Patents

Literature

80 results about "Lithium carbonate preparation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

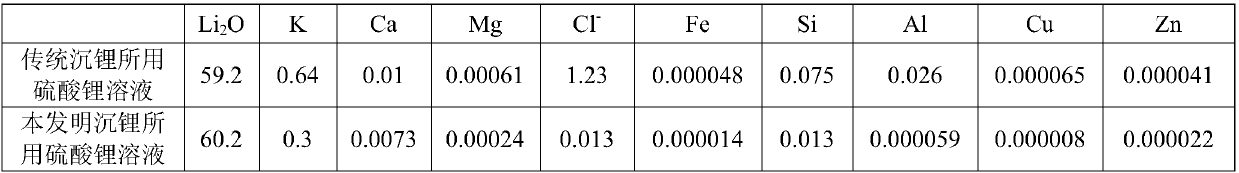

Method for producing high-purity lithium carbonate by using lithium concentrate

ActiveCN103318925AReduce consumptionGuaranteed RecoveryLithium compoundsLithium sulphatePhysical chemistry

The invention relates to a method for producing high-purity lithium carbonate by using lithium concentrate. The method is characterized by comprising the following steps of: preparing an acid clinker, preparing a mixing size, preparing a lithium sulfate leaching solution, preparing a lithium sulfate purification liquid, preparing a lithium sulfate finishing solution, preparing a sodium carbonate solution, performing primary lithium deposition reaction, preparing a sodium separating mother liquor, preparing excellent lithium carbonate in a sweating manner, and preparing 99.99% of high-purity lithium carbonate. By adopting the method, the principle of removing calcium and magnesium ions is ingeniously utilized in preparation of common lithium carbonate; a fussy procedure of removing calcium and magnesium by ion exchange resin is avoided when the common lithium carbonate is purified to prepare the high-purity lithium carbonate; a method of recycling after separating out sodium sulfate in a freezing manner is adopted to process the primary lithium settling mother liquor; the high-purity lithium carbonate mother liquor in precipitation of the high-purity lithium carbonate is used as an optimal lithium carbonate washing liquor for primary lithium sedimentation after being recycled for a plurality of times. Thus, the method has the characteristics of simple process, high production efficiency, high recovery rate and low production cost.

Owner:JIANGSU RONGHUI GENERAL LITHIUM IND CO LTD

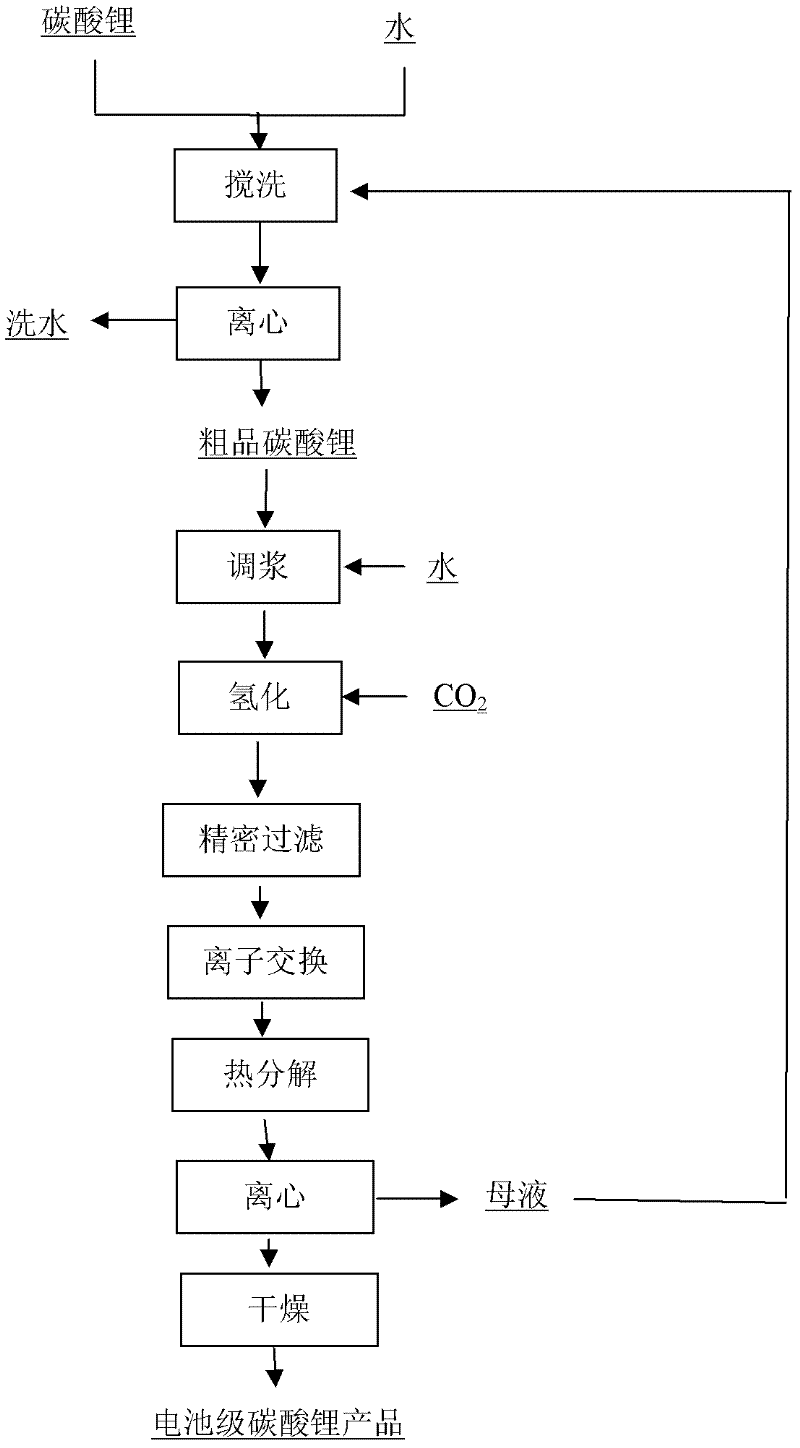

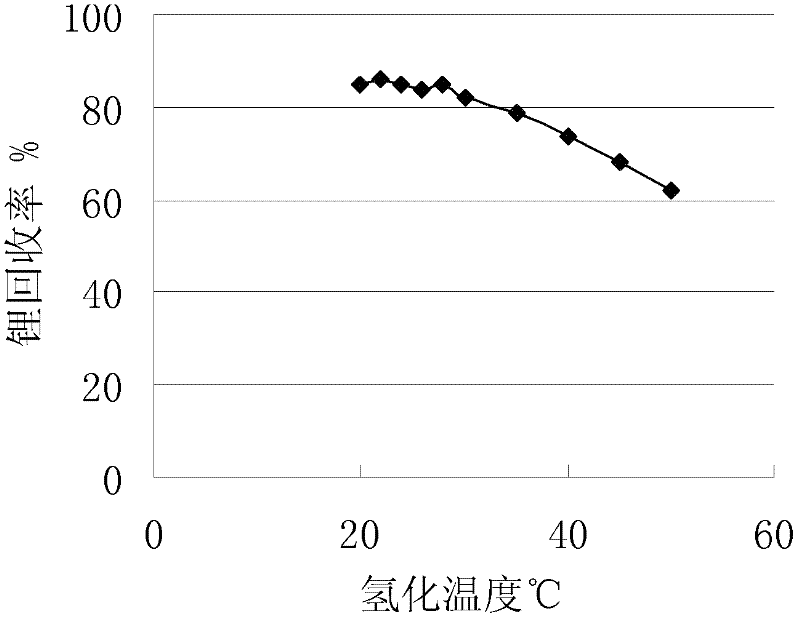

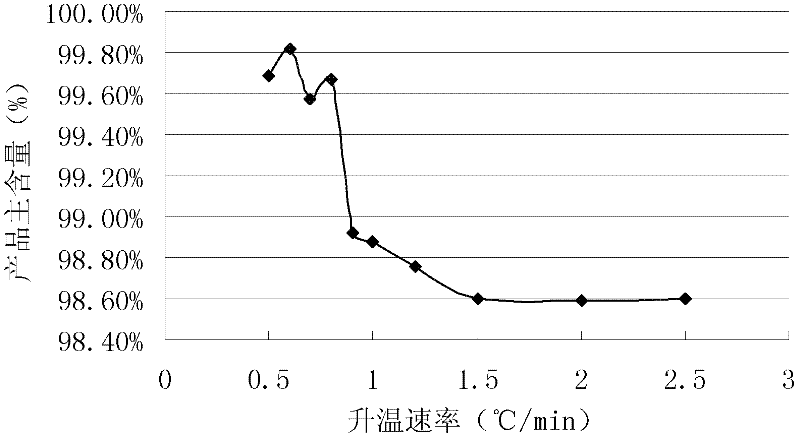

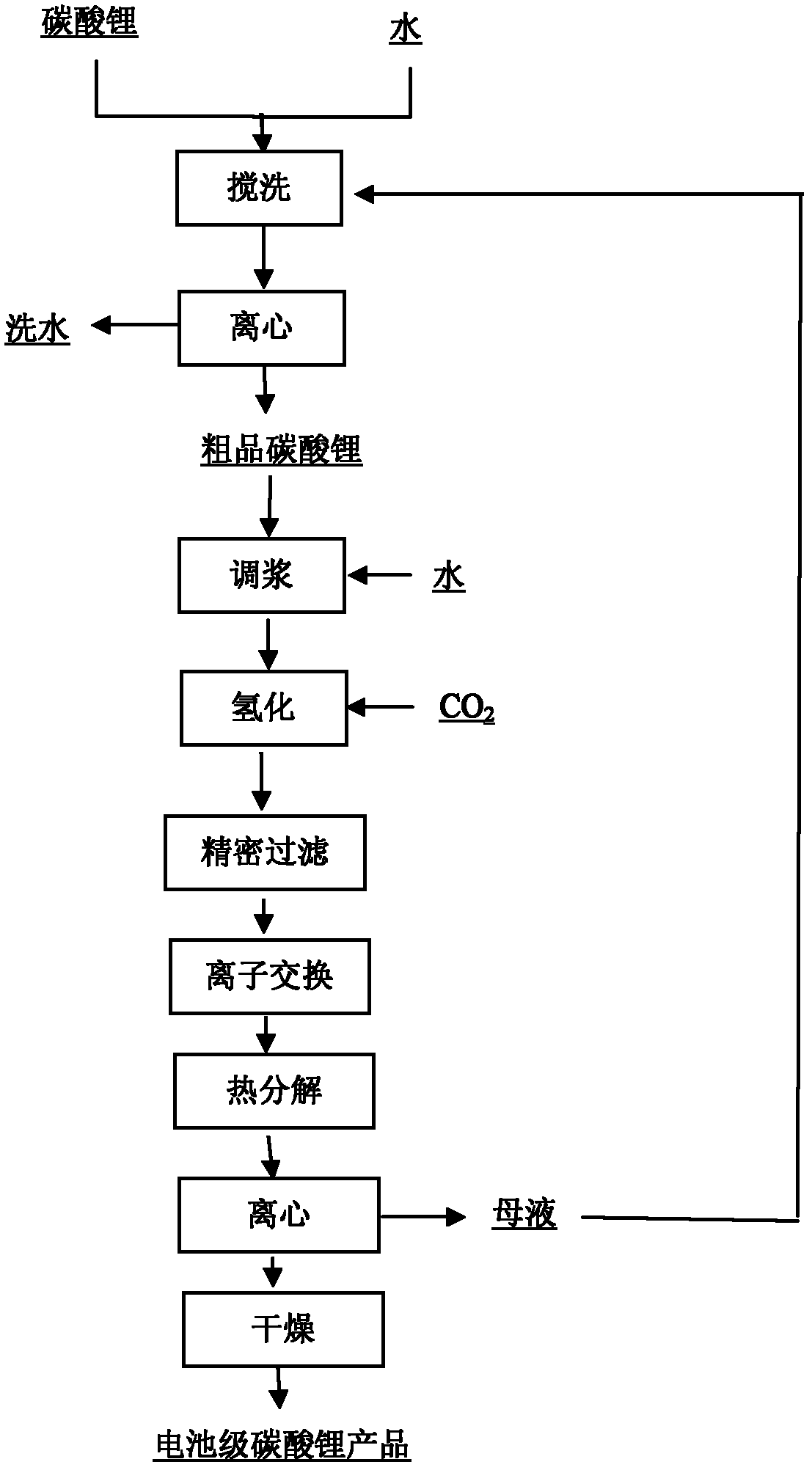

Method for purifying lithium carbonate

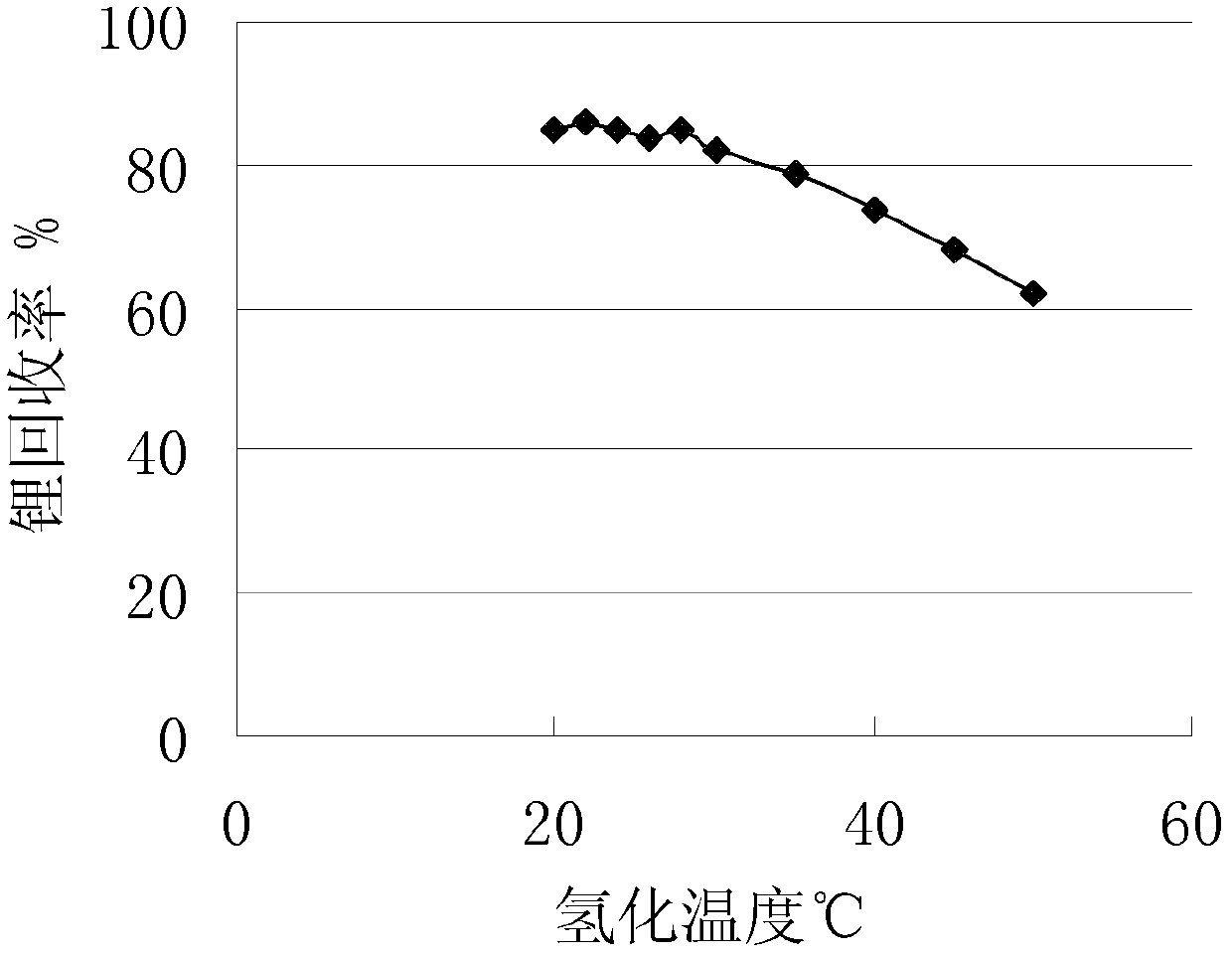

ActiveCN102531002ALow impurity contentImprove qualityLithium carbonates/bicarbonatesLithium oxideHydrogenation reaction

The invention relates to a method for purifying lithium carbonate, belonging to the technical field of the preparation of high-purity lithium carbonate. The method is characterized by safe production process and high lithium yield. The method comprises the following specific steps: (1) washing lithium carbonate to be purified to remove impurities, and adding water to prepare lithium carbonate slurry; (2) introducing CO2 into the lithium carbonate slurry prepared in the step (1) to carry out hydrogenation reaction, stopping introducing CO2 when the concentration of lithium oxide concentration in a solution is 10-30g / L, and filtering the solution to obtain a hydrogenated solution, wherein the hydrogenation reaction is carried out at the pressure of 0.2-0.6Mpa and the temperature of 20-30 DEG C; (3) subjecting the hydrogenated solution obtained in the step (2) to an ion exchange resin to remove impurity ions in the hydrogenated solution; and (4) heating the hydrogenated solution in which the impurity ions are removed in the step (3) to 70-90 DEG C to carry out decomposition reaction, separating solid from liquid to obtain the wet lithium carbonate, and drying the wet lithium carbonate. The produced battery-level lithium carbonate has high main content, excellent quality and stable performance.

