Method for purifying lithium carbonate

A technology of lithium carbonate and hydrogenation solution, applied in the direction of lithium carbonate;/acid carbonate, etc., can solve the problems of unstable product performance, leaking, high recovery rate, etc., and achieve high quality and high main content of the product , The effect of production process safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

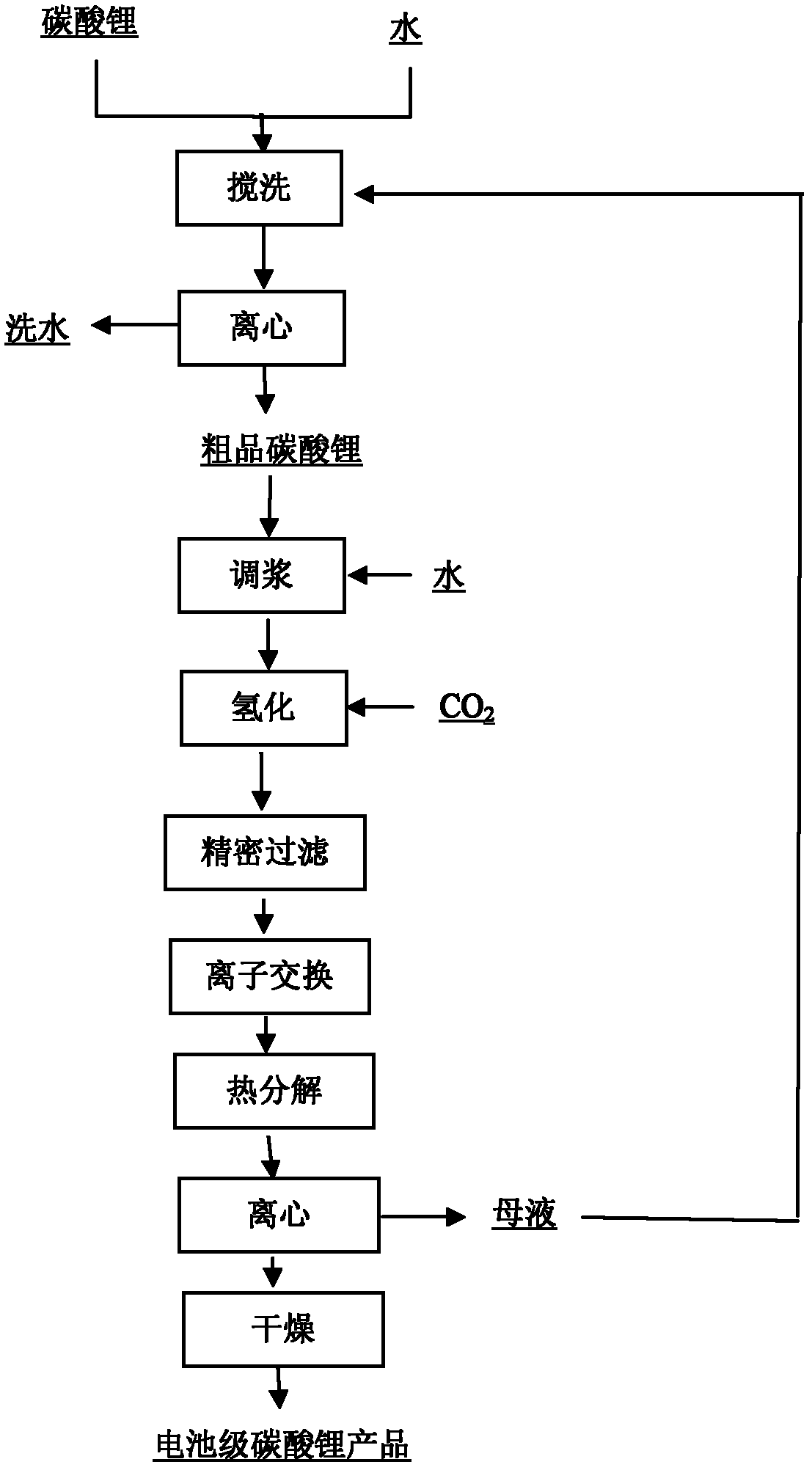

[0050] Present embodiment 1 method comprises the following steps (see figure 1 ):

[0051] 1. Add the defective lithium carbonate to water and stir wash it once according to the liquid-solid ratio of 3:1, remove the impurity ions wrapped in the defective lithium carbonate, and obtain the crude lithium carbonate; 2 CO 3 :H 2 The ratio of 0=1:15 lithium carbonate crude product is added in water and stirred, is configured into lithium carbonate slurry;

