cutter, a driving wheel unit and a positioning unit; the milling cutter is movably connected with the positioning unit; the driving wheel unit is used for driving the outer ring of a gasket to rotate in a definite position; the discharging device is mounted on the discharging table, and comprises a telescopic unit, a transmission unit and a clamp unit; the telescopic unit is telescopically connected with the transmission unit; the transmission unit can drive the telescopic unit to perform expanding or retracting movement, so that the outer rings of the gaskets of different sizes are guided to be superimposed; and the clamping unit separably clamps the outer rings of the gaskets, so as to clamp and move the outer rings of the gaskets to the discharging table from the groove milling table, and ensure that the outer rings of the gaskets face the telescopic unit. Therefore, the gaskets can fall off automatically for discharging along the outer periphery of the telescopic unit and are superimposed orderly.

Owner:慈溪埃弗龙密封件有限公司

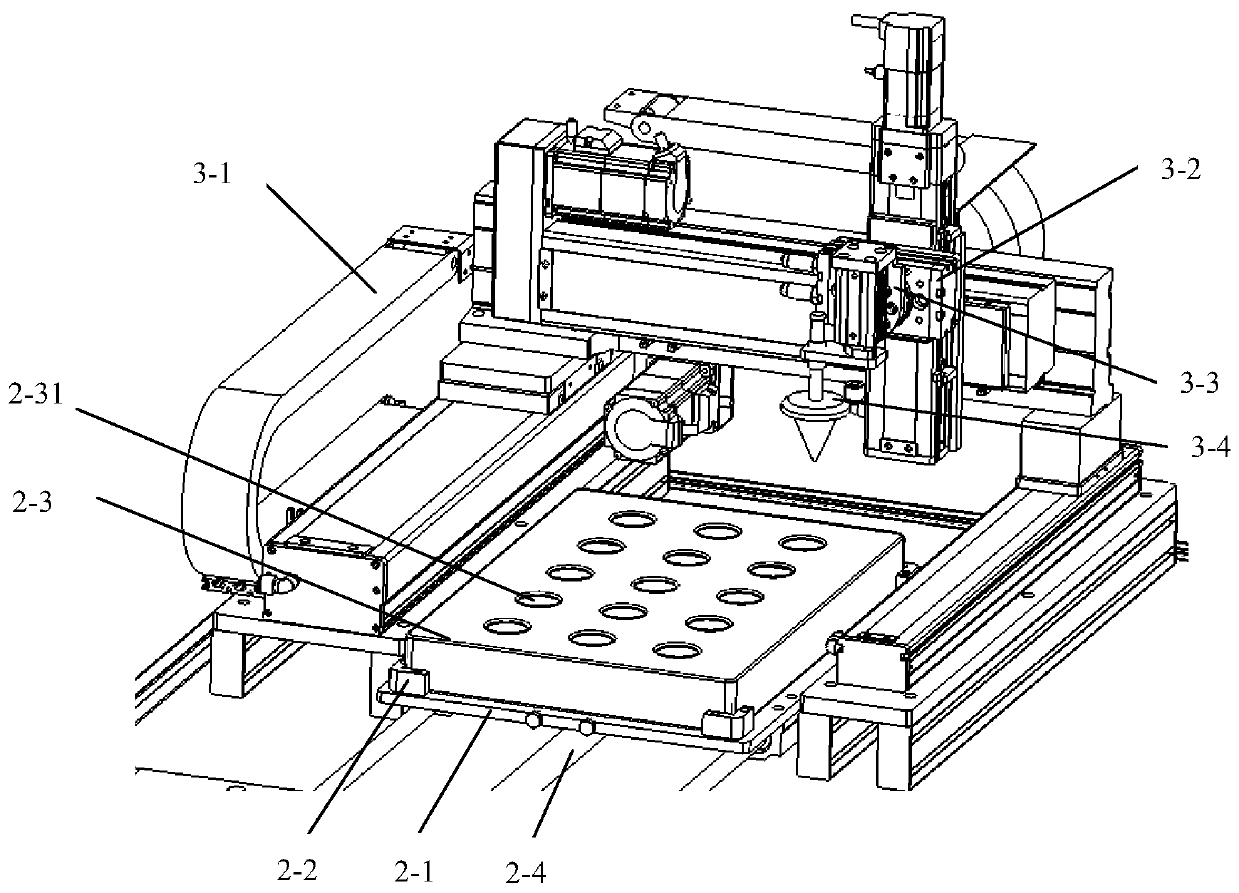

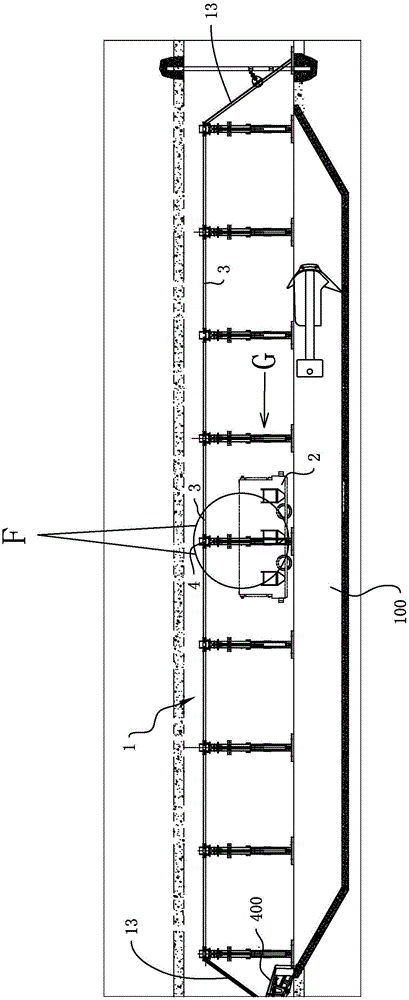

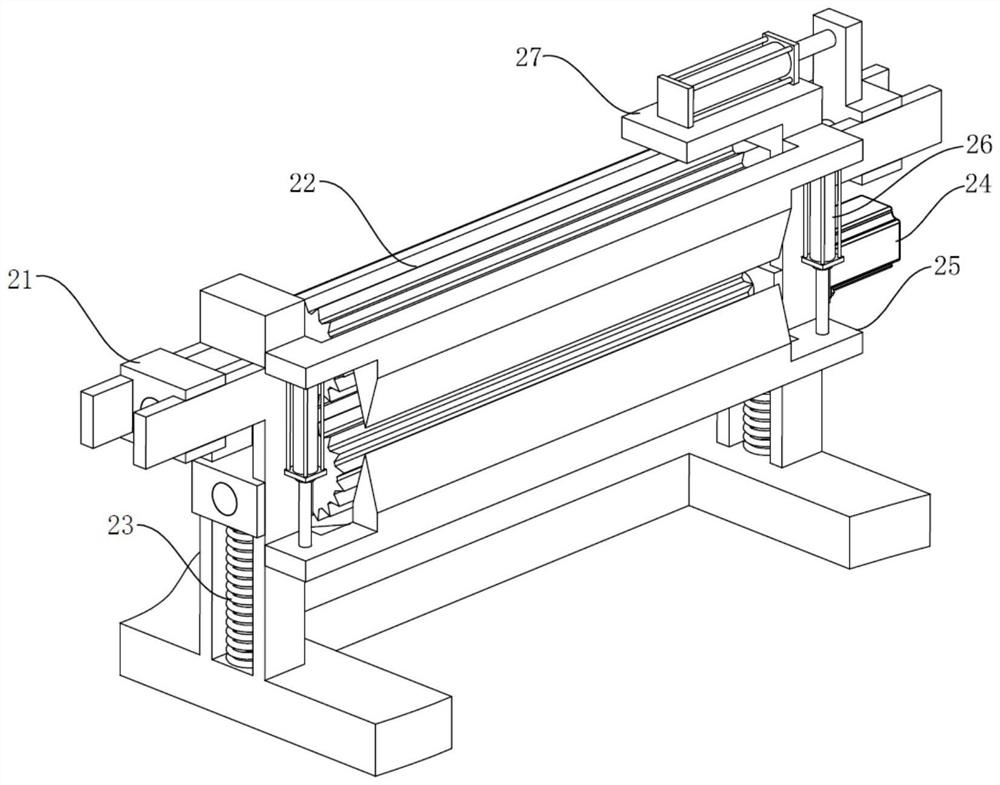

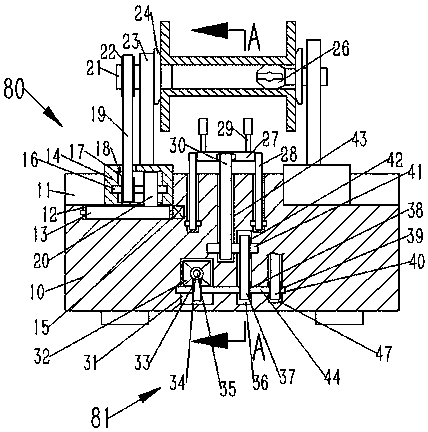

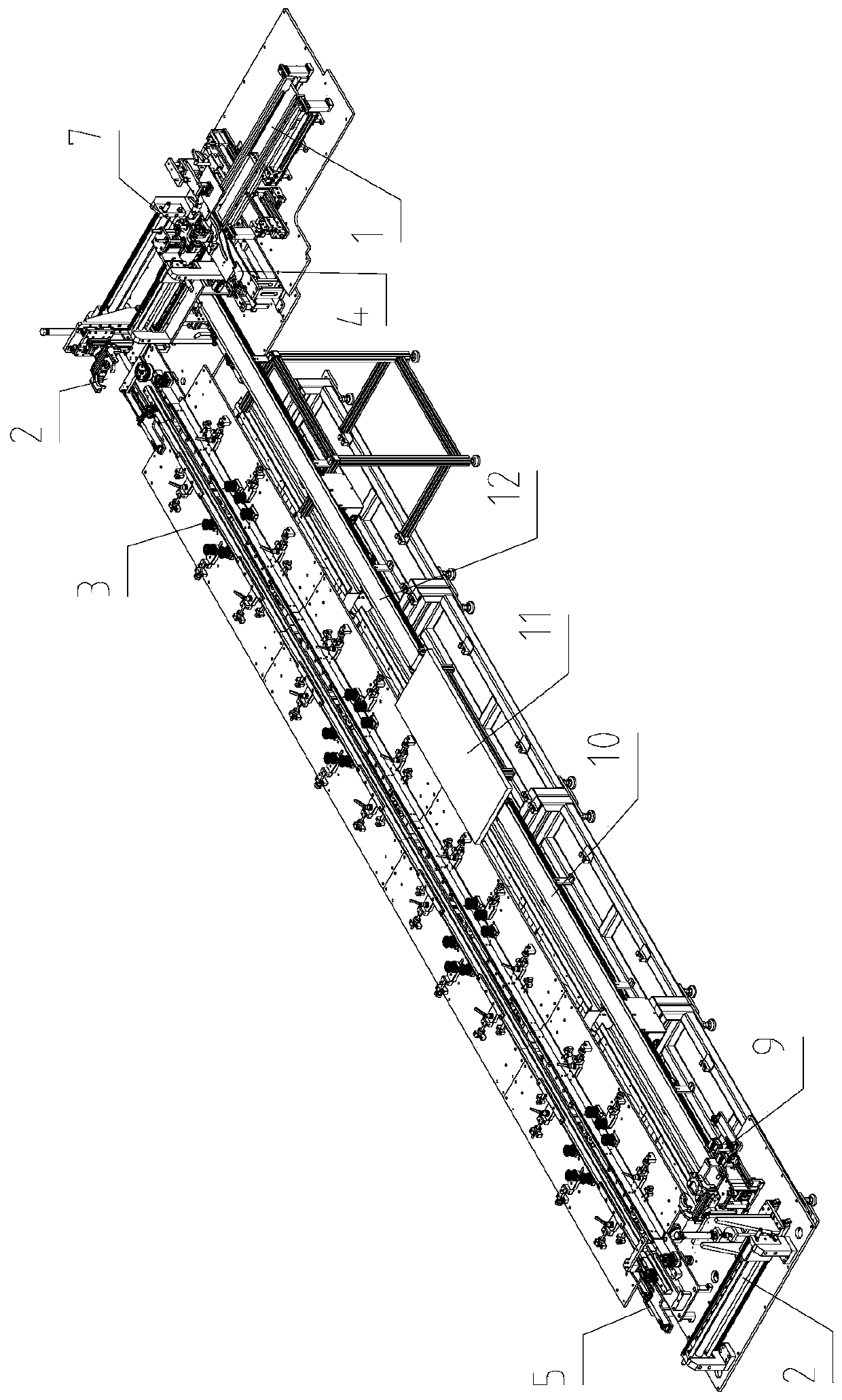

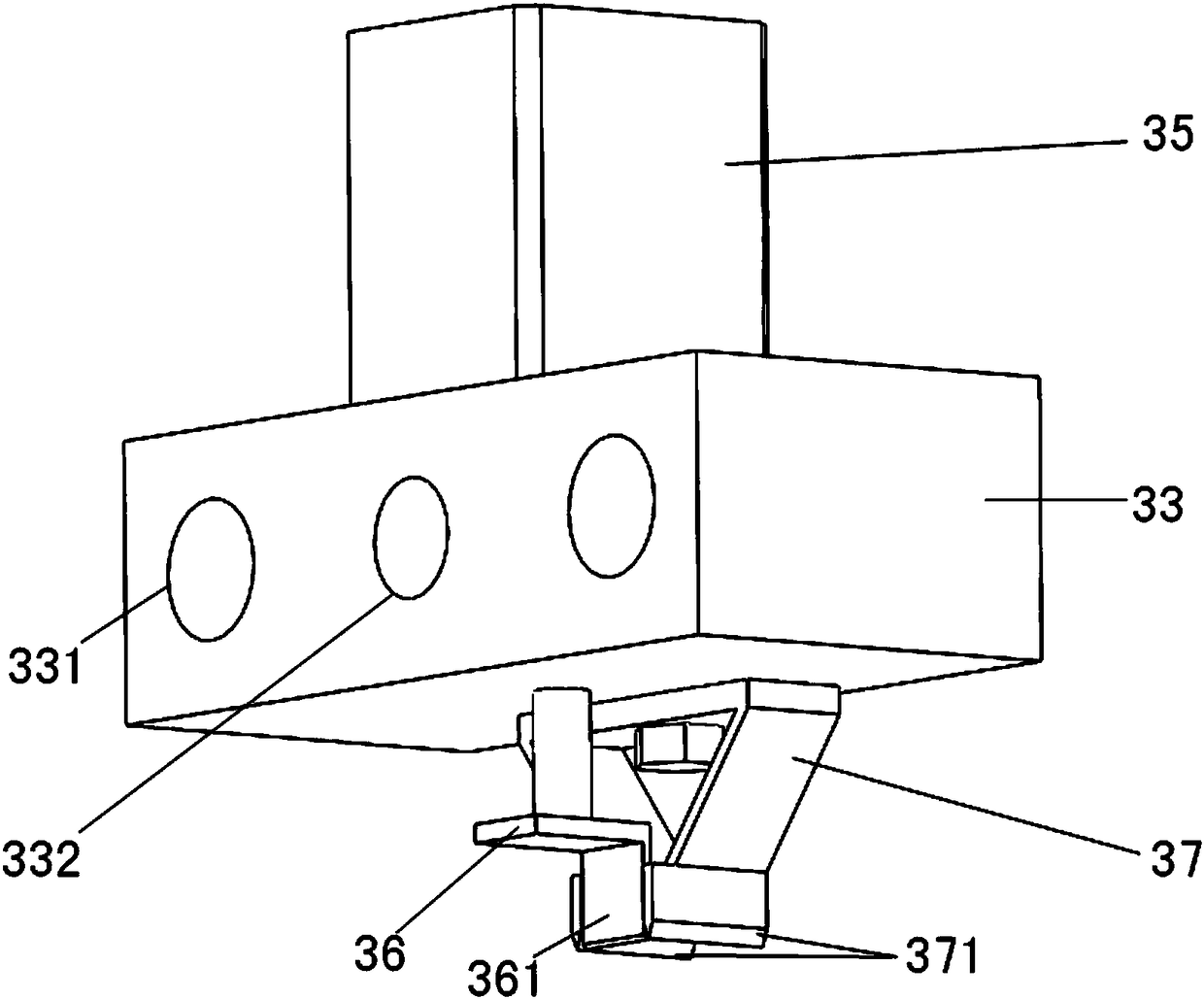

Fiber differential feeding composite grinding device

PendingCN111109834AEnhanced adsorption and adhesionImprove processing efficiencyGrinding drivesBristleGrindingWheel drive

The invention provides a fiber differential feeding composite grinding device, which improves the working efficiency of industrial fiber grinding, improves the grinding quality and grinding consistency, reduces the labor intensity and reduces the manufacturing cost. The device comprises a clamp walking mechanism, and a wire grinding assembly is arranged at the bottom of the clamp walking mechanism. The clamp walking mechanism comprises a walking mechanism supporting plate. A pair of walking sliding rails is arranged on the walking mechanism supporting plate. A positioning walking sliding groove is formed between the pair of walking sliding rails. A left driving belt wheel and a right driving belt wheel are arranged on the walking mechanism supporting plate respectively, the left driving belt wheel and the right driving belt wheel drive synchronous toothed belts to move respectively, and the synchronous toothed belts driven by the left driving belt wheel and the right driving belt wheelrespectively move in the positioning walking sliding groove in a differential mode. The fiber differential feeding composite grinding device can be widely applied to a fiber surface polishing process.

