A kind of preparation method of boron carbide ultrafine powder

A technology of ultra-fine powder and boron carbide, which is applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems that are not suitable for large-scale promotion and development, and difficult to remove, so as to save labor costs and reduce energy consumption , the effect of process stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

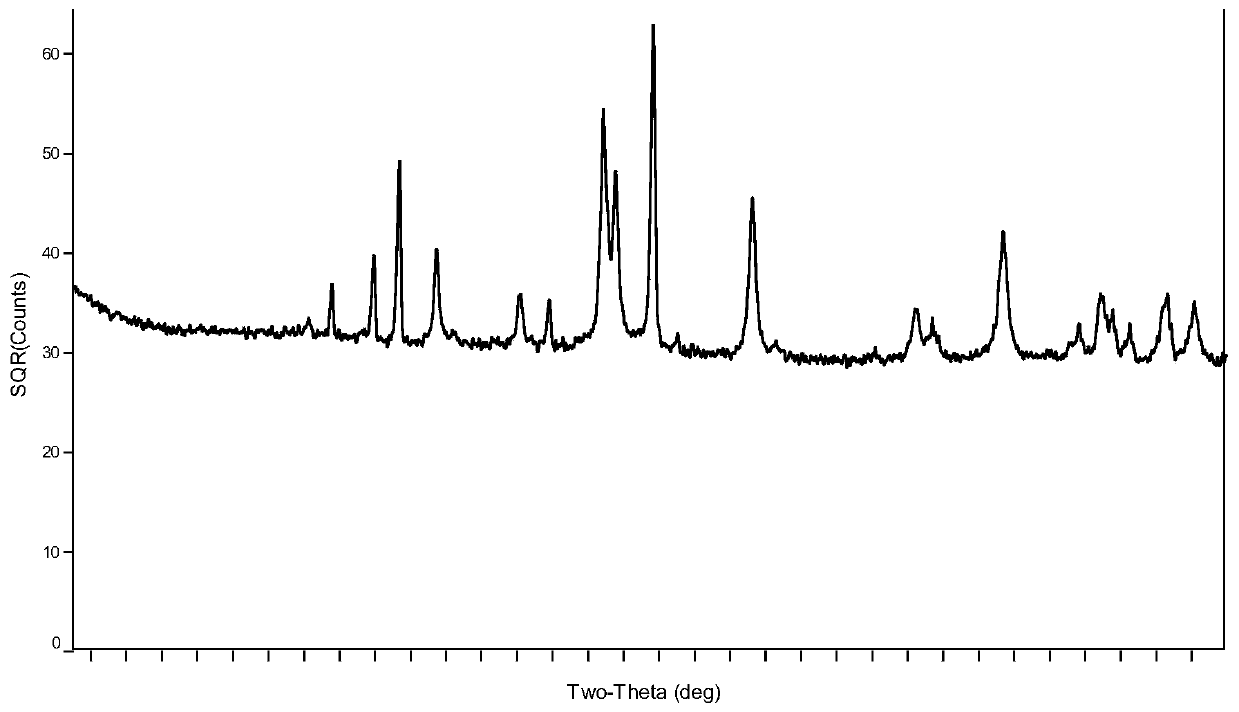

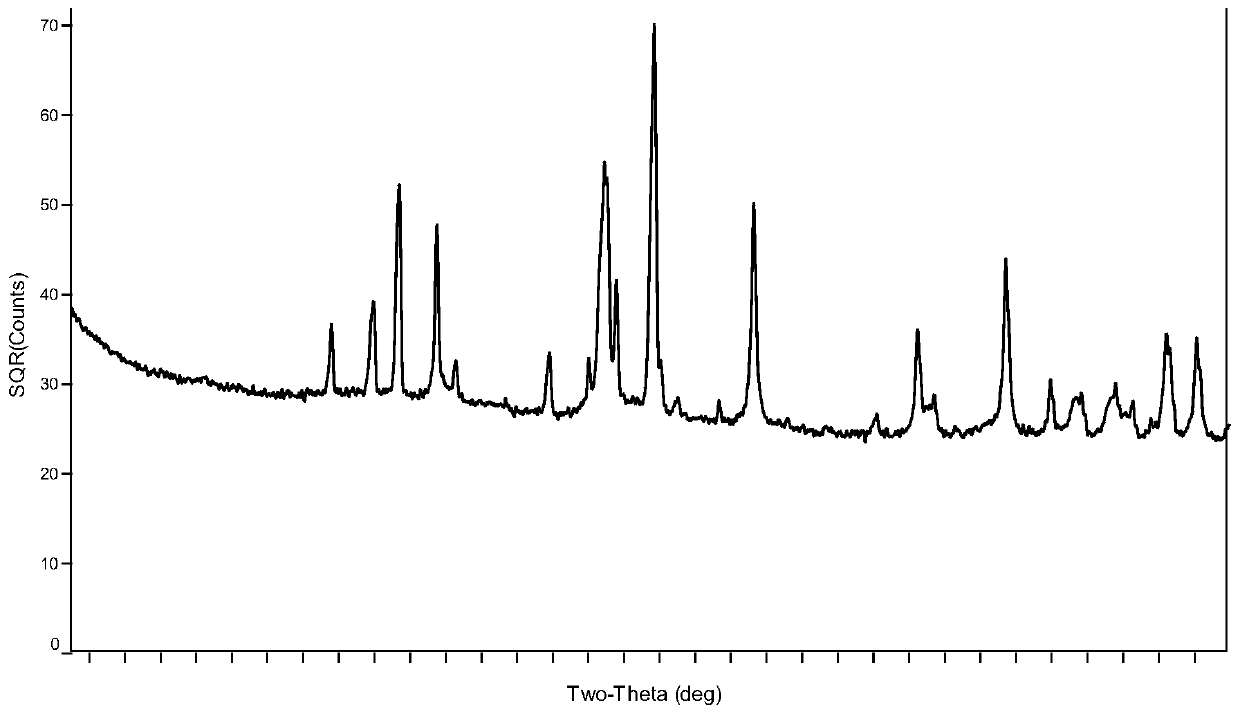

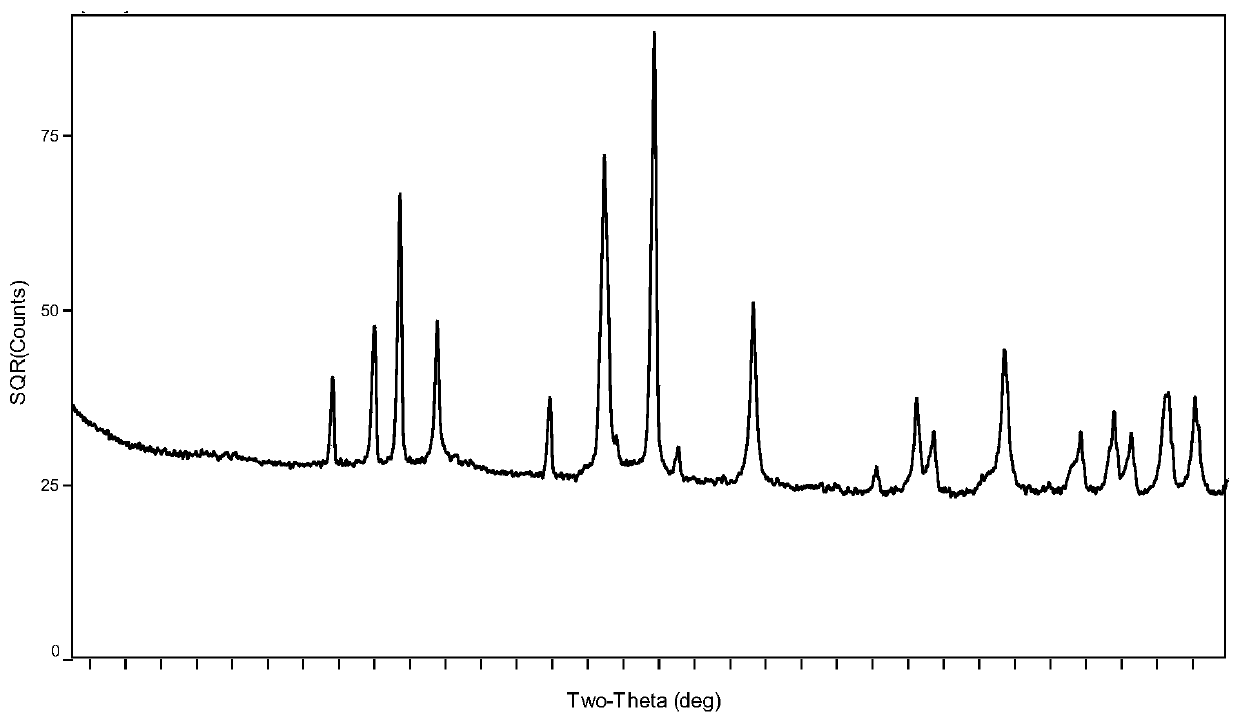

Image

Examples

preparation example Construction

[0030] The invention discloses a preparation method of boron carbide superfine powder. The preparation method is based on a boron carbide smelting device.

[0031] Specifically, the boron carbide smelting device includes a smelting furnace body made of refractory bricks and a sunken cover plate made of high-temperature resistant materials; the smelting furnace body includes a bottom plate and side walls surrounding the bottom plate. The top of the furnace body opposite to the bottom plate has an opening, and the sinking cover plate is fastened on the opening; that is, the smelting furnace body is a "box-shaped body made of refractory bricks with an opening at the top ".