Owner:天齐锂业(射洪)有限公司

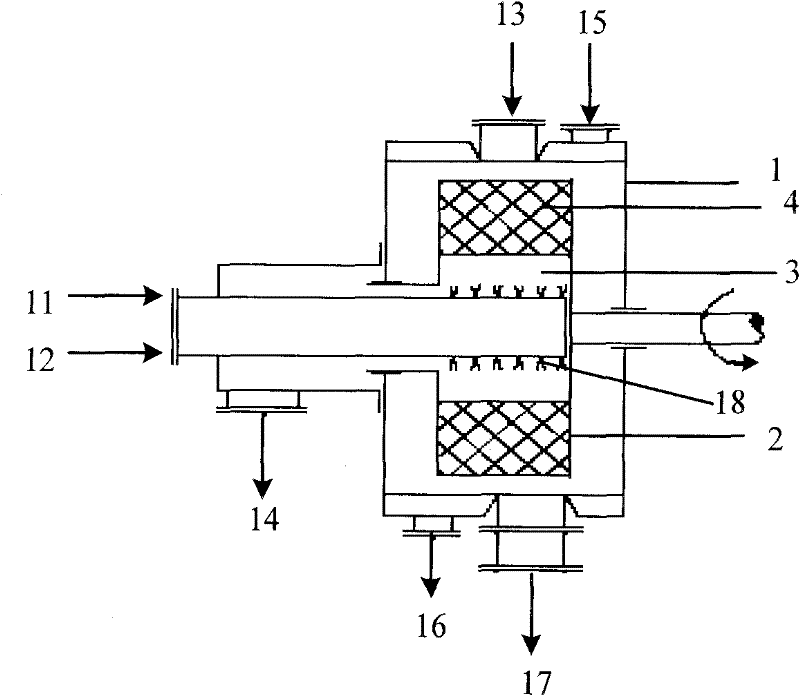

Method for preparing nano lithium carbonate

ActiveCN102180488AReduce volumeReduce energy consumptionNanostructure manufactureLithium carbonates/bicarbonatesHazardous substanceLithium hydroxide

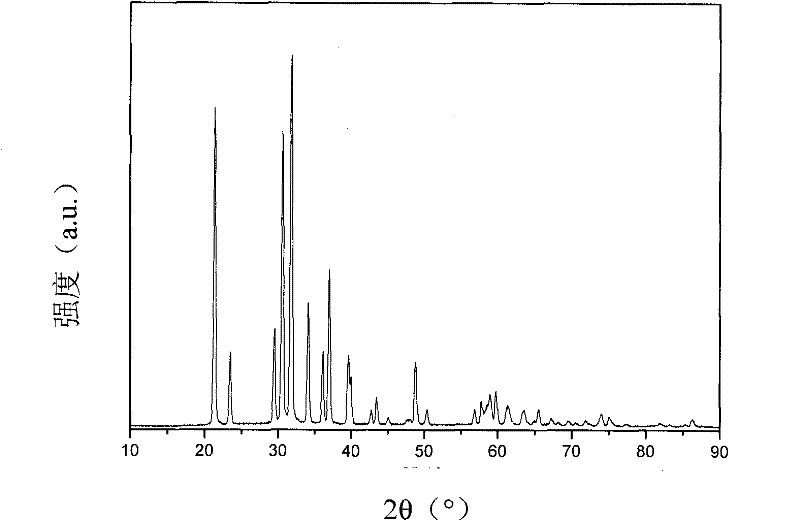

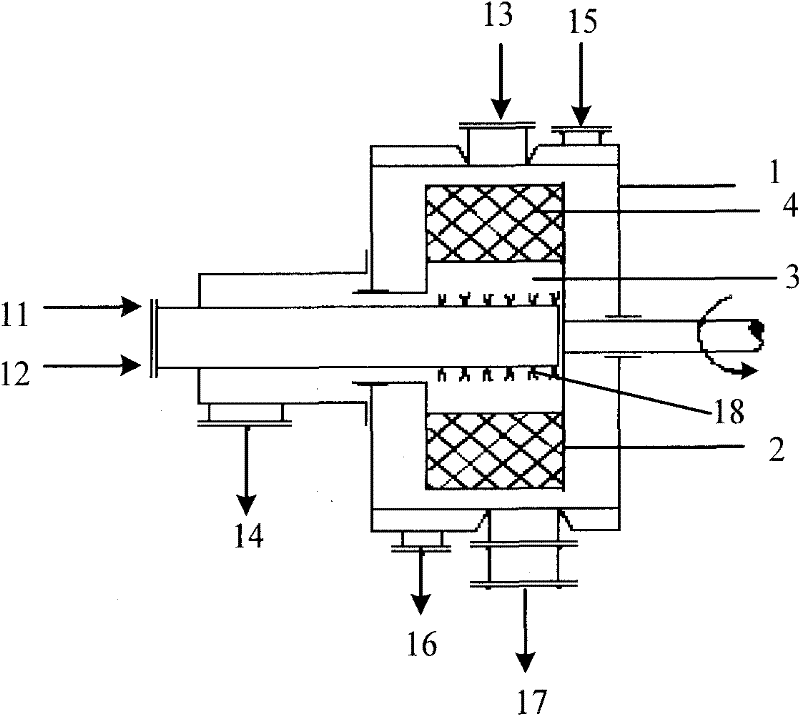

The invention discloses a method for preparing nano lithium carbonate in the technical field of nano lithium carbonate preparation. The method comprises the following steps: preparing water-soluble lithium salt or lithium hydroxide, water and a water-soluble dispersing agent into a mixed solution; then spraying and dispersing the mixed solution to porous aggregate in the annular filling area of arotary filling bed, simultaneously introducing CO2 or a water-soluble carbonate solution, and rapidly and completely mixing under the action of centrifugal force; discharging nano lithium carbonate particles generated by reaction crystallization out of the discharge hole of the rotary filling bed along with the mixed solution; and filtering, washing and drying so as to obtain nano lithium carbonate powder. In the method, a rotary filling bed reactor is used and has the advantages of simple equipment, small volume and small energy consumption, and reaction is carried out at normal pressure, thus the preparation cost is low. The method has the characteristics that the process is simple, the operation is convenient, the production efficiency is high, side reactions and toxic and harmful substances are not generated in the reaction process, and the method is environmental-friendly. The prepared nano lithium carbonate has the advantages of stable components, uniform particle size and narrow particle size distribution range.

Owner:TSINGHUA UNIV

Method for preparing high-purity lithium carbonate with co-production of lithium fluoride by employing crude lithium carbonate

ActiveCN104326495ASolve the single preparation raw materialSolve the costProductsReagentsLithium hydroxideCarbonization

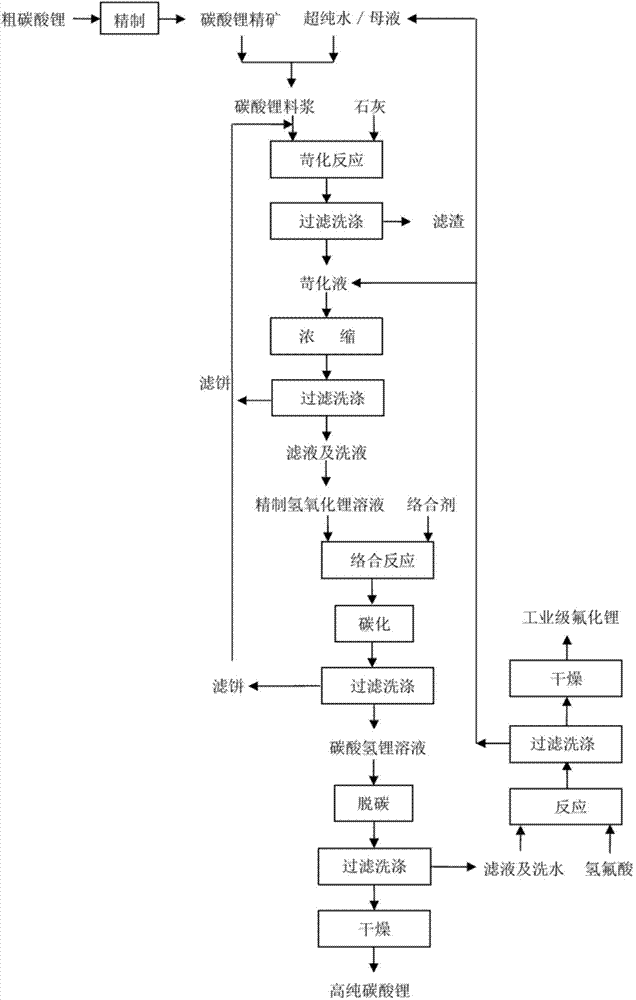

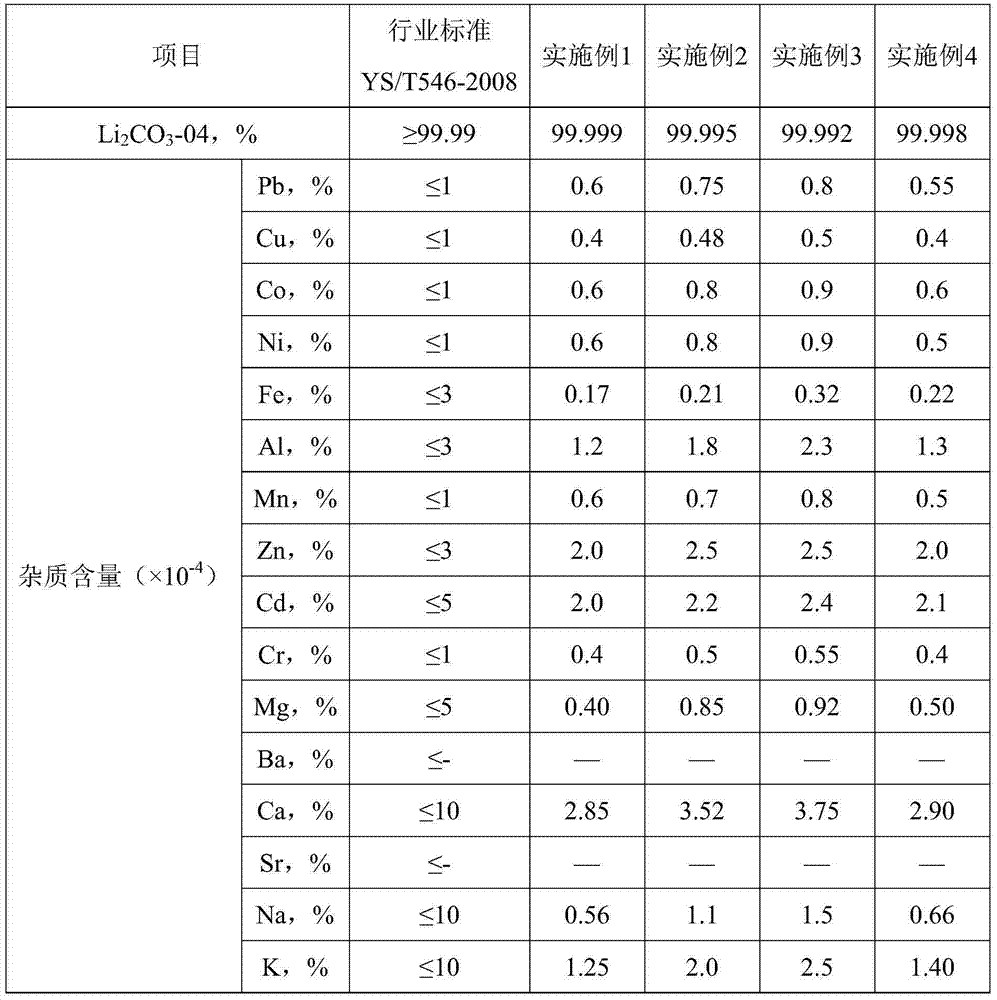

The invention discloses a method for preparing high-purity lithium carbonate with co-production of lithium fluoride by employing crude lithium carbonate. The method includes following steps: (1) preparing the crude lithium carbonate into lithium carbonate concentrate; (2) preparing the lithium carbonate concentrate into a slurry material with addition of lime and performing filtration to obtain a crude lithium hydroxide solution; (3) concentrating and filtering the crude lithium hydroxide solution, adding a complexing agent to remove impurity metal ions to obtain a refined lithium hydroxide solution; (4) feeding CO2 into the refined lithium hydroxide solution for carbonization and performing filtration to obtain a lithium bicarbonate solution; and (5) heating the lithium bicarbonate solution, performing a filtering and washing process, drying a filter cake to obtain the high-purity lithium carbonate, mixing the filtrate and a washing liquid with addition of hydrofluoric acid, performing a filtering and washing process, and then drying the filter cake to obtain the lithium fluoride. By means of the method, impurity ions in the high-purity lithium carbonate is in the trace-amount grade. The quality of the high-purity lithium carbonate is better in an industrial requirement in YS / T546-2008. Problems of poor quality, low lithium yield and high production cost in preparation of the high-purity lithium carbonate from salt lake lithium are solved.

