Patents

Literature

47results about How to "High main content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

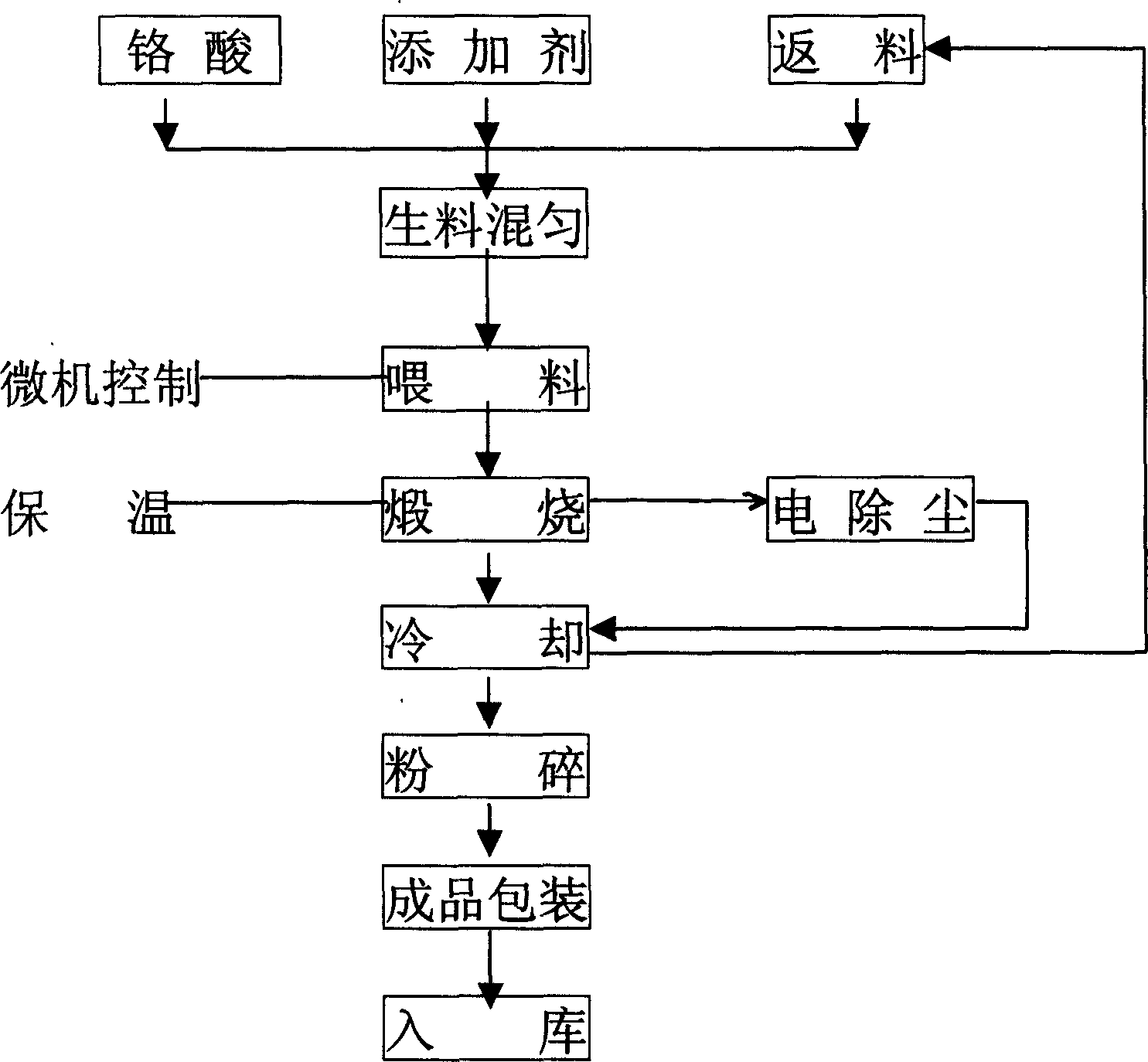

Method of producing dichromium trioxide using chromic acid thermal decomposition continuous method

InactiveCN1459419AHigh thermal efficiencyReduce consumptionChromium trioxideLiquid gasComputer control

A process for preparing Cr2O3 by continuous thermodecomposition of chromic acid includes such steps as proportionally mixing chromic acid, coarse Cr2O3 as returning charge and additive chosen from boric acid (preferable), ammonium chloride, starch and saw dust; after uniformly mixing under a computer control, parallel-flow combustion of the said mixture and liquefied gas as fuel in an insulated rotary furnace, thermodecomposition reaction to generate Cr2O3, keeping the temp. for a certain time, cooling and pulverizing to obtain the product. The unpulverized material is used as the said returning charge.

Owner:民乐县化工厂

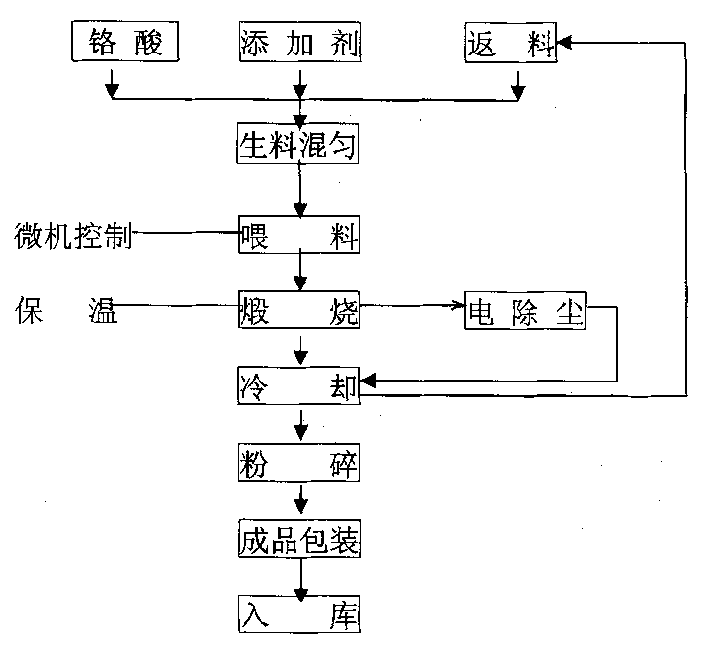

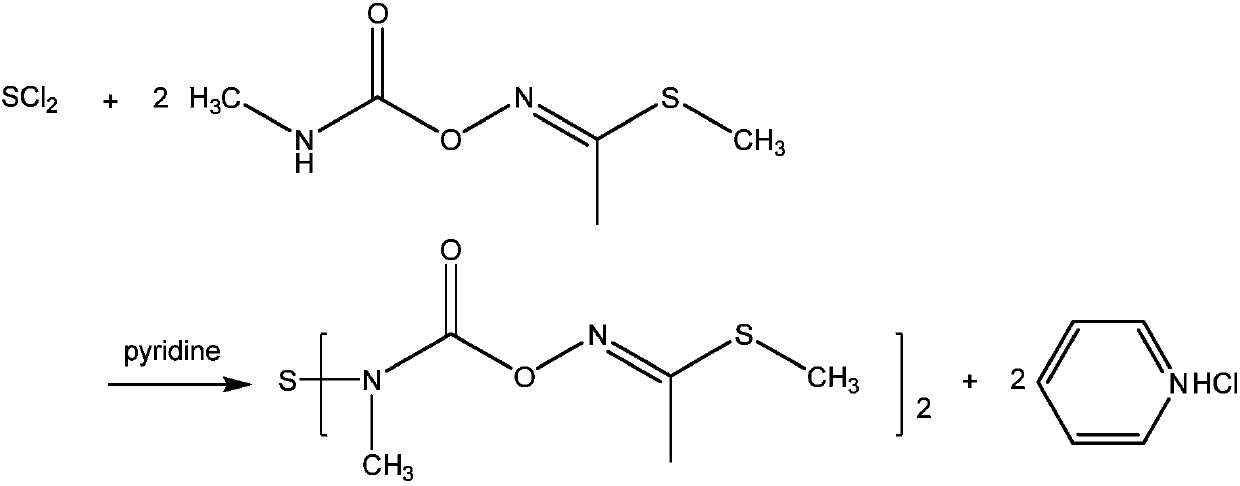

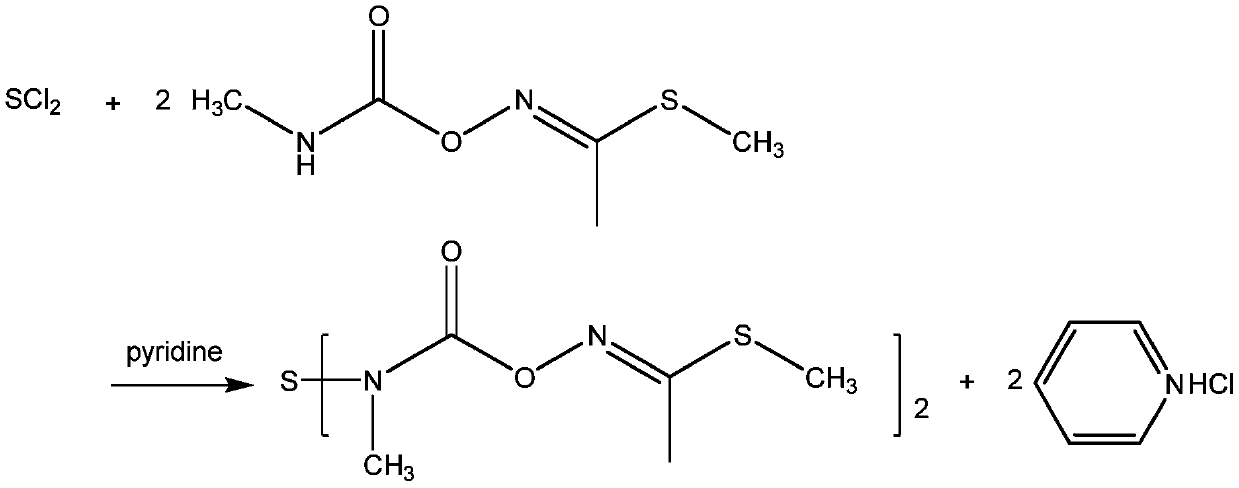

Preparation method of thiodicarb

The invention discloses a preparation method of thiodicarb. The preparation method comprises the following steps: (1) dividing a solvent into two portions, dissolving methomyl in one of the two portions to obtain a methomyl solution, and dissolving 4-dimethylaminopyridine in the other portion to obtain a solvent which contains a catalyst; and (2) dividing sulfur dichloride into two portions, dropwise adding one portion of the sulfur dichloride in the solvent which contains the catalyst under a closed condition, meanwhile, dropwise adding the other portion of sulfur dichloride and carrying outdropwise adding reaction on the other portion of sulfur dichloride and the methomyl solution obtained in step (1), and carrying out insulating reaction after dropwise adding is finished to obtain thethiodicarb. The preparation method of the thiodicarb has the advantages that the reaction selectivity is high, the purity of the obtained product is high, the content of thiodicarb isomer is smaller than 0.4%, the yield is high and the like.

Owner:湖南海利常德农药化工有限公司

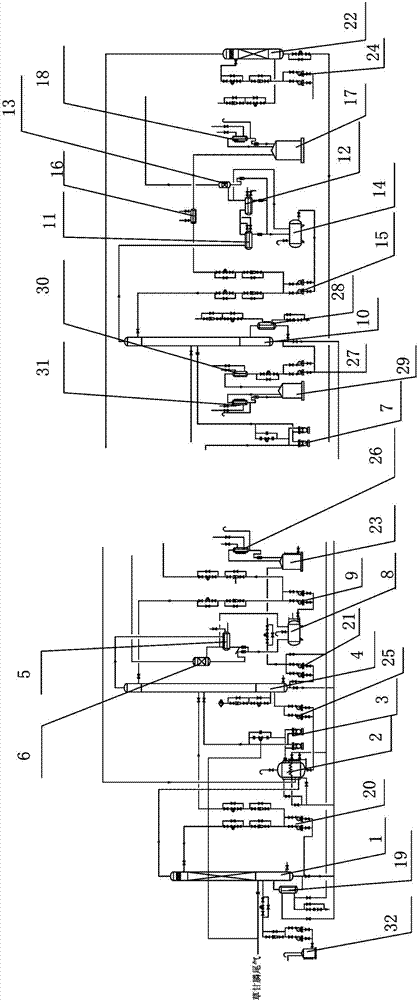

Equipment and process for recovering glyphosate solvent during production with glycine method

ActiveCN104844414ALow yieldHigh yieldOrganic compound preparationHalogenated hydrocarbon separation/purificationGlycineHigh energy

The invention provides equipment and a process for recovering a glyphosate solvent during production with glycine method, particularly relates to a glyphosate solvent recovery continuous production and gas-phase method recovery technology, and aims to overcome the defects of operation intermittence, high labor intensity, high energy consumption, low methyl chloride purity and the like in the prior art. Continuous production in an entire procedure is realized, so that the content of methyl chloride is increased to 99.9 percent, and the energy consumption is lowered. The equipment and process are widely applied to the field of glyphosate production.

Owner:HUBEI TAISHENG CHEM

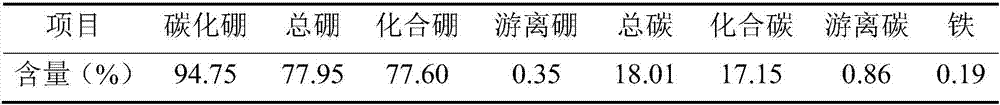

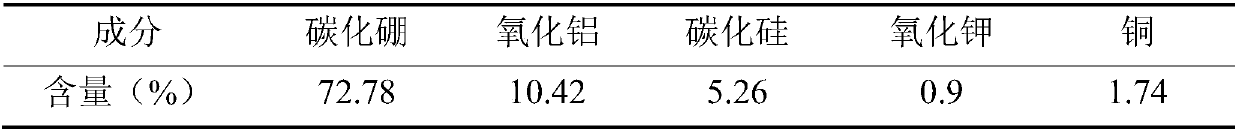

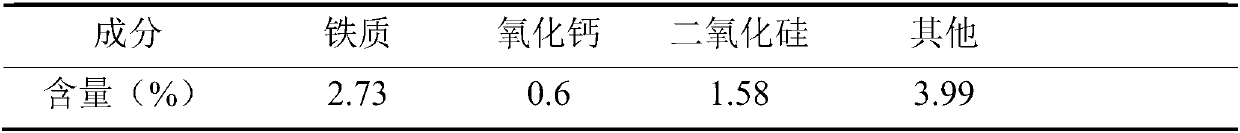

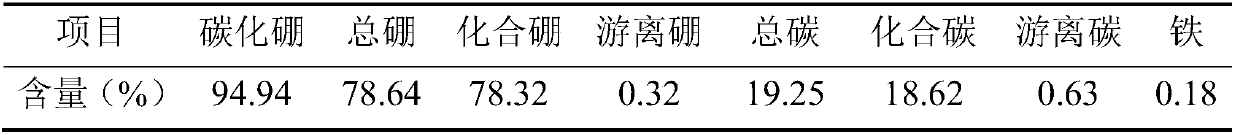

Preparation method of boron carbide superfine powder

ActiveCN107758670ADifficult to operateLarge controllable difficultyCarbon compoundsBrickBoron carbide