[0032] More specifically, the sunken cover plate is provided with vent holes to remove the gas generated during the smelting process inside the smelting furnace body; the two opposite side walls of the smelting furnace body are respectively inserted with positive electrodes and The negative electrode, the positiv...

Embodiment 1

[0052] Ultra-fine boron anhydride and ultra-fine graphite are used as raw materials. The main content of ultra-fine boron anhydride is 99.51%, the average particle size is 8 μm, and the average particle size of ultra-fine graphite is 6 μm. 50kg of superfine boric anhydride and 12kg of superfine graphite are thoroughly mixed through a ball mill, and then pressed into a long strip with an extruder to obtain raw materials for smelting.

[0053] The smelting raw materials are placed in a boron carbide smelting device for sintering. The specific sintering process is: 1000KVA transformer (rectifier), a total of 15 on-load voltage regulating switches, and the furnace is turned on in series. The gears are gradually increased from gear 1. Observe Regarding the rise of primary and secondary currents, adjust the interval of upshifts as appropriate. When the primary current reaches 70A, it will drop one gear. According to the furnace resistance and voltage, it should be adjusted in parallel a...

Embodiment 2

[0059] Taking recycled boron anhydride (that is, dust collected in arc smelting), domestically produced ultrafine boron oxide, ultrafine graphite and ultrafine carbon powder as raw materials, the recycled boron anhydride is pretreated first, including the removal of abnormally large particles and impurities, to obtain the main The content of ultrafine boric anhydride with a content of 98.01% and an average particle size of 12μm, and the particle size of the remaining raw materials are all within 10μm. Stir 40kg ultra-fine boron anhydride, 10kg domestic ultra-fine boron oxide, 8kg ultra-fine graphite and 4kg ultra-fine carbon powder. After stirring and mixing, they are ground by a ball mill and pressed into a block with a length of 8cm-12cm with a block molding machine. The compacted density is about 1.24g / cm 3 , Obtain smelting raw materials.

[0060] The smelting raw materials are placed in a boron carbide smelting device for sintering. The specific sintering process is: 1000KVA...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com