Owner:河南省氟基新材料科技有限公司

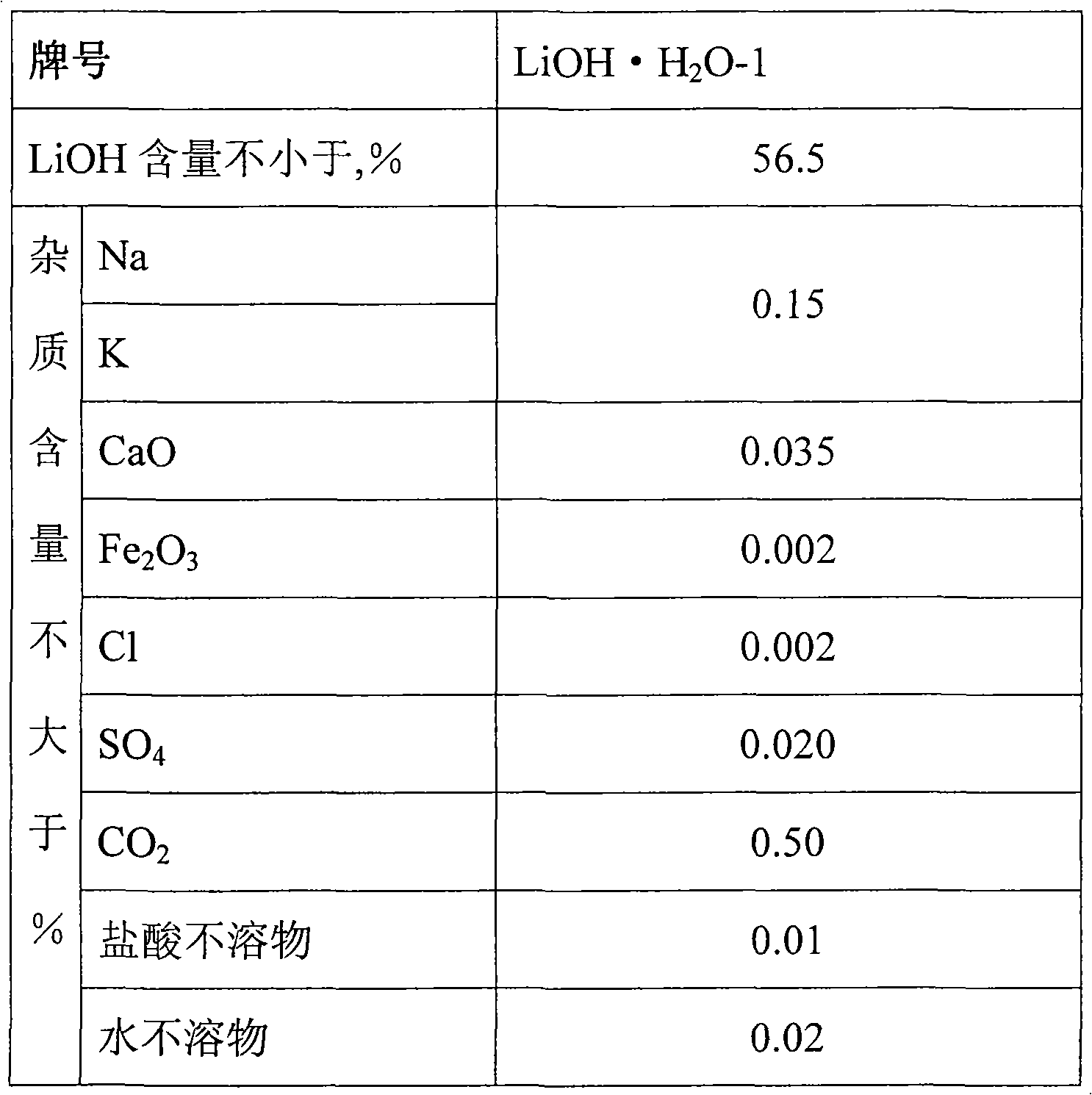

Preparation method of high-purity lithium carbonate

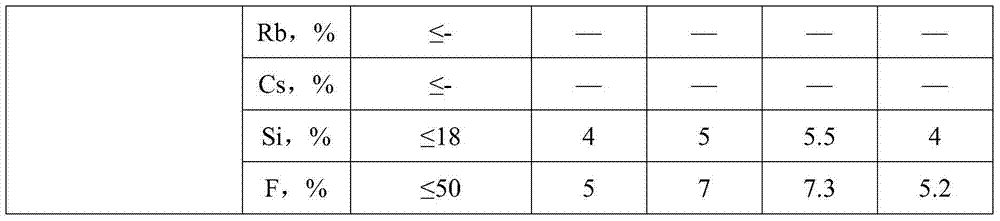

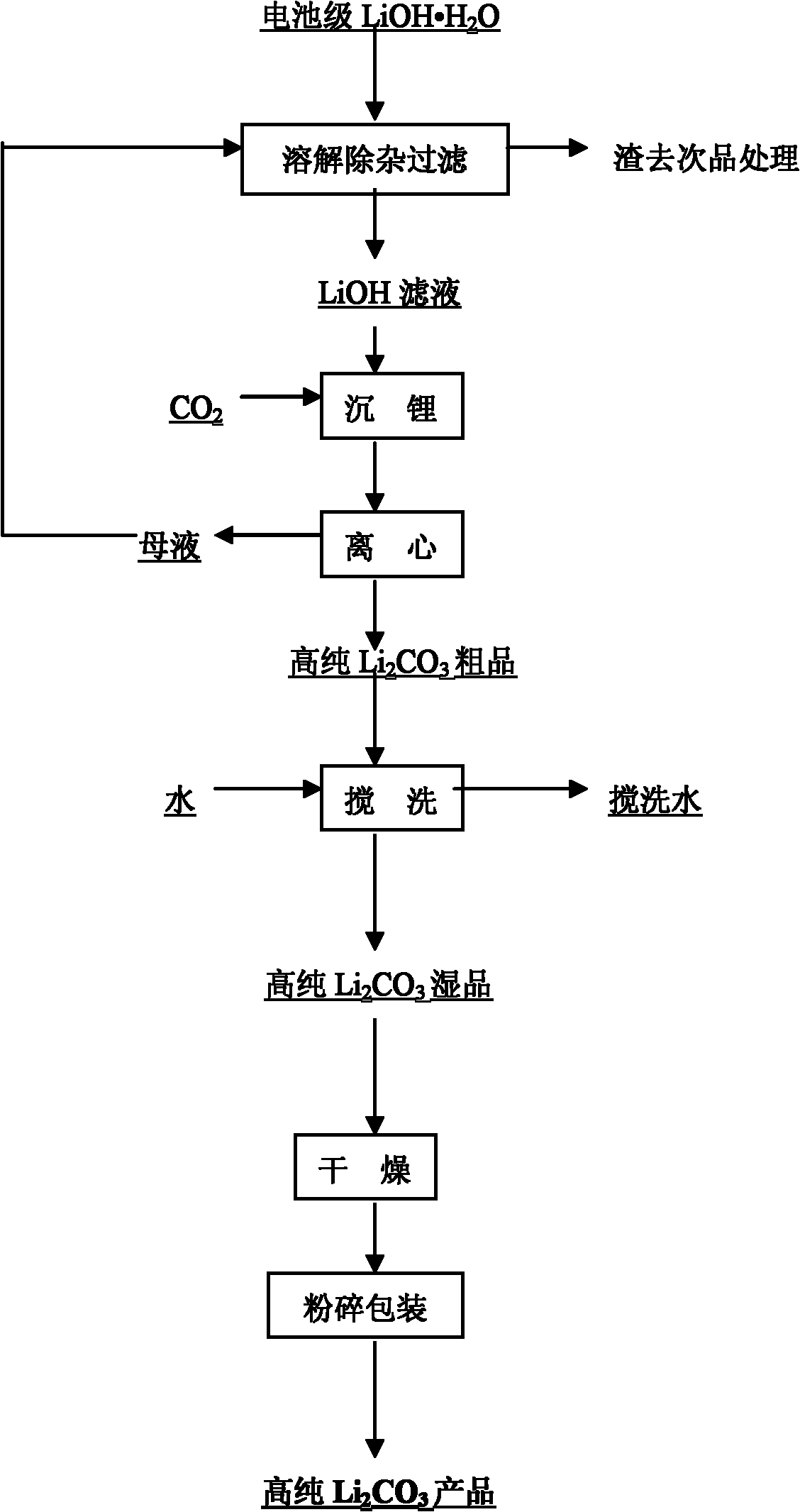

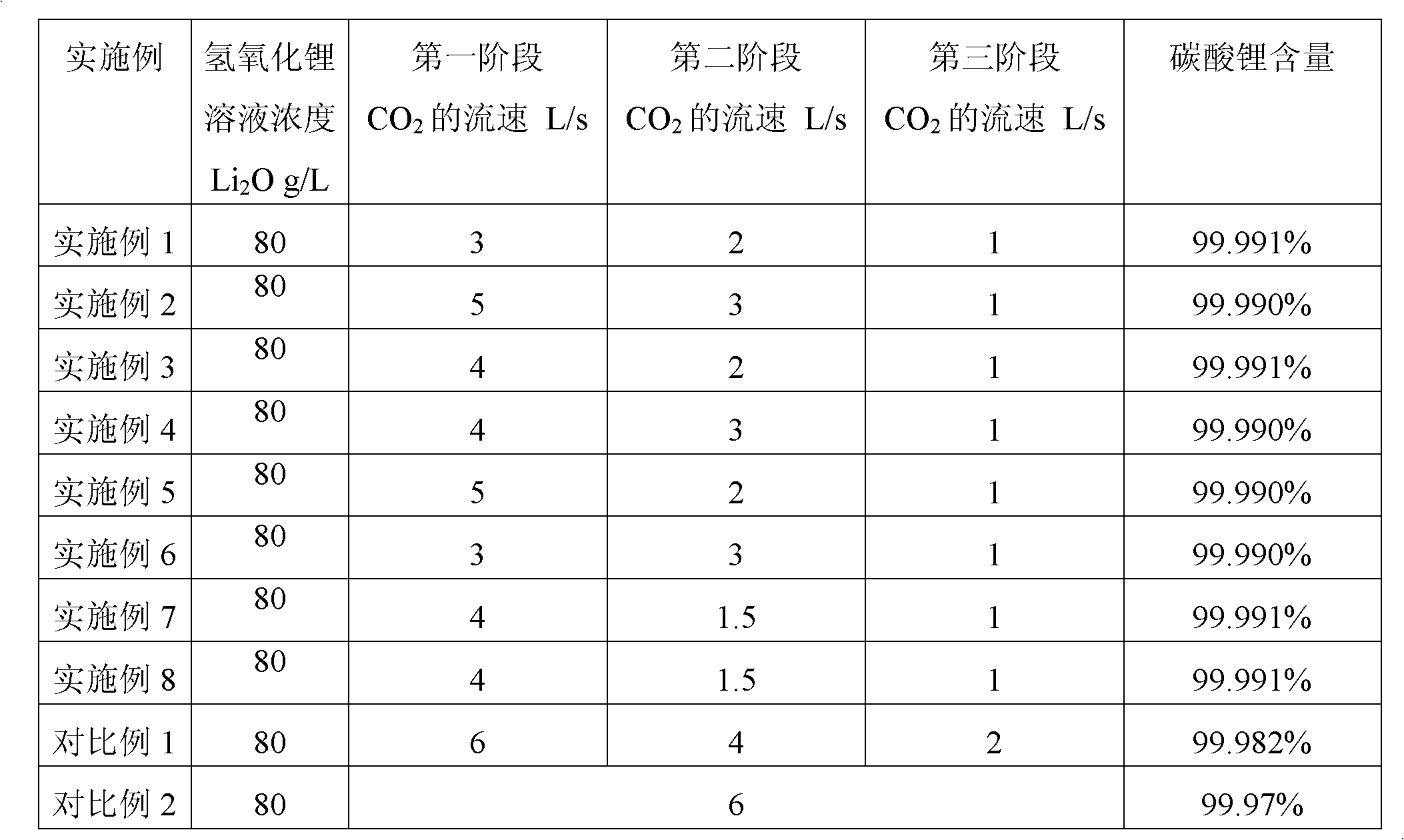

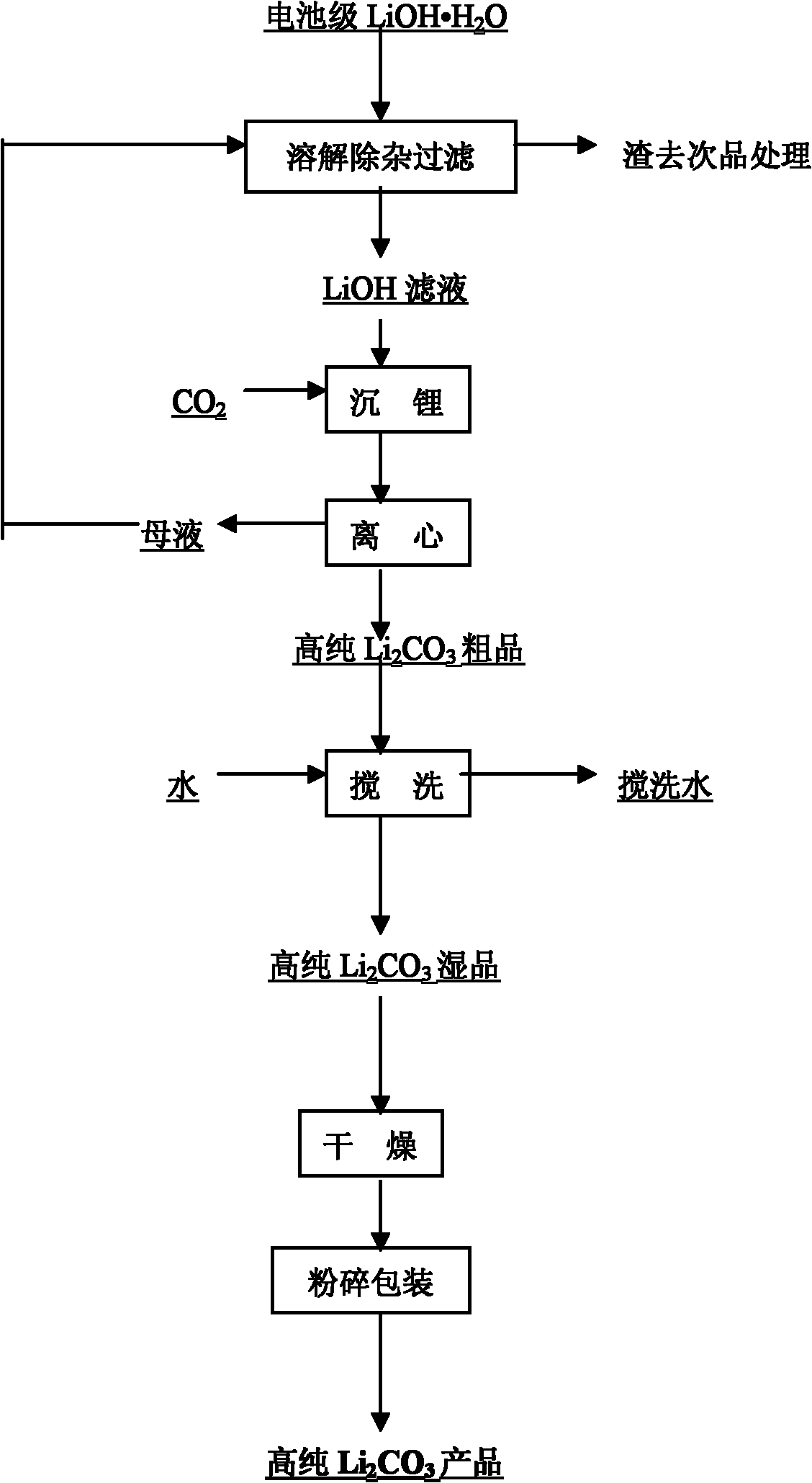

The invention relates to a preparation method of high-purity lithium carbonate, which belongs to the technical field of preparation of high-purity lithium carbonate. The invention aims at providing the method for directly preparing 99.99% lithium hydroxide by adopting lithium hydroxide, which is simple in production process. The technical scheme of the invention is as follows: preparing battery level lithium hydroxide monohydrate into solution of Li2O with concentration of 50-90g / L; introducing CO2 gas at the flow rate of 3-5L / s into the lithium hydroxide solution, wherein the flow rate of CO2 is decreased to 2-3L / s when the concentration of Li2O in the solution is decreased to 40g / L; decreasing the flow rate of CO2 to 0.8-1.2L / s when the concentration of Li2O in the solution is decreased to 20g / L; stop introducing the gas when a large number of liquids appear in the solution, and preparing lithium carbonate slurry; and separating the lithium carbonate slurry, washing the solids, drying until moisture is less than 0.1%, finally preparing the lithium carbonate. The battery level lithium hydroxide monohydrate is adopted as raw material, the high-purity lithium carbonate with the purity of 99.99% can be simply and conveniently prepared by adopting the method, and further purification is not required.

Owner:天齐锂业(江苏)有限公司 +2

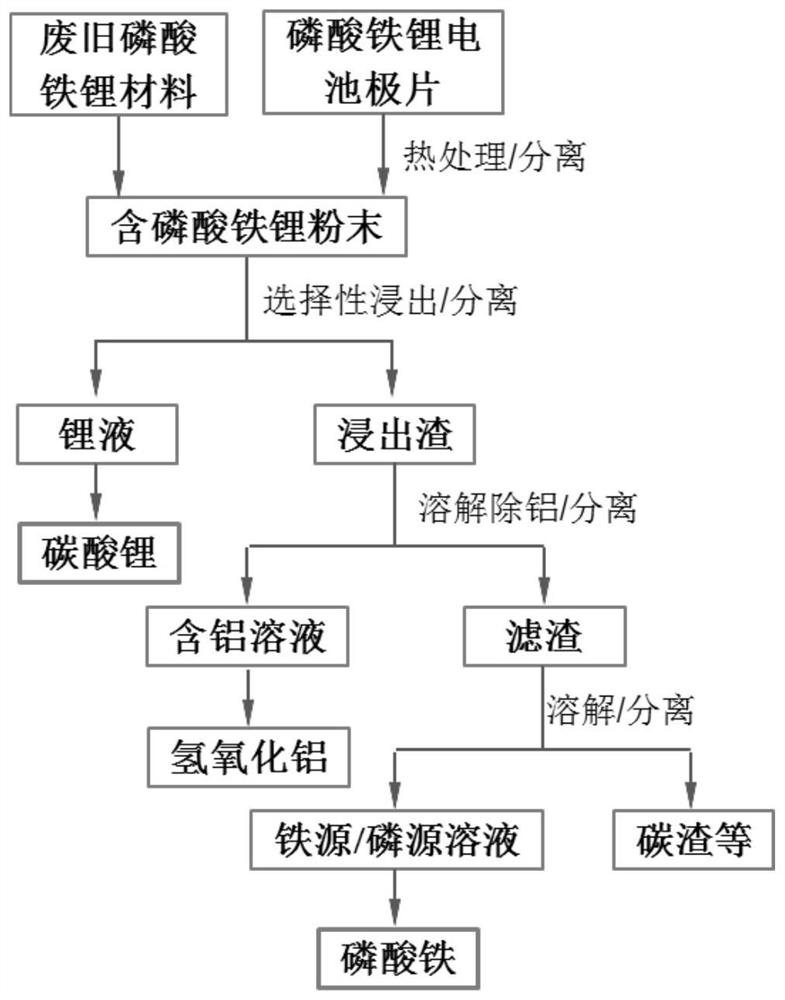

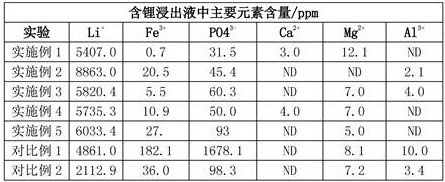

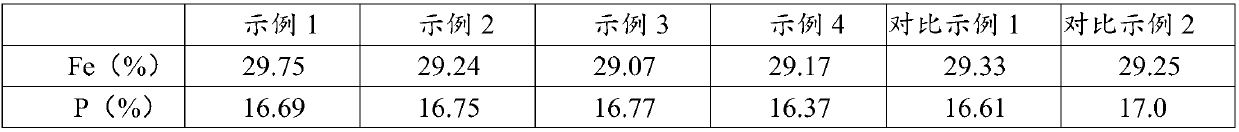

Recovery method of waste lithium iron phosphate positive electrode material

ActiveCN112441572AImprove leaching rateRealize full recyclingAluminium oxide/hydroxide preparationWaste accumulators reclaimingPregnant leach solutionO-Phosphoric Acid

The invention provides a recovery method of a waste lithium iron phosphate positive electrode material. The method comprises the following steps: S1, adding waste lithium iron phosphate powder to a leaching agent A, slowly adding a leaching agent B, adjusting the pH value to be more than or equal to 2, and carrying out solid-liquid separation to obtain a lithium-containing leaching agent and a leaching residue; S2, adding a precipitator into the lithium-containing leachate to obtain lithium carbonate; S3, adding a first alkaline solution into the leaching residues, and filtering to obtain an aluminum-containing solution and filter residues; S4, adjusting the pH value of the aluminum-containing solution to obtain an aluminum hydroxide precipitate; S5, adding the filter residue into a firstacidic solution, performing filtering, adding a second alkaline solution into the obtained filtrate, adjusting the pH value to 2.0-2.7 to obtain basic iron phosphate, and adding phosphoric acid to obtain iron phosphate. The leaching agent A comprises a mixed solution of at least one of a weak base solution or a weak acid solution and a first oxidizing agent; and the leaching agent B comprises a mixed solution of a second acidic solution and a second oxidant. By the adoption of the method, the leaching rate of lithium is high, impurities are few, the purification and wastewater treatment cost during lithium carbonate preparation is reduced, and meanwhile iron phosphate can be efficiently recycled.

