A producing method of a phosphorus-calcium highly-water-soluble fertilizer

A technology for water-soluble fertilizers and production methods, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of poor water solubility and water-soluble phosphorus, affecting environmental balance, aggravating water pollution, etc., and achieving low water-insoluble matter. , The effect of increasing the main content and reducing the insoluble matter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

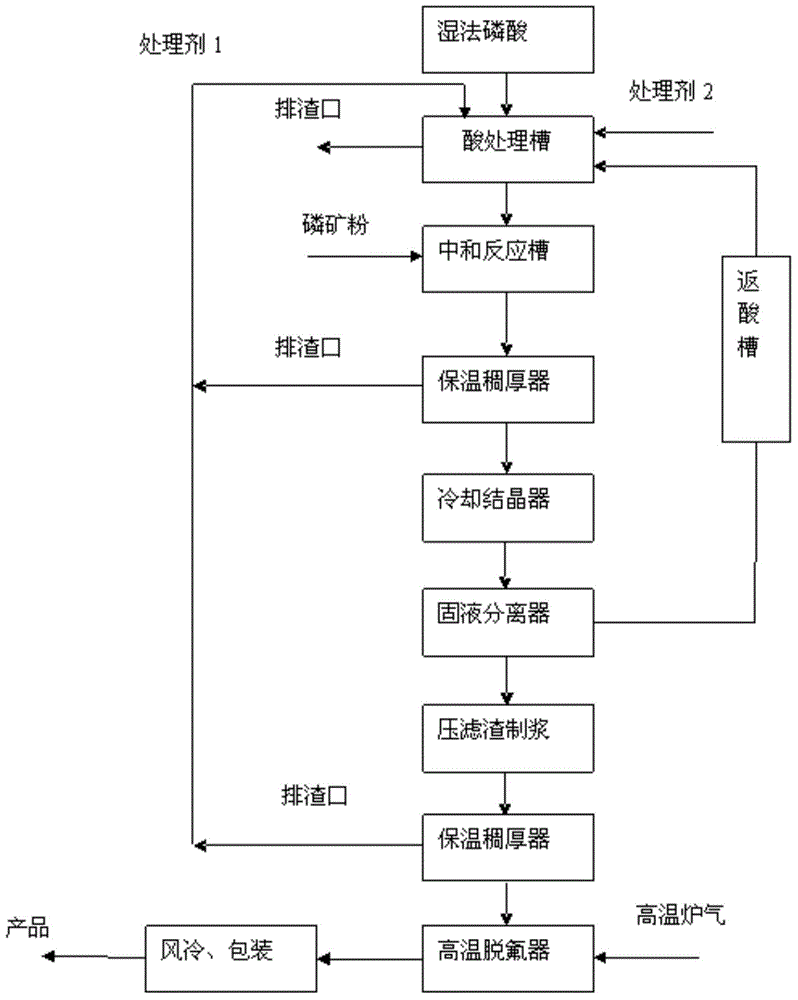

Method used

Image

Examples

Embodiment 1

[0081] Phosphoric acid hemihydrate is produced from phosphate rock in the Mabian area of Sichuan, and is added as a cheap ore. The quality indicators of acid ore for reaction are shown in Table 1:

[0082] Table 1 raw material index

[0083] index P 2 o 5 CaO Fe 2 o 3 MgO al 2 o 3 F SO4 As K Na Phosphoric acid hemihydrate 40.96 0.06 0.37 0.69 0.06 0.73 1.61 0.0031 0.036 0.022 Phosphate Rock 33.89 47.72 0.51 1.47 0.42 3.2 2.28 0.0026 0.088 0.42

[0084] The temperature of the phosphoric acid hemihydrate used for the reaction is raised to 60-80°C in the circulation heater, and the treatment agent 1 (prepared in advance, the composition is similar to the thick slag, the same below) (the addition amount of each substance in the embodiment is as long as within the range of the amount described in the specific embodiment), react for 30 minutes, detect that the CaO content of the slurry is 1% to 2%, and filter; ...