Owner:威海联创工业自动化科技股份有限公司

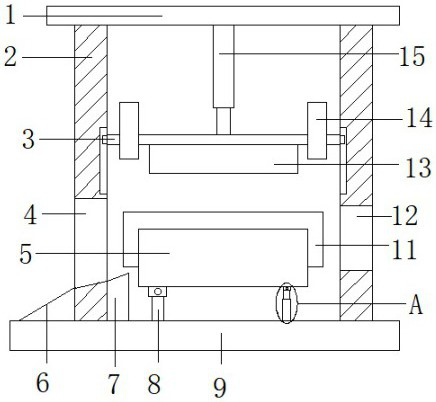

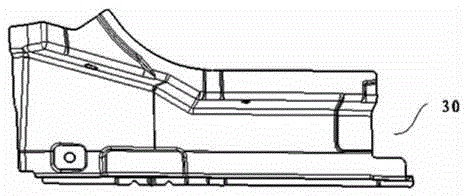

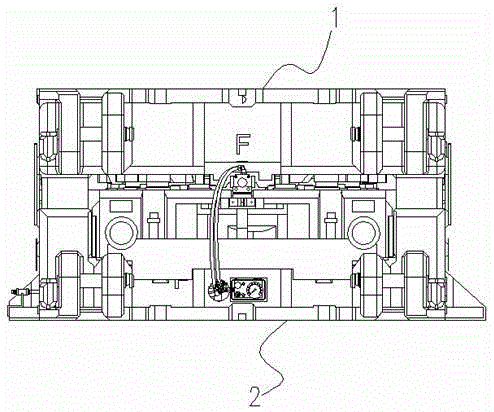

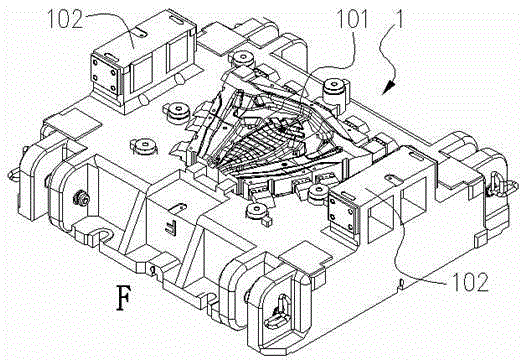

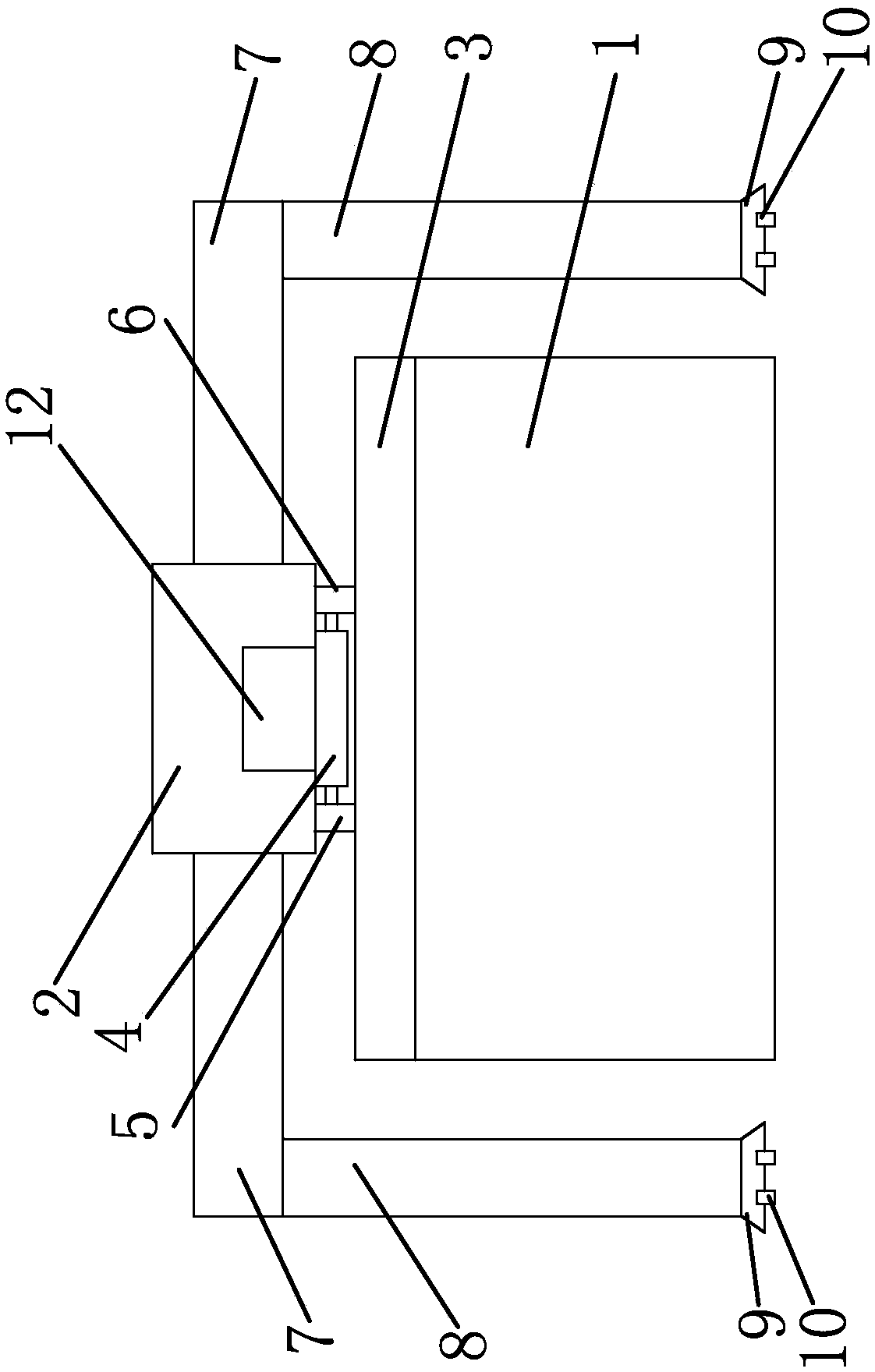

Automatic discharging structure of stamping die for doorsill inner plate connecting part

InactiveCN105328070AIngenious and reasonable structureImprove efficiencyShaping toolsEjection devicesEngineeringMachining

The invention discloses an automatic discharging structure of a stamping die for a doorsill inner plate connecting part. The stamping die comprises an upper die, a blank holder die and a lower die. The upper die is provided with an upper insert, and a lower insert corresponding to the upper insert is composed of a middle insert and peripheral inserts arranged in a circle of the periphery of the middle insert. The middle insert is integrally fixed to the upper surface of a boss. The peripheral inserts are fixedly arranged at the edge of the upper end of a middle vertical hole formed in the blank holder die in an inserted mode. The automatic discharging structure is characterized by further comprising a discharging air cylinder transversely fixed to the blank holder die, and a material pushing plate capable of being connected with the shortest side edge of a sheet material to be machined in an abutting mode when a push rod is in a folded state is fixed to the outer end of the push rod of the discharging air cylinder. The automatic discharging structure has the advantage of being ingenious and reasonable in structure, and is capable of automatically discharging materials after stamping is completed and improving the work efficiency of stamping machining.

Owner:CHONGQING DAFA TIANDI MACHINERY MFG IND CO LTD

Dust removal device of filament wrapping machine

The invention provides a dust removal device of a filament wrapping machine, and belongs to the technical field of dust removal devices. The problem is solved that in the prior art, time and labor arewasted when waste fibers on the two sides of the filament wrapping machine are cleared off. According to the dust removal device of the filament wrapping machine, the filament wrapping machine comprises a machine frame, the dust removal device comprises a dust removal box and a rail, the rail is horizontally fixed to the top of the machine frame, the dust removal box is slidingly arranged on therail, a driving mechanism is arranged at the bottom of the dust removal box and can drive the dust removal box to move back and forth on the rail, a dust outlet is formed in the front side of the dustremoval box, an air outlet is formed in the rear side of the dust removal box, air inlets are formed in the two ends of the dust removal box respectively and connected with dust sucking pipeline assemblies respectively, the air inlet ends of dust sucking pipelines are vertically downward, a distance is formed between the air inlet ends of the dust sucking pipelines and the ground, and a driving motor is arranged inside the dust removal box and connected with a fan. The dust removal device has the advantage of automatically clearing off the waste fibers.

Owner:浙江宇昌纺织科技有限公司

Paperboard notch-cutting machine capable of achieving automatic discharge

The invention discloses a paperboard notch-cutting machine capable of achieving automatic discharge. The mechanism includes a working platform; the two sides of a base of the working platform are provided with supporting plates through molding, the upper surface of each supporting plate is provided with a pair of rails, a moving mechanisms is slidingly arranged in each pair of rails, a bi-directional notch-cutting mechanism is connected between the moving mechanisms located on the two sides of the base respectively, and the center of the upper surface of the base is provided with a long rectangular groove; a first air cylinder is fixed in the long rectangular groove, a piston rod of the first air cylinder is connected with a top plate, a pair of fixation plates are arranged on the surfaceof the front end of the base, and a roll shaft is hinged between the two fixation plates; the upper surface of the bi-directional notch-cutting mechanism is symmetrically provided with a pair of smallrectangular grooves, second air cylinders are fixed on the upper surfaces of the small rectangular grooves, and piston rods of the second air cylinders pass through the small rectangular grooves andare connected with baffles. The paperboard notch-cutting machine has the advantages that rapid notch cutting can be conducted on a paperboard, the cost is low, the work efficiency is high, the machineis convenient to use and maintain, automatic discharge can be achieved, and much labor is saved.