Owner:BYD CO LTD +1

Method for preparing lithium carbonate through salt lake brine with high ratio of magnesium to lithium

ActiveCN105152191ALow costAddress process complexityLithium carbonates/bicarbonatesSalt lakeHydrotalcite

The invention relates to the field of salt lake resource comprehensive utilization, in particular to a method for preparing lithium carbonate through salt lake brine with the high ratio of magnesium to lithium. The salt lake brine with the high ratio of magnesium to lithium serves as a raw material, a certain amount of soluble trivalent metal salt is added, the ratio of magnesium to lithium in the salt lake brine is reduced by synthesizing magnesium-based stratified functional materials, magnesium and lithium in the salt lake brine with the high ratio of magnesium to lithium are separated, and then lithium carbonate is prepared through hydrotalcite mother liquor with the low ratio of magnesium to lithium. The technical problems that an existing method is complex in process, cost is high, and the magnesium and lithium separation effect is not ideal can be effectively solved through magnesium and lithium separation and lithium carbonate preparation methods, the lithium carbonate preparation process is simplified, cost is reduced, waste magnesium resources are fully utilized, and meanwhile the cost of the magnesium-based functional materials is reduced; high-valued and comprehensive utilization of salt lake magnesium, lithium and boron resources is achieved, and good industrialization prospects are achieved.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

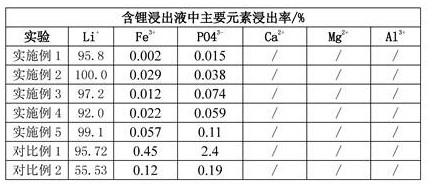

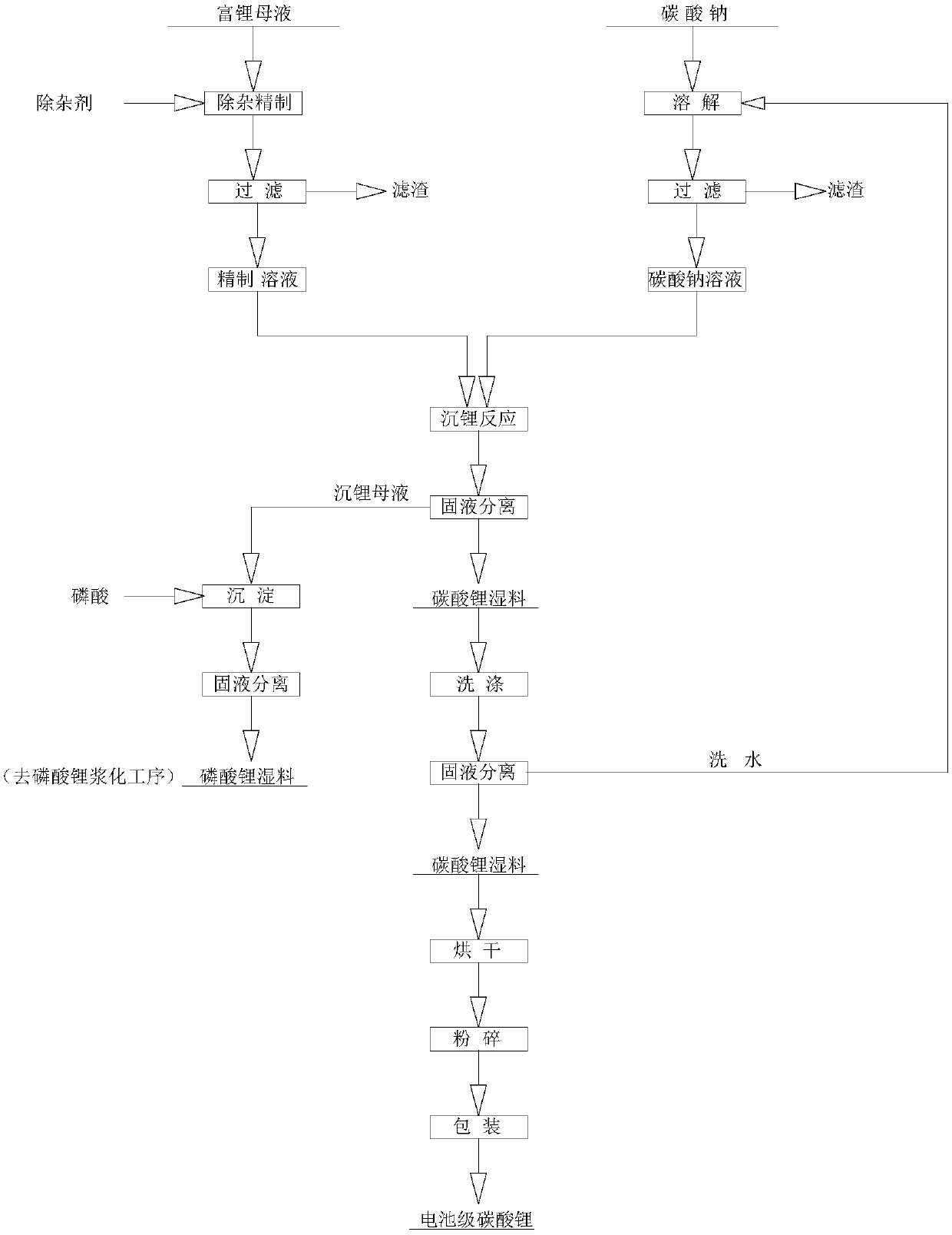

Process for recovering lithium phosphorous from lithium phosphate crude product to prepare battery-level lithium carbonate and iron phosphate

ActiveCN107720716AAchieve recyclingIncrease surface areaPhosphorus compoundsLithium carbonates/bicarbonatesWater basedPhosphoric acid

The invention provides a process for recovering lithium phosphorous from a lithium phosphate crude product to prepare battery-level lithium carbonate and iron phosphate, and belongs to the technical field of resource recycling. The process comprises: lithium phosphate slurrying: adding pure water or washing water to the lithium phosphate crude product to prepare slurry, and performing high-speed dispersion and grinding dispersion to obtain uniform lithium phosphate slurry; iron solution preparation: filtering an iron solution to obtain a refined iron solution; iron orthophosphate preparation:adding inorganic acid into a pure water base solution to regulate pH to 2-3, adding the lithium phosphate slurry and the refined iron solution after temperature rise, performing solid-liquid separation after reaction is completed, initially washing a solid by the pure water, re-washing the solid by slurry mixing, and drying and crushing the solid, so as to obtain iron orthophosphate; battery-levellithium carbonate preparation: purifying a lithium-containing mother solution obtained by preparing the iron orthophosphate, and inputting into a mixed solution of sodium carbonate and EDTA to perform lithium deposition reaction, and performing separation, washing, drying and crushing to obtain lithium carbonate. The lithium phosphate crude product is treated by means of the process of the invention, so that iron orthophosphate and lithium carbonate products meeting quality requirements of a lithium battery can be obtained.

Owner:CHENGDU CHEMPHYS CHEM IND

Method for preparing low-magnetism high-purity lithium carbonate by using saline lithium salt

ActiveCN104386715ASimple processEmission reductionLithium carbonates/bicarbonatesImpurityCrystallization

The invention belongs to the technical field of lithium carbonate preparation, and discloses a method for preparing low-magnetism high-purity lithium carbonate by using saline lithium salt. The method using the saline lithium salt as a raw material mainly comprises the following steps: pulping the saline lithium salt, carrying out countercurrent washing, hydrogenating carbonic acid, removing magnetic substances, carrying out resin purification to remove impurities, carrying out evaporative crystallization, refining, calcining, and crushing to prepare the low-magnetism high-purity lithium carbonate product. The purity of the lithium carbonate product prepared through the method is 99.95-99.98%, and the contents of magnetic Fe, magnetic Cr and magnetic Zn in the product are not greater than 0.081g / t, not greater than 0.002g / t and not greater than 0.002g / t respectively. The method has the advantages of simplicity, stable operation process, short production period and small device investment, the prepared lithium carbonate is highly pure, contains a small amount of magnetic substances, has a comprehensive recovery rate of lithium of 98.65%, has a low production cost, and is suitable for industrial production.

Owner:JINCHUAN GROUP LIMITED

Preparation method for lithium carbonate

The invention provides a preparation method for lithium carbonate. The method comprises the following steps of: (1) mixing lithium hydroxide serving as a raw material and water for dissolving, adding a precipitating agent, and collecting filtrate of the lithium hydroxide, wherein the lithium hydroxide serving as the raw material is in an industrial grade; (2) introducing carbon dioxide into water, adding lithium carbonate serving as a raw material, adding a precipitating agent, introducing carbon dioxide until the pH is between 8 and 9, and collecting filtrate of solution of lithium hydrogen carbonate, wherein the lithium carbonate serving as the raw material is in an industrial grade; (3) mixing the solution of the lithium hydrogen carbonate obtained in the step (2) and the solution of the lithium hydroxide obtained in the step (1), heating the solution, and preserving the heat; (4) separating solid from liquid of a product in the step (3), and collecting the separated lithium carbonate wet material; and (5) drying a product in the step (4) in vacuum to obtain a product. By the process, the defects of the conventional process are better overcome, the product prepared from two industrial-grade raw materials can meet the requirement on 99.9 percent or higher-grade index, and the total yield of the product is over 95 percent.

Owner:SHANGHAI CHINA LITHIUM INDAL

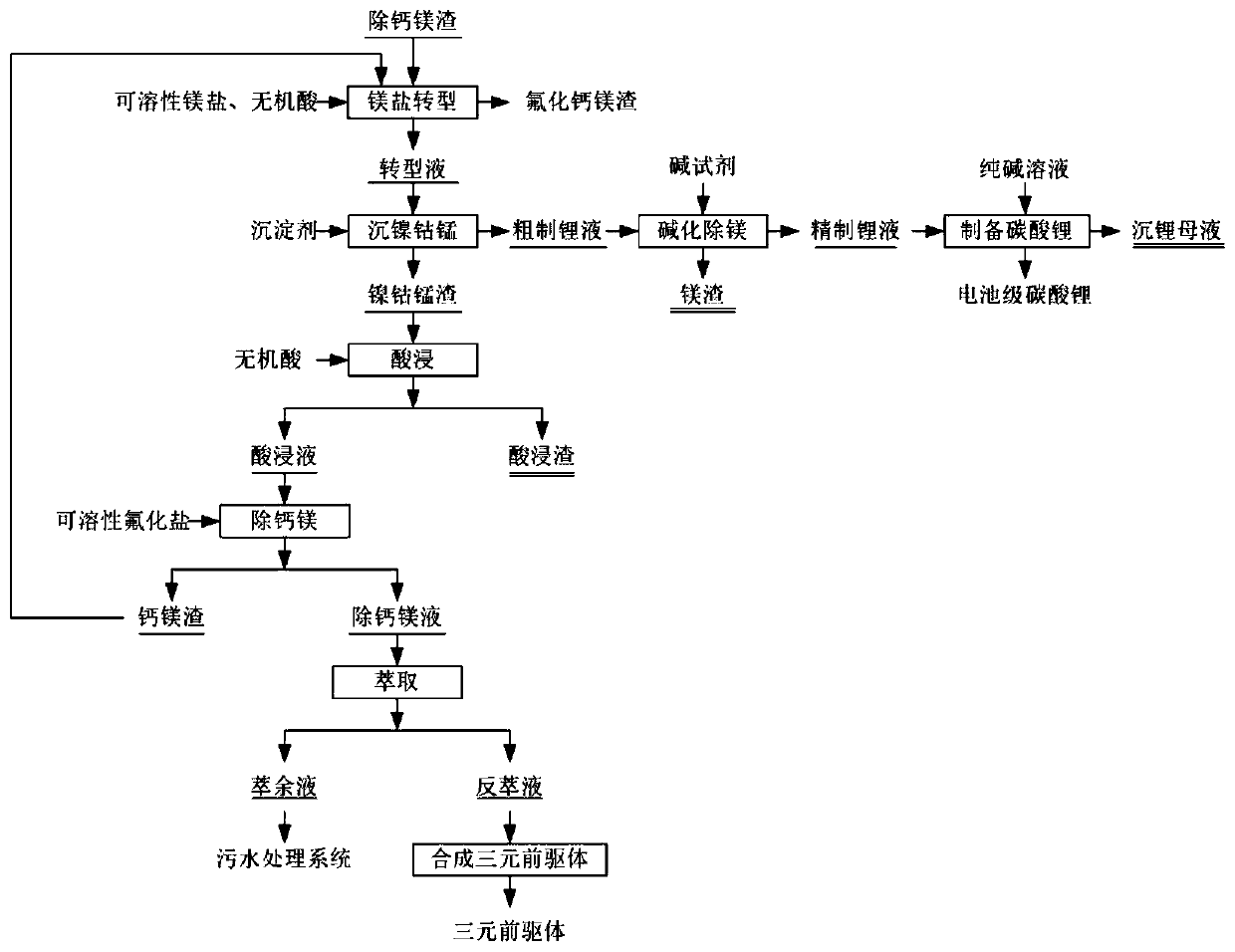

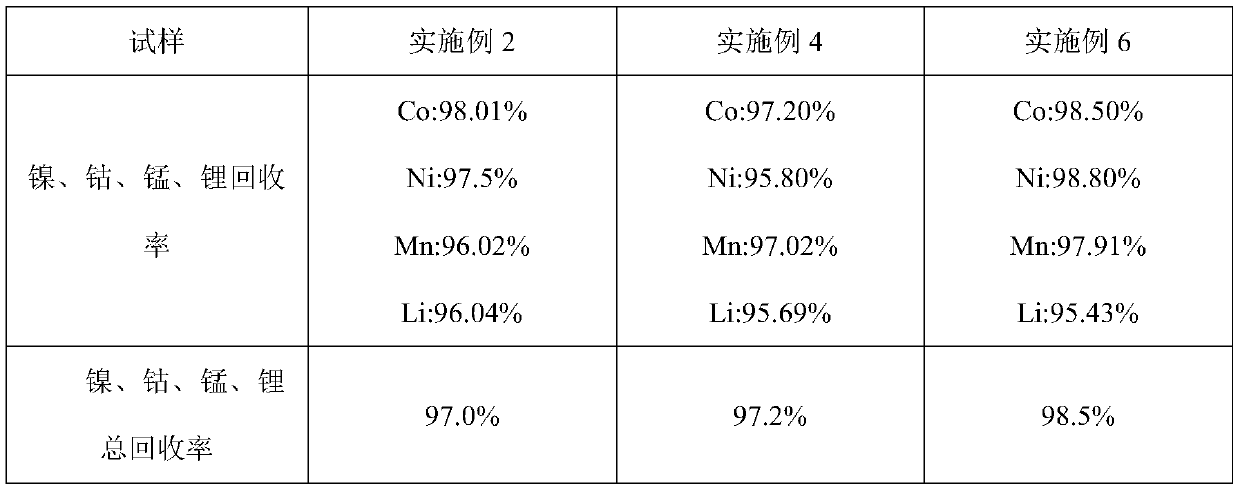

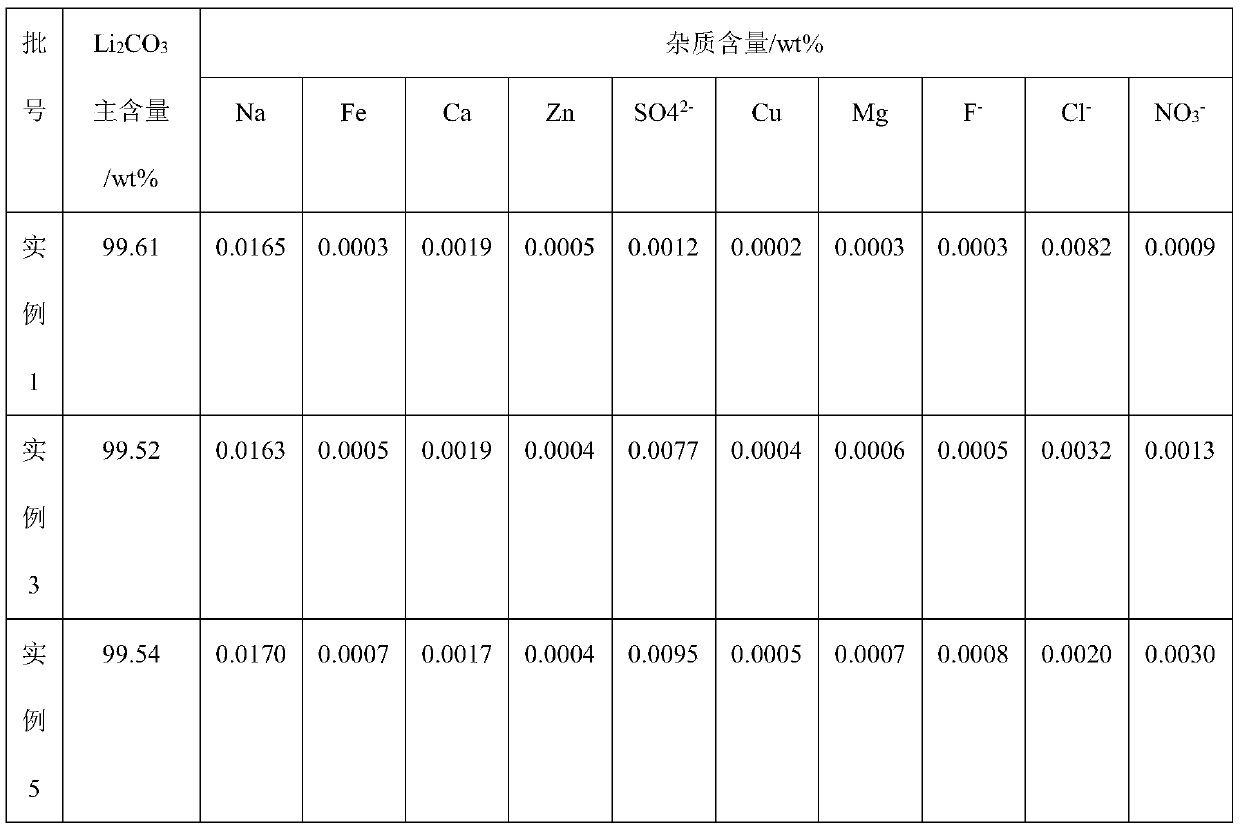

Method for removing calcium magnesium slag and recycling lithium and preparing ternary precursor material

