A Release Structure for Thin Skins of Sticky Foods

A technology for demoulding and food, applied in application, food science, dough processing, etc., can solve the problems of affecting the taste of the final product, inability to carry out high-speed transportation, and the conveyor belt occupies a large space, preventing deformation and falling off, preventing adhesion, Uniform lift effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific embodiment of the utility model will be further described below in conjunction with accompanying drawing:

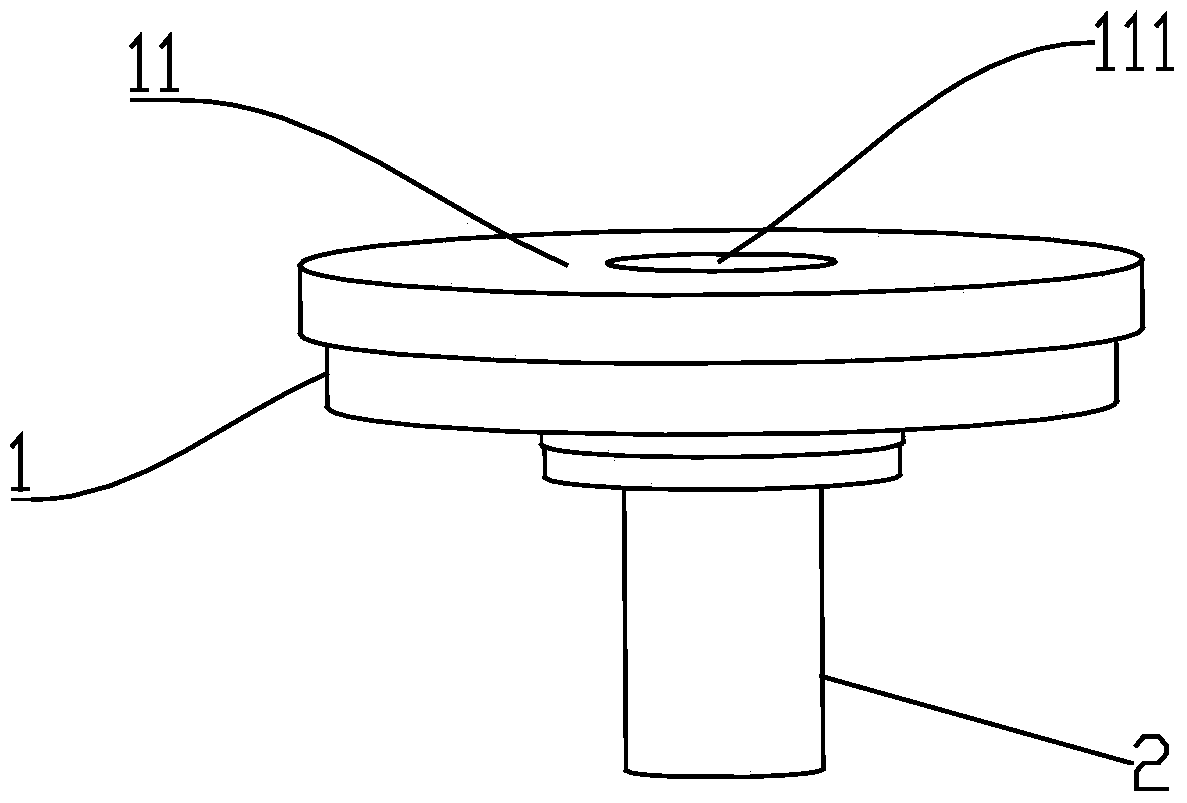

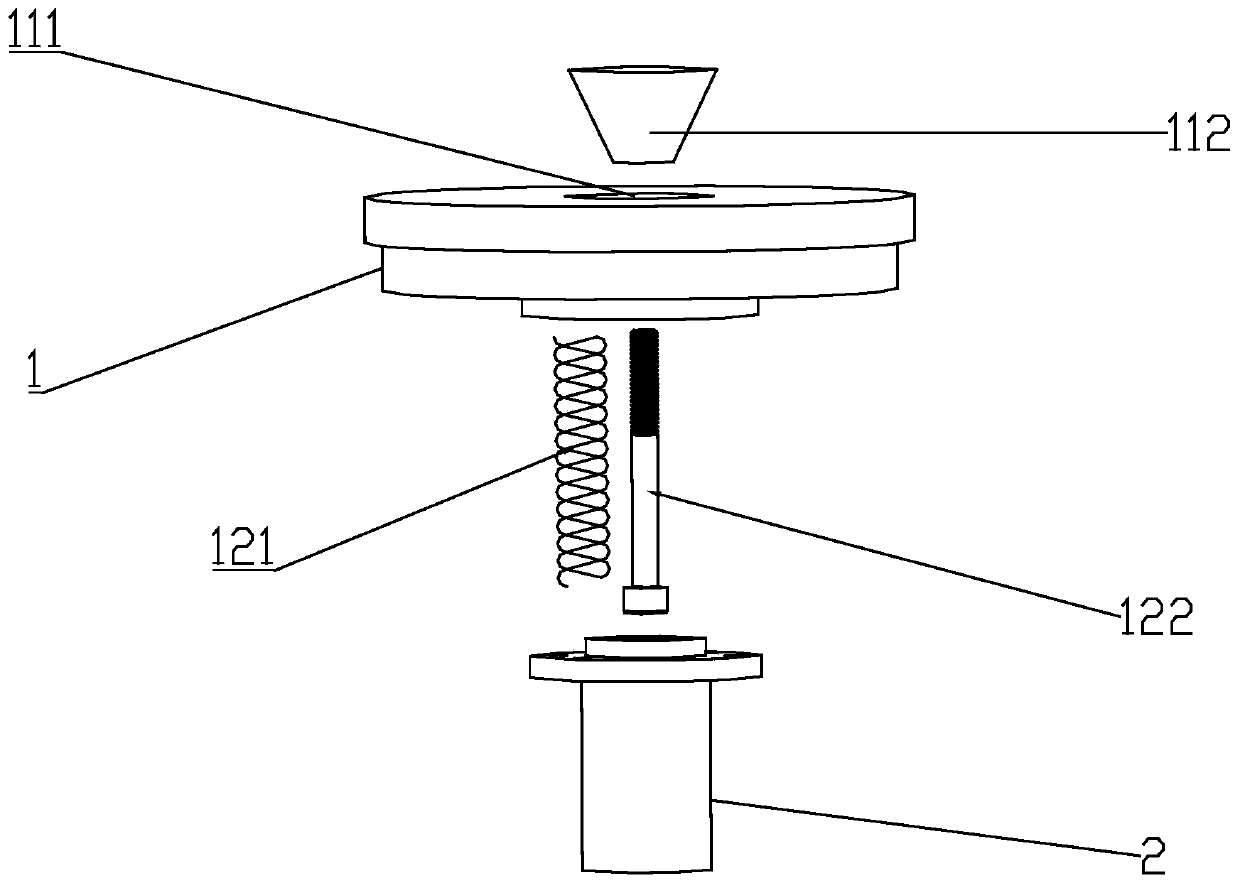

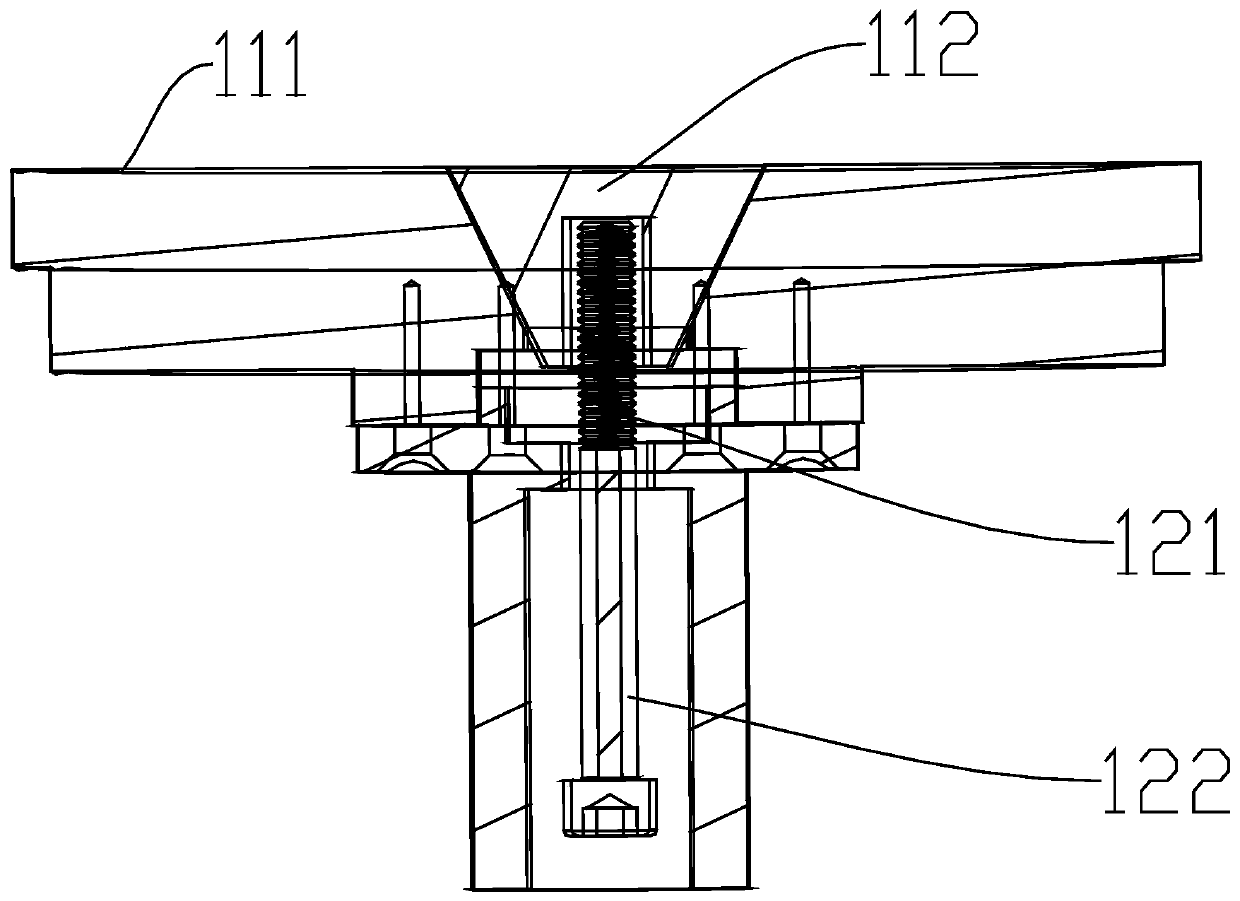

[0034] Such as Figure 1 to Figure 4 As shown, a demoulding structure suitable for viscous food thin skins includes a main body 1, a demoulding surface 11 is provided on the main body 1, a concave movable cavity 111 is provided in the middle of the demoulding surface 11, and the side wall of the movable cavity 111 is A curved surface that gradually expands outward; the bottom of the movable chamber 111 is connected with an air chamber 12, and a movable block 112 is provided in the movable chamber 111; an elastic mechanism is provided in the air chamber 12, and the elastic mechanism is connected to the movable block 112, and moves toward the movable block. 112 exerts an elastic force towards the inside of the air chamber 12; the side wall of the movable block 112 has a shape that matches the side wall of the movable chamber 111. The surface is seamles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com