Owner:HUZHOU HUIXIN CULTURE COMM CO LTD

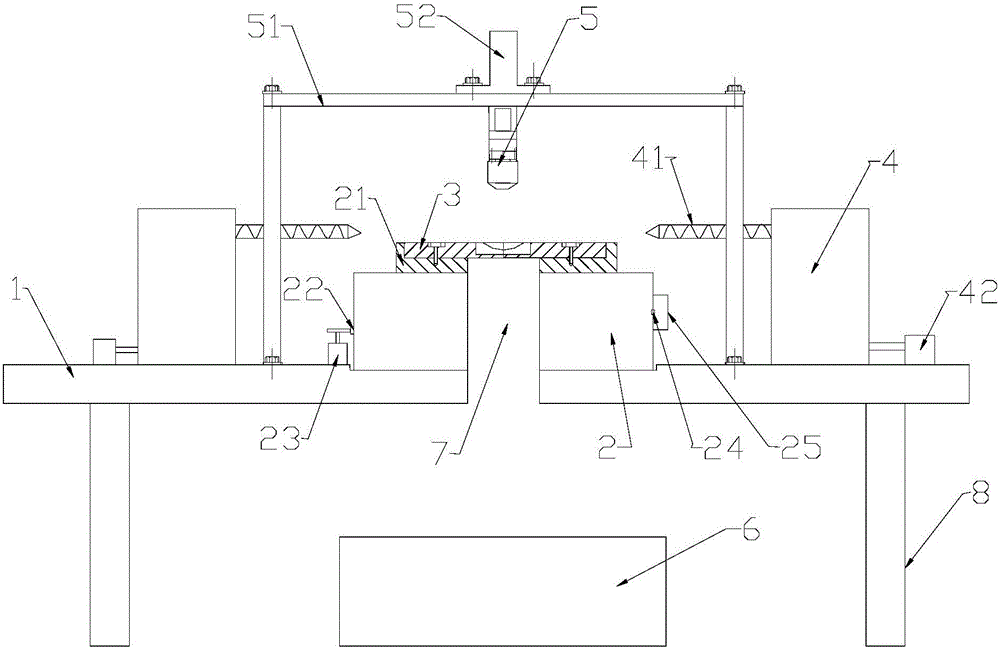

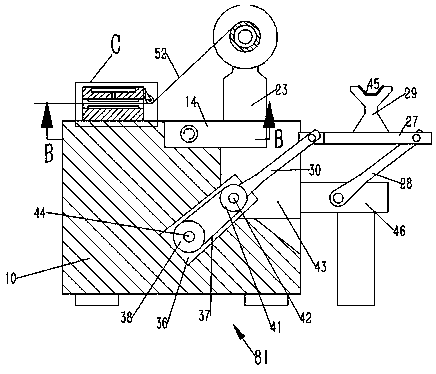

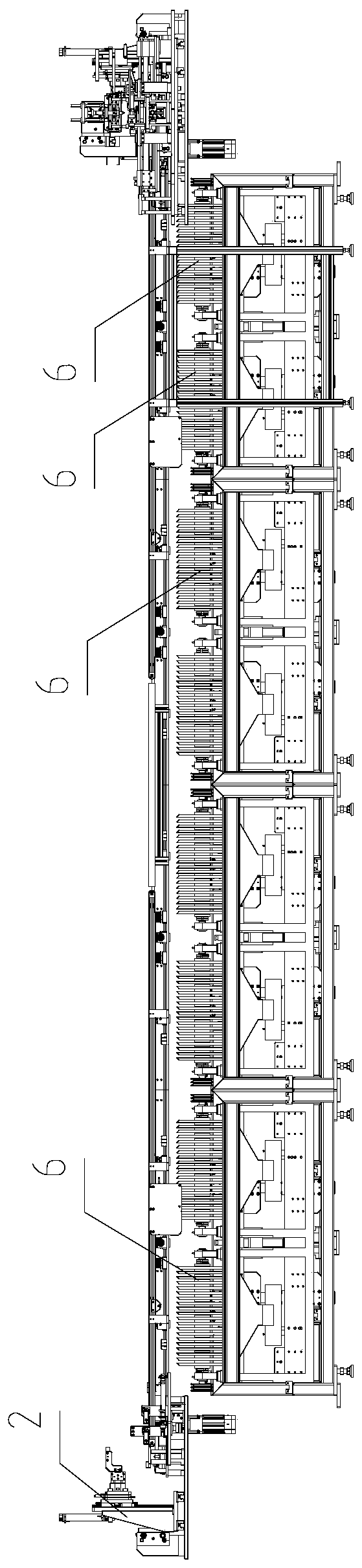

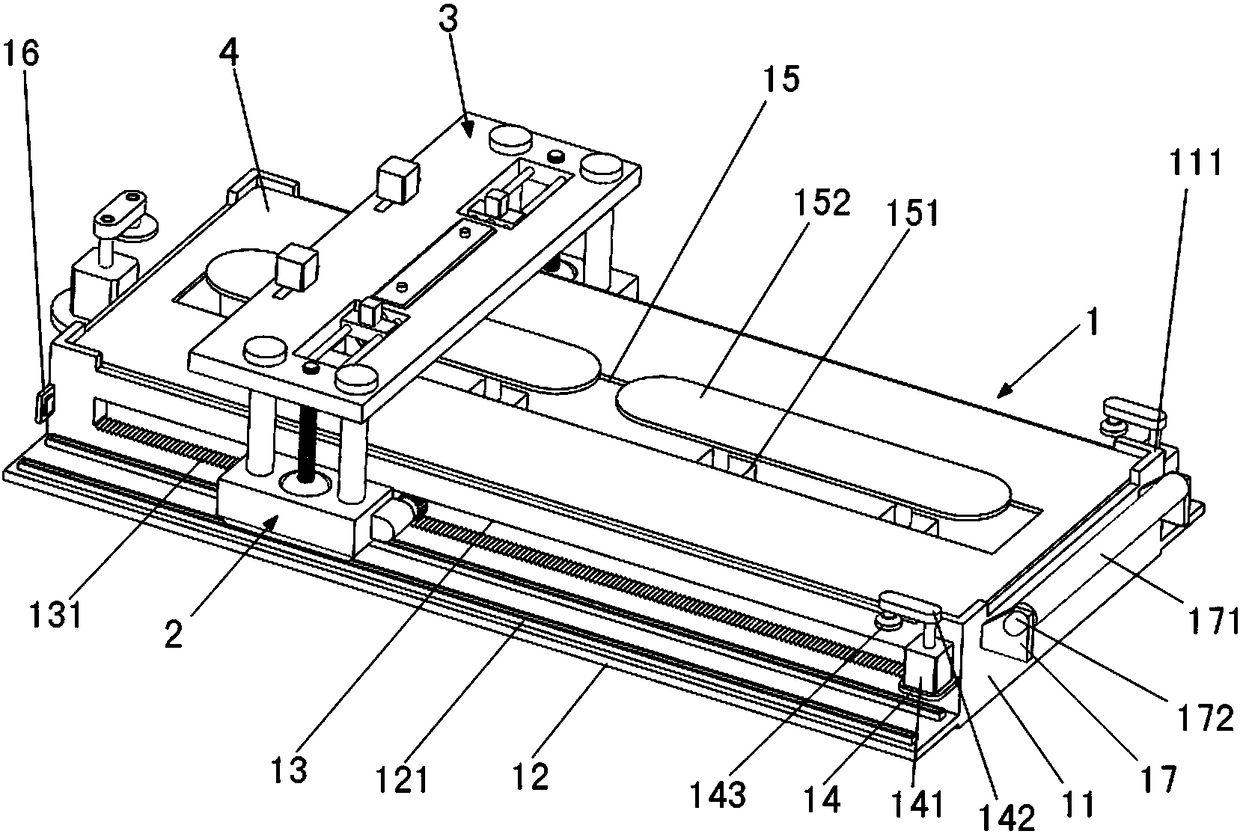

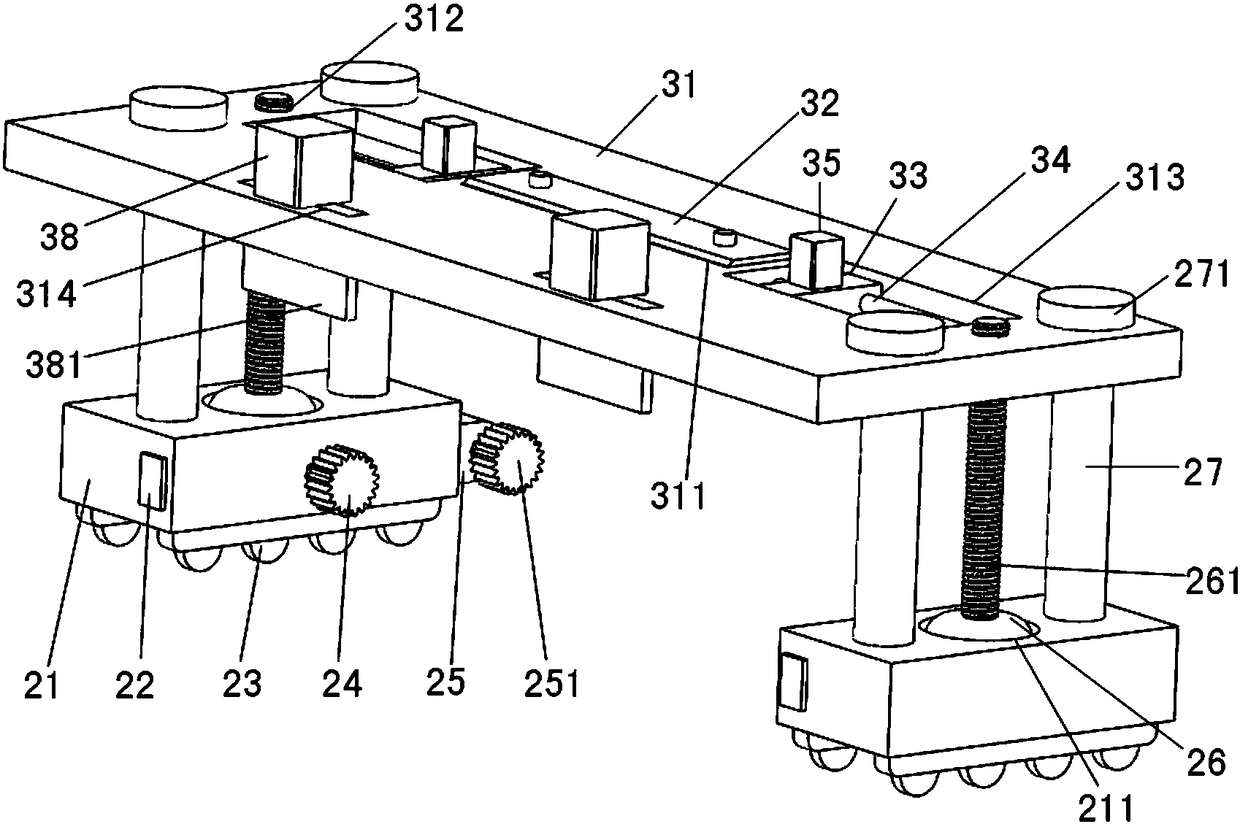

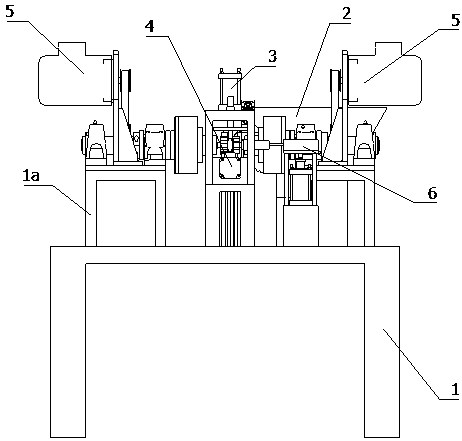

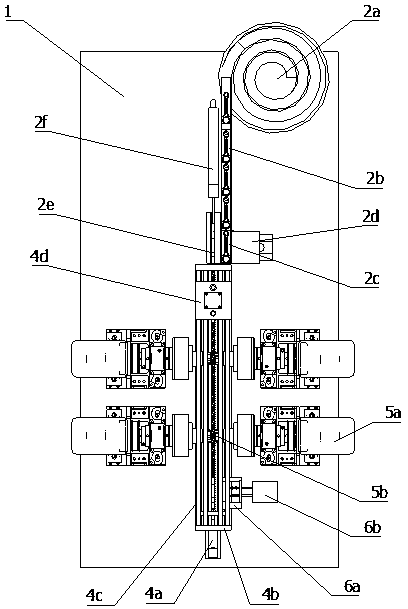

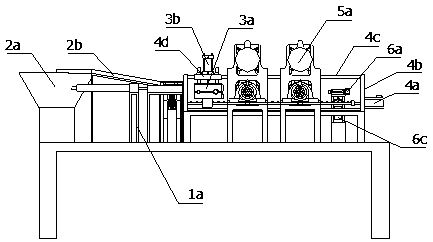

Double-ended continuous milling equipment of automobile part crank connecting rods

ActiveCN108856825AAutomatic feedingAutomatic unloadingMilling equipment detailsPositioning apparatusReciprocating motionEngineering

The invention relates to the field of manufacture of automobile parts and particularly relates to double-ended continuous milling equipment of automobile part crank connecting rods. The double-ended continuous milling equipment comprises a table, a feeding device, a fixing device, a conveying device, milling devices and an unloading device, wherein a bracket for fixedly mounting the conveying device, the milling device and the unloading device is arranged on the table; the fixing device is mounted at a discharge port of the feeding device, and the conveying device capable of driving the fixingdevice to horizontally reciprocate is mounted on the fixing device; a plurality of milling devices which are arranged in opposite directions are arranged at two sides of the conveying device; and theunloading device is arranged at the side of the tail end of the conveying device. The equipment provided by the invention can perform multiple milling processes for crank connecting rods, can realizeautomatic feeding, can fix the crank connecting rods during processing, and can realize automatic unloading after processing.