Embodiment 2

[0086] Use phosphate rock in Fuquan area, Guizhou to produce phosphoric acid hemihydrate, and use this ore to add as cheap ore. The quality index of acid ore for reaction is as shown in Table 2:

[0087] Table 2 raw material index

[0088] index P 2 o 5 CaO Fe 2 o 3 MgO Al 2 o 3 F SO4 As K Na Phosphoric acid hemihydrate 42.53 0.14 0.36 1.38 0.17 0.84 1.72 0.0025 0.035 0.026 Phosphate Rock 30.34 43.98 0.58 0.94 0.62 2.76 2.08 0.0031 0.09 0.22

[0089] The temperature of phosphoric acid hemihydrate for reaction is raised to 60-80°C in the circulation heater, adding treatment agent 1 (prepared in advance), reacting for 30 minutes, and detecting that the CaO content of the slurry is 1.5%-2%, and filtering; the filter residue is used A small amount of clean water was washed in countercurrent three times, and the filtrate acid was heated to 60-80°C, and the treatment agent 2 sodium sulfide was added, reacted for ...

Embodiment 3

[0091] Phosphoric acid hemihydrate is produced from phosphate rock in Shangzhou, Sichuan, and added as a cheap ore. The quality indicators of acid ore for reaction are shown in Table 3:

[0092] Table 3 raw material index

[0093] index P2O5 CaO Fe 2 o 3 MgO al 2 o 3 F SO4 As K Na Phosphoric acid hemihydrate 39.56 0.08 0.53 1.2 0.46 1.23 1.53 0.002 0.037 0.016 Phosphate Rock 31.12 44.72 2.4 1.62 1.98 2.46 4.73 0.0031 0.14 0.082

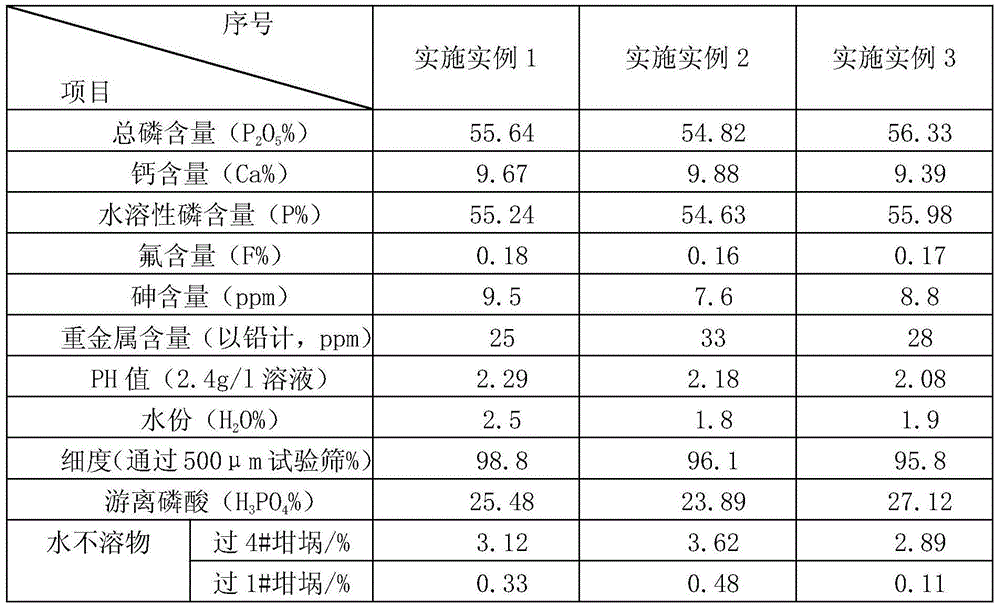

[0094] The implementation process is as in Example 2, and the product indicators are shown in Table 5.

[0095] Table 4. PCA Quality Indicators of Enterprise Acidic Water-Soluble Fertilizers (Internal Control)

[0096] serial number project index 1 Exterior White or other very light monochrome 2 Total P 2 o 5 % 53—54 3 Water solubility% ≥98 4 Free phosphoric acid (as phosphoric acid) ≥25 5 PH value >2 6 Calcium Ca% ≥9 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com