Method for removing aluminium fluoride crystal water

A technology of aluminum fluoride and crystal water, applied in the direction of aluminum fluoride, aluminum halide, etc., can solve the problems of main content reduction, aluminum fluoride hydrolysis, crystal water cannot be removed, etc., and achieve the effect of low water content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

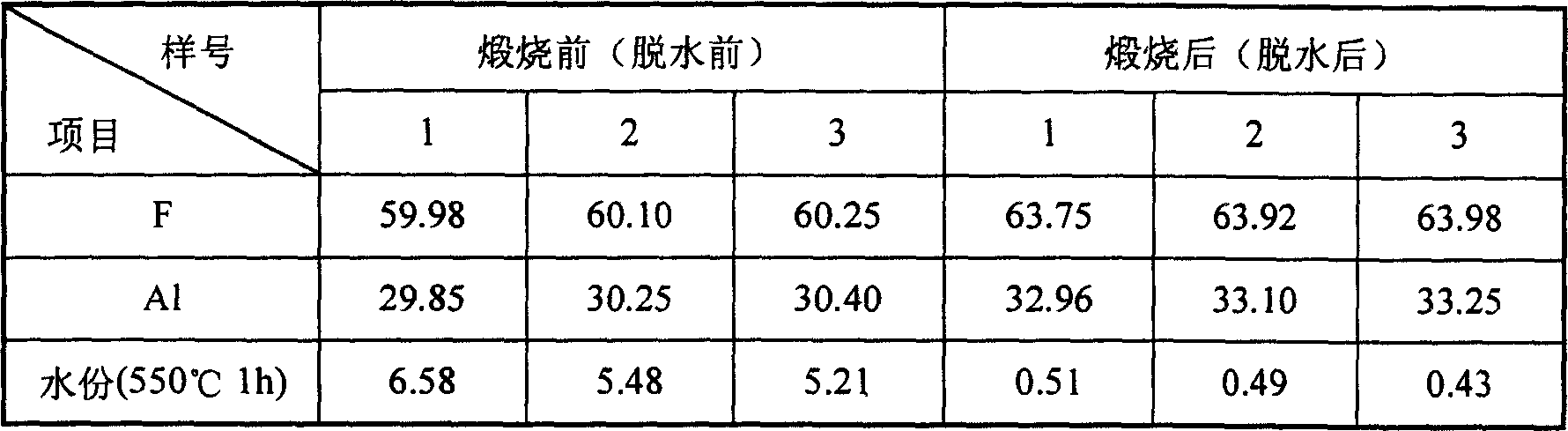

[0009] Aluminum fluoride with a water content of 6.58%, an F content of 59.89%, and an Al content of 29.85% is placed in the high temperature zone of a high-temperature static calciner at a temperature of 400°C for 30 minutes, and then cooled to obtain an aluminum fluoride product. The water content is 0.51%, the F content is 63.75%, and the Al content is 32.96%.

Embodiment 2

[0011] Aluminum fluoride with a water content of 5.48%, an F content of 60.10%, and an Al content of 30.25% is placed in the high temperature zone of a high-temperature static calciner at a temperature of 500°C for 25 minutes, and then cooled to obtain an aluminum fluoride product. The obtained water content is 0.49%, the F content is 63.92%, and the Al content is 33.10%.

Embodiment 3

[0013] Aluminum fluoride with a water content of 5.21%, an F content of 60.25%, and an Al content of 30.40% is placed in the high temperature zone of a high-temperature static calciner at a temperature of 600°C for 20 minutes, and then cooled to obtain an aluminum fluoride product. The water content is 0.43%, the F content is 63.98%, and the Al content is 33.25%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com