Owner:宁波市奉化区力迅机械制造有限公司

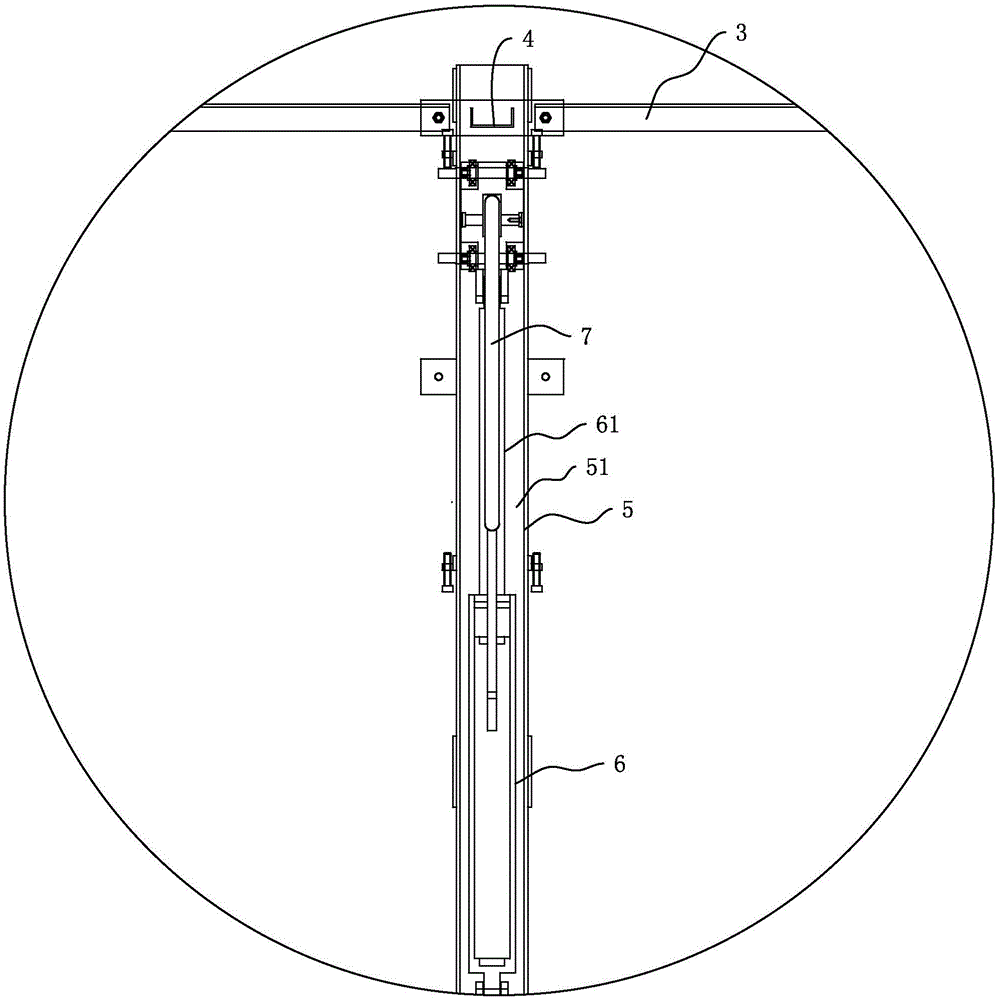

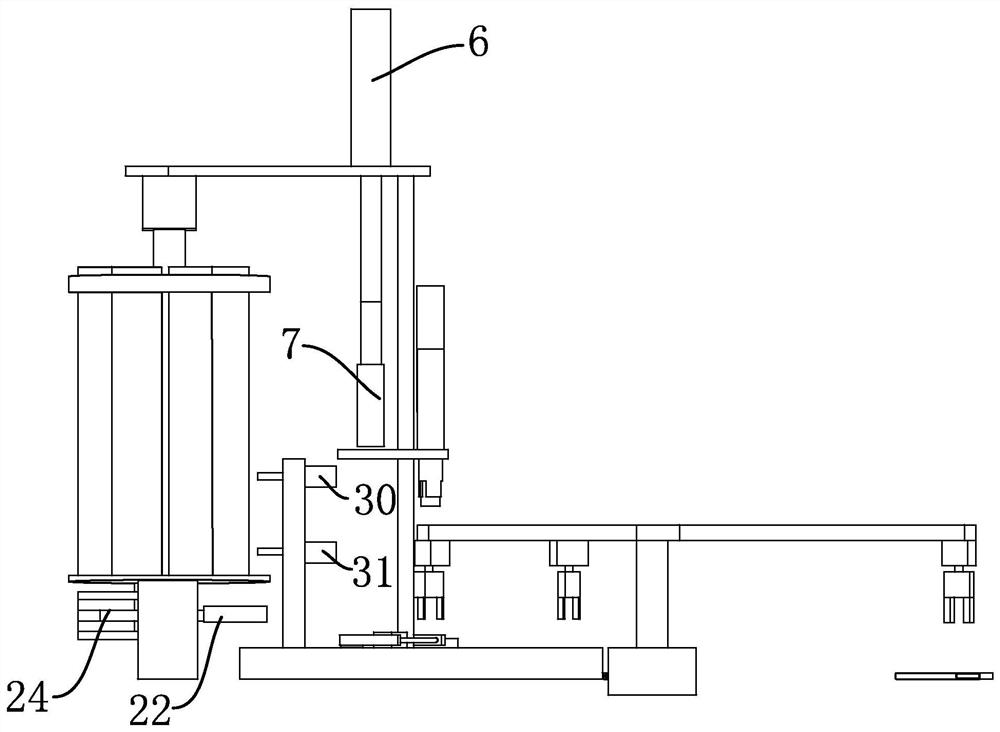

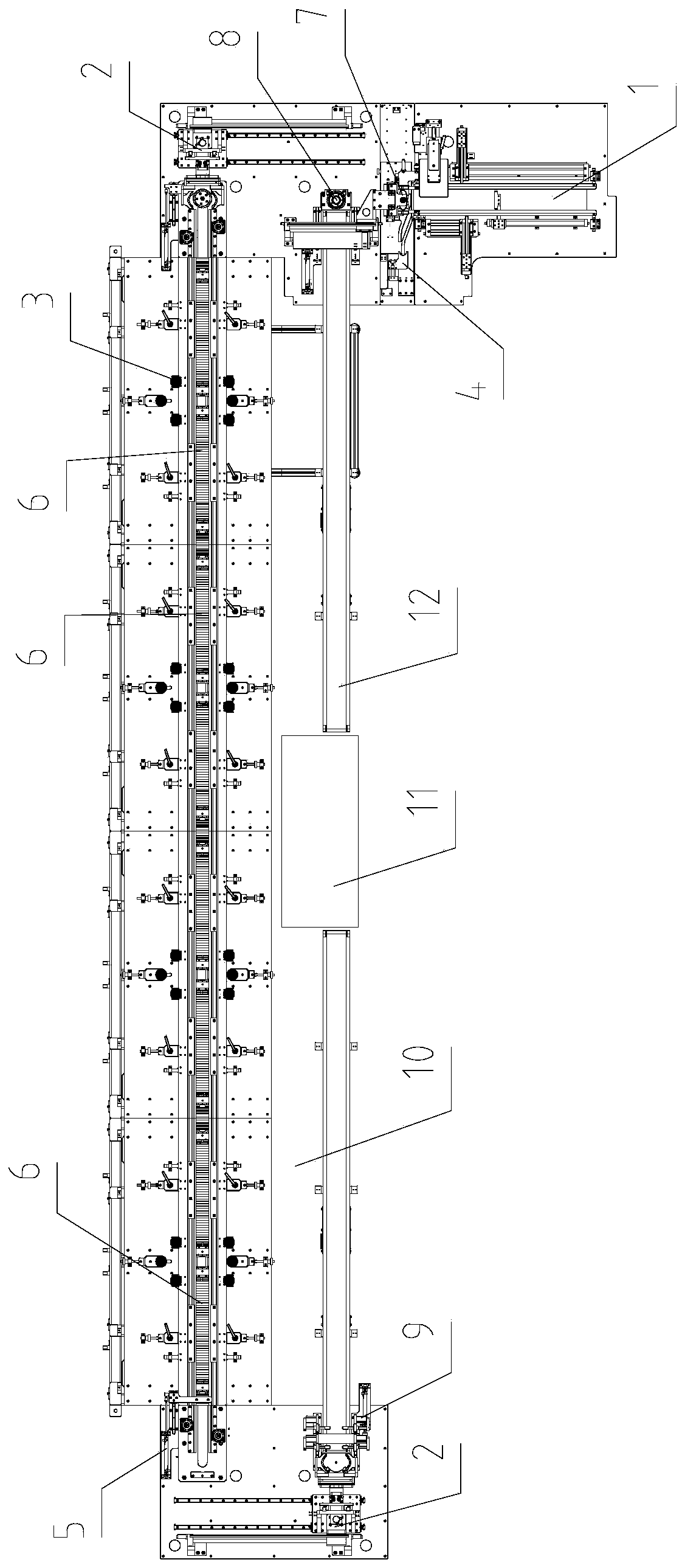

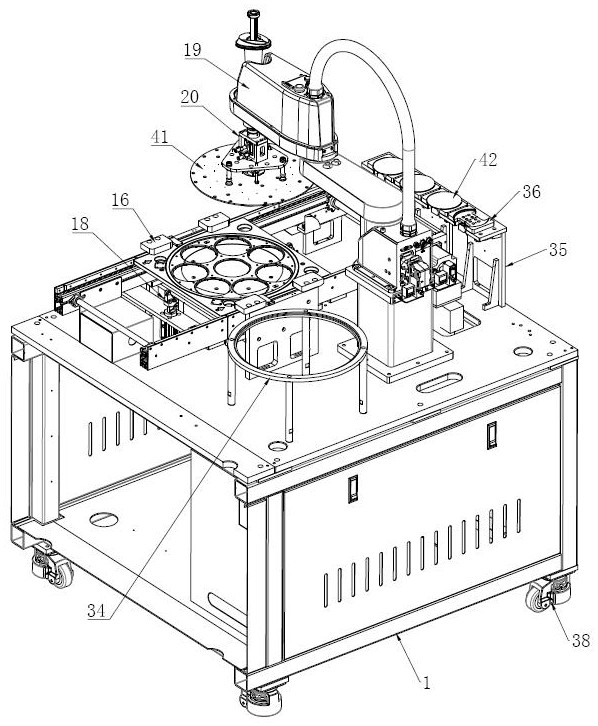

Pick-and-place device for automatic wafer unloading

ActiveCN112420578AAchieve pre-positioningRealize fine positioningSemiconductor/solid-state device manufacturingConveyor partsWaferTransfer line

The invention belongs to the technical field of wafer unloading and provides a taking and placing device for automatic wafer unloading. The taking and placing device comprises a rack, a speed chain conveying line, a carrier positioning mechanism, a taking and placing mechanical arm, a cover plate placing table and a wafer placing table are arranged on the rack, wherein a blocking cylinder is arranged on the speed chain conveying line; the taking and placing mechanical arm and the cover plate placing table are both located on one side of the speed chain conveying line, a taking and placing mechanism is arranged at the shaft end of the taking and placing mechanical arm, and the wafer placing table is located at one end of the speed chain conveying line; the material taking and placing mechanism comprises an installation frame installed on a working shaft of the taking and placing mechanical arm, a Bernoulli suction cup driven by a piece taking air cylinder is installed on the installation frame, a suction nozzle installation plate is further installed at the bottom of the installation frame, and a plurality of cover plate suction nozzles are installed at the bottom of the suction nozzle installation plate. Compared with a traditional manual wafer taking mode, wafer taking efficiency is greatly improved, the phenomenon that the wafer is accidentally scratched in the wafer discharging process is effectively avoided, and it is guaranteed that the quality and the percent of pass of the wafer are not affected in the wafer discharging process.