ActiveCN109735709AImprove separation efficiencyHigh recovery rateWaste accumulators reclaimingProcess efficiency improvementMagnesium saltSlag

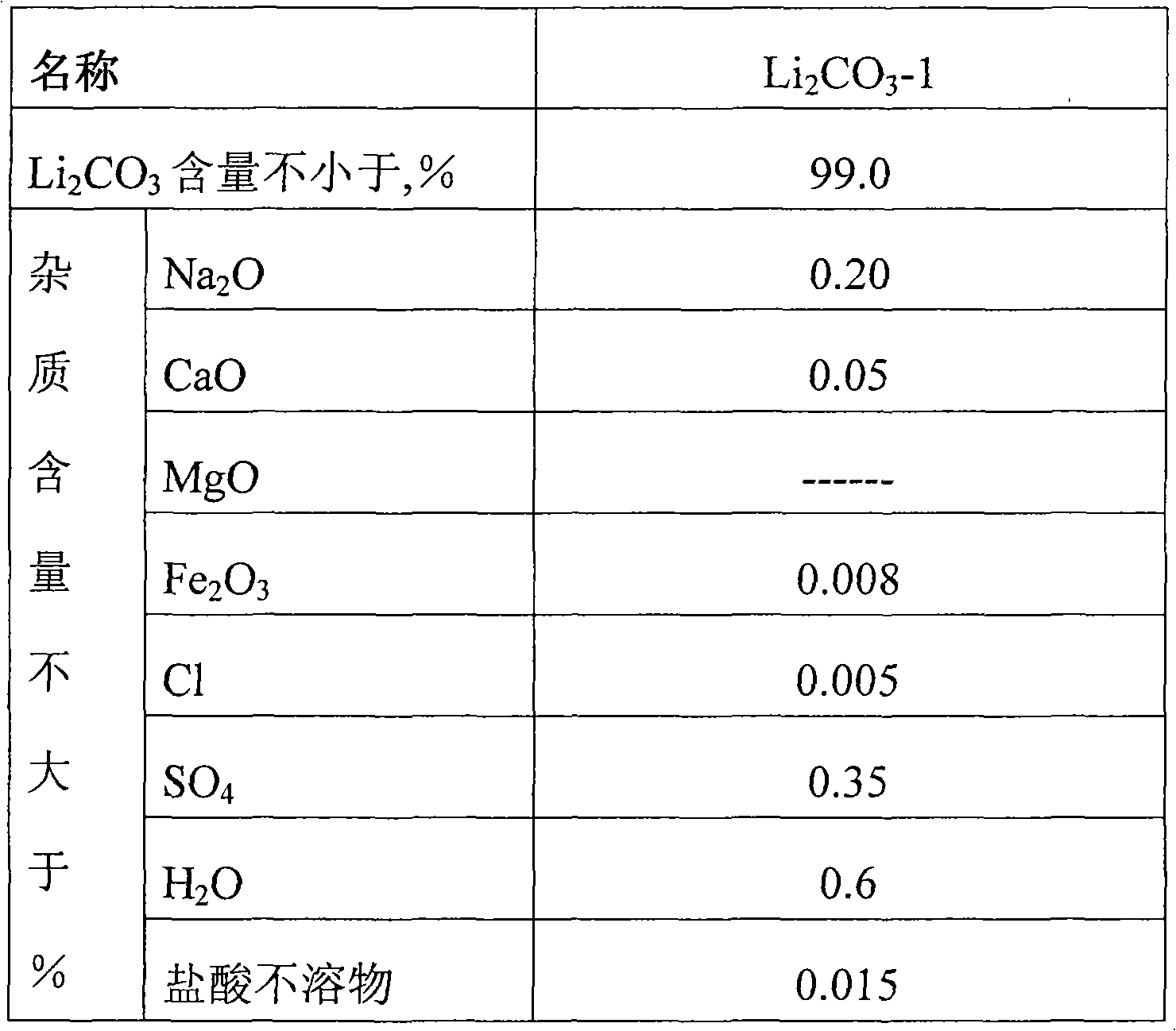

The invention discloses a method for removing calcium magnesium slag and recycling lithium and preparing a ternary precursor material, and belongs to the field of waste lithium ion battery wet recycling. The method comprises the following steps of (1) magnesium salt transformation, (2) cobalt, nickel and manganese precipitation, (3) alkalization and magnesium removal, (4) lithium carbonate preparation, (5) nickel, cobalt and manganese slag acid leaching, (6) calcium magnesium removal, (7) extraction, (8) precursor synthesis, and (9) ternary precursor material preparation by drying. The technology is simple, is low in energy cost and is safe and stable. Efficiency of separating the cobalt, the nickel and the manganese from lithium is high, and the comprehensive recycling rate of each valuable metal is high. The main content of prepared lithium carbonate is up to 99.61%, the battery level requirements can be met, the overall recycling rate of the nickel, the cobalt, the manganese and thelithium in the calcium magnesium slag is up to 98.5%, and the lithium recycling rate is up to 98.8%. The method is suitable for industrial production, and can achieve high economic benefits.

Owner:江西赣锋循环科技有限公司

Method for extracting lithium from brine to prepare battery-grade lithium carbonate by ion exchange method

ActiveCN106629789AHigh recovery rateLarge particle sizeHydrotalciteLithium carbonates/bicarbonatesDesorptionManganese

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Method of producing battery-grade lithium carbonate through sulfuric acid process

InactiveCN107915240AReduce concentrationReduce dosageLithium carbonates/bicarbonatesHigh concentrationIncreased calcium

The invention provides a method of producing battery-grade lithium carbonate through a sulfuric acid process and belongs to the technical field of battery-grade lithium carbonate preparation. The method includes: transform-roasting, acidify-roasting, leaching, purifying, lithium-setting, washing, drying, and smashing. A circulatory leaching mode is adopted, so that lithium concentration in leachate can be increased effectively, and high-concentration lithium-containing leachate can be produced directly; evaporation and concentration are not needed, and lithium setting can be directly performedafter purifying to produce lithium carbonate. The high-concentration lithium-containing leachate can be obtained through circulatory leaching, so that requirements of lithium setting on high-concentration lithium can be met without increasing calcium ion concentration in purified liquid, and product quality is improved effectively. By adopting the method, using of triple-effect high-temperature evaporation equipment can be avoided, so that energy conservation and consumption reduction are realized, equipment investment cost is lowered, technological processes are simplified, and battery-gradelithium carbonate produced by the method is stable and high in quality and environment-friendly.

Owner:TIANQI LITHIUM CORP

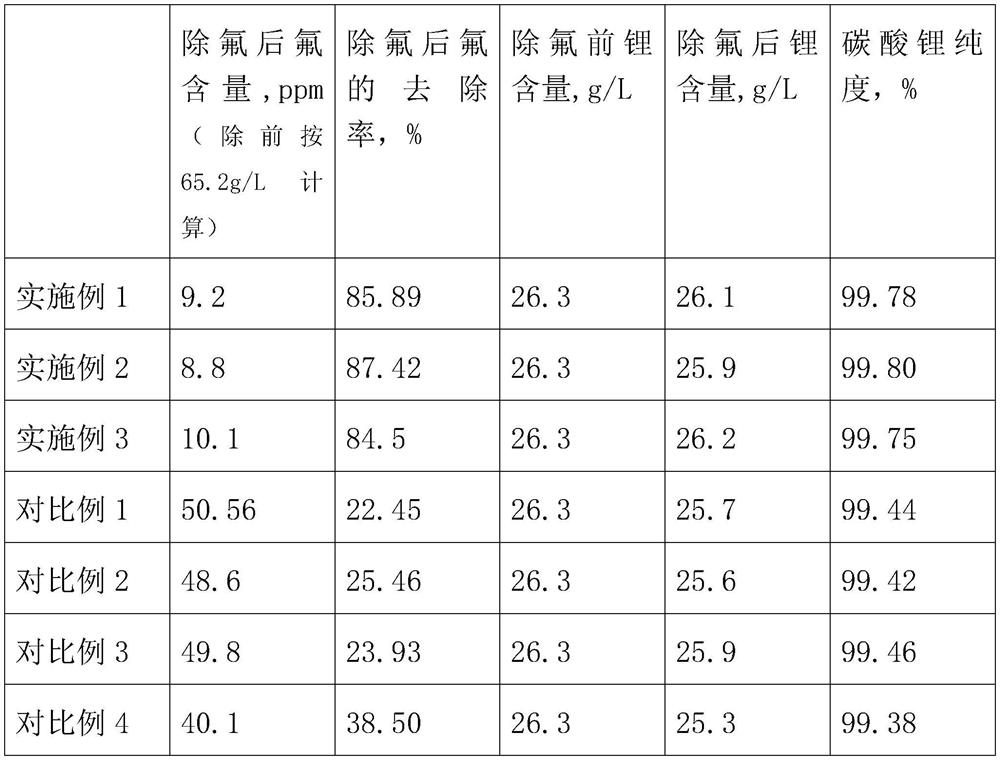

Method for preparing battery-grade lithium carbonate from lepidolite

ActiveCN112142081AHigh removal rateImprove qualityLithium carbonates/bicarbonatesPhysical chemistryIon exchange

The invention provides a method for preparing battery-grade lithium carbonate from lepidolite, and belongs to the field of battery-grade lithium carbonate preparation. The method specifically comprises the following steps: roasting and leaching lepidolite, adding a fluorine removal agent to remove fluorine, carrying out concentrating, removing calcium and magnesium by chelating ion exchange resinto obtain a refined lithium solution, adding the refined lithium solution into a refined sodium carbonate solution of which calcium and magnesium are removed by chelating ion exchange resin, carryingout reacting, and settling to obtain crude lithium carbonate and lithium settling mother liquor; concentrating and evaporating the lithium precipitation mother liquor, freezing and salting out, addingthe product into a refined lithium solution for recycling, washing crude lithium carbonate, precipitating, centrifugally separating, drying, carrying out jet milling, mixing and packaging to obtain the battery-grade lithium carbonate. According to the method, the leachate is subjected to fluorine removal treatment, calcium and magnesium removal and then added into the refined sodium carbonate solution for reaction, the lithium precipitation mother liquor is recycled for production after being treated, and the method disclosed by the invention is simple in process step and relatively low in cost, ensures the quality of the battery-grade lithium carbonate and can be used for continuous production.