The invention discloses a preparation method of boron carbide superfine powder. The preparation method is based on a boron carbide smelting device which comprises a smelting furnace body built with refractory bricks and a sunken cover plate buckled at a top opening of the smelting furnace body, wherein a positive pole and a negative pole communicating a power supply are inserted into the side wallof the smelting furnace body. The preparation method comprises the following steps: S1, mixing a boron source with a carbon source fully to obtain a smelting raw material; S2, fully filling the smelting furnace body with the smelting raw material and covering the furnace with the sunken cover plate; and S3, applying a voltage to heat the smelting raw material to 1500-1900 DEG C and keeping the temperature for 24-48h to obtain the boron carbide superfine powder. Boron carbide is prepared by means of a nearly closed high-temperature treatment method according to the preparation method disclosedby the invention, so that impurity pollution is reduced, the product is good in crystallinity, the primary content of the obtained boron carbide superfine powder is greater than 96%, and the productgraded meets the demand of an abrasive material, and meets the quality demand on boron carbide powder in the field of grinding industry or engineering ceramics.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI +1

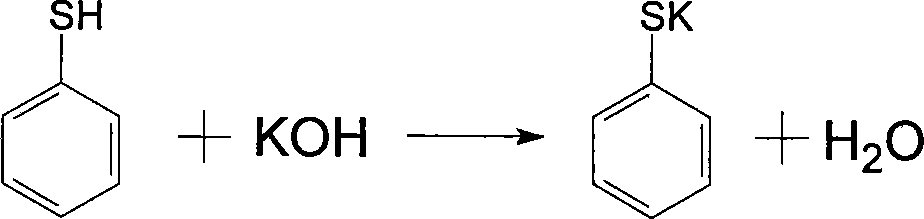

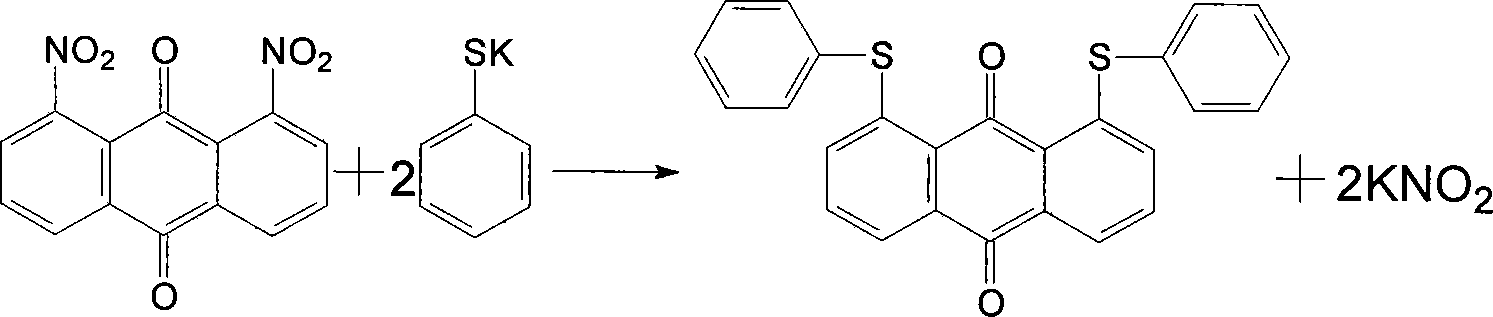

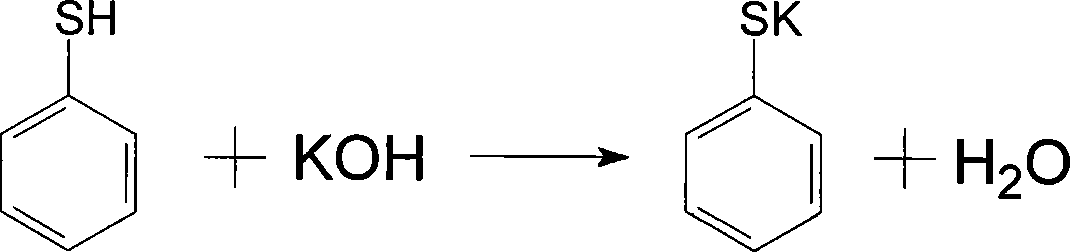

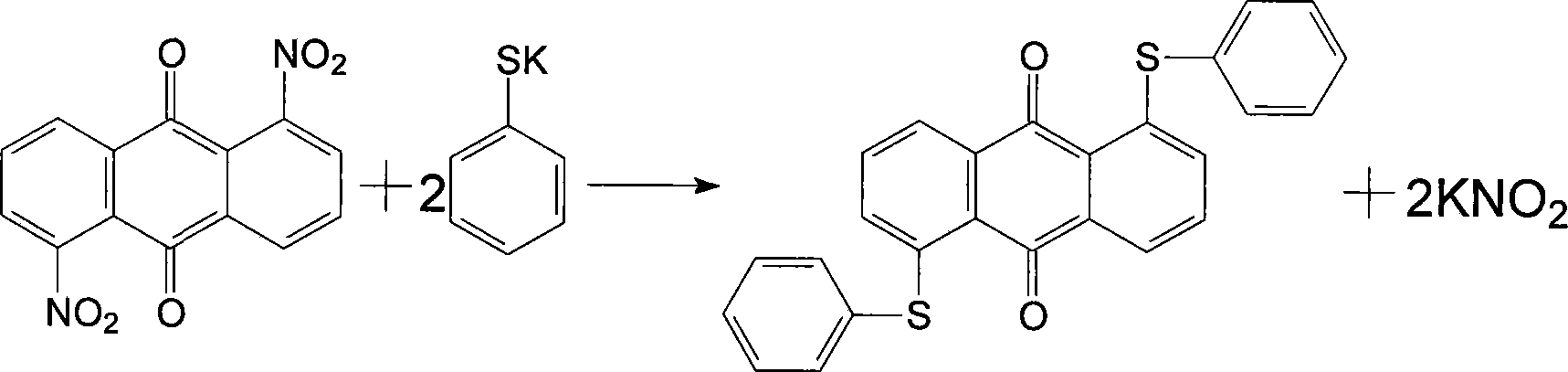

Novel technique for synthesizing solvent yellow 163

The invention discloses a new synthesizing technique of solvent yellow 163, which comprises the following steps: adopting 1, 8-dinitroanthraquinone as raw material to react with thiophenol in the strongly polar solvent of dimethyl formamide or dimethyl acetamide based on potassium hydroxide as acid-attaching agent at 30-100 deg. c to make the solvent yellow 163; cooling below 30 deg. c after finishing the reaction; filtering until the product is evolved sufficiently; washing the filter pie; drying; obtaining the product. The method reduces the manufacturing cost greatly and improves the main content of the product obviously, which modifies the appearance of the product with simple operation and easy control, in order to stabilize the manufacturing and increase the economical benefit.

Owner:JIANGSU YABANG DYE

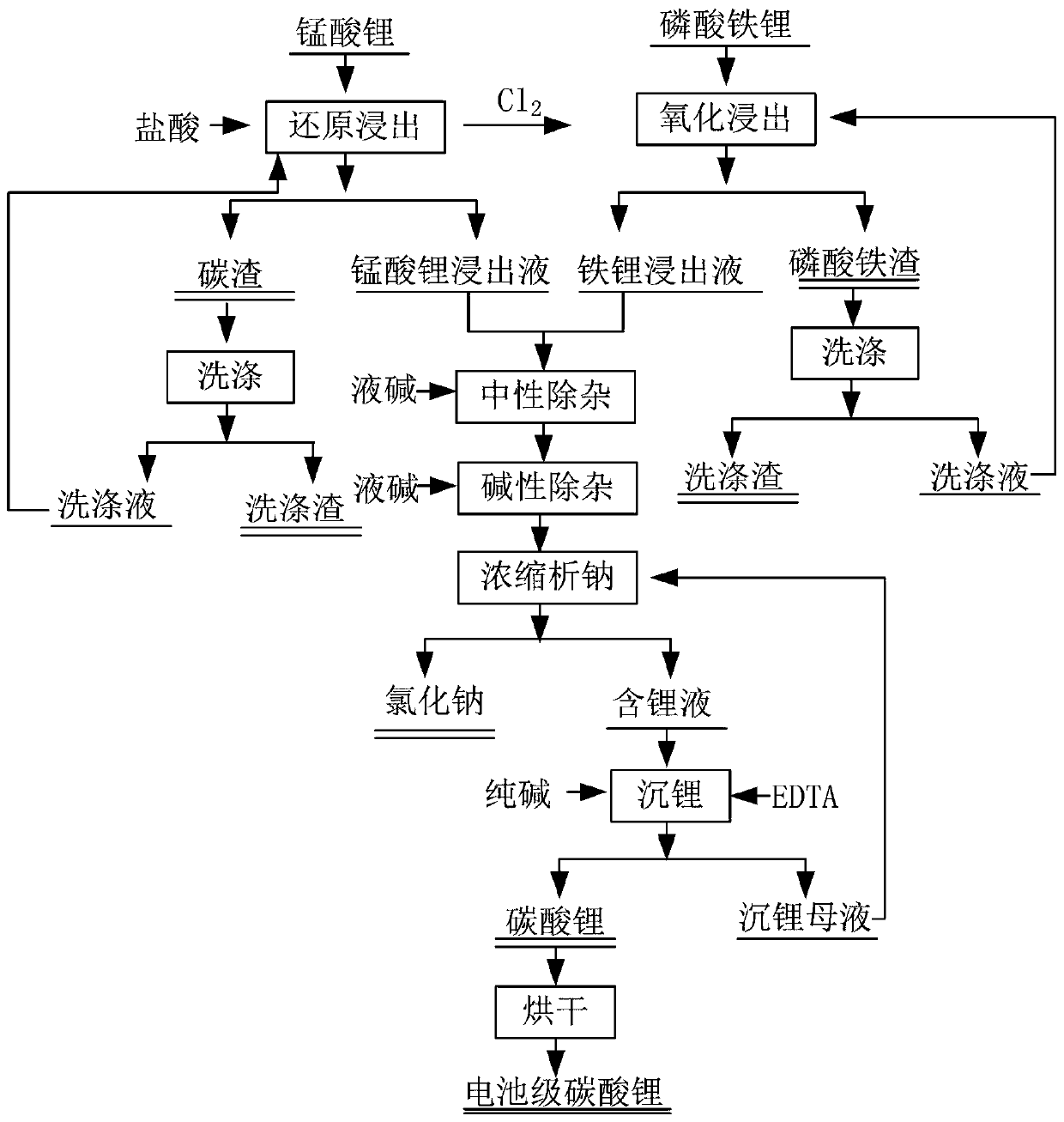

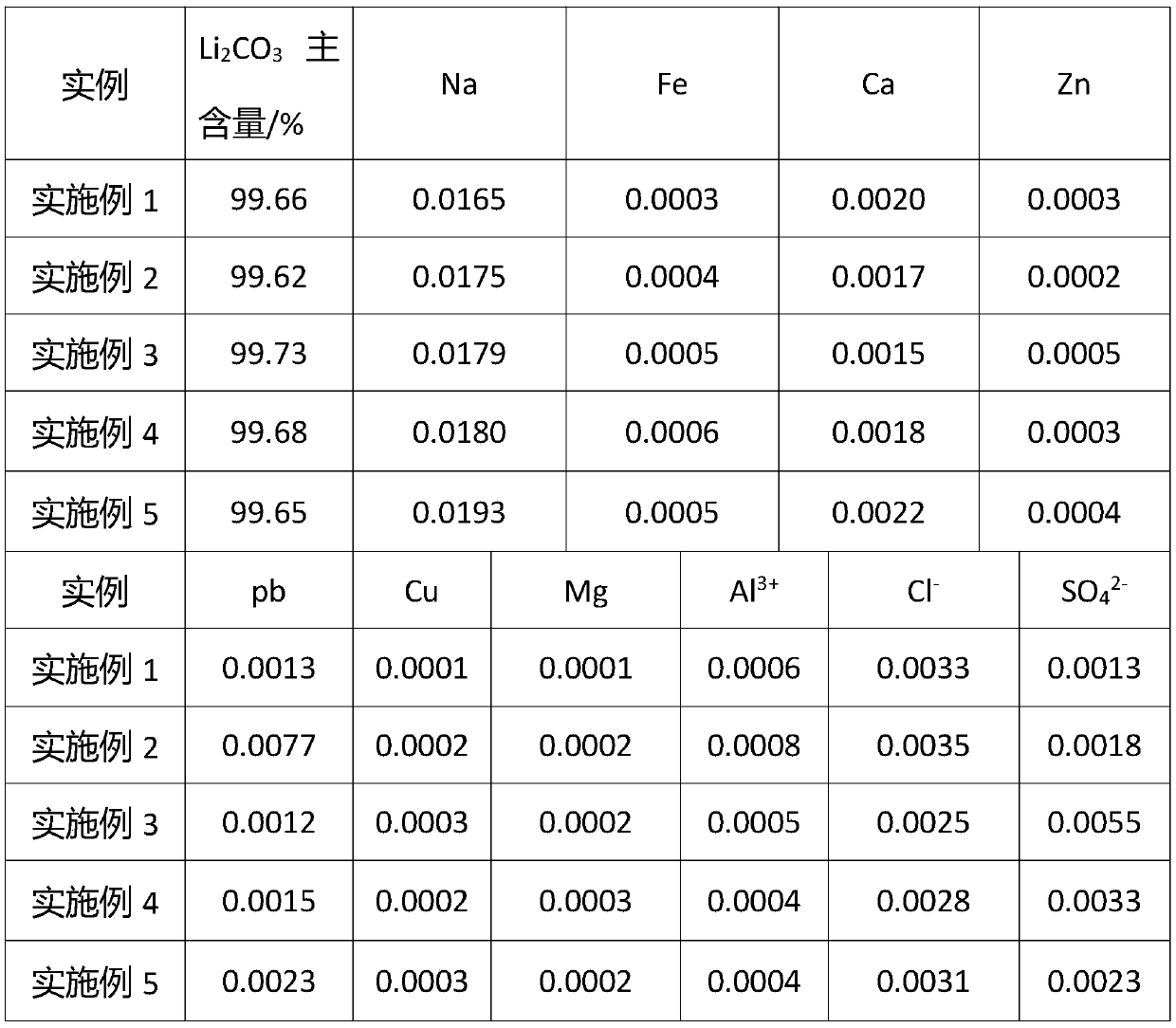

Comprehensive recovery method of waste lithium manganate and lithium iron phosphate positive electrode material

PendingCN111484043AReduce manufacturing costSimple processWaste accumulators reclaimingProcess efficiency improvementLithium electrodeOxidizing agent

The invention discloses a comprehensive recovery method of a waste lithium manganate and lithium iron phosphate positive electrode material. The recovery method aims at solving the technical problemsthat in the prior art, the energy consumption is large, the energy utilization rate is low, certain potential safety hazards exist, meanwhile, the environment is greatly damaged, and process conditiondetails are difficult to control in the process operation process. The method comprises the steps of lithium iron phosphate powder size mixing, lithium manganate reduction leaching, lithium iron phosphate oxidation leaching, solid-liquid separation, washing, neutral impurity removal, alkaline impurity removal, concentration and sodium precipitation, and lithium precipitation, recovery of the waste lithium manganate and the lithium iron phosphate positive electrode material to obtain battery-grade lithium carbonate. The recovery method can be used for simultaneously recovering and treating thepositive electrode materials of the two waste lithium ion batteries; an oxidizing agent and a reducing agent needed in the prior art do not need to be added, high-temperature reaction is not needed,energy consumption is low, the energy utilization rate is high, meanwhile, the process is simple, the comprehensive recovery rate is high, the technological process is energy-saving, environment-friendly and high in safety, and high economic benefits are achieved.

