Strain aging method for improving mechanical properties of aluminum alloy

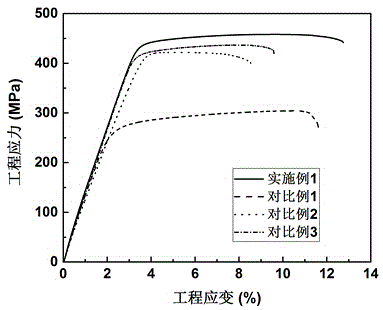

An aging method and aluminum alloy technology, which is applied in the field of material processing, can solve the problems of difficult precipitation of β″ phase, poor aging strengthening effect, and low aging temperature, so as to achieve easy operation, low processing cost, and high tensile strength and yield strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

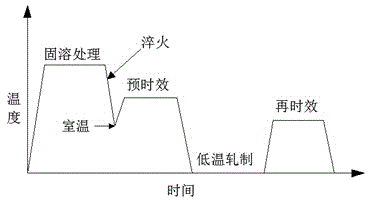

[0025] Example 1 A deformation aging method for improving the mechanical properties of aluminum alloys, comprising the steps of:

[0026] 1) 6016 aluminum alloy was used for heat treatment, and the 6016 aluminum alloy was heat-treated in an air furnace at 520°C for 60 minutes for solid solution treatment;

[0027] 2) Water-cooling and quenching the solid-solution aluminum alloy in step 1) to room temperature;

[0028]3) Perform pre-aging treatment on the aluminum alloy material quenched in step 2) at 180°C, and keep it warm for 10 minutes, so that the aluminum alloy material is in an under-aging state;

[0029] 4) After immersing the aluminum alloy material treated in step 3) in liquid nitrogen for 30 min, carry out multi-pass low-temperature rolling, immediately put the aluminum alloy material back into liquid nitrogen for 8 min after each rolling pass, and then Carry out the next pass of rolling to keep the temperature of the aluminum alloy material at -150°C~-180°C durin...

Embodiment 2

[0042] Example 2 A deformation aging method for improving the mechanical properties of aluminum alloys, comprising the steps of:

[0043] 1) 6061 aluminum alloy is used for heat treatment, and the 6061 aluminum alloy is kept at 560°C in an air furnace for 20 minutes for solid solution treatment;

[0044] 2) Water-cooling and quenching the solid-solution aluminum alloy in step 1) to room temperature;

[0045] 3) Perform pre-aging treatment on the aluminum alloy material after quenching in step 2) at 170°C, and keep it warm for 20 minutes, so that the aluminum alloy material is in an under-aging state;

[0046] 4) After immersing the aluminum alloy material treated in step 3) in liquid nitrogen for 30 min, perform multi-pass low-temperature rolling, immediately put the aluminum alloy material back into liquid nitrogen for 10 min after each rolling pass, and then Carry out the next pass of rolling to keep the temperature of the aluminum alloy material at -150...

Embodiment 3

[0049] Example 3 A deformation aging method for improving the mechanical properties of aluminum alloys, comprising the steps of:

[0050] 1) 6063 aluminum alloy was used for heat treatment, and the 6063 aluminum alloy was heat-treated in an air furnace at 550°C for 30 minutes for solid solution treatment;

[0051] 2) Water-cooling and quenching the solid-solution aluminum alloy in step 1) to room temperature;

[0052] 3) Perform pre-aging treatment on the aluminum alloy material quenched in step 2) at 150°C, and keep it warm for 30 minutes, so that the aluminum alloy material is in an under-aging state;

[0053] 4) After immersing the aluminum alloy material treated in step 3) in liquid nitrogen for 20 min, perform multi-pass low-temperature rolling, immediately put the aluminum alloy material back into liquid nitrogen for 10 min after each pass of rolling, and then Carry out the next pass of rolling to keep the temperature of the aluminum alloy material at -1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com