Owner:JIANGXI YONGXING SPECIAL STEEL NEW ENERGY TECH CO LTD

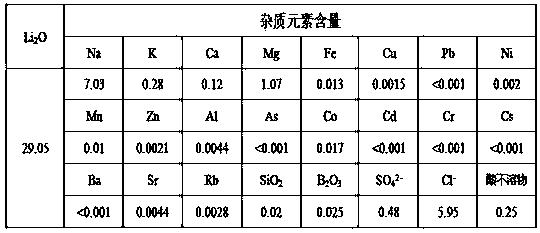

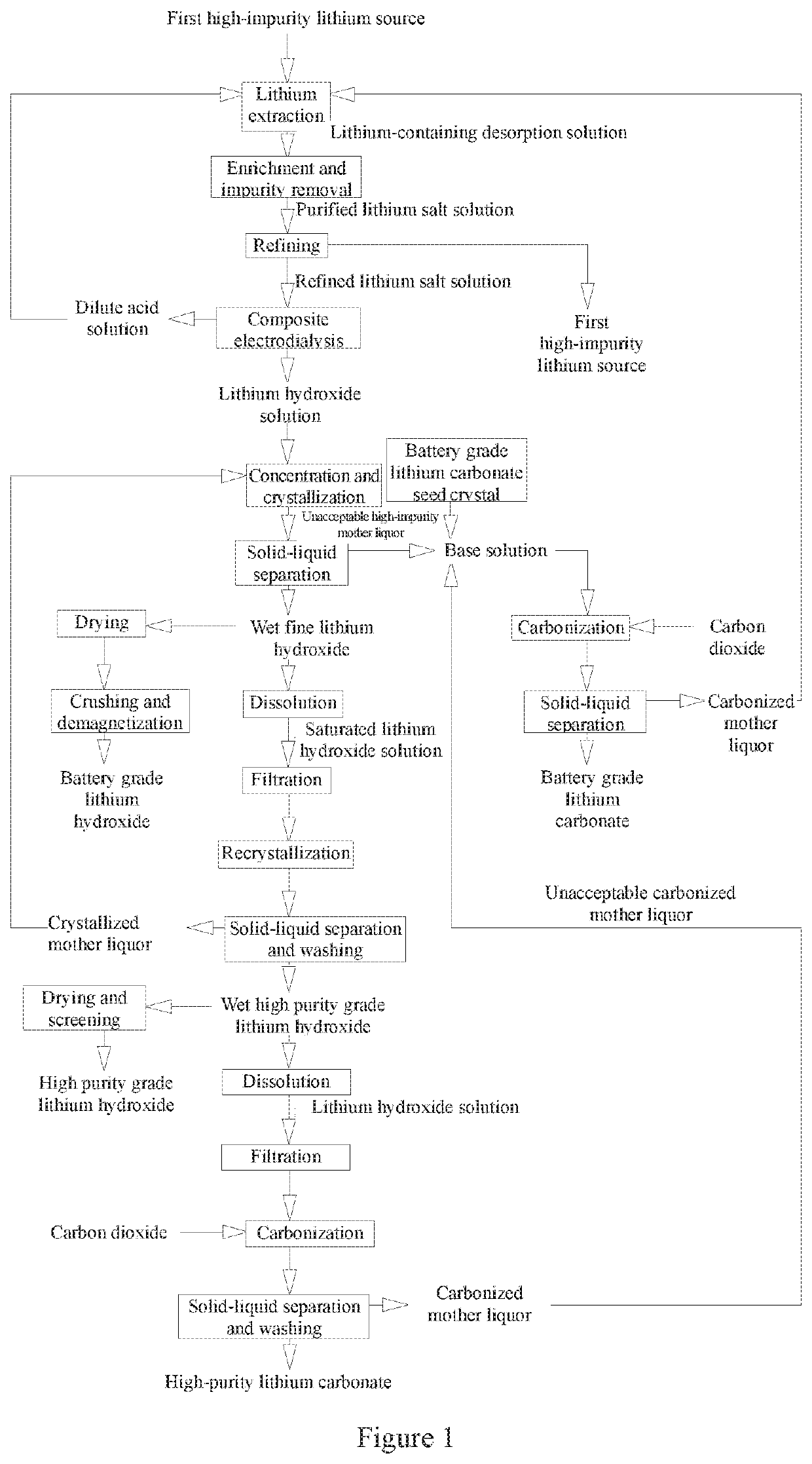

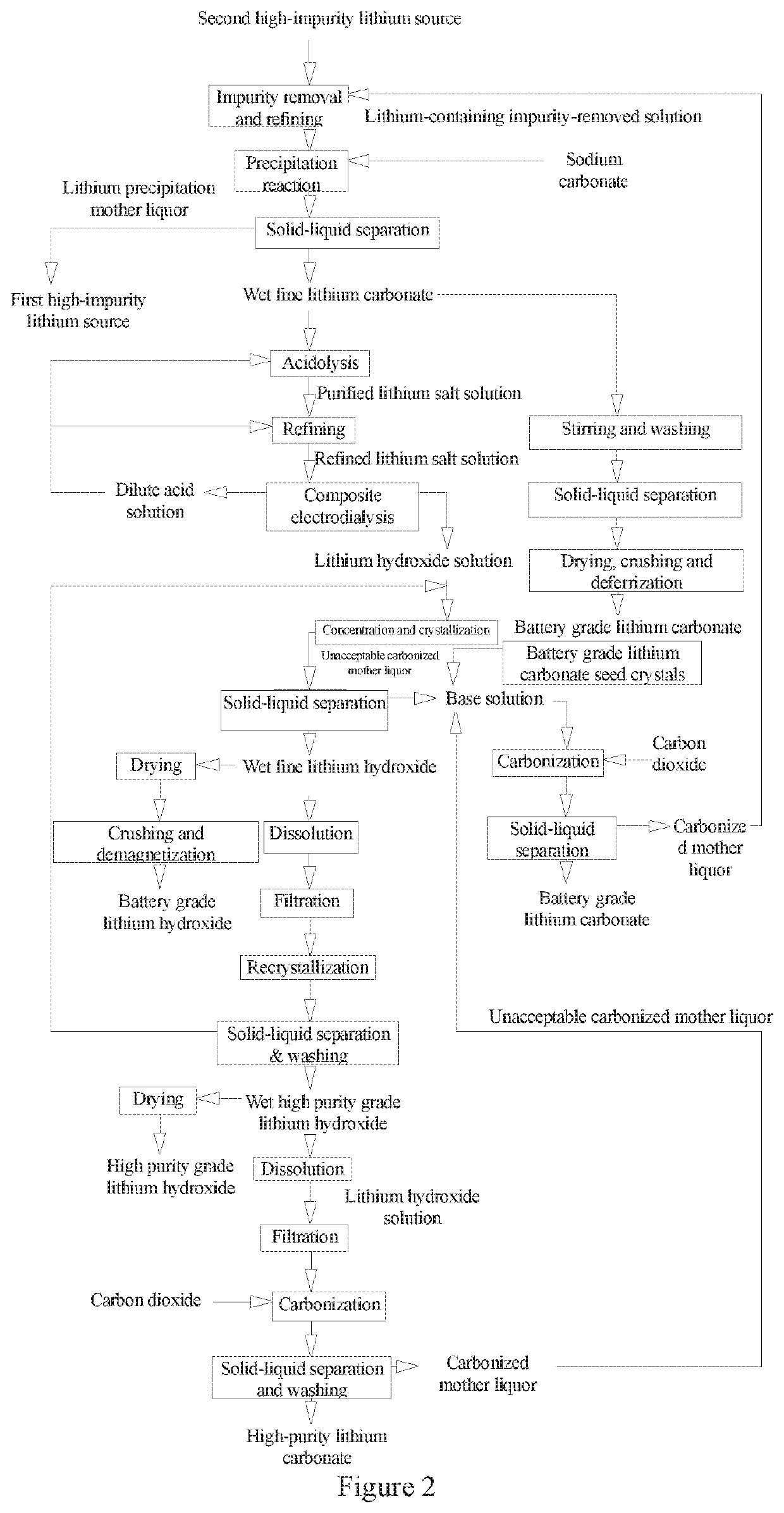

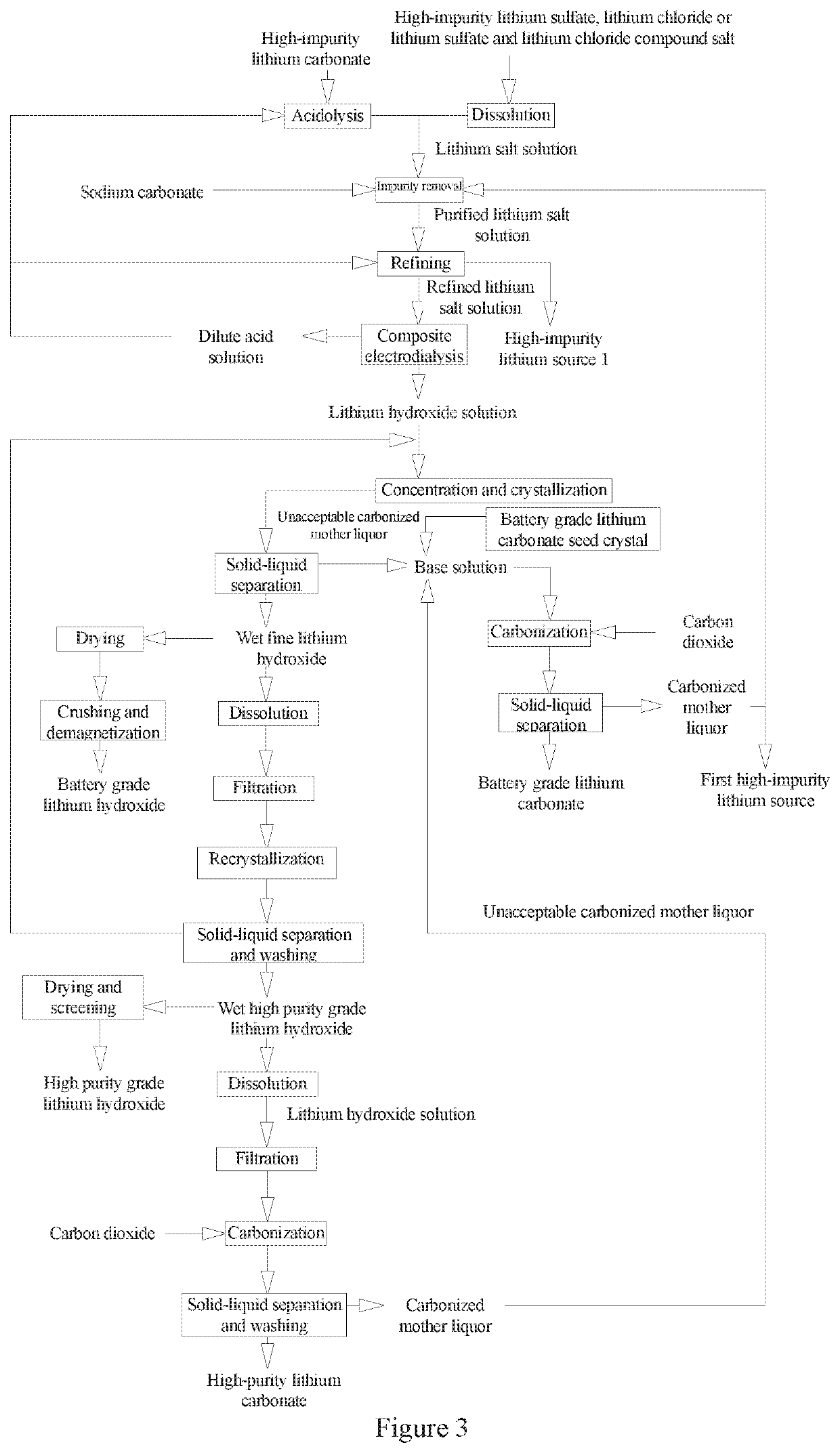

Method and System for Preparing Battery Grade and High Purity Grade Lithium Hydroxide and Lithium Carbonate from High-Impurity Lithium Sources

A method for preparing battery grade and high purity grade lithium hydroxide and lithium carbonate from high-impurity lithium sources includes steps for preparation of a refined lithium salt solution, preparation of battery grade lithium hydroxide, preparation of high purity grade lithium hydroxide, preparation of high purity grade lithium carbonate and preparation of battery grade lithium carbonate. The system to carry out the preparation includes a refined lithium salt solution preparation subsystem, a battery grade lithium hydroxide preparation subsystem, a high purity grade lithium hydroxide preparation subsystem, a high purity grade lithium carbonate preparation subsystem and a battery grade lithium carbonate preparation subsystem arranged in turn according to production sequence. A combination of physical and chemical treatment methods are used to treat the high-impurity lithium sources having variations in lithium contents, impurity categories, and impurity contents.

Owner:CHENGDU CHEMPHYS CHEM IND +1

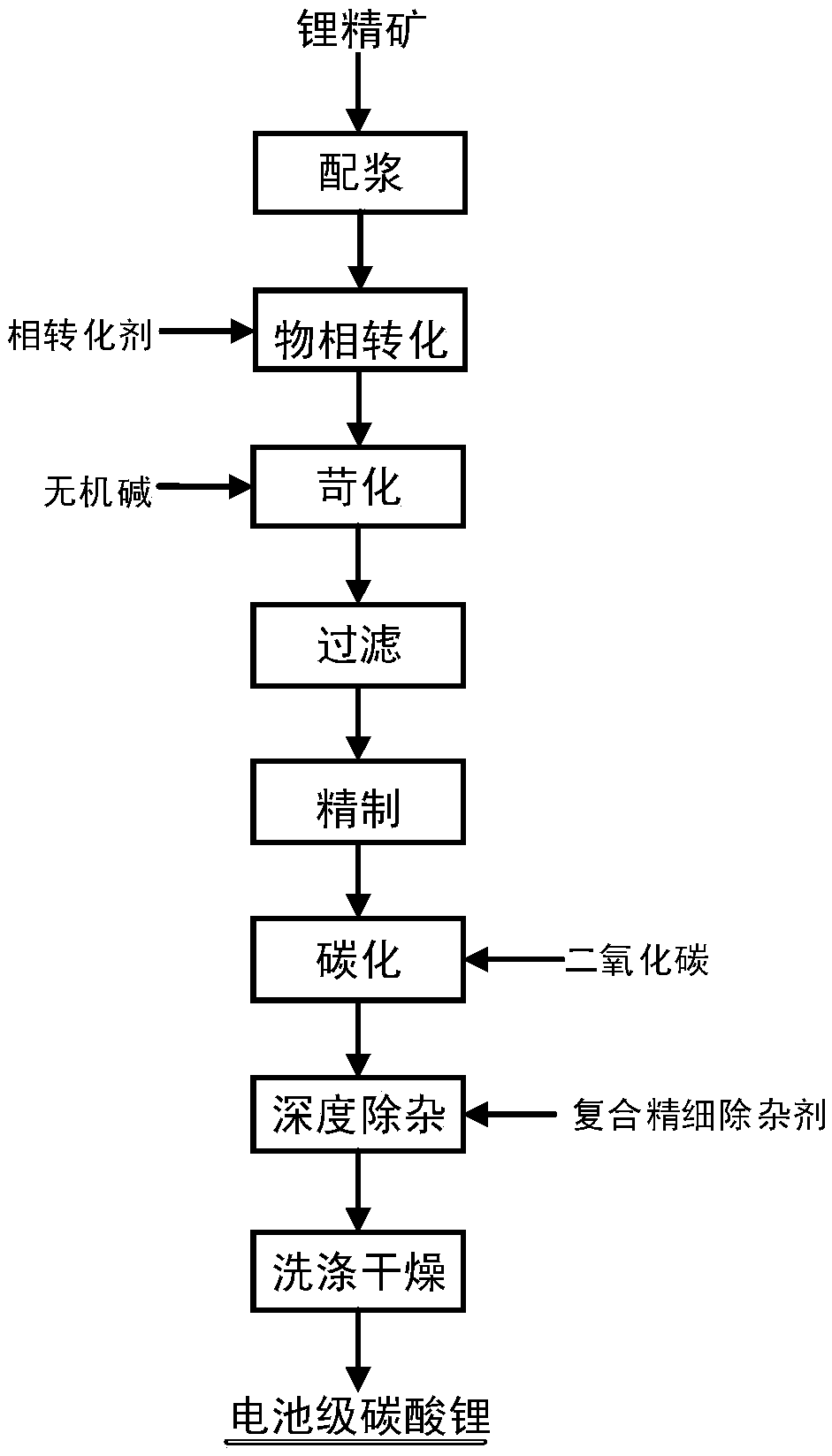

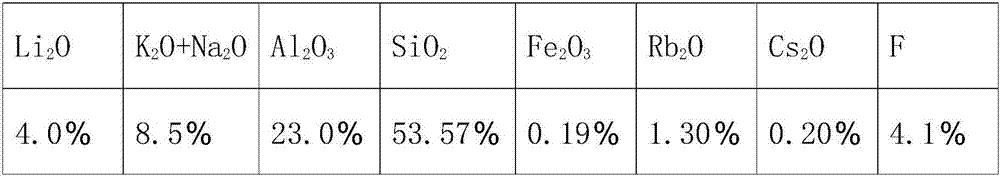

Battery-grade lithium carbonate preparation method based on phase transformation

InactiveCN105502442AHigh purityAchieve separationLithium carbonates/bicarbonatesHigh concentrationInorganic Chemical

The invention relates to a battery-grade lithium carbonate preparation method based on phase transformation, belonging to the technical field of the preparation of inorganic chemical materials. The preparation method comprises the following steps: by taking lithium concentrate as a raw material, first mixing the lithium concentrate and water to prepare 10 to 50% serous fluid, then adding a phase transformation agent, and reacting for 0.5 to 5 hours at 10 to 100 DEG C to obtain a high-concentration lithium salt solution; then mixing the lithium salt solution and inorganic alkali, and reacting to obtain a high-concentration causticization solution; introducing the causticization solution into a cation exchange column to obtain a refined causticization solution, and then introducing carbon dioxide into the refined causticization solution to obtain crude lithium carbonate; and finally mixing the crude lithium carbonate and an appropriate amount of composite refined impurity removal agent in water, and reacting to obtain a battery-grade lithium carbonate product with a main content more than or equal to 99.5 percent by weight. By adopting the phase transformation method, the concentration of the lithium salt solution is remarkably increased, the high-concentration causticization and carbonization can be realized, the preparation efficiency of the battery-grade lithium carbonate is increased, and a novel way is provided for the industrialized preparation of the battery-grade lithium carbonate.

Owner:TSINGHUA UNIV +1

Method of extracting lithium carbonate from lepidolite ore

ActiveCN107098365AImprove qualityGood cleaning effectLithium carbonates/bicarbonatesLithium-ion batteryLepidolite

The invention relates to a method of extracting lithium carbonate from lepidolite ore, and belongs to the field of preparation of lithium batteries. For overcoming the technical defect of low purity of lithium carbonate extracted from lepidolite in the prior art, the invention provides the method of extracting lithium carbonate from lepidolite ore, which includes the steps of sulfuric acid reaction, low-temperature vanadium deposition, impurity removal with Ca(OH)2 and Na2CO3, etc., so that metal ions in a leaching liquid of lepidolite are removed almost, and finally, saturated Na2CO3 is added to carry out a heating reaction to produce a high-purity lithium carbonate product. The method is low in energy consumption and demand on equipment, has significant impurity removal effects, and is suitable for promotion and application of preparation technologies of lithium carbonate with the lepidolite as raw material.