Owner:赣州龙凯科技有限公司

Method for producing ibuprofen through multistage continuous reaction crystallization

InactiveCN110627629AResolve side effectsUniform particle sizePreparation from carboxylic acid saltsOrganic chemistry methodsNucleationSolvent

The invention discloses a continuous crystallization process for ibuprofen. The ibuprofen product is obtained in a multistage continuous crystallization manner; and multistage continuous reaction crystallization comprises the steps of oil forming through a reaction, 2-4-stage reaction crystallization and dehydrating washing, wherein a pH and a temperature of each step are regulated and controlled.According to the process, a burst nucleation phenomenon caused by oil separating during the reaction crystallization of the ibuprofen is effectively solved; the crystallization is stable in process conditions and simple in operation control; by taking water as a solvent, environmental pollution is reduced; and the obtained ibuprofen crystal is large and uniform in size, the product is high in purity and yield, the stability of running of the crystallization process and the quality of the product are improved, the production cost is reduced, and the stabilized industrial production of the ibuprofen is achieved.

Owner:SHANDONG XINHUA PHARMA CO LTD

Production method of medical sodium iodide

A process for preparing medicinal sodium iodide from iodine, Fe powder and dicarbonate includes such steps as preparing ferrous iodide, reaction between ferrous iodide and dicarbonate to obtain ferrous carbonate, sodium iodide and water, separating sodium iodide, removing SO4 radicals, filtering, concentrating and crystallizing.

Owner:自贡市金典化工有限公司

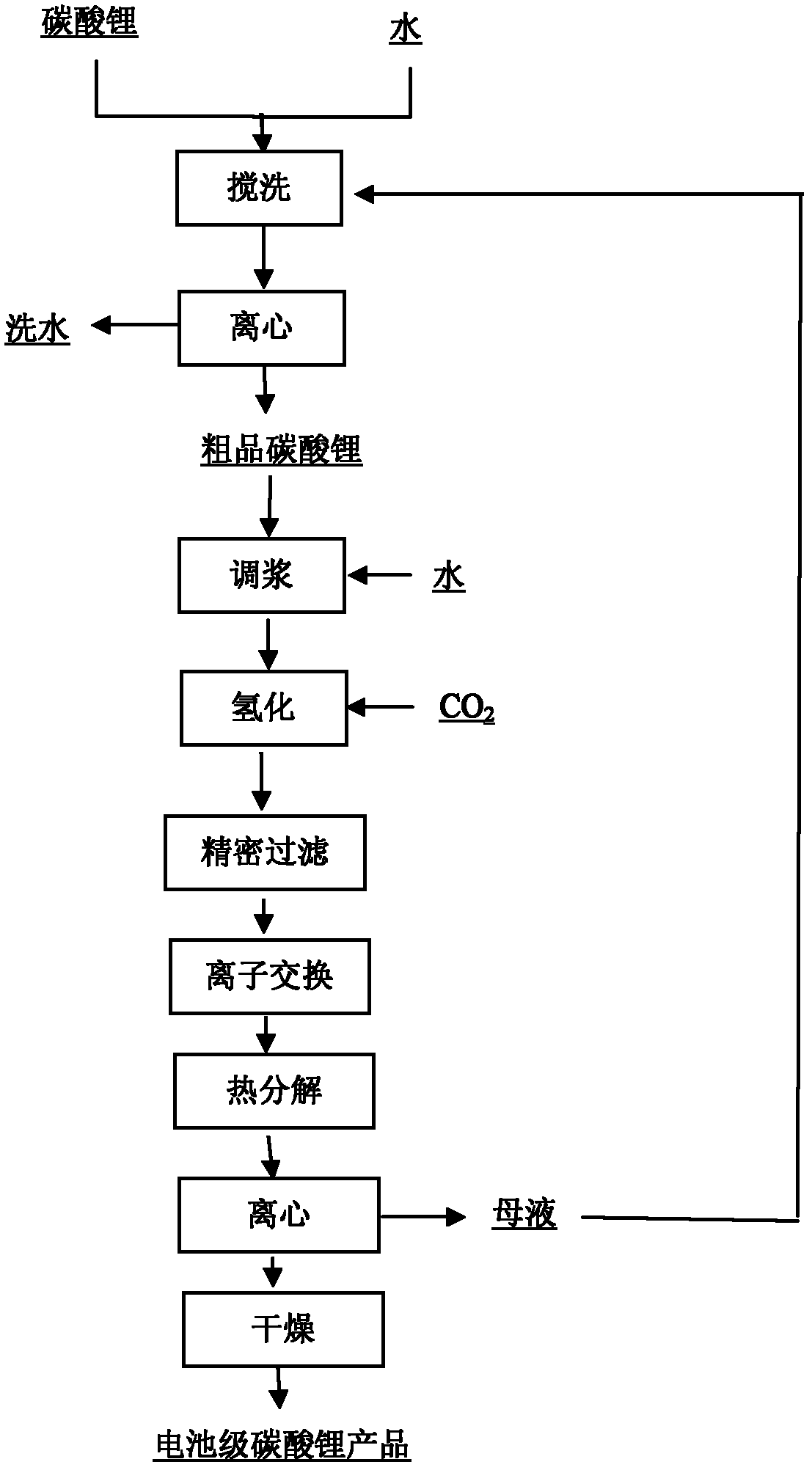

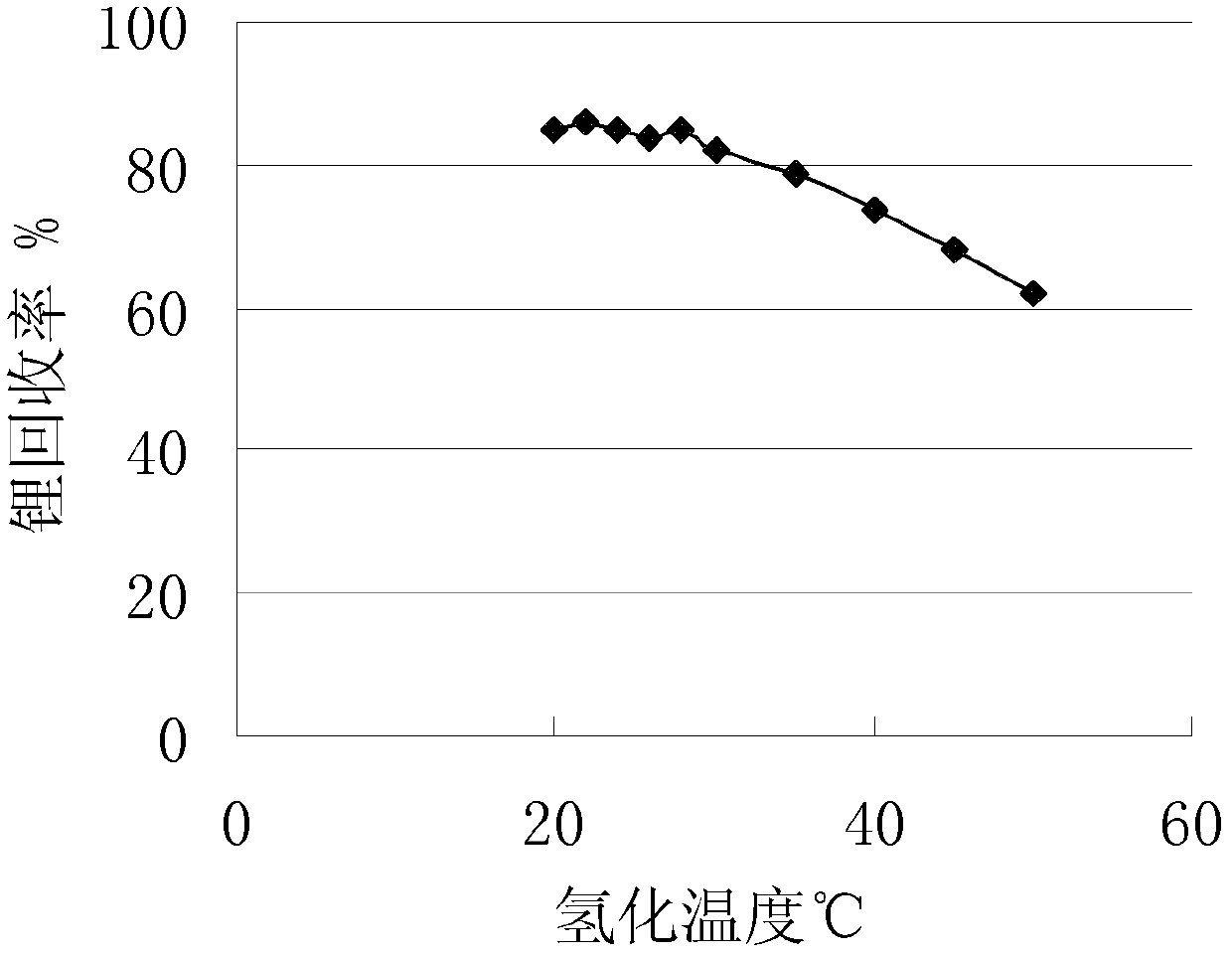

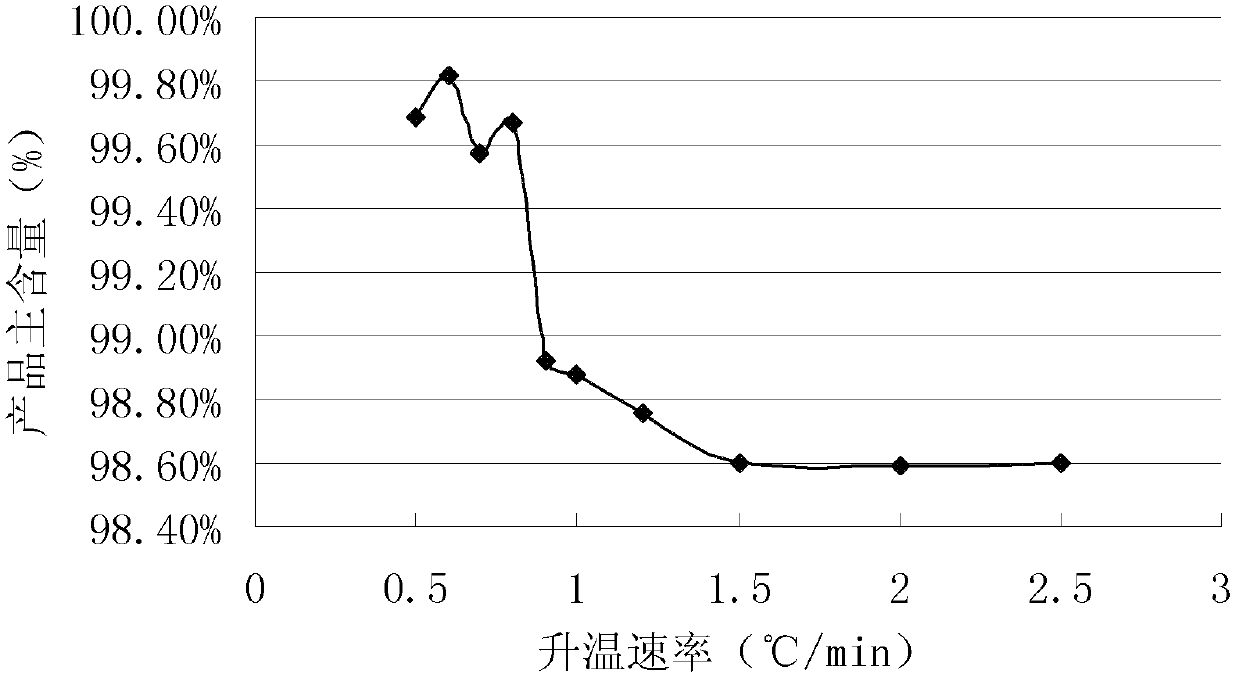

Method for purifying lithium carbonate

ActiveCN102531002BLow impurity contentImprove qualityLithium carbonates/bicarbonatesLithium oxideHydrogenation reaction

The invention relates to a method for purifying lithium carbonate, belonging to the technical field of the preparation of high-purity lithium carbonate. The method is characterized by safe production process and high lithium yield. The method comprises the following specific steps: (1) washing lithium carbonate to be purified to remove impurities, and adding water to prepare lithium carbonate slurry; (2) introducing CO2 into the lithium carbonate slurry prepared in the step (1) to carry out hydrogenation reaction, stopping introducing CO2 when the concentration of lithium oxide concentration in a solution is 10-30g / L, and filtering the solution to obtain a hydrogenated solution, wherein the hydrogenation reaction is carried out at the pressure of 0.2-0.6Mpa and the temperature of 20-30 DEG C; (3) subjecting the hydrogenated solution obtained in the step (2) to an ion exchange resin to remove impurity ions in the hydrogenated solution; and (4) heating the hydrogenated solution in which the impurity ions are removed in the step (3) to 70-90 DEG C to carry out decomposition reaction, separating solid from liquid to obtain the wet lithium carbonate, and drying the wet lithium carbonate. The produced battery-level lithium carbonate has high main content, excellent quality and stable performance.