Owner:SHANDONG NOVOSHINE OPTOELECTRONICS CO LTD

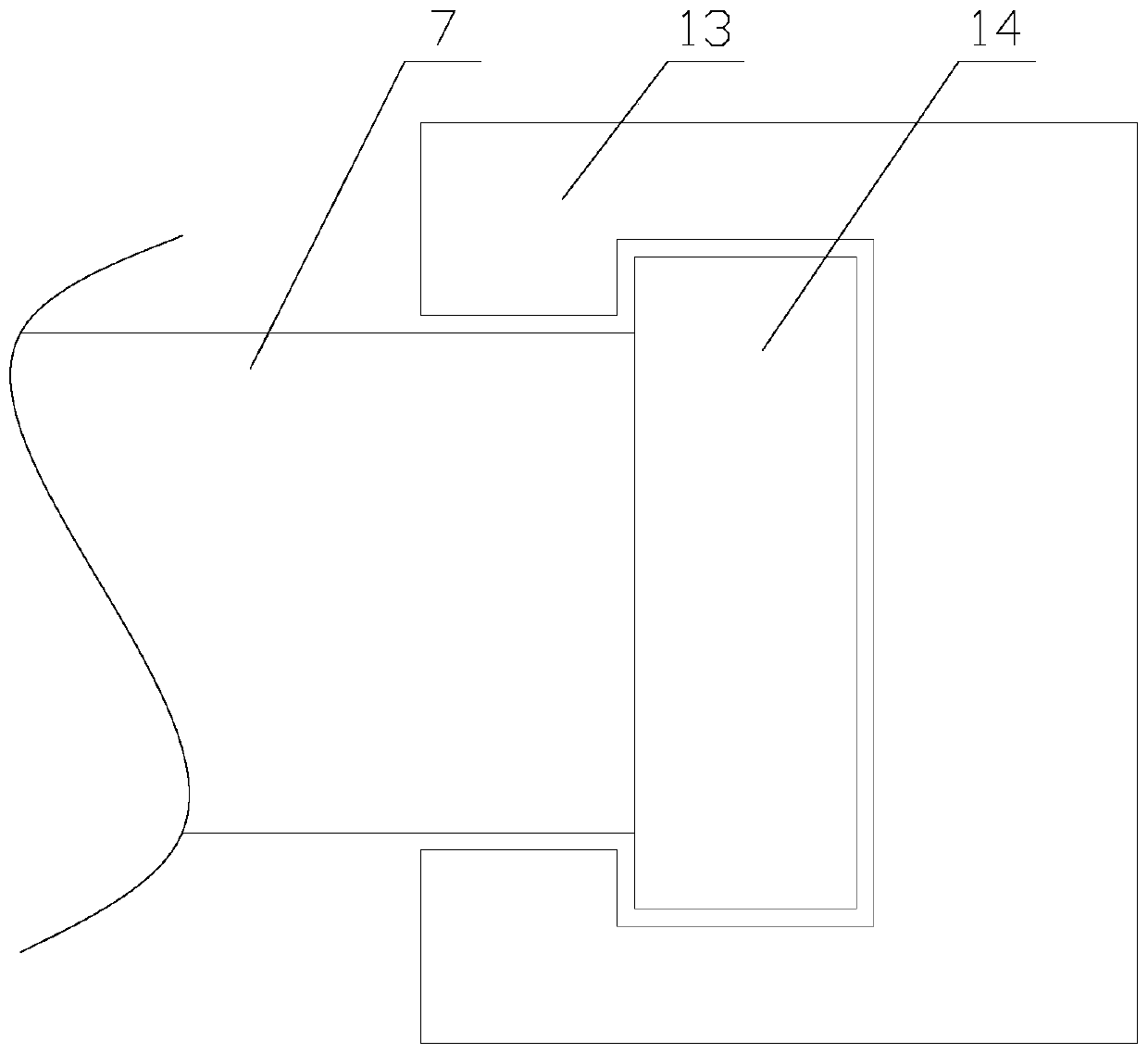

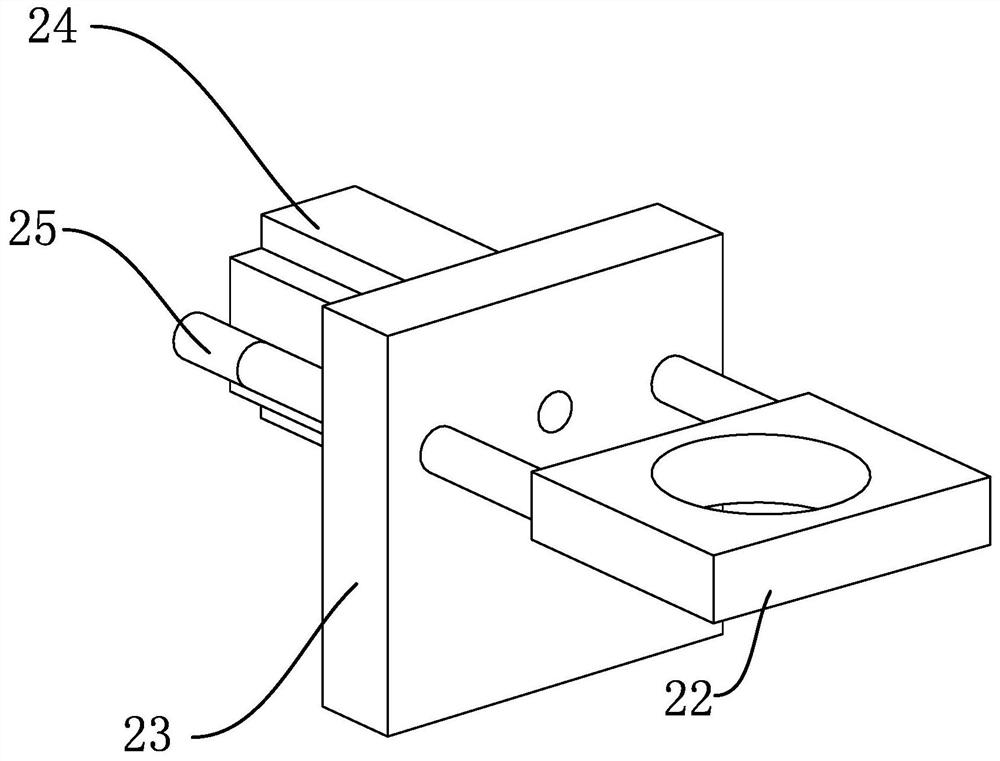

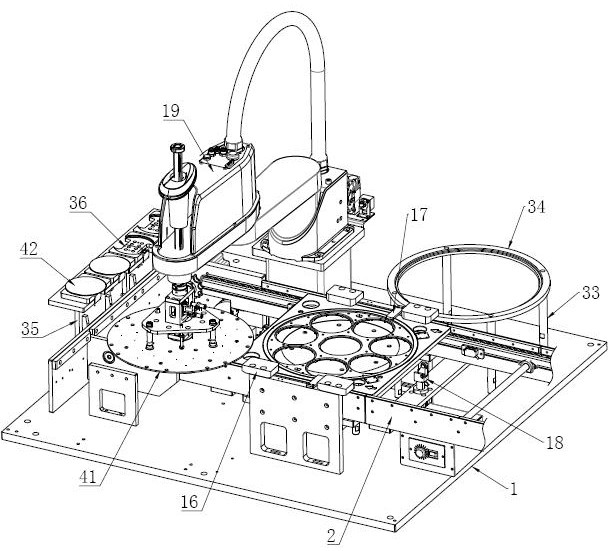

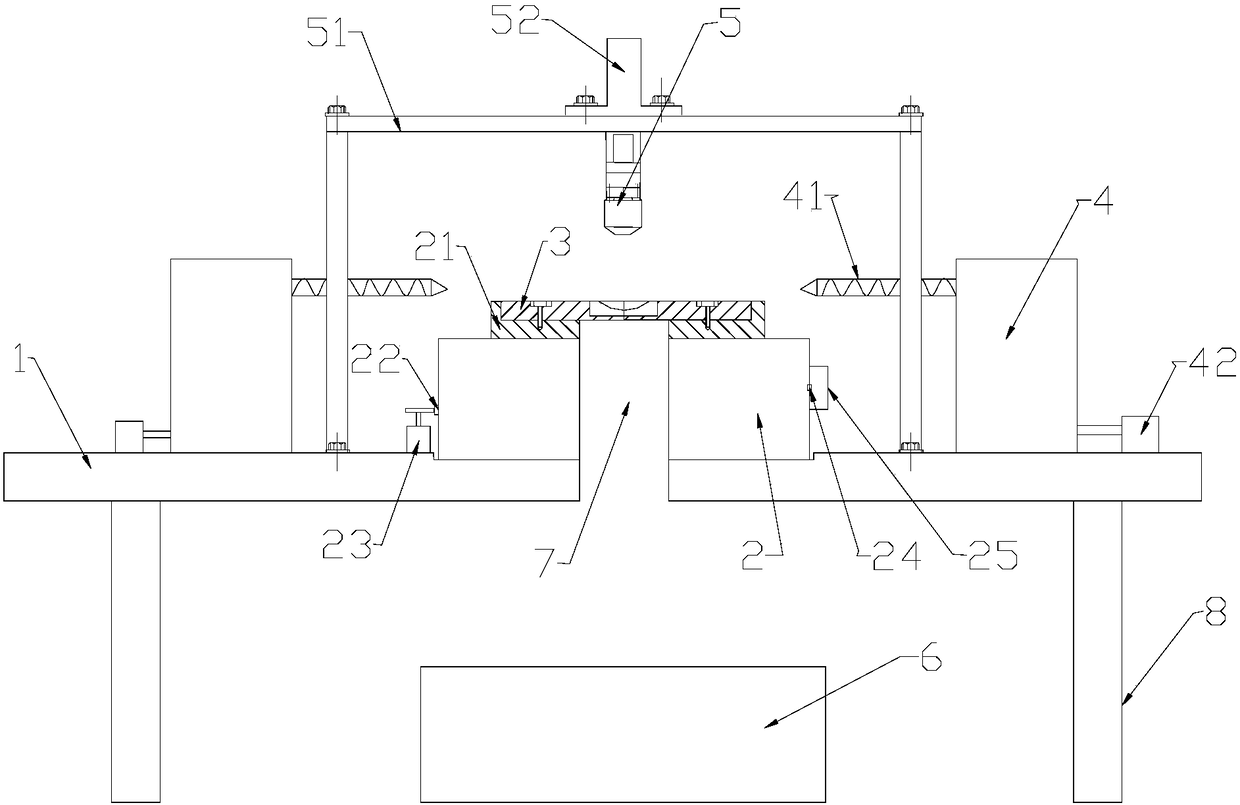

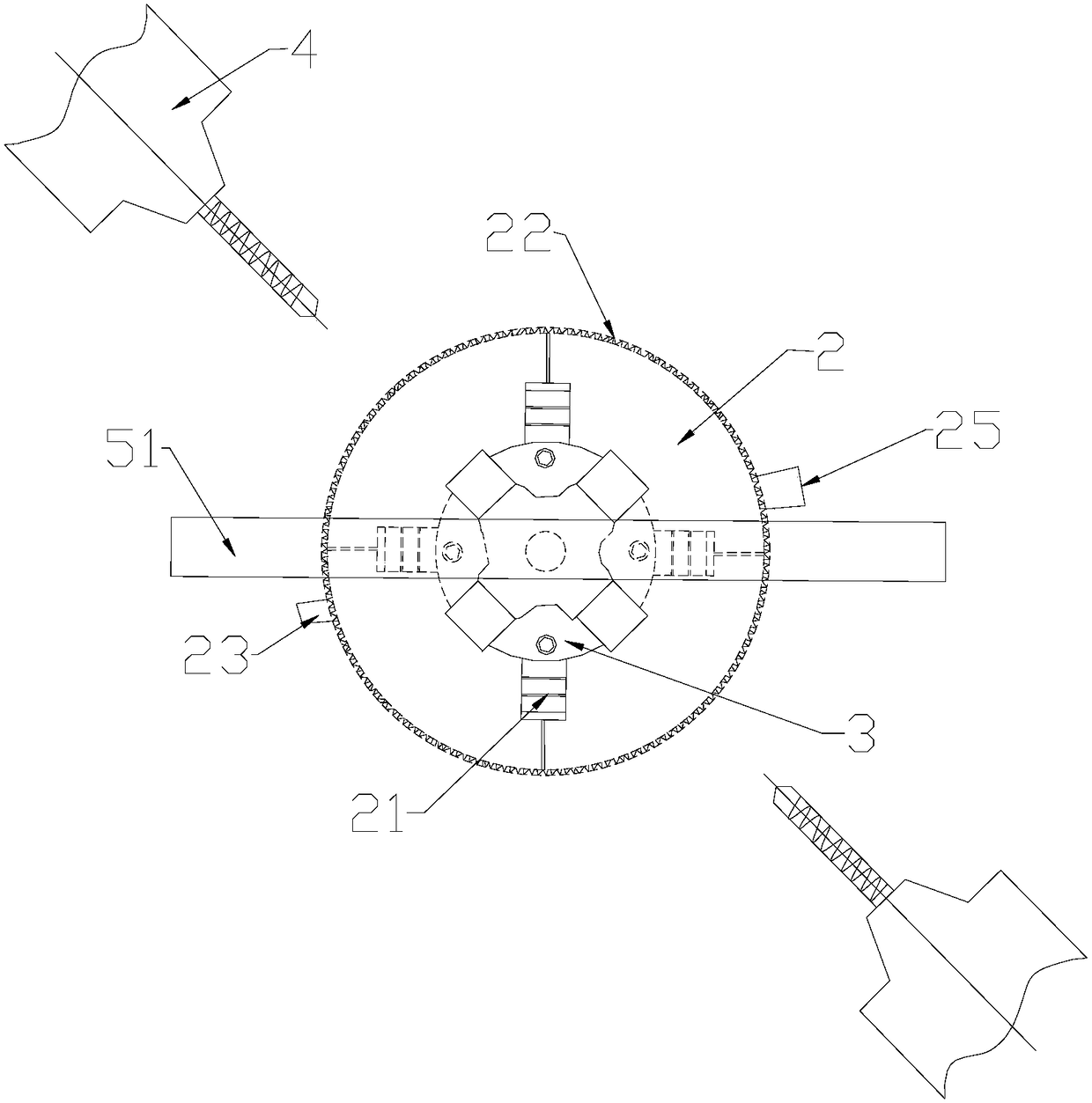