Owner:江西南氏锂电新材料有限公司

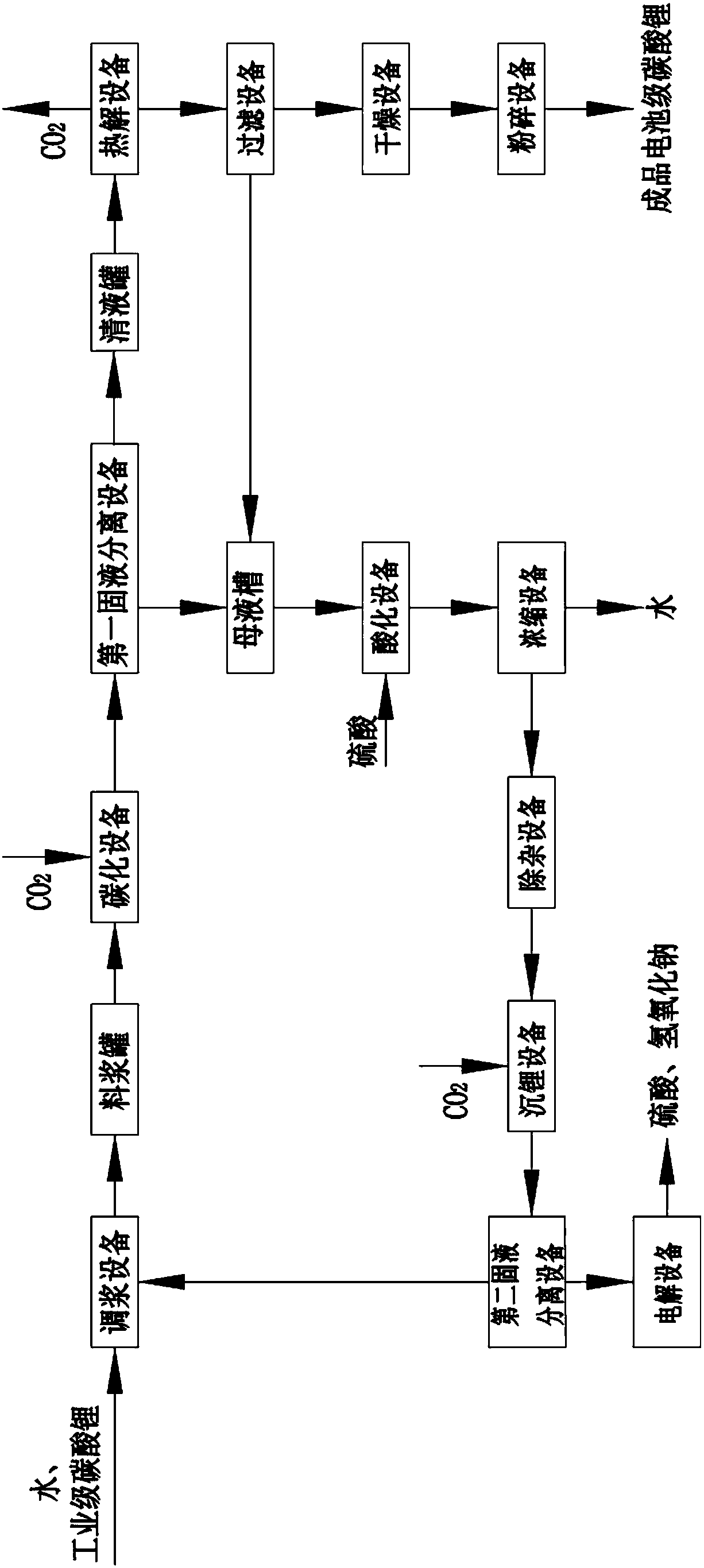

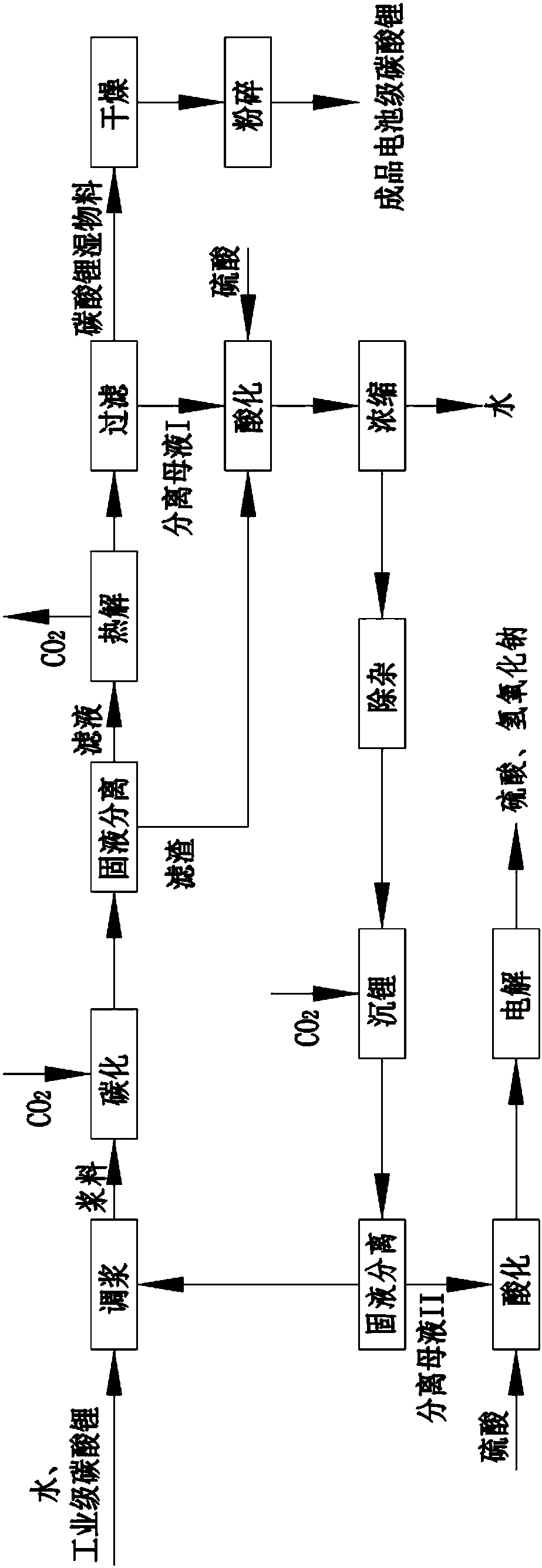

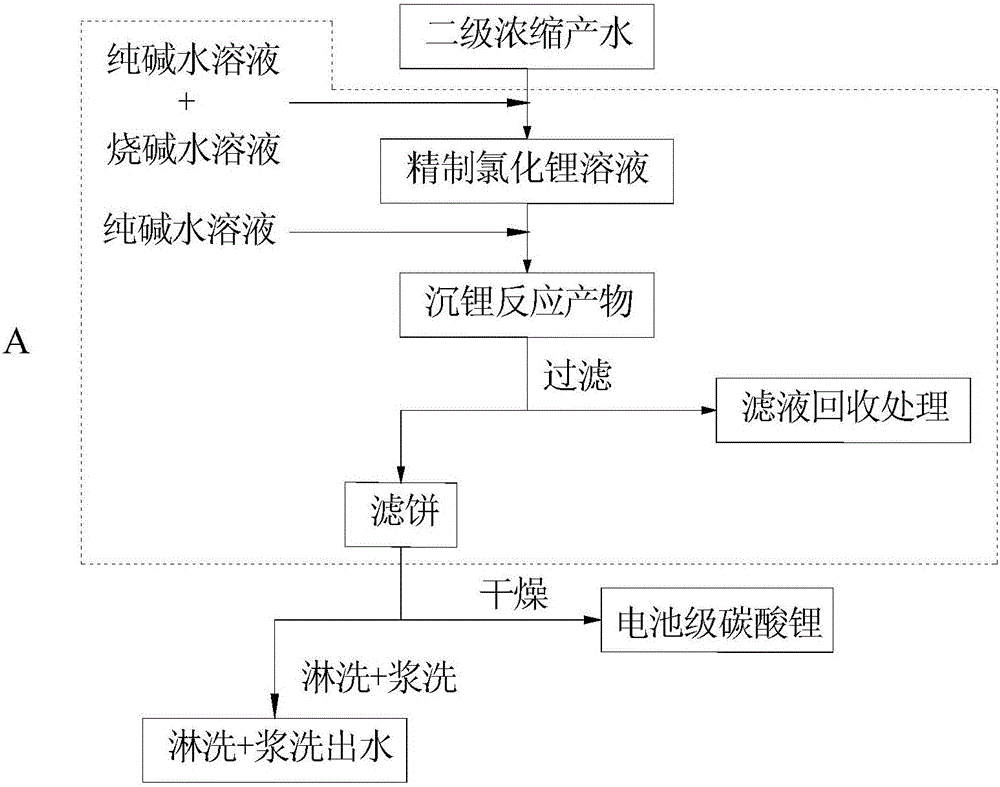

System and method for preparing battery-grade lithium carbonate

PendingCN108217700AHigh purityTo avoidElectrolysis componentsLithium carbonates/bicarbonatesElectrolysisFiltration

The invention discloses a system and method for preparing battery-grade lithium carbonate, belongs to the field of resource recycling and aims to solve the problem that waste resources generated in the conventional battery-grade lithium carbonate preparation process cannot be recycled or reused. According to the system and the method, filtrate generated from solid-liquid separation and separationmother liquor generated from filtration are subjected to acidification, concentration, decontamination and lithium settlement in acidification equipment, concentration equipment, decontamination equipment and lithium settlement equipment, the water outlet of the concentration equipment is connected with the raw material inlet of pulping equipment, the carbon dioxide outlet of pyrolysis equipment is connected with the carbon dioxide inlet of carbonization equipment and the carbon dioxide inlet of the lithium settlement equipment, and the sulfuric acid outlet of electrolysis equipment is connected with the sulfuric inlet of the acidification equipment. By adopting the system and the method, waste resources generated in the battery-grade lithium carbonate preparation process can be recycled and reused.

Owner:KEDA (ANHUI) NEW MATERIAL CO LTD

Lithium carbonate preparation method

InactiveCN108017072AReduce consumptionLithium carbonates/bicarbonatesLithium sulphateEconomic benefits

The invention discloses a lithium carbonate preparation method, which comprises: enriching natural spodumene into a concentrate, feeding into a rotary kiln, roasting to convert alpha-spodumene in theore into beta-spodumene, stopping the heating, and naturally cooling; crushing when the temperature of spodumene is reduced to 80-120 DEG C, screening, adding excess concentrated sulfuric acid, feeding into a converter, sintering, and leaching the sulfuric acid sintering block by using water to prepare water-soluble lithium sulfate; neutralizing the excess sulfuric acid to achieve the pH value of5.5-6.5, filtering, removing calcium, magnesium, iron and aluminum from the filtrate, carrying out decolorization, and concentrating the material liquid to prepare a saturated lithium sulfate solution; and adding a saturated sodium carbonate solution to the saturated lithium sulfate solution to generate lithium carbonate precipitate, separating the precipitate to obtain lithium carbonate with a product purity of more than 70%, repeatedly washing with hot water to obtain lithium carbonate with a purity of 96-97%, and drying to obtain the product. According to the present invention, the preparation method is simple, the energy consumption is greatly reduced, and the economic benefits of the enterprise are improved.

Owner:余成辰

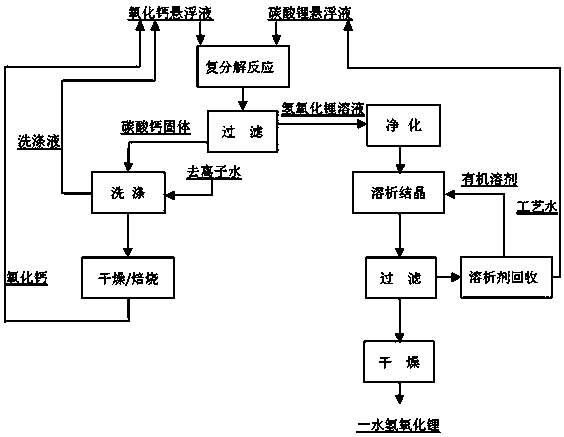

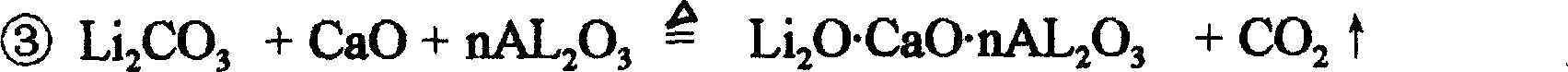

Method for preparing lithium hydroxide monohydrate by using lithium carbonate

ActiveCN108821313ALow raw material requirementEasy to implement industrial productionLithium oxides/hydroxidesLiquid wasteFiltration

The invention relates to a method for preparing lithium hydroxide monohydrate by using lithium carbonate. The method comprises the steps: adopting industrial grade lithium carbonate as a raw material,performing a reaction on suspension of the lithium carbonate, calcium oxide and water under the conditions of heating, pressurizing and stirring for 90-110 min, and performing filtration, purification, elution crystallization, drying and the like so as to obtain lithium hydroxide monohydrate. The method has the advantages that industrialization can be realized easily through adoption of industrial grade lithium carbonate to prepare the lithium hydroxide monohydrate, and improvement of the reaction speed and shortening of the reaction time are achieved by adopting a pressurized mode to increase the reaction temperature, so that the conversion rate of lithium carbonate is achieved; by adopting the elution crystallization method, the problems that a previously adopted evaporative crystallization method has large energy consumption and a high temperature, and lithium hydroxide is easily converted into lithium carbonate during evaporation are solved, and conversion, caused by water loss, of lithium hydroxide monohydrate into anhydrous lithium hydroxide can be prevented during evaporation; the product has stable quality and high purity, and organic solvents used during the elution crystallization can be recycled, so that discharge without solid and liquid waste is achieved.

Owner:QINGHAI UNIVERSITY

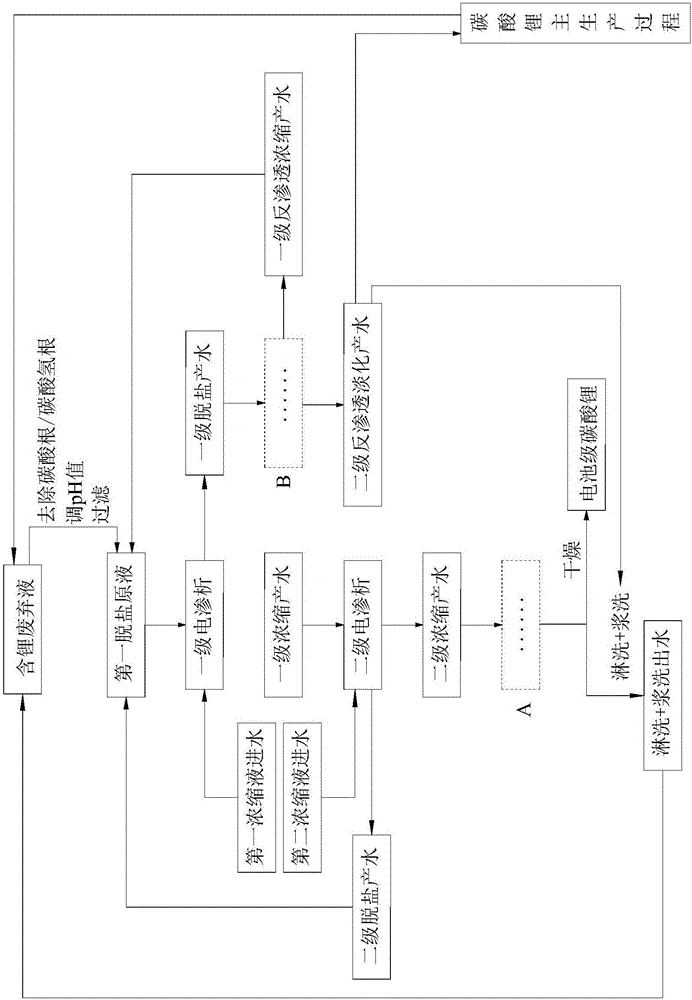

Comprehensive utilization method of lithium-containing waste fluids

ActiveCN106379919ASynchronous full collectionSolve the problem of saturated precipitationLithium halidesLithium carbonates/bicarbonatesElectricityDesalination

The invention discloses a comprehensive utilization method of lithium-containing waste fluids. Lithium carbonate washing water in lithium carbonate preparation technology, pyrolysis mother-liquor generated during high-purity lithium carbonate preparation by a carbonization-decomposition method, or a liquid with similar composition of the lithium carbonate washing water or the pyrolysis mother-liquor is used as a raw material. The raw material undergoes primary or secondary electrodialysis treatment, and a cation exchange membrane and an anion exchange membrane are utilized. On one hand, Li<+> is concentrated and enriched so as to obtain a lithium-rich concentrate with Li<+> content being 10g / L-20g / L; and on the other hand, water produced by primary desalination can be purified so as to obtain deionized water with TDS value being lower than 20mg / L for reuse. By combination of electrodialysis and reverse osmosis, a closed-cycle technology is formed. Then, comprehensive yield of Li<+> is close to 100%, and water loss is zero. Thus, Li<+> and water in the lithium carbonate washing water and the solution with the similar composition are synchronously and completely recovered.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Preparation method of antibacterial coating for household appliances

ActiveCN105838241AHigh antibacterial efficiencyLow toxicityAntifouling/underwater paintsPaints with biocidesUltravioletAntibacterial property

The invention provides a preparation method of an antibacterial coating for household appliances .According to the preparation method, the antibacterial effect and the continuous antibacterial capacity of the coating are improved through the antibacterial efficacy of silver, and the adhesive force of the coating is improved by taking white carbon black as a carrier and taking silicone rubber as a substrate, wherein nano-white carbon black antibacterial powder is prepared from silver nitrate, nickel carbonate, zinc oxide and lithium carbonate to generate the synergistic effect, and therefore the antibacterial property of the coating is better; antibacterial liquid is prepared by taking carbon black and titanium dioxide as raw materials, active substances such as .OH and O2 are generated on the surface of titanium dioxide and have the high oxidation effect to enable bacteria to be decomposed, and then the sterilizing effect is achieved; the substrate of the coating can generate the bacterial adhesion resisting effect through ultraviolet irradiation .Therefore, the prepared antibacterial coating for the household appliances has the advantages of being high in antibacterial efficiency, low in toxicity and good in heat resistance.

Owner:中山市国辉五金实业有限公司

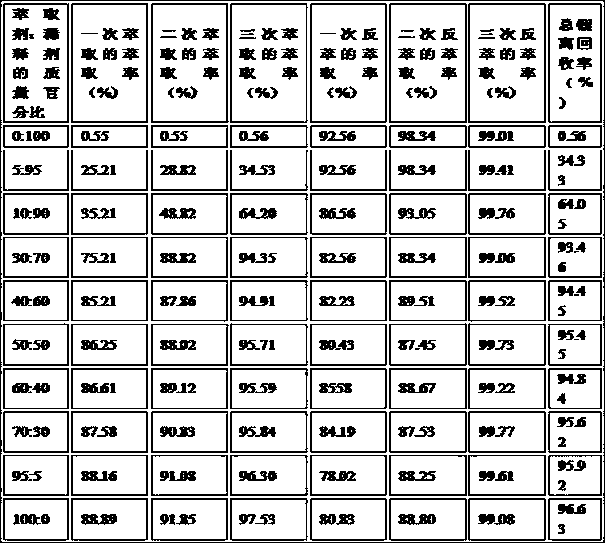

Lithium carbonate preparation method

PendingCN110240183AHigh purityAbundant raw materialsLithium carbonates/bicarbonatesChemical industryHydrogen

The invention belongs to the field of chemical industry, and provides a lithium carbonate preparation method, which comprises: mixing an extraction organic phase and a lithium-containing solution according to a volume ratio of 1:1-10 to form an alkaline extraction system, and extracting 1-3 times to obtain a lithium-containing organic phase, wherein the single extraction time is 1-15 min; mixing the lithium-containing organic phase and a back extraction solution according to a volume ratio of 1:1-10, carrying out back extraction 1-3 times, and collecting a lithium ion-containing lithium hydrogen carbonate aqueous solution, wherein the single back extraction time is 1-15 min, and the back extraction solution is an aqueous solution prepared by introducing carbon dioxide into a combination comprising one or any materials selected from pure water, an alkali metal salt and an ammonium salt aqueous solution; and heating the lithium ion-containing lithium hydrogen carbonate aqueous solution to crystallize and precipitate the lithium hydrogen carbonate in the aqueous solution, and thermally decomposing to obtain lithium carbonate. According to the present invention, the method has high extraction efficiency, can directly extract lithium ions from alkaline brine or aqueous solutions to prepare lithium carbonate, and further has advantages of low corrosion on production equipment, low production cost and environmental protection.

Owner:ZHEJIANG XINHUA CHEM

Method for purifying lithium carbonate

ActiveCN102531002BLow impurity contentImprove qualityLithium carbonates/bicarbonatesLithium oxideHydrogenation reaction

The invention relates to a method for purifying lithium carbonate, belonging to the technical field of the preparation of high-purity lithium carbonate. The method is characterized by safe production process and high lithium yield. The method comprises the following specific steps: (1) washing lithium carbonate to be purified to remove impurities, and adding water to prepare lithium carbonate slurry; (2) introducing CO2 into the lithium carbonate slurry prepared in the step (1) to carry out hydrogenation reaction, stopping introducing CO2 when the concentration of lithium oxide concentration in a solution is 10-30g / L, and filtering the solution to obtain a hydrogenated solution, wherein the hydrogenation reaction is carried out at the pressure of 0.2-0.6Mpa and the temperature of 20-30 DEG C; (3) subjecting the hydrogenated solution obtained in the step (2) to an ion exchange resin to remove impurity ions in the hydrogenated solution; and (4) heating the hydrogenated solution in which the impurity ions are removed in the step (3) to 70-90 DEG C to carry out decomposition reaction, separating solid from liquid to obtain the wet lithium carbonate, and drying the wet lithium carbonate. The produced battery-level lithium carbonate has high main content, excellent quality and stable performance.