Owner:天齐锂业(射洪)有限公司

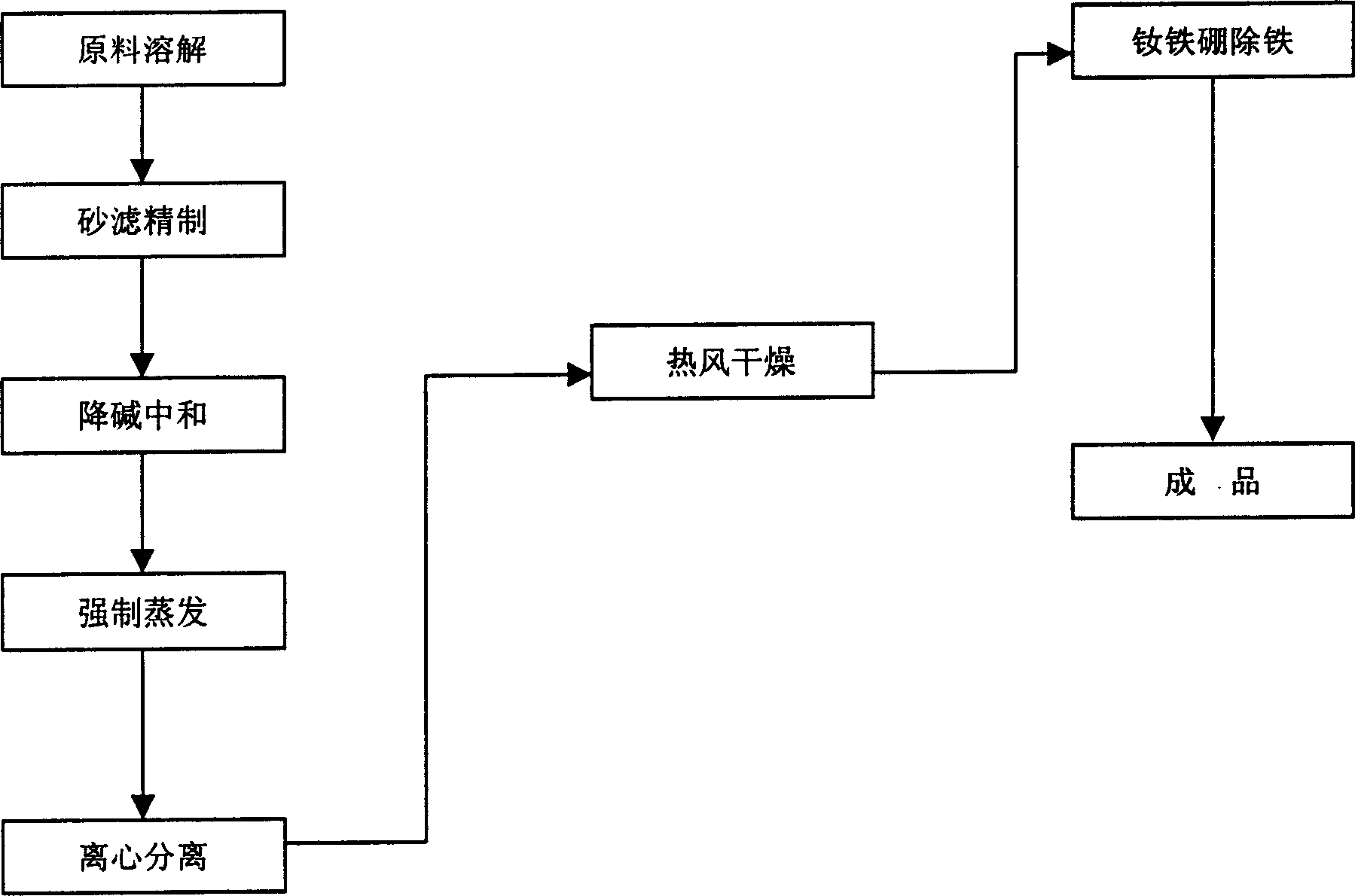

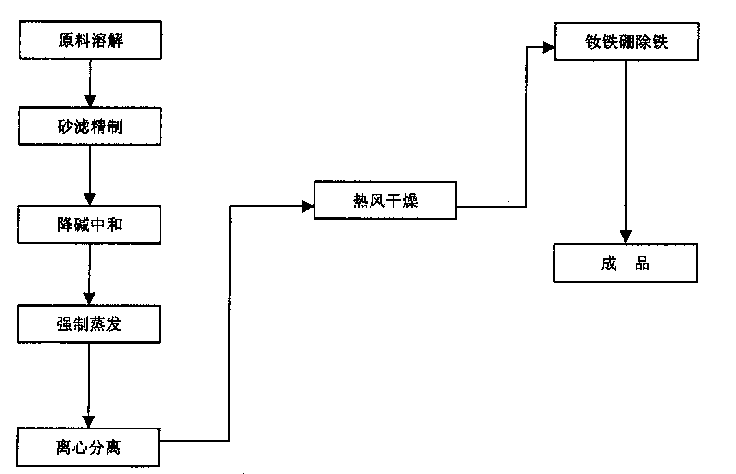

Method of producing neutral high quality anhydrous sodium sulfate using natucal salt lake sodium sulfate decahydrate

InactiveCN1475443AHigh purityHigh whitenessAlkali metal sulfite/sulfate purificationAlkali metal sulfite/sulfate dehydrationSalt lakeEvaporation

A process for preparing the refined neutral sodium sulphate from the sodium mirabilite of natural salt lake includes dissolving raw material, sand filtering, adding ammonium sulfate, forced evaporation, centrifugal separation, hot-air drying and magnetically removing iron. Its advantages are high purity (more than 99.3%), high whiteness (90%) and pH value 6-8.

Owner:INNER MONGOLIA YUANXING ENERGY

The preparation method of thiodicarb

ActiveCN108047106BHigh selectivityReduce self-decompositionOrganic chemistryPtru catalystCombinatorial chemistry

The invention discloses a preparation method of thiodicarb. The preparation method comprises the following steps: (1) dividing a solvent into two portions, dissolving methomyl in one of the two portions to obtain a methomyl solution, and dissolving 4-dimethylaminopyridine in the other portion to obtain a solvent which contains a catalyst; and (2) dividing sulfur dichloride into two portions, dropwise adding one portion of the sulfur dichloride in the solvent which contains the catalyst under a closed condition, meanwhile, dropwise adding the other portion of sulfur dichloride and carrying outdropwise adding reaction on the other portion of sulfur dichloride and the methomyl solution obtained in step (1), and carrying out insulating reaction after dropwise adding is finished to obtain thethiodicarb. The preparation method of the thiodicarb has the advantages that the reaction selectivity is high, the purity of the obtained product is high, the content of thiodicarb isomer is smaller than 0.4%, the yield is high and the like.

Owner:湖南海利常德农药化工有限公司

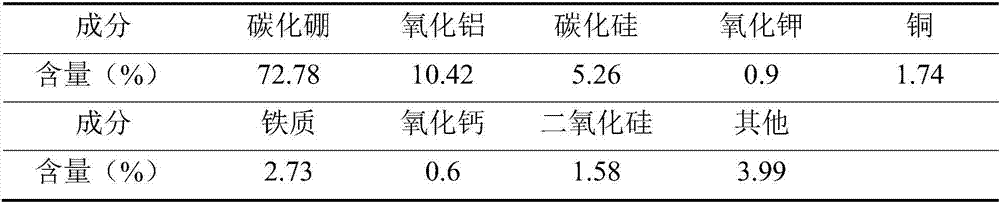

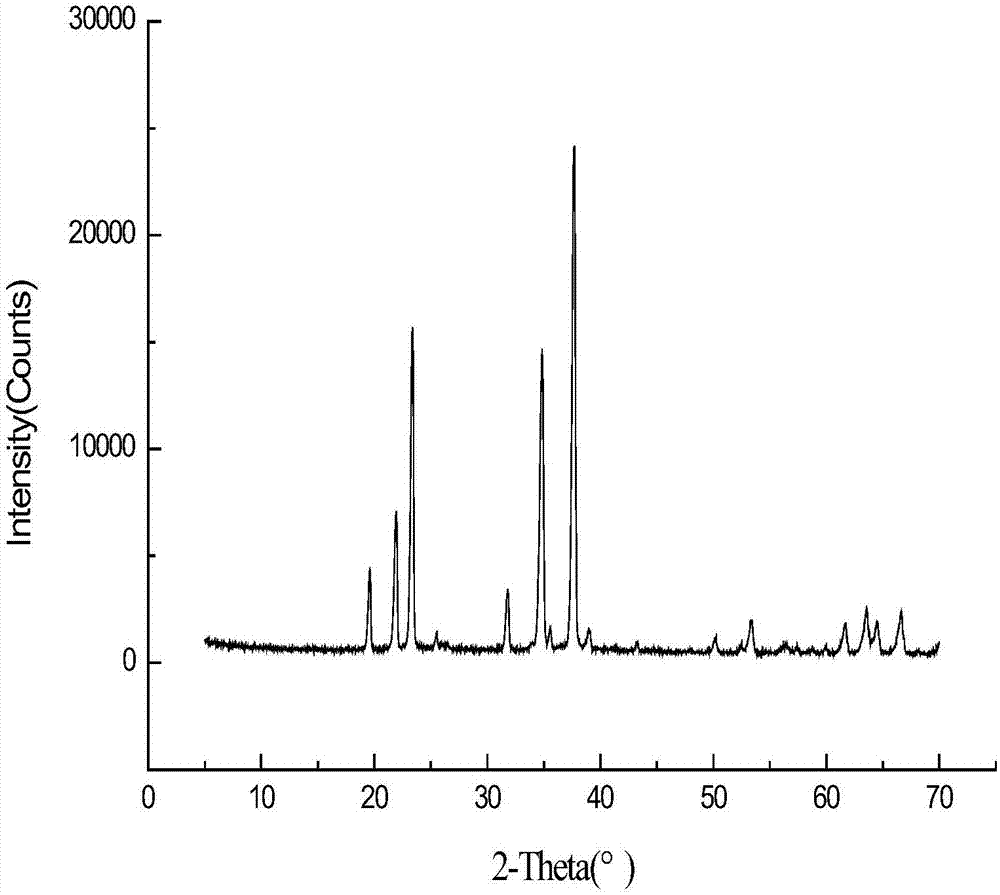

Method for recycling boron carbide from sapphire ground waste materials

InactiveCN107986284AAchieve recyclingRemove completelyCarbon compoundsOther chemical processesAcid dissolutionBoron carbide

The invention discloses a method for recycling boron carbide from sapphire ground waste materials. The method comprises the following steps: S1, sieving the sapphire ground waste materials through a 200-mesh sieve, so as to obtain a magnetic separation material; S2, performing magnetic separation on the magnetic separation material, so as to remove iron impurities and obtain an acid dissolution material; S3, putting the acid dissolution material into a acidification medium, so as to perform acid dissolution on the acid dissolution material, removing silicon impurity, and performing solid-liquid separation, so as to obtain a sintering material; S4, mixing and grinding the sintering material and an alkaline medium, and performing sintering for 4h to 48h at 300 DEG C to 800 DEG C, so as to obtain a sintered product; S5, performing water dissolution, solid-liquid separation and drying on the sintered product, so as to obtain boron carbide. According to the method, recycling of boron carbide ultrafine powder in the sapphire ground waste material is realized, resources and energy consumption are greatly saved, the recycled boron carbide meets the requirement on a grinding material and can be directly used, and the recycle rate of the boron carbide ultrafine powder reaches 93 percent or more.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

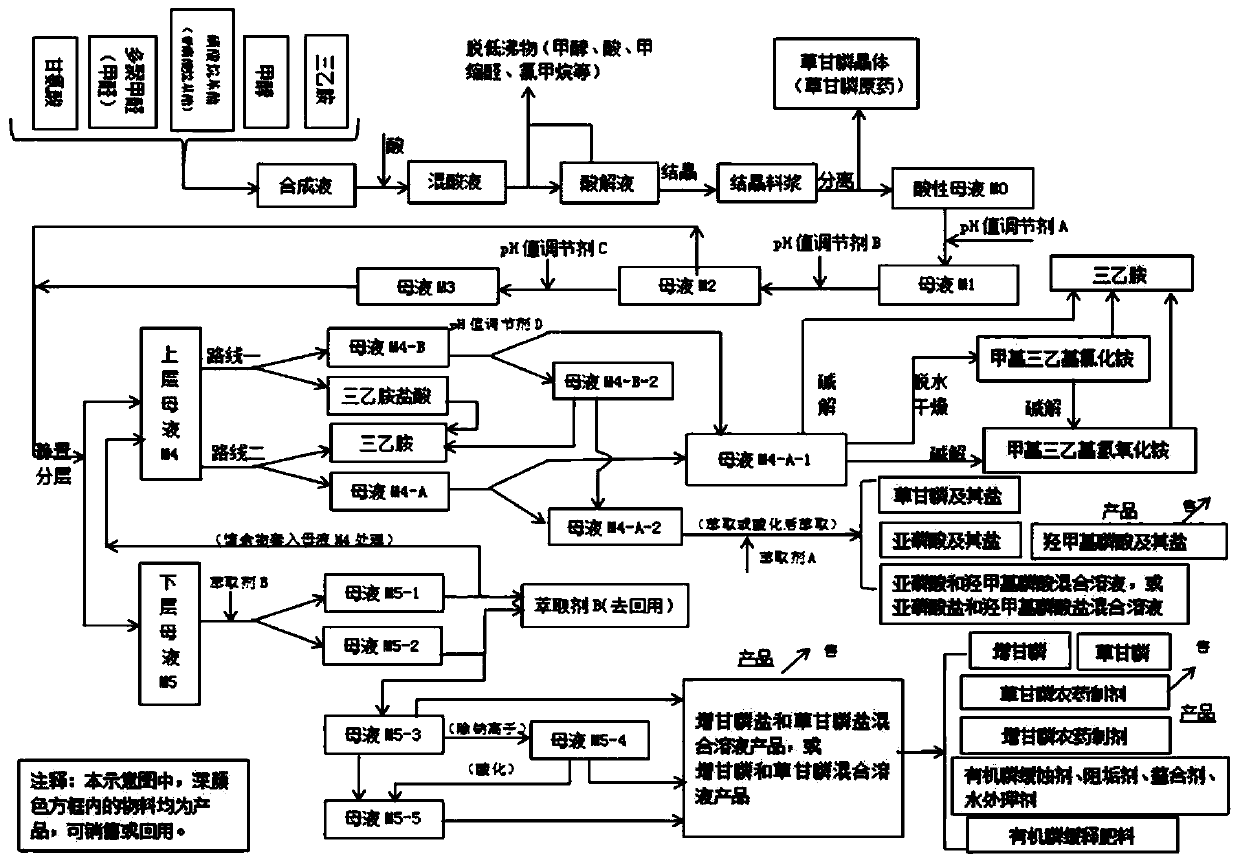

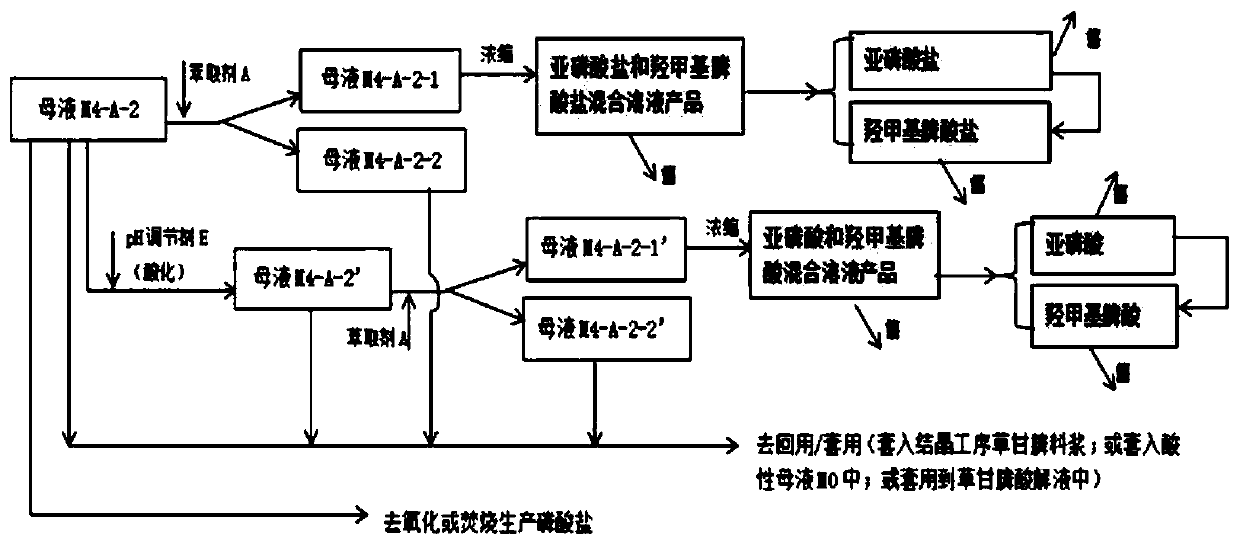

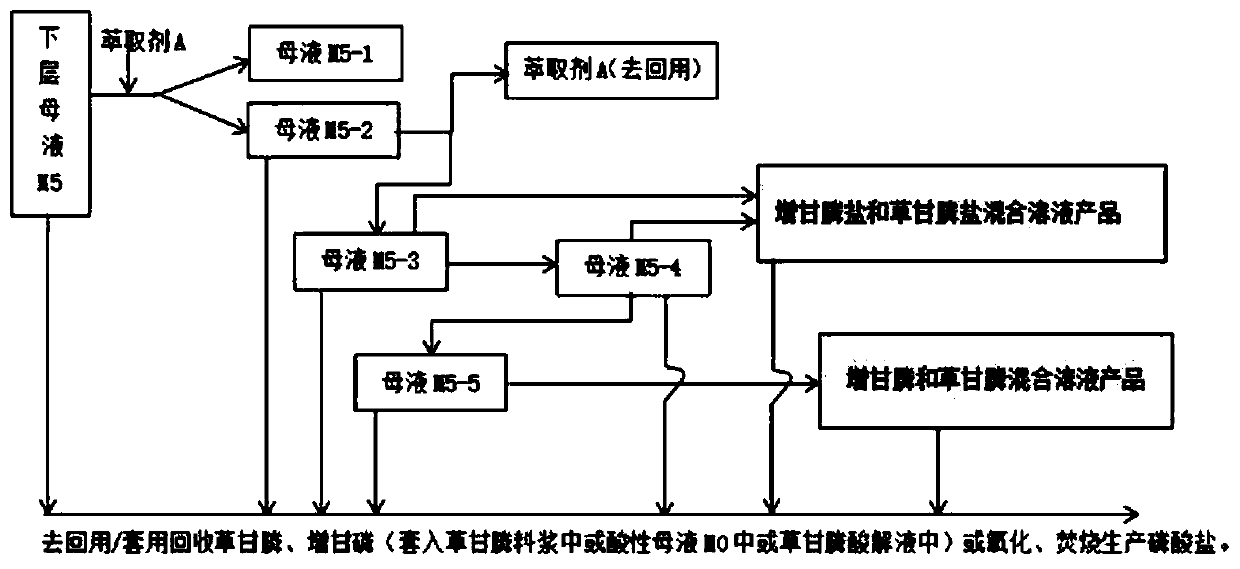

Glyphosate mother liquor comprehensive treatment and resource recycling method

PendingCN111333519AReduce volume and handling costsLess impuritiesAmino compound purification/separationGroup 5/15 element organic compoundsPhosphorous acidPulp and paper industry