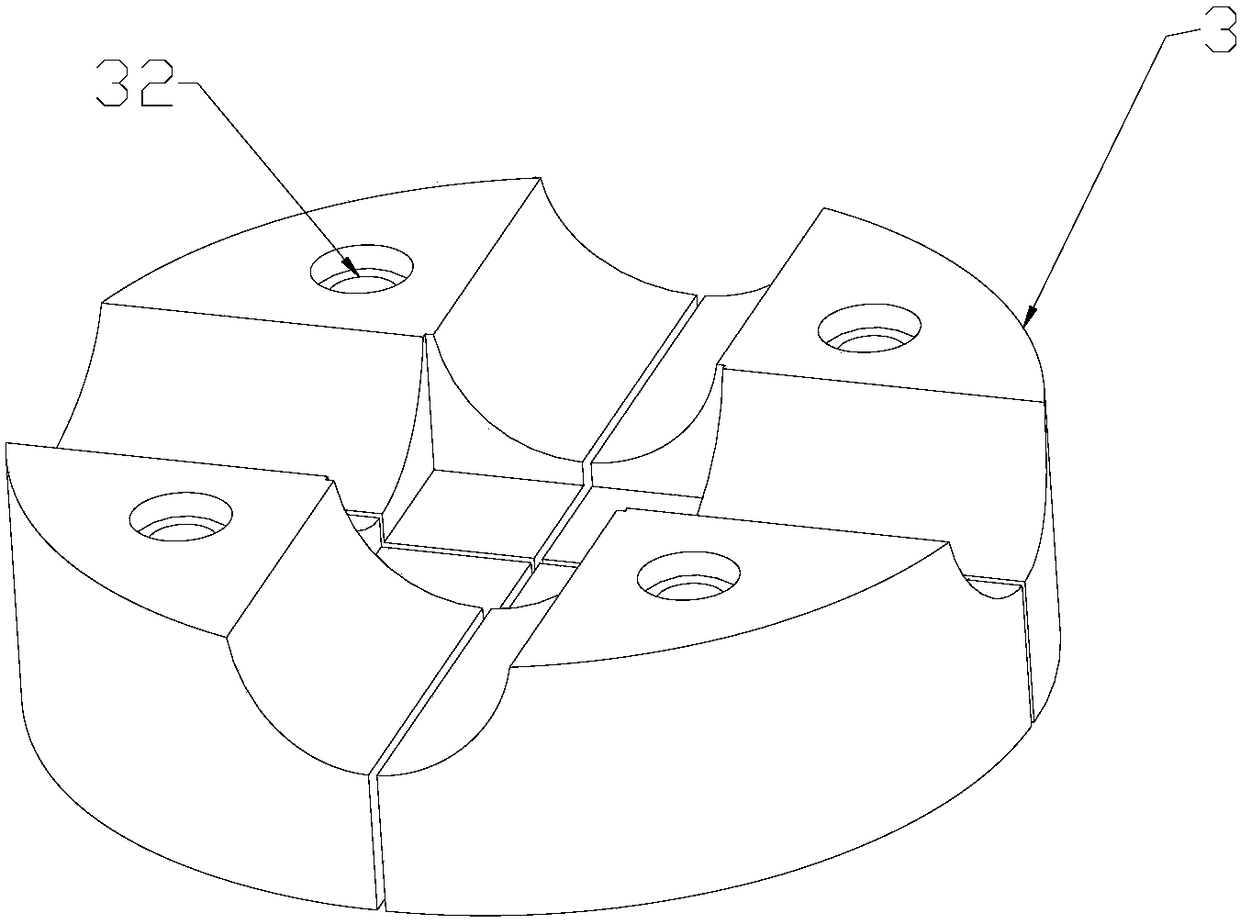

Positioning conveying-unloading device for assembly for disc parts

InactiveCN107243726AEasy assembly workAutomatic unloadingMetal working apparatusHydraulic cylinderEngineering