Owner:天齐锂业(射洪)有限公司

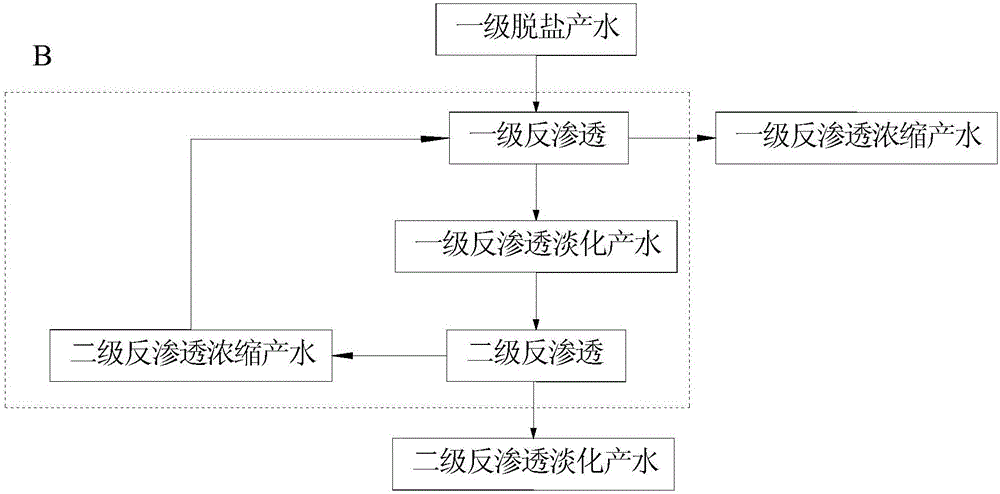

Method for extracting lithium from old brine in salt field

ActiveCN108996528AHigh puritySolve the problem of excessive lithium ratioLithium carbonates/bicarbonatesHigh magnesiumElution

The invention discloses a method for extracting lithium from old brine in a salt field. The method comprises: (1) magnesium adsorption removal, (2) stepwise speed-variable elution of lithium, (3) deepmagnesium adsorption removal based on an ion exchange resin, (4) reverse osmosis and (5) lithium carbonate preparation. The method comprehensively utilizes various processes such as magnesium adsorption removal, stepwise speed-variable elution of lithium, deep magnesium adsorption removal based on an ion exchange resin and reverse osmosis, completely solves the problems of too high magnesium-lithium ratio of the old brine in a salt field, realizes a low production cost and a low building cost and has strong adaptability. The product has lithium carbonate purity reaching to the purity of electronic grade lithium carbonate.

Owner:CHANGSHA DESIGN & RES INST OF CHEM IND MIN

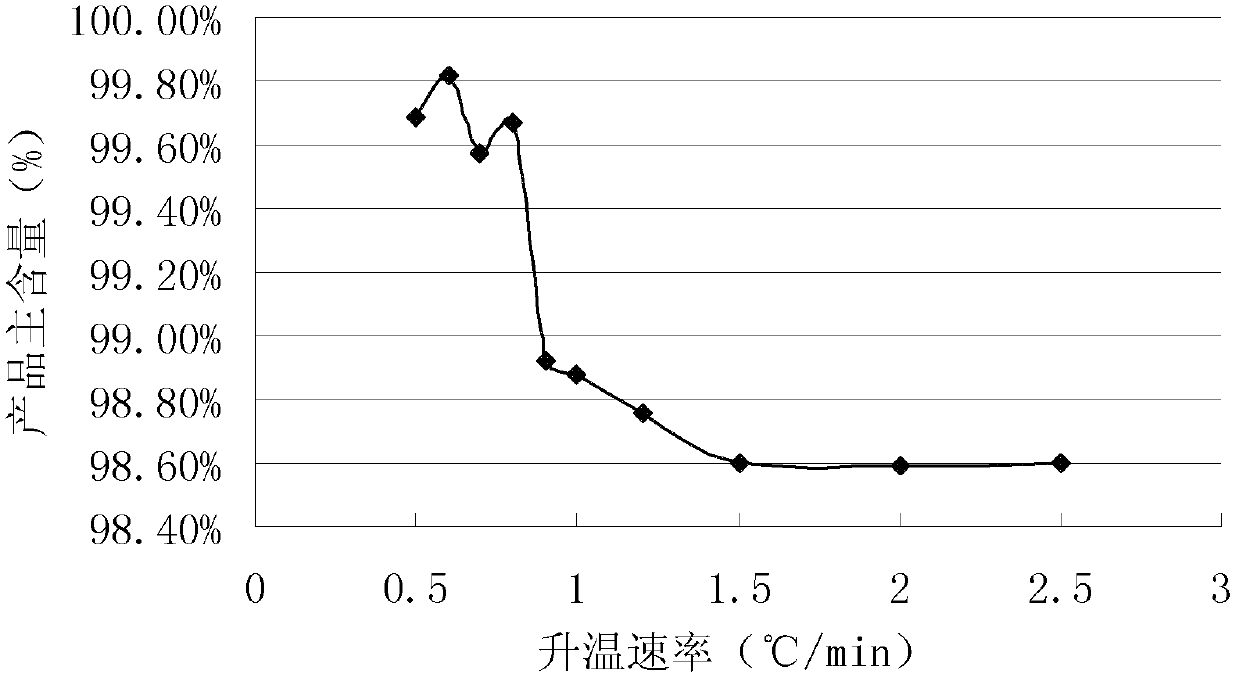

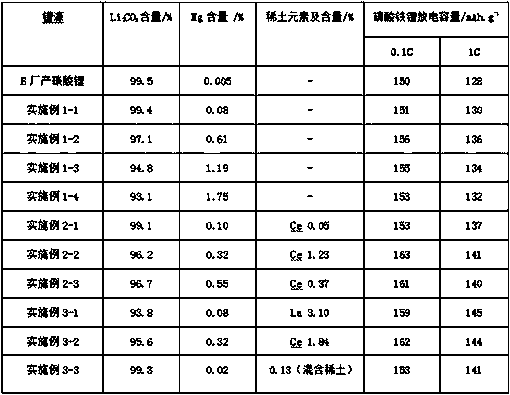

Battery-grade lithium carbonate preparation method

ActiveCN108423695AAchieve high qualityEliminates purification and magnesium removal processLithium carbonates/bicarbonatesLithium sulphateRare earth

The invention discloses a battery-grade lithium carbonate preparation method, which comprises: removing impurities from a lithium sulfate solution produced by using lithium ore as a raw material to obtain a lithium sulfate purification liquid, adding the lithium sulfate purification liquid into a Na2CO3 solution with dissolved EDTA and polyethylene glycol under a stirring condition, or adding a Na2CO3 solution with dissolved EDTA and polyethylene glycol to the lithium sulfate purification liquid, carrying out a stirring reaction for 30-60 min at a temperature of 85-97 DEG C, filtering, washing, and drying to prepare the battery-grade lithium carbonate product with the Li2CO3 content of 93.1-99.4% and the Mg content of 0.02-1.75%. According to the present invention, the deep or multiple magnesium removal is not required, the high value of magnesium is achieved, the uniform doping of magnesium and rare earth in the lithium ion battery positive electrode material can be achieved, and theelectrical property of the lithium ion battery positive electrode material can be easily improved; and the method has characteristics of low production cost, short process flow, high performance priceratio of the product, easy industrial production and significant economic benefits.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

Lithium preparing process with lithium carbonate

The lithium preparing process with lithium carbonate includes the following steps: mixing lithium carbonate, lime and alumina in certain proportion; pelletizing the mixture; calcining the mixture pellet at 900-1100 deg.c for lithium carbonate to decompose completely and for contained CO2 to be exhausted completely; crushing the pellet; mixing the obtained powder and silicoferrite in certain ratio; pelletizing the mixture powder; reducing the pellet at 1500-1600 deg.c and vacuum degree lower than or equal to 30 pa to produce lithium vapor; condensation to obtain solid lithium. The present invention has the features of high product purity, low cost, less environmental pollution and less investment in apparatus.

Owner:黄启新

Method for preparing battery-grade lithium carbonate

InactiveCN109987618ALow costReduced forced evaporationLithium carbonates/bicarbonatesReverse osmosisEvaporation

The invention provides a method for preparing battery-grade lithium carbonate based on salt lake old halogen, which comprises the following steps: S1, preliminary magnesium lithium separation of saltlake old brine; S2, reverse osmosis first stage concentration; S3, electrodialysis second stage concentration; S4, deep magnesium removal; and S5, preparation of battery-grade lithium carbonate. Withthe method for preparing battery-grade lithium carbonate with a high magnesium-lithium ratio by magnesium lithium separation, lithium enrichment and deep magnesium removal provided by the invention, the technical problems that conventional methods are complicated, high in cost and unsatisfactory in separation effect of magnesium and lithium can be effectively solved, in the preparation process oflithium carbonate, the process flow is greatly shortened, a plurality of processes such as forced evaporation, adjustment of pH, purification of lithium carbonate and conversion from two-step magnesium removal into one step of magnesium removal are reduced, the cost of preparing battery-grade lithium carbonate is also greatly reduced, and better industrialization prospects are achieved.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

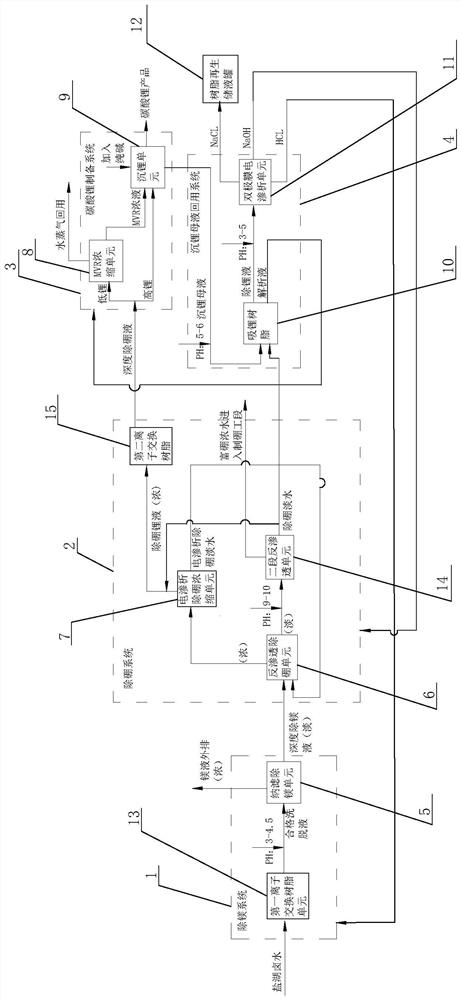

Salt lake lithium extraction system and method based on membrane separation

PendingCN112661321AImproving the Efficiency of Boron Removal by ElectrodialysisImprove boron removal efficiencyWater contaminantsChemical industryChemical industryReverse osmosis

The invention relates to the technical field of salt chemical industry, and particularly relates to and discloses a salt lake lithium extraction system based on membrane separation. The system comprises a magnesium removal system, a boron removal system, a lithium carbonate preparation system and a lithium precipitation mother liquor recycling system which are connected in sequence; themagnesium removal system comprises a nano-filtrationmagnesium removal unit; the boron removal system comprises a reverse osmosis boron removal unit and an electrodialysis boron removal concentration unit, which are connected in sequence; the lithium carbonate preparation system comprises an MVR concentration unit and a lithium precipitation unit, which are connected in sequence; and the lithium precipitation mother liquor recycling system comprises lithium absorption resin and a bipolar membrane electrodialysis unit, which are connected in sequence. The invention also discloses a salt lake lithium extraction method based on membrane separation. The method comprises the following steps: 1) deeply removing magnesium; 2) deeply removing boron; 3) preparing lithium carbonate; and 4) recycling the lithium precipitation mother liquor. The salt lake lithium extraction system and method based on membrane separation have the advantages that no extra pollution is generated, the cost is saved, the energy consumption is reduced, the product purity is high, the production cost is low, and the pollution degree is low.

Owner:ZHEJIANG CREATION ENVIRONMENT TECH

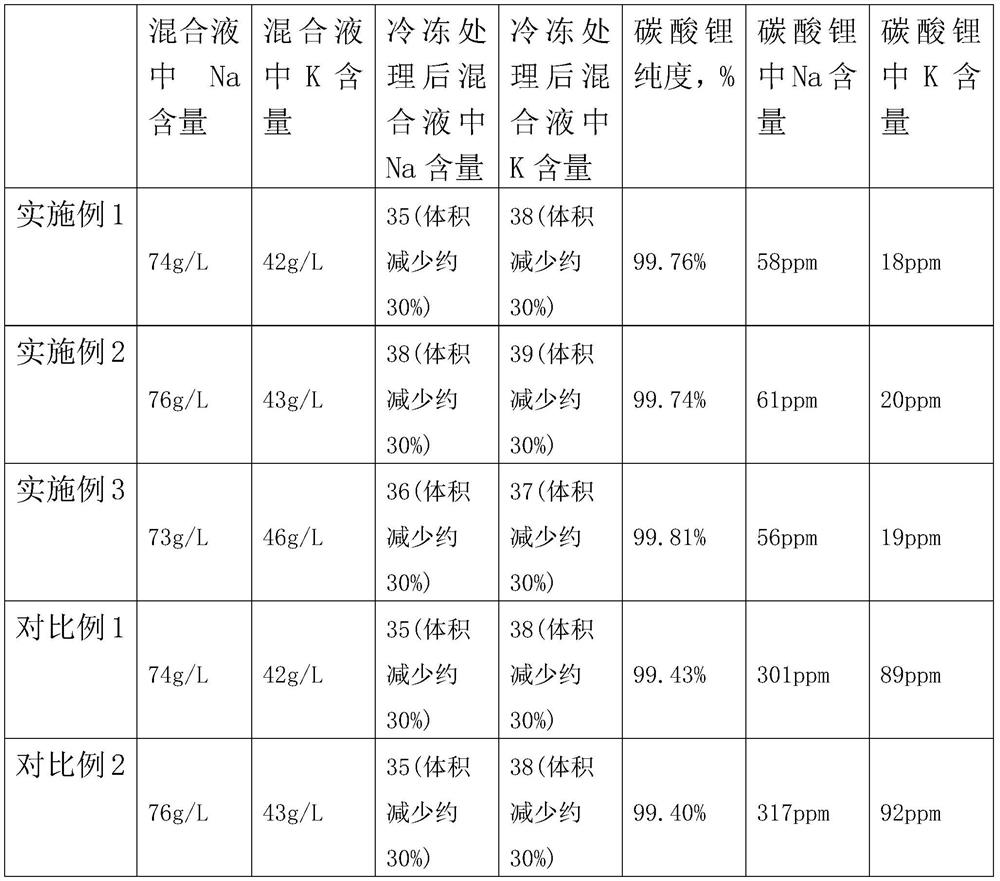

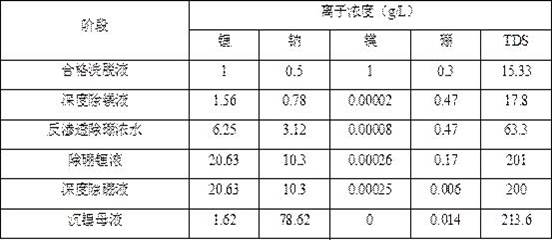

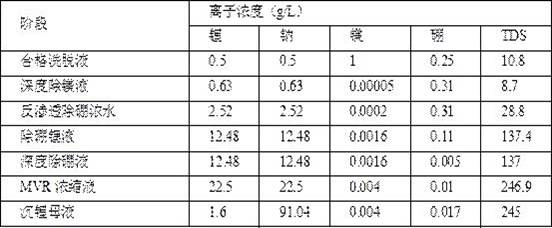

Method for preparing battery-grade lithium carbonate by freezing and recycling lithium precipitation concentrated mother liquor

ActiveCN112142080AIncrease profitReduce adverse effectsLithium carbonates/bicarbonatesIon exchangeEnvironmental engineering

The invention provides a method for preparing battery-grade lithium carbonate by freezing and recycling lithium precipitation concentrated mother liquor, and belongs to the field of lithium carbonatepreparation. The method comprises the following steps: (1) roasting and leaching lepidolite to obtain leachate, and purifying, concentrating, evaporating, lithium precipitating and filtering the leachate to obtain lithium carbonate and lithium precipitation mother liquor; (2) concentrating and evaporating the lithium precipitation mother liquor to obtain lithium precipitation concentrated mother liquor; and (3) adding the lithium precipitation concentrated mother liquor in the step (2) into the leachate to obtain a mixed solution, purifying, concentrating, evaporating and freezing the mixed solution to remove potassium and sodium salts, filtering, introducing ion exchange resin to remove calcium and magnesium, precipitating to obtain battery-grade lithium carbonate and lithium precipitation mother liquor, treating the lithium precipitation mother liquor, and recycling the lithium precipitation mother liquor in the process. According to the method, the lithium precipitation mother liquor is treated and then mixed with the leachate according to a certain volume ratio, lithium precipitation is carried out after potassium and sodium are removed through freezing, and the obtained lithium precipitation mother liquor can be recycled in the production process, so that the cost is reduced, and the production efficiency can be improved.

Owner:JIANGXI YONGXING SPECIAL STEEL NEW ENERGY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com