The invention discloses a glyphosate mother liquor comprehensive treatment and resource recycling method which comprises the following steps: adding a pH value regulator into acidic mother liquor M0,standing for layering, and separating the solution to obtain mother liquor M4 at the upper layer and mother liquor M5 at the lower layer; the mother liquor M4 and the mother liquor M5 are treated andapplied, triethylamine hydrochloride, triethylamine, chloride salt, methyltriethylammonium chloride, phosphorous acid or salt thereof, hydroxymethylphosphonic acid or salt thereof, glyphosate or saltthereof, glyphosate or salt thereof and glyphosate or salt thereof are recovered from the mother liquor M4 and the mother liquor M5, and are respectively and correspondingly converted into products with higher additional values for utilization. The glyphosate mother liquor comprehensive treatment and resource recycling method has the advantages that the emission is reduced from the source; the method reduces the total amount and treatment load of the glyphosate mother liquor, reduces environmental pollution, realizes reasonable recycling and appreciation of resources, improves economic benefits, is environment-friendly, outstanding in economic benefits and good in technical implementation effect, and is suitable for large-scale industrial application.

Owner:陈兴华

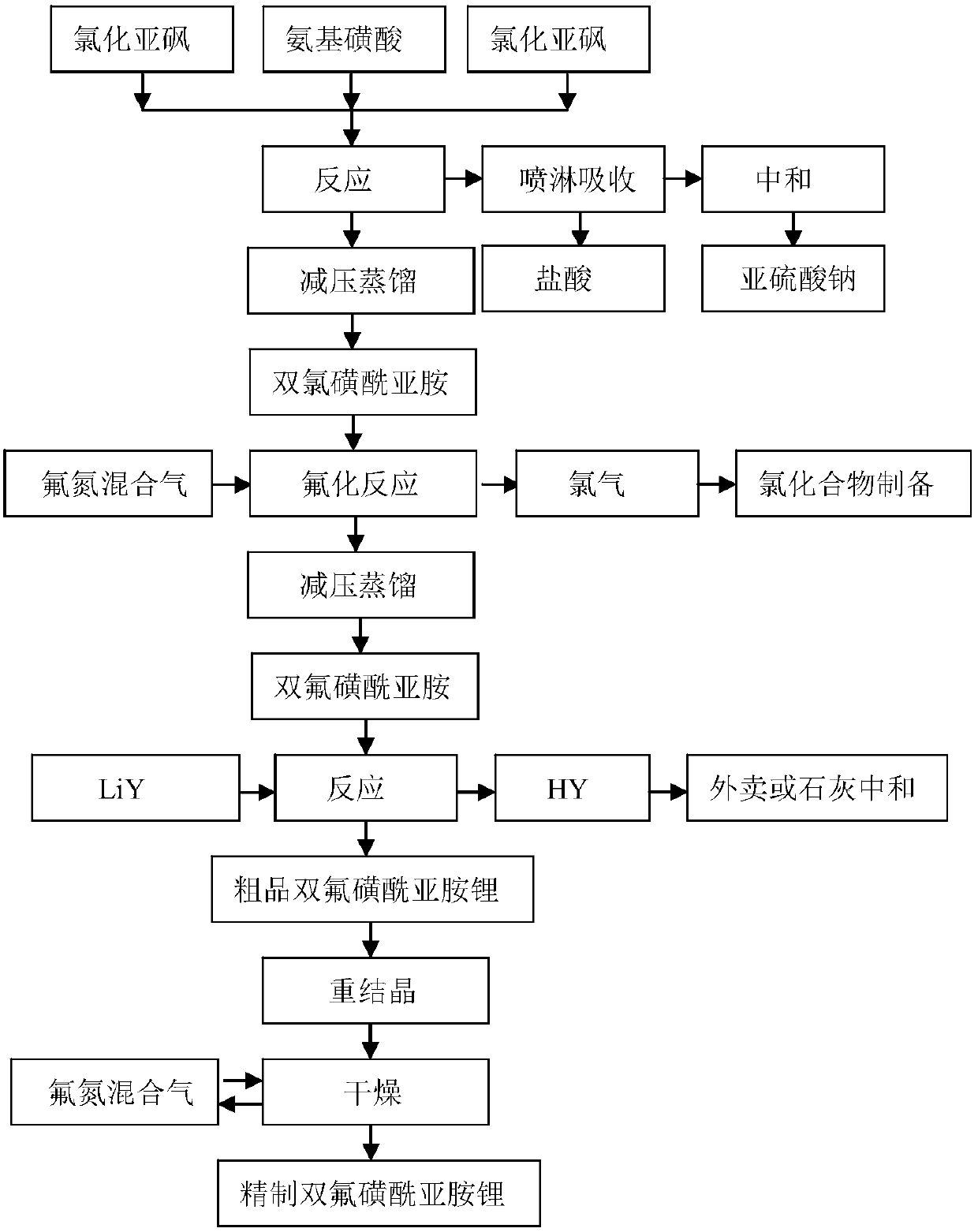

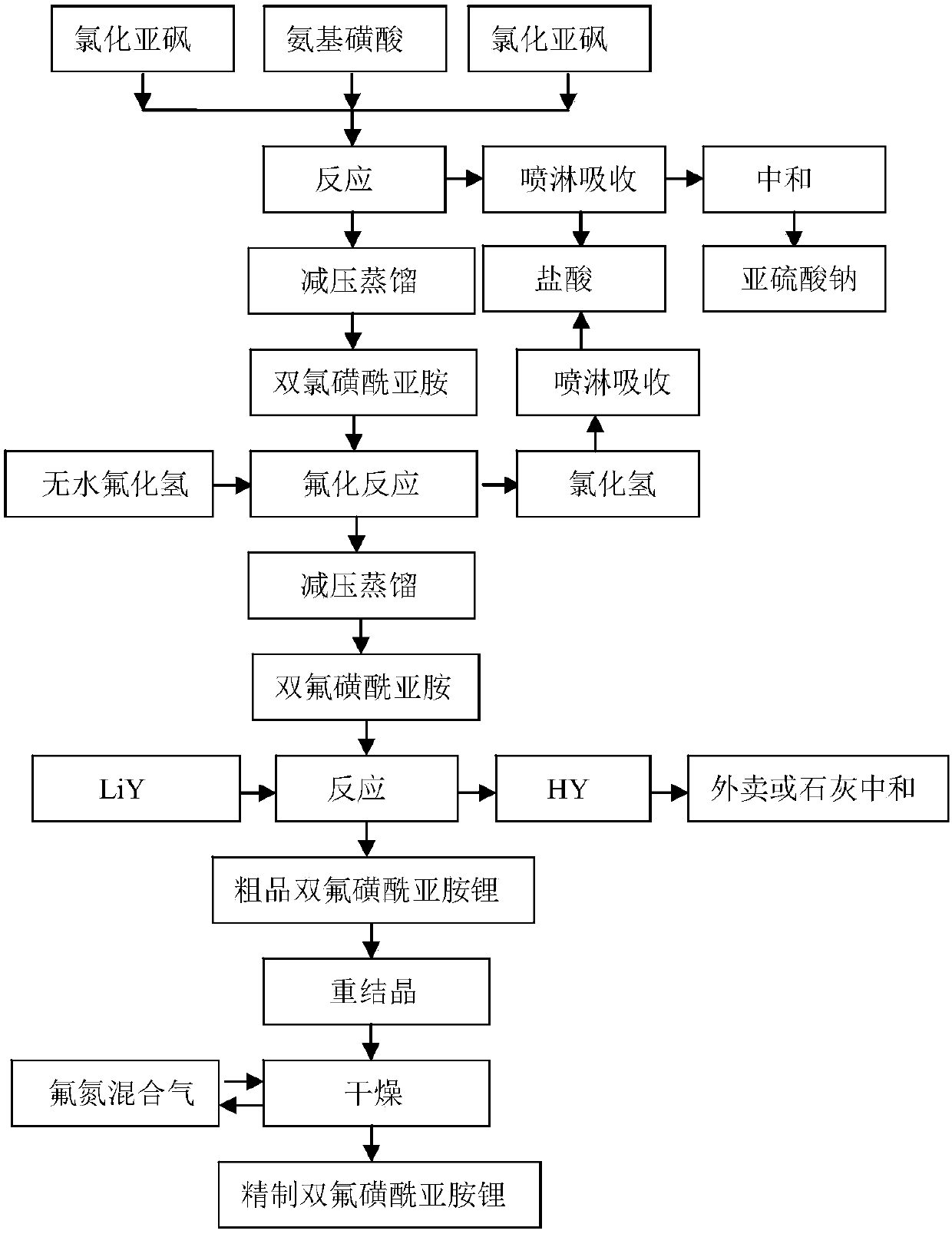

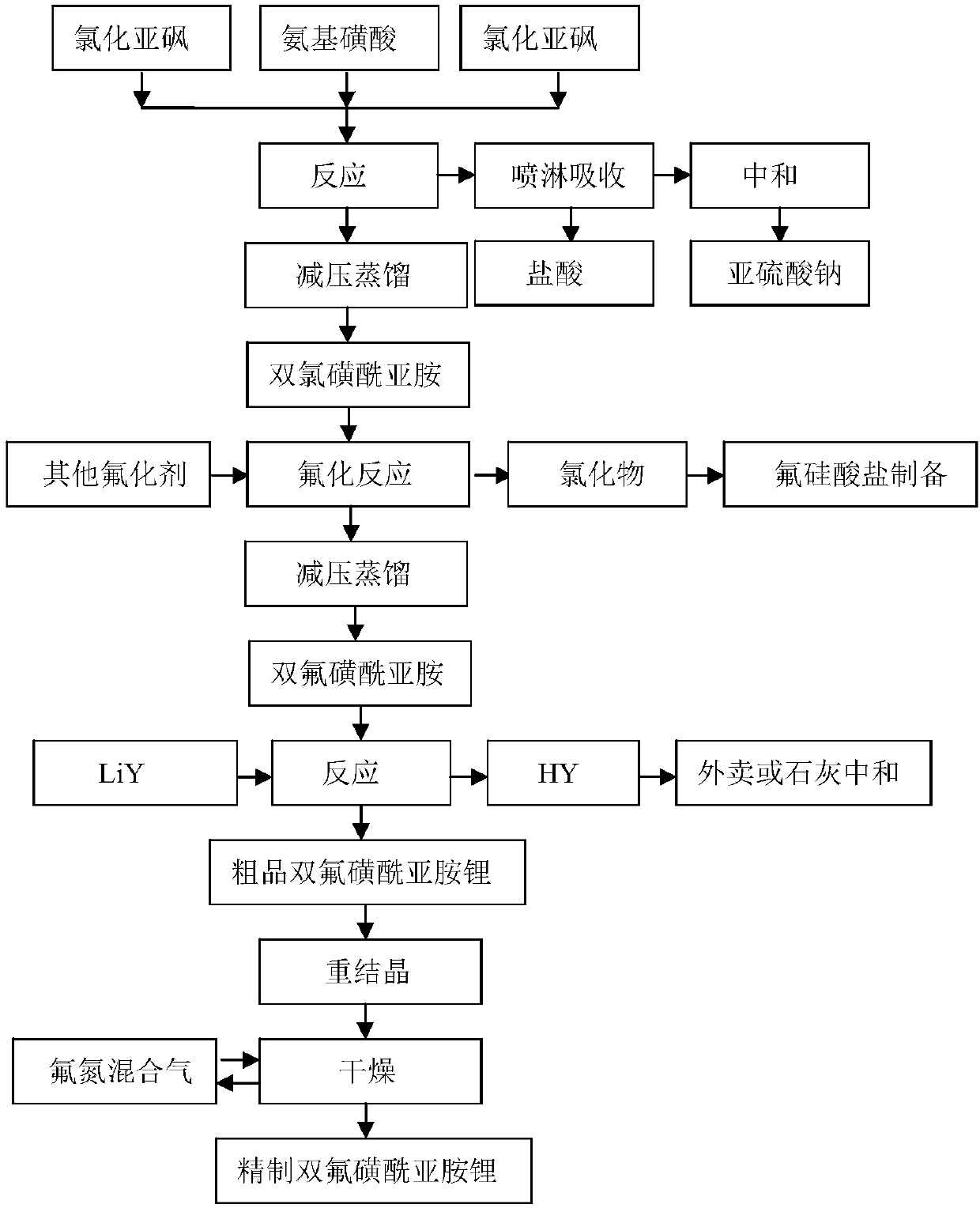

A kind of preparation method of lithium bisfluorosulfonyl imide

The invention discloses a preparation method of difluoro-sulfonyl imide lithium. The preparation method comprises the following steps: 1) under a protective atmosphere, adding a fluorizating agent into difluoro-sulfonyl imide to perform a fluorination reaction so as to obtain a mixture, wherein the fluorizating agent is one of or a combination of fluorine, a fluorine-containing mixed gas, anhydrous hydrogen fluoride, potassium fluoride, antimonic fluoride and rubidium fluoride; 2) performing reduced pressure distillation on the obtained mixture to obtain a di(fluoro-sulfonyl) imide intermediate; and 3) under a protective atmosphere, performing synthetic reaction on the obtained di(fluoro-sulfonyl) imide intermediate and a lithium source, and performing solid-liquid separation to obtain difluoro-sulfonyl imide lithium. According to the preparation method disclosed by the invention, the fluorination reaction does not need a solvent or other auxiliary agent, is less in types of adopted reagents, does not introduce a new impurity, is simple in operation, and is easy to control; the method is less in side reaction, good in fluorination effect and low in fluorination cost; and the purity and the yield of the product namely difluoro-sulfonyl imide lithium obtained by a subsequent synthetic reaction are improved on the whole, and the method has good economic and environmental benefits.

