Single-chuck destacking machine

A depalletizer and collet technology, which is applied in the stacking of objects, destacking, transportation and packaging of objects, etc., can solve the problems of high labor intensity and low labor efficiency of workers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

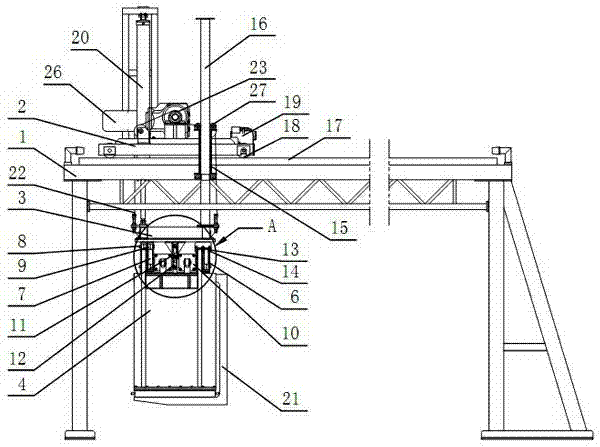

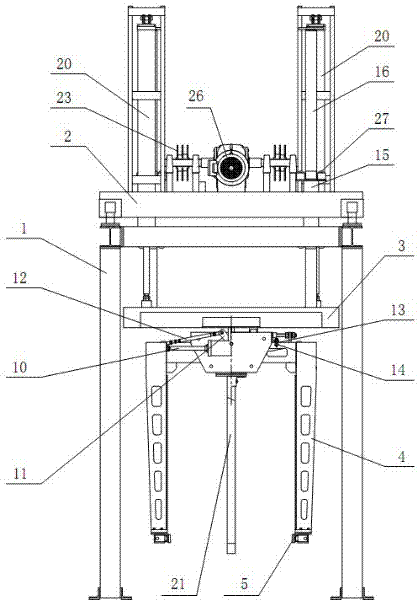

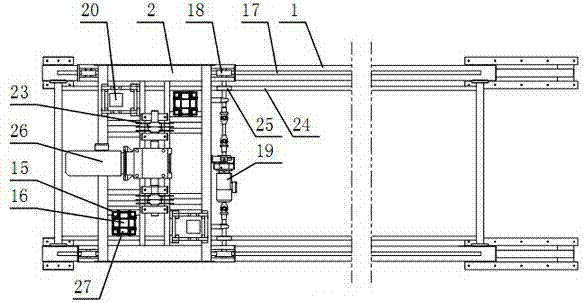

[0023] Such as figure 1 , figure 2 and image 3 The shown single-clamp depalletizer, for the convenience of description, takes the traveling direction of the trolley 2 as the longitudinal direction, figure 1 The middle walking trolley 2 is located at the rear of the frame 1, and the direction of the relative movement of the splint 4 is transverse, which includes a frame 1 in a truss structure, and the top of the frame 1 is slidably connected with a walking trolley 2 driven by a walking power device to slide longitudinally. , the top of the frame 1 is provided with a longitudinally arranged guide rail 17, the bottom of the traveling trolley 2 is equipped with a traveling wheel 18 rolling along the guide rail 17, and the walking power device includes two longitudinally arranged synchronous belts symmetrically fixed on the frame 1 24. The front part of the walking trolley 2 is rotatably equipped with a main shaft, and a synchronous wheel 25 meshing with the synchronous belt 24...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com