The invention relates to a positioning conveying-unloading device for assembly for disc parts. The positioning conveying-unloading device comprises a bottom plate, wherein a storage box, a first discharge slide way, a backing plate and a second discharge slide way are sequentially and fixedly installed at the front side of the bottom plate towards the right, hydraulic cylinders and a positioner are correspondingly installed at the left side and the right side of the backing plate separately, the positioner is connected with a disc, and storage grooves adaptive to the hydraulic cylinders are uniformly distributed in the disc in an annular direction; and a high frame fixedly installed on the bottom plate is arranged at the rear side of the first discharge slide way, a cylinder is installed on the high frame, the cylinder is connected with a slide seat, and a suction disc is installed at the lower end of the slide seat. The positioning conveying-unloading device disclosed by the invention is high in automation degree, capable of controlling rotary conveying for the disc parts through the positioner and a rotary disc to facilitate assembly working for the disc parts, and further capable of automatically carrying out automatic boxing-unloading on the disc parts.

Owner:ANHUI PULUN INTELLIGENT EQUIP CO LTD

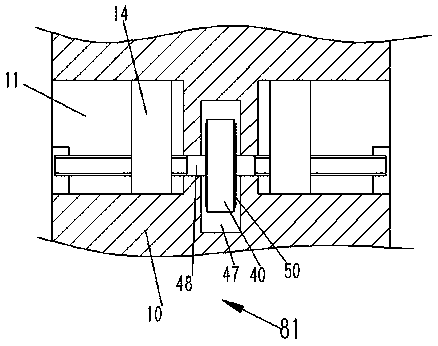

A cross-axis universal automatic drilling device

ActiveCN105772783BIncrease productivityAutomatic unloadingWork clamping meansChucksHydraulic cylinderGear drive

The invention discloses a cross-shaped axle type automatic universal drilling device. The cross-shaped axle type automatic universal drilling device comprises a processing tabletop, a four-jaw chuck which is detachably connected with the processing tabletop, a plurality main motors and a plurality of drill bits connected with the main motors. The cross axle type automatic universal drilling device is characterized in that a support is also arranged on the processing tabletop; a hydraulic cylinder is arranged at the central position of a support cross bar; the lower part of the hydraulic cylinder is connected to a pressure head; the four-jaw chuck is arranged under the pressure head; four jaws on the four-jaw chuck are separately connected with corresponding limiting blocks; straight teeth are arranged on the circumferential surface of the four-jaw chuck and are connected with a gear driving mechanism; a square hole is formed in the circumference of the four-jaw chuck; an auxiliary motor is connected onto the square hole; a through hole penetrates through a center position of the four-jaw chuck and a corresponding position of the processing tabletop; and a material receiving box is arranged under the through hole. According to the cross-shaped axle type automatic universal drilling device disclosed by the invention, two drill bits are arranged for simultaneously processing, so that the production efficiency is improved; and by adopting an improving structure, the device can automatically discharge after the processing is finished.

Owner:诸暨市富邦环保机械有限公司

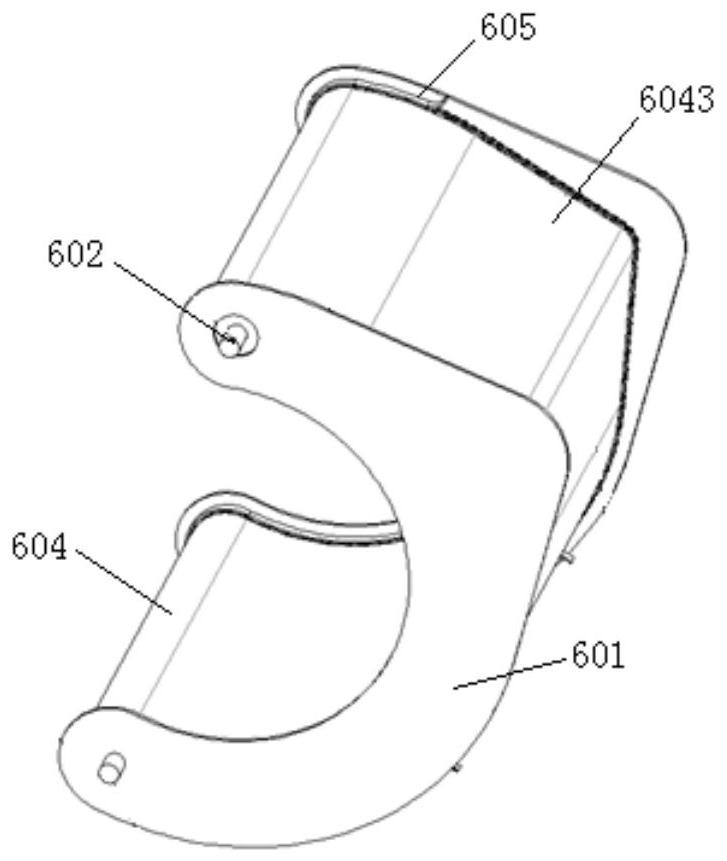

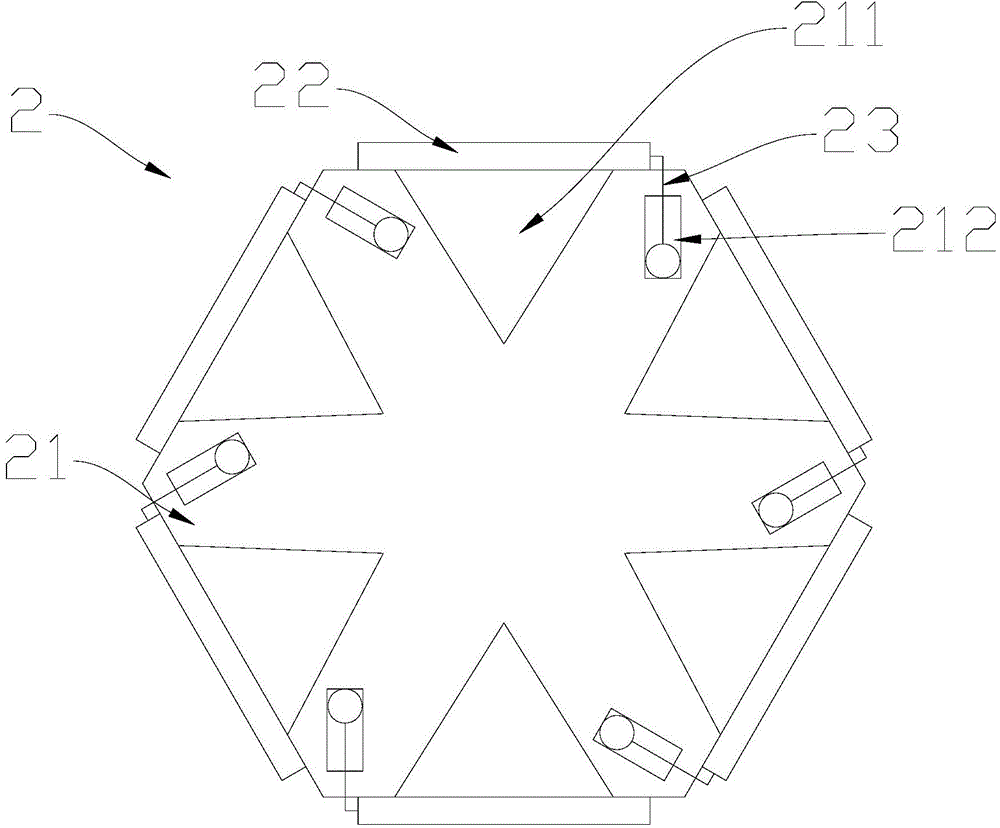

Clamp for machining automobile oil pump valve element

InactiveCN104625774AAutomatic unloadingPositioning apparatusGrinding work supportsEngineeringClosed space

The invention discloses a clamp for machining an automobile oil pump valve element. The clamp comprises a body, the body is in a regular polygon shape in the radial section, and the body can rotate around the central axis of the polygon shape. A plurality of grooves are formed in the outer wall face of the body, each groove is provided with a pressing plate corresponding to the groove, the first side of each pressing plate is hinged to the body, the second side of each pressing plate is connected with the first end of an elastic element, and a plurality of sliding grooves corresponding to the pressing plates are formed in the body. The second end of each elastic element is arranged in the corresponding sliding groove in a sliding mode. Each sliding groove is provided with a first end and a second end, each pressing plate has two working positions, the second end of each elastic element is located at the first end of the corresponding sliding groove, and a closed space is formed by each pressing plate relative to the corresponding groove, wherein an automobile oil pump valve element is located in the closed space. When the body rotates, the second end of each elastic element slides to the second end of the corresponding sliding groove from the first end of the corresponding sliding groove, and the pressing plates are opened relative to the grooves.

Owner:SUZHOU KELIAN PRECISION MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com