Owner:DO FLUORIDE CHEM CO LTD

Method capable of increasing content and yield of gamma-chloropropyltriethoxysilane simultaneously

InactiveCN101648966AImprove conversion rateHigh yieldSilicon organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsLithium chlorideTriethoxysilane

The invention discloses a method capable of increasing the content and yield of gamma-chloropropyltriethoxysilane simultaneously, and the method comprises the following steps: adopting gamma-chloropropyltrichlorosilane prepared by the reaction of trichlorosilane and chloropropene to react with ethanol and finally obtaining gamma-chloropropyltriethoxysilane though esterification, neutralization anddistillation. The invention adds lithium chloride, 4-methylaminopyridine and fatty alkyl dimethyl tertiary amine as esterifying catalyst in esterification reaction for the synergetic catalysis to thereaction between gamma-chloropropyltrichlorosilane and ethanol so as to increase the product content, greatly increase the conversion rate of gamma-chloropropyltrichlorosilane, increase the product yield, inhibit the side effect, shorten the reaction time, reduce the impurity content of the product and reduce the Cl<-> content in the product of which target value is not more than 50ppm.

Owner:青岛荣达新材料研究所

Novel technique for synthesizing solvent yellow 189

InactiveCN101130637AImprove solubilityHigh main contentMercapto-anthraquinone dyesPotassium hydroxideThiophenol

The invention discloses a new synthesizing technique of solvent yellow 189, which comprises the following steps: adopting 1, 5-dinitroanthraquinone as raw material to react with thiophenol in the strongly polar solvent of dimethyl formamide or dimethyl acetamide based on potassium hydroxide as acid-attaching agent at 30-100 deg. c to make the solvent yellow 189; cooling below 30 deg. c after finishing the reaction; filtering until the product is evolved sufficiently; washing the filter pie; drying; obtaining the product. The method reduces the manufacturing cost greatly and improves the main content of the product obviously, which modifies the appearance of the product with simple operation and easy control, in order to stabilize the manufacturing and increase the economical benefit.

Owner:JIANGSU YABANG DYE

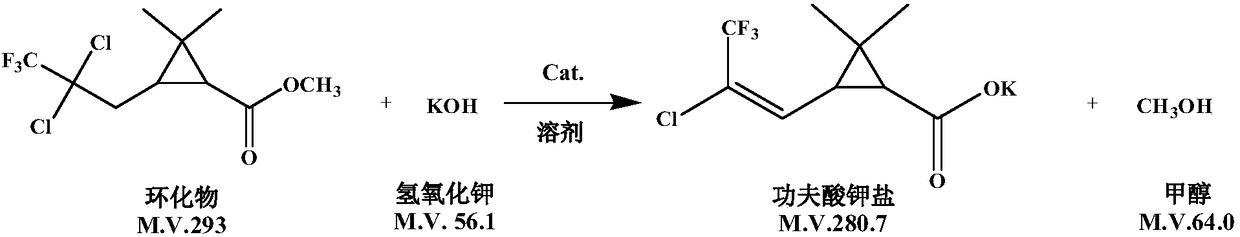

Production process of lambda-cyhalothric acid

InactiveCN108084019AStrong alkalineStrong three-dimensionalityPreparation from carboxylic acid saltsOxygen-containing compound preparation4-pentenoic acidOrganic synthesis

The invention discloses a production process of lambda-cyhalothric acid and belongs to the field of organic synthesizing. The lambda-cyhalothric acid is produced by dimethyl-4-pentenoic acid methyl ester, trifluorotrichloroethane and potassium 2-methyl-2-butoxide through addition, cyclization, saponification, acidification and refining. The production process has the advantages that the potassium2-methyl-2-butoxide used as the catalyst of cyclization reaction is high in selectivity and can increase cyclic compound cis-trans ratio; ethylene glycol is used as the solvent in the saponification process for the first time, a used staged heat preservation method can greatly lower the generation of side reaction, increase main content and increase reaction yield, reaction cycle can be shortenedgreatly, and productivity can be increased.

Owner:LIANYUNGANG CCA CHEM CO LTD

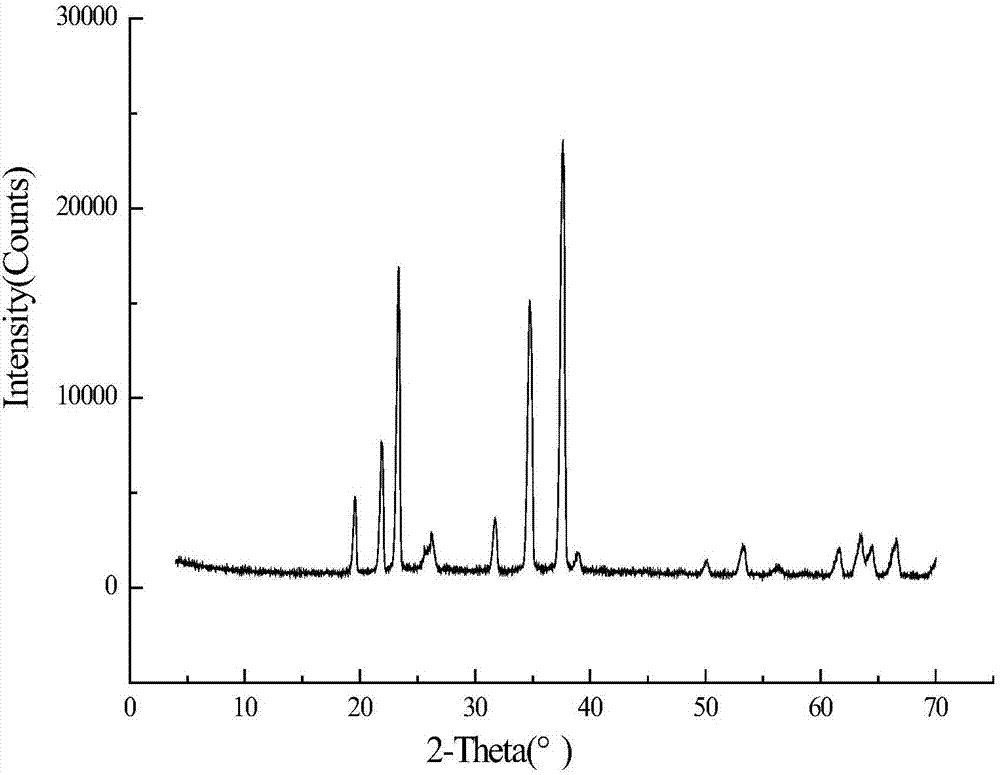

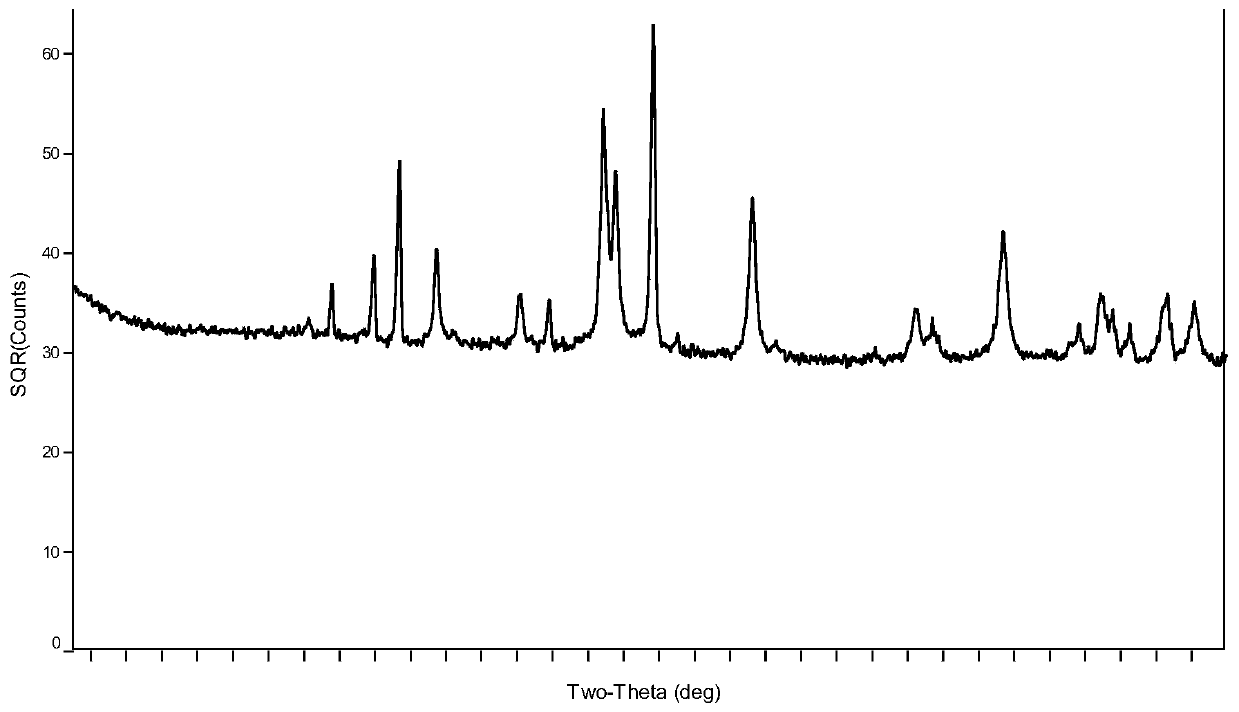

Method for recovering and purifying boron carbide from sapphire grinding wastes

The invention discloses a method for recovering and purifying boron carbide from sapphire grinding wastes. The method comprises the following steps: S1, screening sapphire grinding wastes by a 200-mesh sieve to obtain a magnetic separation raw material; S2, carrying out magnetic separation on the magnetic separation raw material to remove iron impurities, so as to obtain an acid-soluble raw material; S3, placing the acid-soluble raw material in an acidification medium for acid dissolution to remove siliceous impurities, and obtaining a hydrothermal raw material through first-time solid-liquidseparation; S4, mixing the hydrothermal raw material with an alkaline solution, carrying out a hydrothermal reaction for 1-20h at 150-300 DEG C, and obtaining a hydrothermal product through second-time solid-liquid separation; and S5, carrying out water dissolution, third-time solid-liquid separation and drying on the hydrothermal product to obtain recovered boron carbide. According to the methodfor recovering and purifying boron carbide from the sapphire grinding wastes, provided by the invention, the recovery of boron carbide ultra-fine powder in the sapphire grinding wastes is realized, resources and energy consumption are greatly saved, the recovered boron carbide obtained through recovery meets an abrasive-grade requirement, and can be directly used, and the recovery rate of the boron carbide ultra-fine powder reaches 96% or more.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

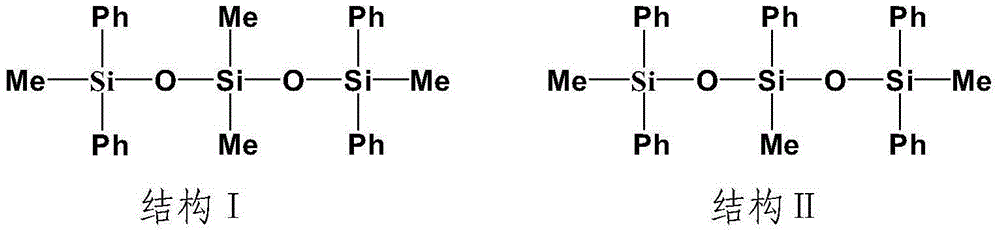

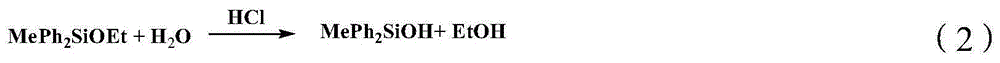

Diffusion pump oil synthesis method

ActiveCN106366107AReduce purification energy consumptionReduce energy consumptionSilicon organic compoundsChemical industryChlorobenzene

The invention relates to the chemical industry field, particularly to a diffusion pump oil synthesis method, which specifically comprises: (1) carrying out a hydrolysis reaction on methyl triethoxysilane to obtain 1,3-dimethyl-1,1,3,3-tetraethoxydisiloxane (short for compound B); (2) under a strong alkali condition, carrying out balanced telomerization on the compound B and a dimethyl ring body or methylphenyl ring body to obtain a compound D; (3) carrying out a sodium condensation reaction on the compound D, chlorobenzene and sodium to obtain the diffusion pump oil. According to the present invention, the reaction order is re-combined, and the method has advantages of low energy consumption and environmentally friendly process compared to the method in the prior art.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