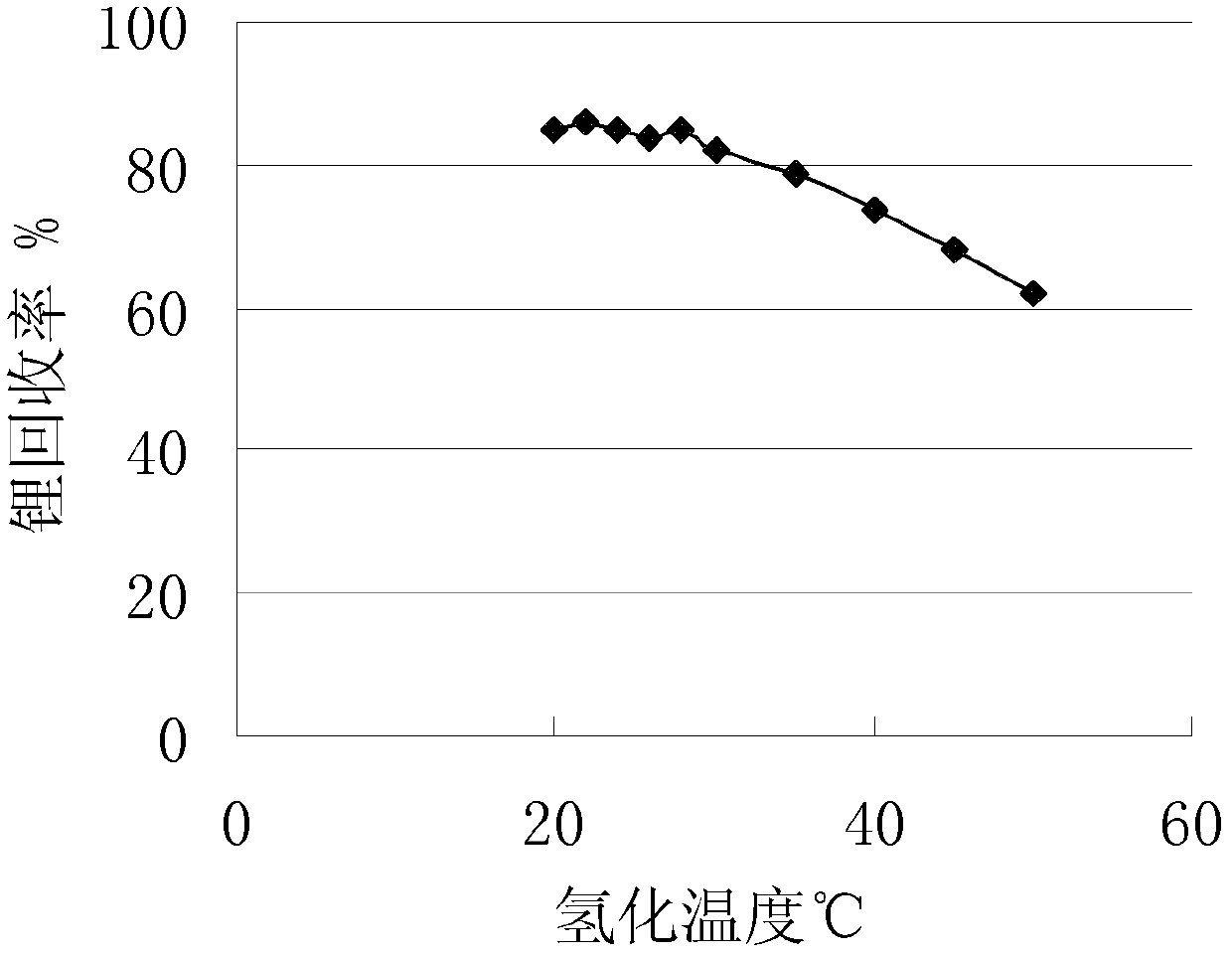

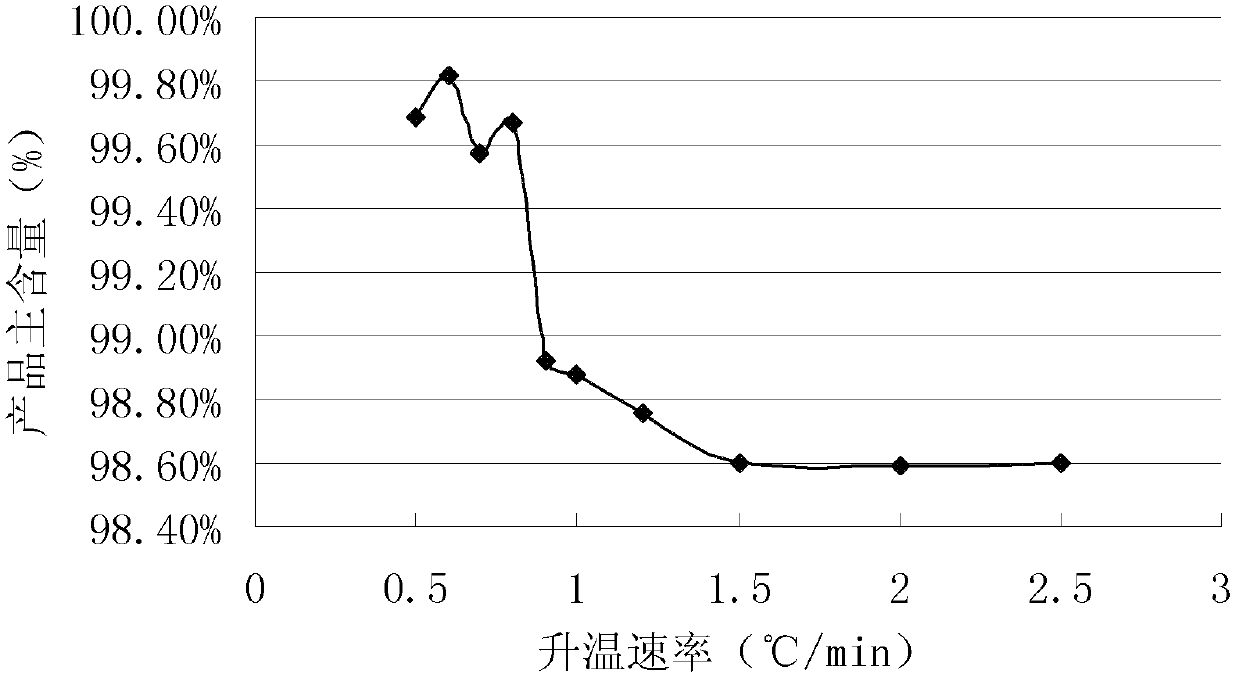

[0052] 2. Control the temperature of the lithium carbonate slurry at 20°C, and inject CO 2 Gas, keep the pressure in the hydrogenation tank at 0.2Mpa, hydrogenation reaction occurs with lithium carbonate, stop ventilation when the concentration of lithium oxide in the solution is 10g / L, and filter the solution to obtain hydrogenated liquid. Pass the hydrogenation solution through D732 ion exchange resin at 8BV / h to remove impurity ions in the hydrogenation solution. The hydrogenated solution after impurity removal is slowly ...

Embodiment 2

[0055] Present embodiment 2 method comprises the following steps (see figure 1 ):

[0056] 1. Add defective lithium carbonate to water and stir wash once in the ratio of liquid-solid ratio 3.5:1, remove impurity ions wrapped in defective lithium carbonate (A), obtain lithium carbonate crude product; 2 CO 3 :H 2 The ratio of 0=1:28 lithium carbonate crude product is added in water and stirred, is configured into lithium carbonate slurry;

[0057] 2. Control the temperature of the lithium carbonate slurry at 25°C, and inject CO 2 Gas, keep the pressure in the hydrogenation tank at 0.4Mpa, hydrogenation reaction occurs with lithium carbonate, stop ventilation when the concentration of lithium oxide in the solution is 20g / L, and filter the solution to obtain hydrogenated liquid. Pass the hydrogenation solution through D401 ion exchange resin at 10BV / h to remove impurity ions in the hydrogenation solution. The hydrogenation solution after impurity removal is slowly heated (at ...

Embodiment 3

[0060] This embodiment includes the following steps (see figure 1 ):

[0061] 1, by the ratio of liquid-solid ratio 4: 1, the defective lithium carbonate is added to water and stirred and washed once, and the impurity ions wrapped in the defective lithium carbonate (A) are removed to obtain lithium carbonate crude product; 2 CO 3 :H 2 The ratio of 0=1:38 lithium carbonate crude product is added in water and stirred, is configured into lithium carbonate slurry;

[0062] 2. Control the temperature of the lithium carbonate slurry at 30°C, and inject CO 2 Gas, keep the pressure in the hydrogenation tank at 0.6Mpa, hydrogenation reaction occurs with lithium carbonate, stop ventilation when the concentration of lithium oxide in the solution is 28g / L, and filter the solution to obtain hydrogenated liquid. Pass the hydrogenation solution through D751 ion exchange resin at 15BV / h to remove impurity ions in the hydrogenation solution. The hydrogenation solution after impurity remov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com