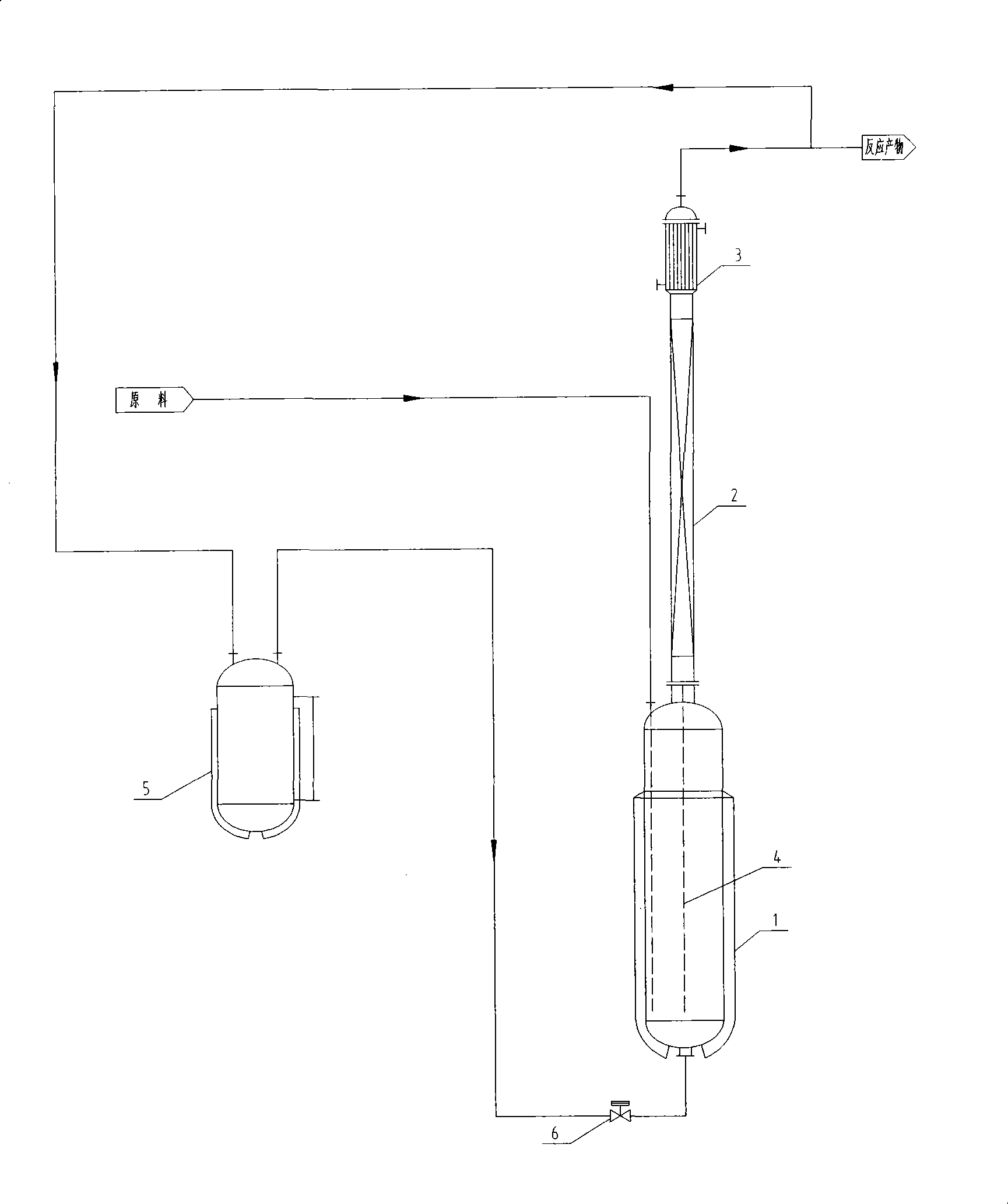

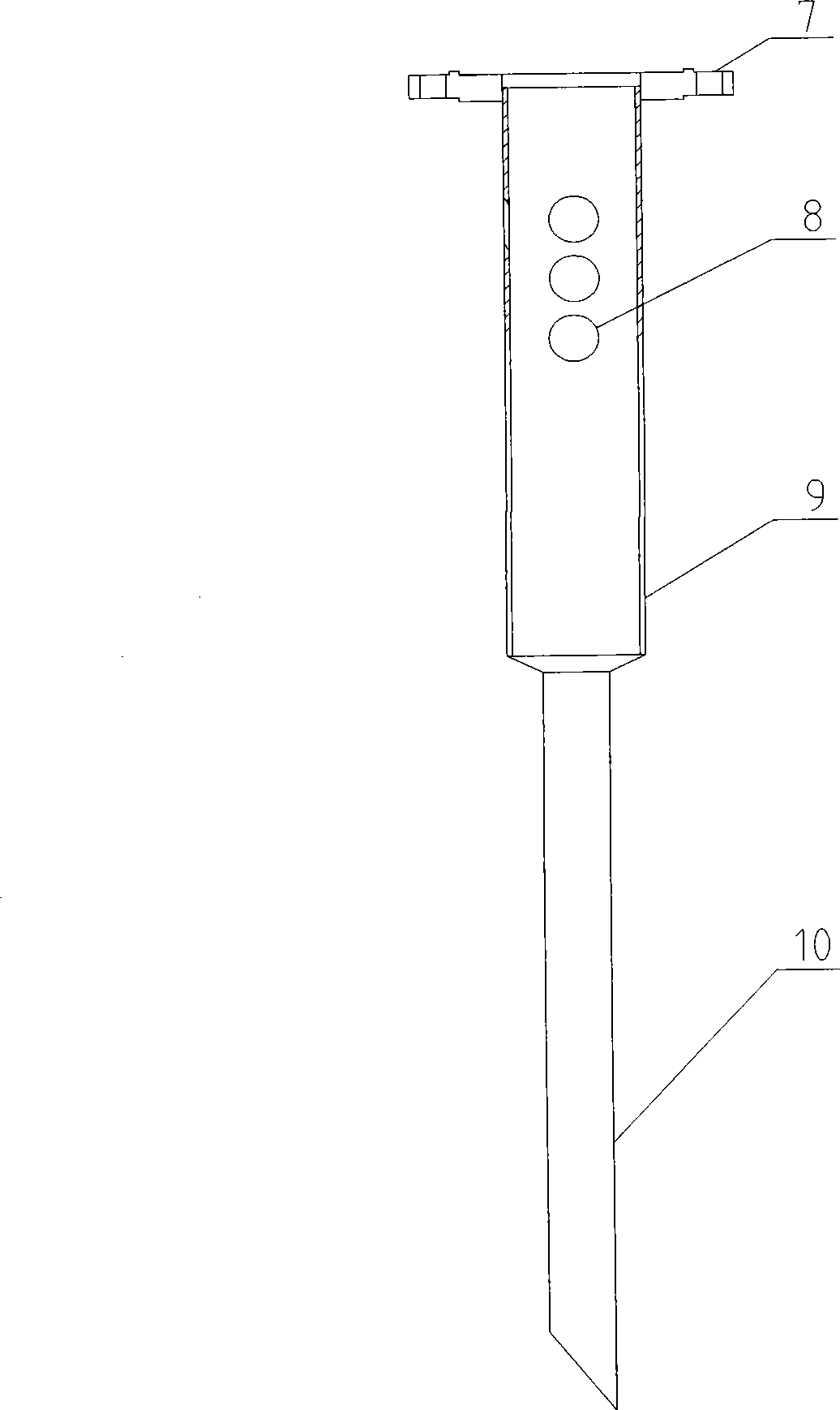

A kind of glyphosate continuous production device and method

ActiveCN104163832BReduce energy consumptionHigh yieldOrganic compound preparationGroup 5/15 element organic compoundsBiotechnologyPulp and paper industry

The invention provides a glyphosate continuous production device and method, specifically related to the continuous production of glyphosate synthetic liquid, pipeline reaction technology of hydrolyzed liquid and tail gas recovery technology. The purpose of the invention is to solve the existing shortcomings of intermittent operation, high labor intensity, high energy consumption and low purity of methyl chloride, improve the yield of glyphosate, the purity of methyl chloride and reduce energy consumption. The present invention increases the content of methyl chloride to 99.9%, increases the yield of glyphosate by 0.5% by realizing the continuous production of the whole process, reduces energy consumption, and is widely used in the field of glyphosate production.

Owner:HUBEI TAISHENG CHEM

Low-temperature reduction technology of ilmenite

The invention provides a low-temperature reduction technology of ilmenite. The technology comprises the following steps: mixing ilmenite and pulverized coal based on the mass ratio of 5: 1-1.2 under normal temperature condition; conveying the material into a rotary kiln or a tunnel kiln after mixing; igniting the pulverized coal; heating until the temperature is 600-700 DEG C, and reacting for 0.5-1h; cooling until normal temperature is reached after reaction; treating the cooled material through an airflow classifier; and magnetically separating twice, namely, magnetically separating for thefirst time under 1000-2000Gs to obtain titanium-containing magnetite and tailings, and magnetically separating the tailings for the second time under 5000-8000Gs to obtain ilmenite concentrate. According to the technology, pulverized coal is treated as a reducing agent, and the rotary kiln or the tunnel kiln is provided, so that the solubility of the ilmenite can be obviously improved under intermediate and low temperature conditions, and meanwhile, the main TiO2 content can be increased, and the titanium-containing magnetite and quality ilmenite concentrate can be obtained; the production cost of titanium dioxide is decreased, and the quality of the titanium dioxide is increased.

Owner:HAINAN WENSHENG HIGH TECH MATERIALS +1

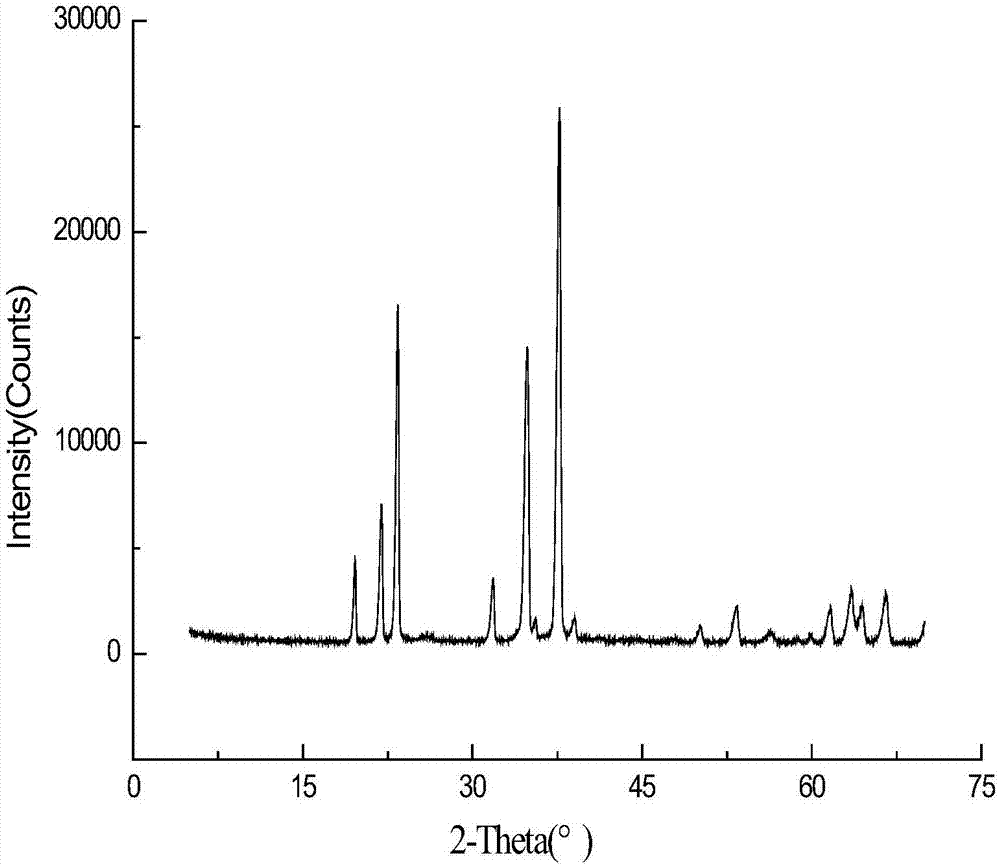

Boron carbide smelting device and boron carbide preparation method

ActiveCN107954718AEasy to useEasy to operateMaintainance of heating chambersCrucible furnacesBrickCrystallinity

The invention discloses a boron carbide smelting device. The boron carbide smelting device comprises a smelting furnace body, wherein the smelting furnace body is built by refractory bricks and comprises a bottom plate and side walls surrounding the bottom plate, and an opening is formed in the top of the smelting furnace body and allows buckling of a sunken type cover plate provided with exhaustholes; the smelting furnace body is filled with smelting raw materials; a positive pole and a negative pole are inserted into two opposite side walls of the smelting furnace body and both penetrate into the smelting furnace, end parts of the positive pole and the negative pole are opposite, and accordingly, the power is switched on for heating and smelting the smelting raw materials; the sunken type cover plate is gradually sunken with phase transformation of the smelting raw materials. The invention further discloses a boron carbide preparation method based on the boron carbide smelting device. According to the boron carbide smelting device, boron carbide is prepared with a nearly closed high-temperature treatment method, impurity pollution is reduced, product crystallinity is good, maincontent of the obtained boron carbide products is higher than 95%, and the products meet the abrasive material requirement after grading and meet the quality requirement of the grinding industry or the engineering ceramic field for boron carbide powder.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI +1

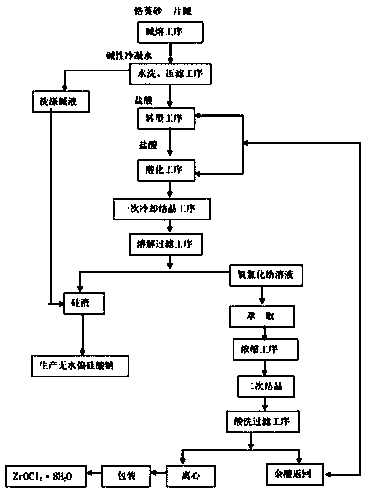

High-purity zirconium oxychloride extraction process

InactiveCN111017991AReduce contentHigh main contentAlkali metal silicatesZirconium compounds preparationDissolutionDiiron Trioxide

The invention discloses a high-purity zirconium oxychloride extraction process, which comprises the following steps: (1) alkali fusion, (2) water washing and filter pressing, (3) transformation, (4) acidification, (5) primary cooling crystallization, (6) dissolution and filtration, (7) extraction, (8) concentration, (9) secondary crystallization and (10) acid washing and filtration. According to the invention, an extraction process is added after the filter-pressing silicon removal process; ferric oxide and some impurities in the clear liquid are extracted into an extracting agent by using theextracting agent, so that the content of the impurities in the clear liquid is reduced, the content of the ferric oxide can be controlled to be below 1ppm, the residual impurities in the crystal areleached out by using a leaching method, the content of the impurities is reduced, and the main content of the product is increased.

Owner:山东鸿远新材料科技股份有限公司

Preparation method of gamma-chloropropyl triethoxysilane coupling agent

InactiveCN103254224AReliable principleReduce manufacturing costGroup 4/14 element organic compoundsEvaporationFine chemical

The invention belongs to the technical field of fine chemical product preparation and relates to a preparation method of a gamma-chloropropyl triethoxysilane coupling agent. The preparation method comprises the following steps: adding a systhesis raw material gamma-chloropropyl trichlorosilane in an overhead tank into a glass lining synthesis kettle through a rotor flow meter so as to carry out one-step synthesis between the synthesis raw material and ethanol, timely discharging a by-product HCl gas produced by the synthesis in vacuum through an exhaust pipeline to enter a hydrochloric acid recovery tank; carrying out secondary synthesis by pumping the one-step synthesis liquid into the bottom of a heater through pipe connection by the use of a matching pump by the utilization of pipeline liquid level difference; adding a synthesis raw material absolute ethyl alcohol in the overhead tank into an absolute ethyl alcohol evaporation container through the rotor flow meter so as to carry out vaporization and then entering a main tower; and carrying out separation of components by the utilization of boiling point gradients of different components while carrying out third synthesis. The preparation method has advantages of reliable principle, low production cost, high conversion rate, large capacity, low energy consumption and high main content, is environmentally friendly, and is suitable for large-scale production.

Owner:QINGDAO CHENGKE MATERIAL CO LTD

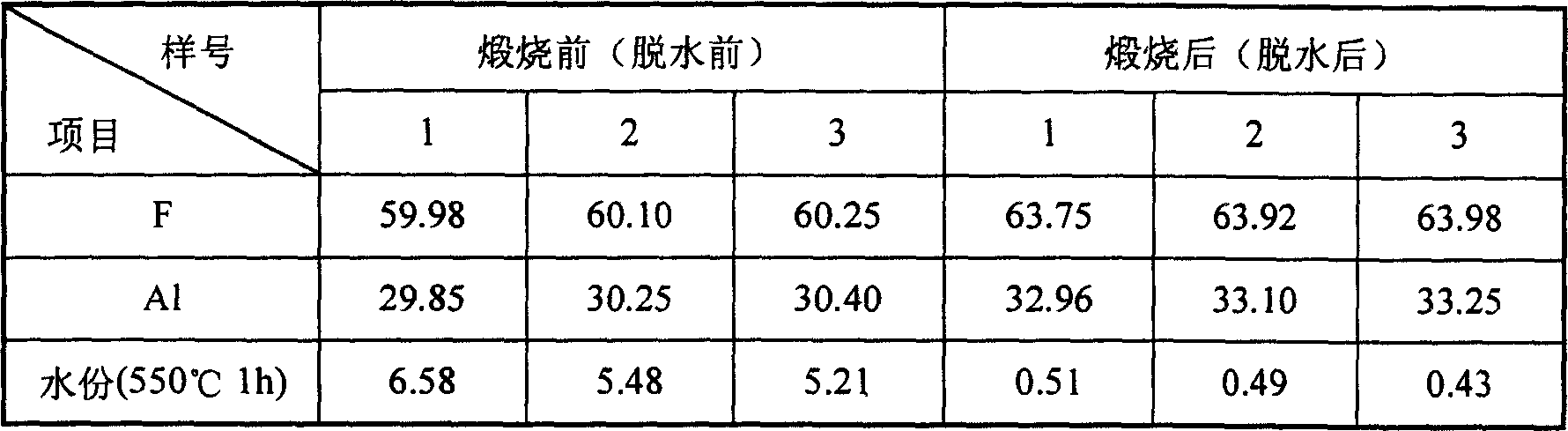

Method for removing aluminium fluoride crystal water

The process of eliminating crystalline water in aluminum fluoride includes the following steps: producing aluminum fluoride product with hydrofluoric acid in a wet process; calcining aluminum fluoride product statically under 400-600 deg.c for 20-30 min; cooling to eliminate crystalline water in aluminum fluoride. The said process can eliminate crystalline water in aluminum fluoride completely to obtain aluminum fluoride product with high aluminum fluoride content and low water content without hydrolysis of aluminum fluoride.

Owner:焦作市多氟多化工有限公司

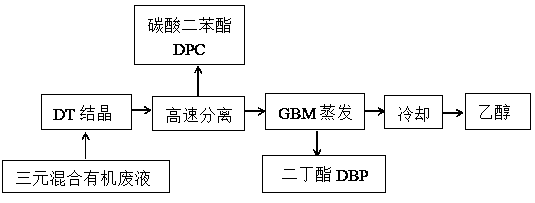

Separation method and system for mixture of ethanol, diphenyl carbonate and diphenyl carbonate

InactiveCN109336764AAvoid wastingEasy to operateOrganic compound preparationCarboxylic acid esters separation/purificationLiquid temperatureThermal solution

The invention relates to a separation method for a mixture of ethanol, diphenyl carbonate and diphenyl carbonate. The method comprises the following steps: feeding a thermal solution of ternary mixedorganic waste liquor of ethanol, DPC and DBP into a crystallizer to be cooled circularly, wherein the feed liquid temperature is reduced to be lower than constant temperature; then separating the feedliquid through a centrifugal machine, wherein solid crystals are DPC, and a liquid is a mixed solution of ethanol and DBP; feeding the mixed solution of ethanol and DBP into an evaporator, controlling the quantity of steam and the material feeding amount by adopting a temperature variable of the evaporator, and evaporating and separating the mixed solution, wherein ethanol escapes from the upperpart and is cooled by circulating cooling water, to obtain an ethanol liquid; a DBP solution flows from the lower part. A separation system for the mixture of ethanol, diphenyl carbonate and diphenylcarbonate is used for achieving the method. The method is simple to operate, finishes thorough separation at a relatively low temperature, the main contents of separated DPC and ethanol reach 98.5% orhigher, the main contents of DBP also reach 97.0% or higher, a recycling demand is met, material waste is avoided, the cost is reduced, and the environment is protected.

Owner:四川久润环保科技有限公司

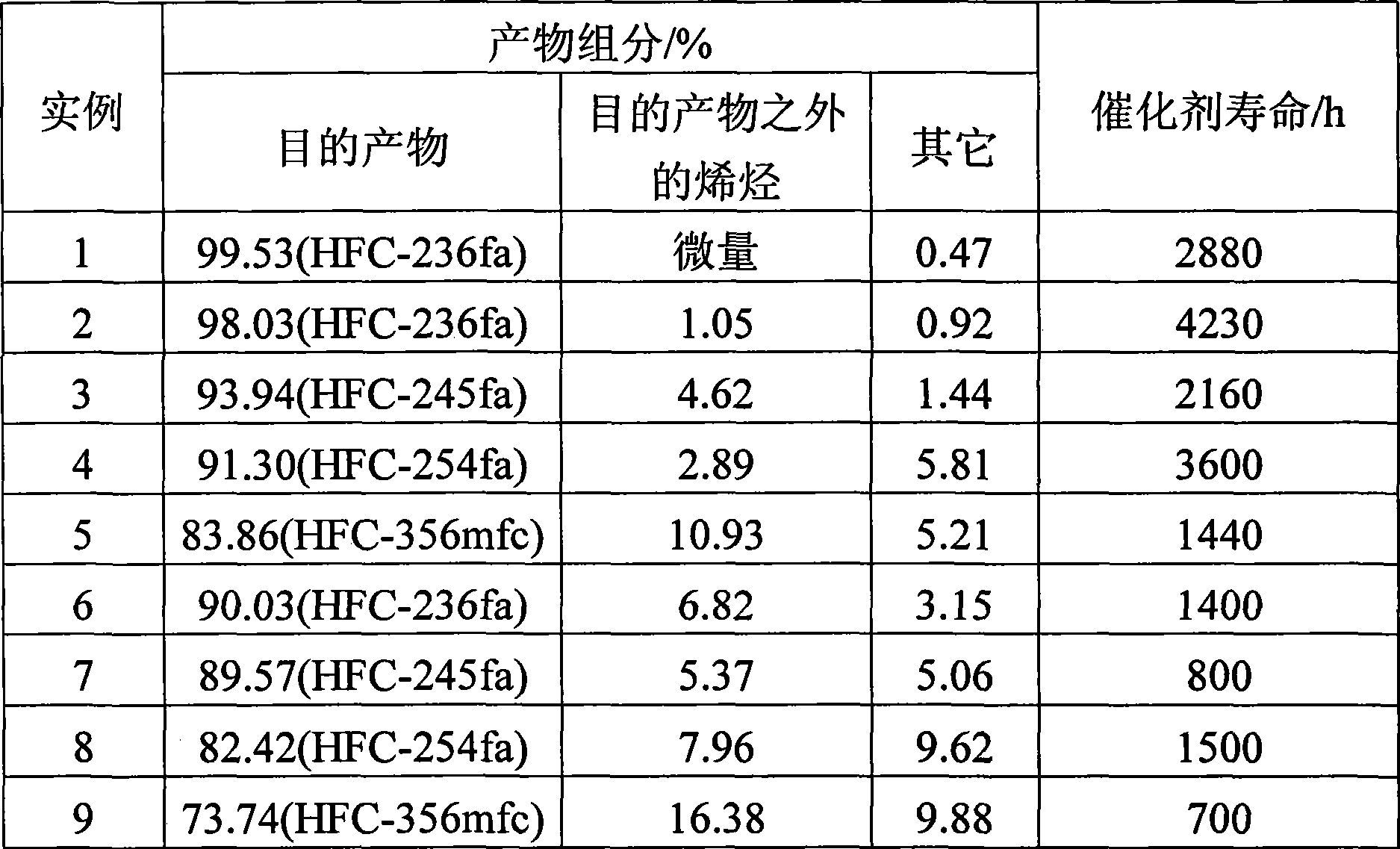

Method for prolonging the life of liquid-phase fluorination catalyst

InactiveCN101422742AEnhanced mass transferIncrease exposurePhysical/chemical process catalystsPreparation by halogen replacementEtherProduct gas

The invention discloses a method for prolonging the service life of a liquid fluorination catalyst, which comprises following steps: (1) an antimony halide catalyst is firstly added into a reactor, raw materials of AHF and hydrochloric ether are continuously added, and chlorine gas is introduced, thus obtaining a rough hydrofluoric ether product after reaction; (2) the rough hydrofluoric ether product is rinsed for removing an inorganic acid, the rough hydrofluoric ether product is collected after condensed liquefaction, and the total 97 to 99 percent of rough product is distilled, thus obtaining a hydrofluoric ether product; and (3) the total 1 to 3 percent of rough hydrofluoric ether product is heated, vaporized and pressure increased by an impulsive device, and then returned to the reactor for being recycled. By arranging a guide tube inside the reactor, the method leads the top condensed materials to return to the liquid phase of the reactor, and simultaneously adds the gas impulsive device for introducing gas medium is into the reactor, improving mass transferring state inside the reactor, and increasing contact probability of alkyl halide, an activating agent and the catalyst, thus effectively prolonging the service life of the liquid fluorination catalyst. The method has the advantages of high reaction selectivity and yield, long catalyst use time and less device investment, etc.

Owner:JUHUA GRP

Preparation method of high-content pentaerythritol tetra (3-mercaptopropionic acid) ester

The invention belongs to the field of chemical industry, and particularly relates to a preparation method of high-content pentaerythritol tetra (3-mercaptopropionic acid) ester, and the method comprises the following steps: reacting pentaerythritol, mercaptopropionic acid and an acylating reagent as raw material and organic alkali as a catalyst in a certain solvent at a certain temperature, and finally carrying out alkali washing, acid washing, water washing and negative pressure solvent recovery to obtain the target product. The preparation method disclosed by the invention has the advantagesof high reaction rate, low product chromaticity, small smell, high main content and the like.

Owner:SHANDONG EFIRM BIOCHEMISTRY & ENVIRONMENTAL PROTECTION CO LTD

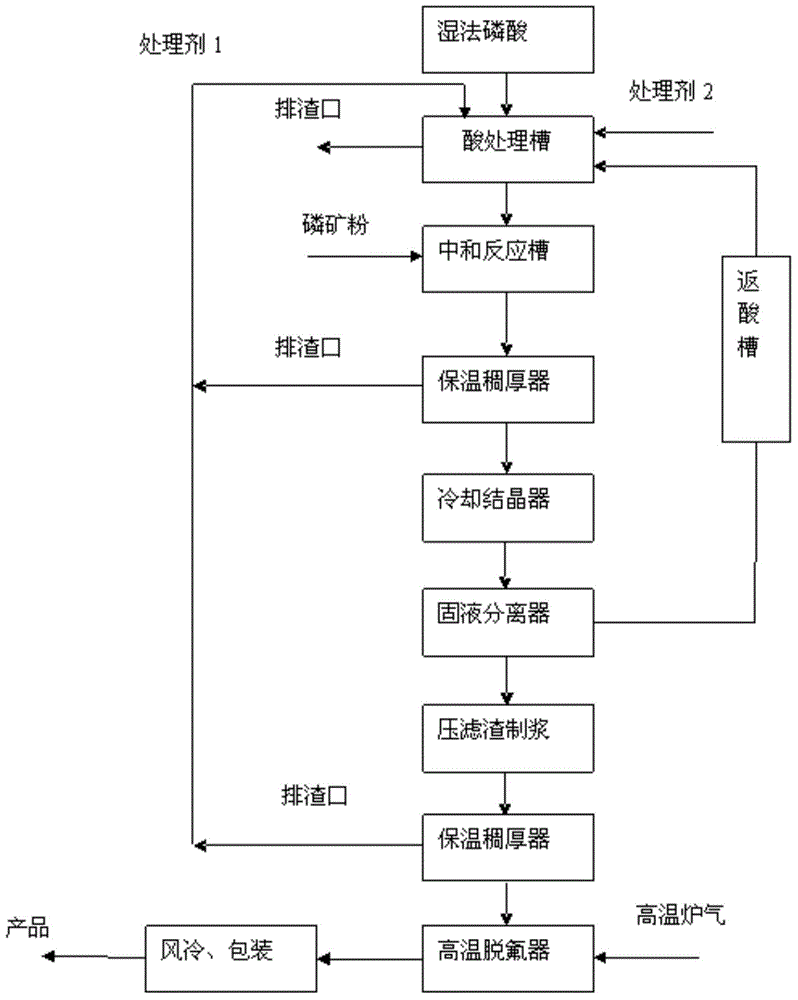

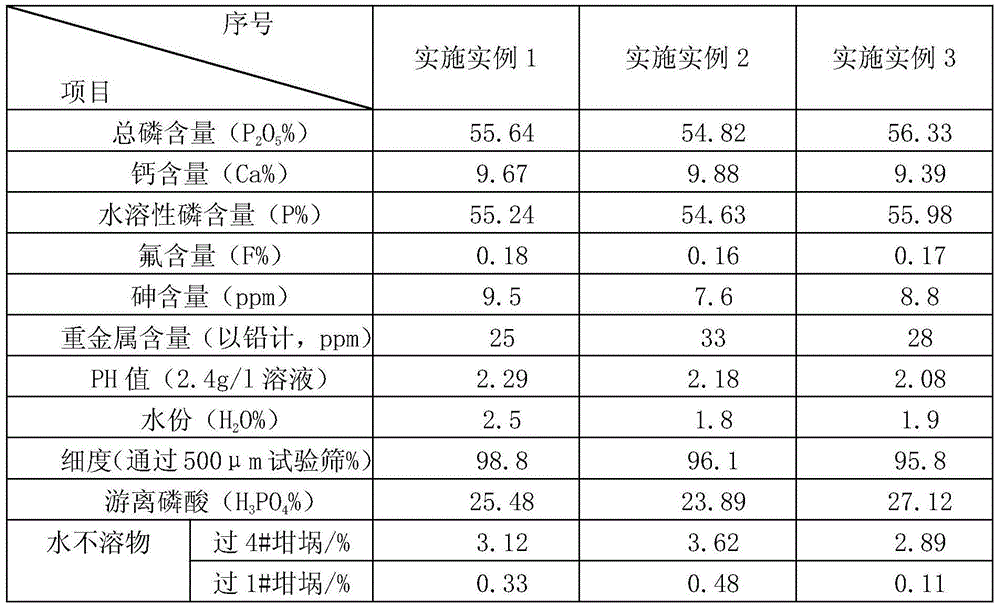

A producing method of a phosphorus-calcium highly-water-soluble fertilizer

The invention discloses a producing method of a phosphorus-calcium highly-water-soluble fertilizer and belongs to the technical field of fertilizers. The method includes steps of: a) adding a calcium-containing compound into a raw material that is wet-process phosphoric acid, reacting, filtering, adding a sulfide into the acid solution after filtration, reacting and filtering; b) subjecting the acid solution treated by the step a) and a raw material that is powdered rock phosphate to an acidolysis reaction, with the using amount of phosphoric acid being more than 500% of a theoretical reaction amount; c) thickening by maintaining the temperature of the slurry after acidolysis; d) transferring the supernatant liquid after thickening into a cooling and crystallizing tank, cooling and crystallizing, and performing solid liquid separation; e) adding water into filter residue of the step d) to prepare slurry, and thickening by maintaining the temperature; and f) transferring the supernatant liquid after thickening to a dryer having high-temperature air streams, and drying to obtain a product that is the phosphorus-calcium highly-water-soluble fertilizer. The method can control the content of water insoluble compounds of the product to be less than 3% and the main content to be higher than 98%, and is low in cost, high in phosphorus utilization rate and less in residue discharge.

Owner:GUIZHOU CHANHEN CHEM CO LTD

A kind of preparation method of boron carbide ultrafine powder

ActiveCN107758670BDifficult to operateLarge controllable difficultyCarbon compoundsFire brickCrystallinity

The invention discloses a preparation method of boron carbide superfine powder. The preparation method is based on a boron carbide smelting device which comprises a smelting furnace body built with refractory bricks and a sunken cover plate buckled at a top opening of the smelting furnace body, wherein a positive pole and a negative pole communicating a power supply are inserted into the side wallof the smelting furnace body. The preparation method comprises the following steps: S1, mixing a boron source with a carbon source fully to obtain a smelting raw material; S2, fully filling the smelting furnace body with the smelting raw material and covering the furnace with the sunken cover plate; and S3, applying a voltage to heat the smelting raw material to 1500-1900 DEG C and keeping the temperature for 24-48h to obtain the boron carbide superfine powder. Boron carbide is prepared by means of a nearly closed high-temperature treatment method according to the preparation method disclosedby the invention, so that impurity pollution is reduced, the product is good in crystallinity, the primary content of the obtained boron carbide superfine powder is greater than 96%, and the productgraded meets the demand of an abrasive material, and meets the quality demand on boron carbide powder in the field of grinding industry or engineering ceramics.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com