Preparation method of high-purity lithium carbonate

A technology of high-purity lithium carbonate and lithium carbonate, which is applied in the direction of lithium carbonate;/acid carbonate, etc., can solve problems such as inaccessibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Embodiment 1 adopts the inventive method to prepare high-purity lithium carbonate

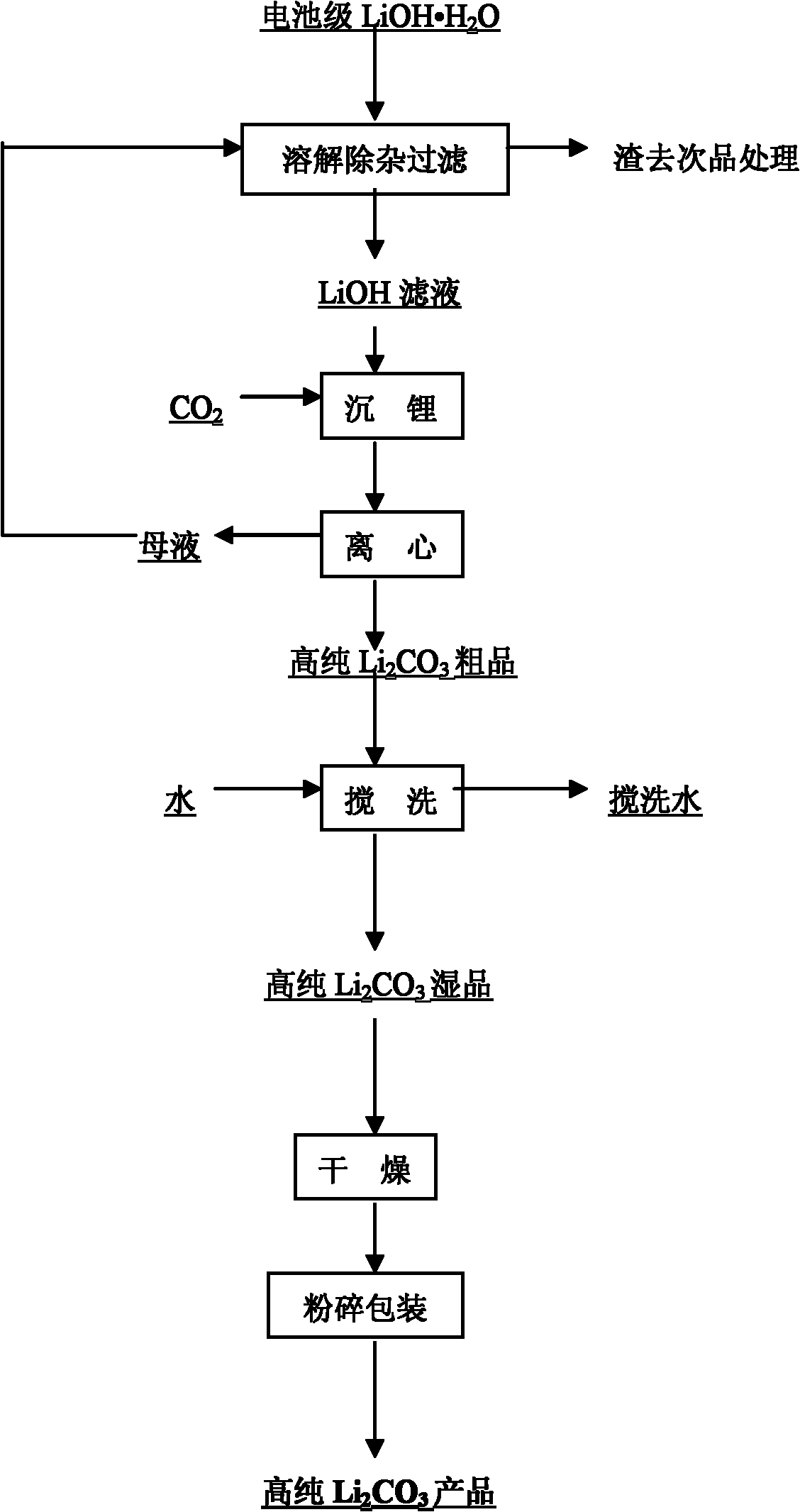

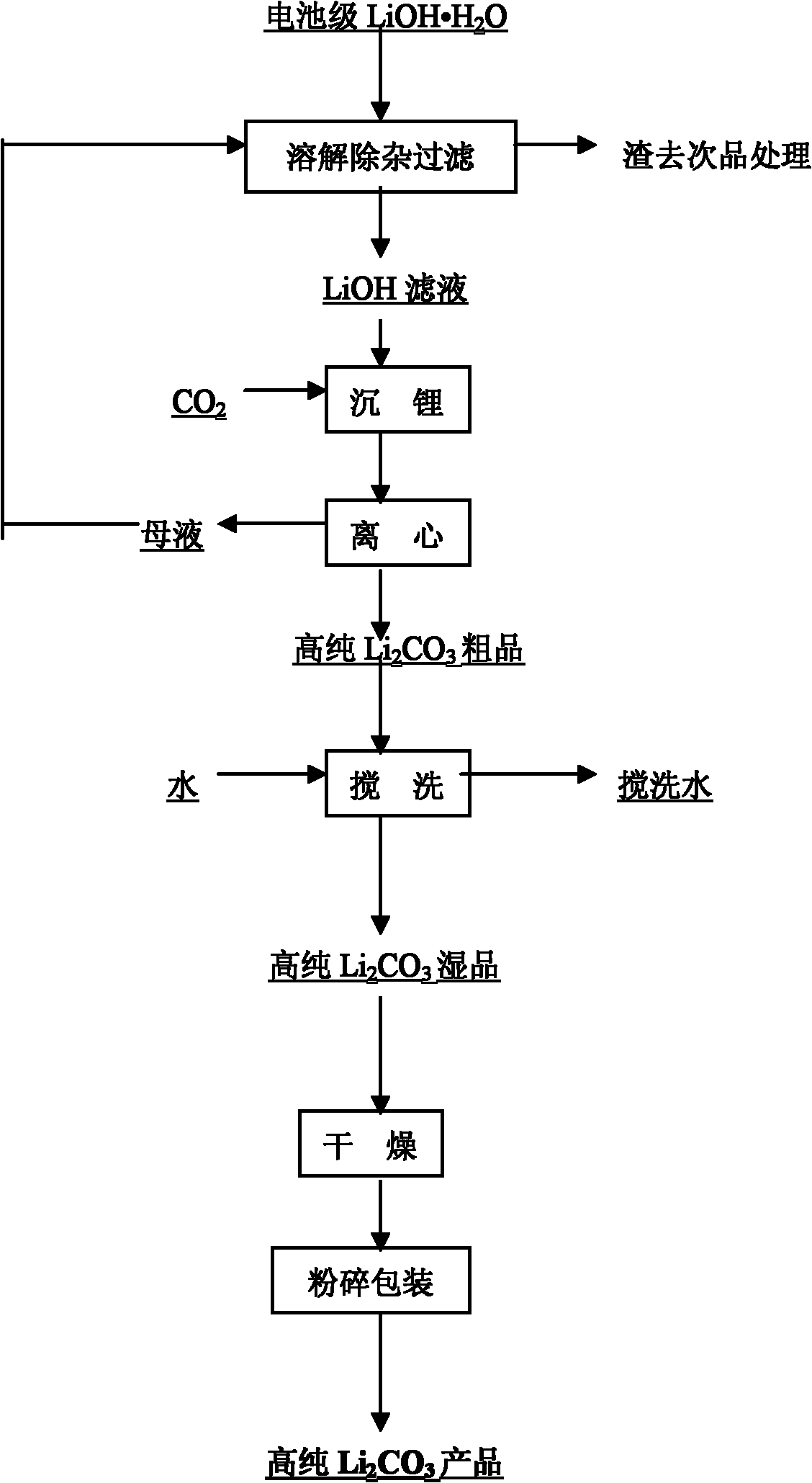

[0048] The method includes the following steps (see figure 1 ): Add about 600kg of battery-grade lithium hydroxide monohydrate into the reactor and dissolve in distilled water to prepare Li 2 O concentration is the lithium hydroxide solution of 80g / L, stirring and reacting for a period of time, according to the Ca in the lithium hydroxide solution 2+ , Mg 2+ Concentration, adding an excess of 3% EDTA, the Ca in the complex solution 2+ , Mg 2+ , to obtain lithium hydroxide purification solution, and then remove insoluble impurities by pressure filtration to obtain lithium hydroxide filtrate; make Ca in the product 2+ The concentration is lower than 3ppm, making Mg in the product 2+ The concentration is less than 1ppm.

[0049] Add the lithium hydroxide filtrate to the reaction vessel first, then feed CO into the lithium hydroxide filtrate 2 gas, at the start of ventilation, CO 2 T...

Embodiment 2-8

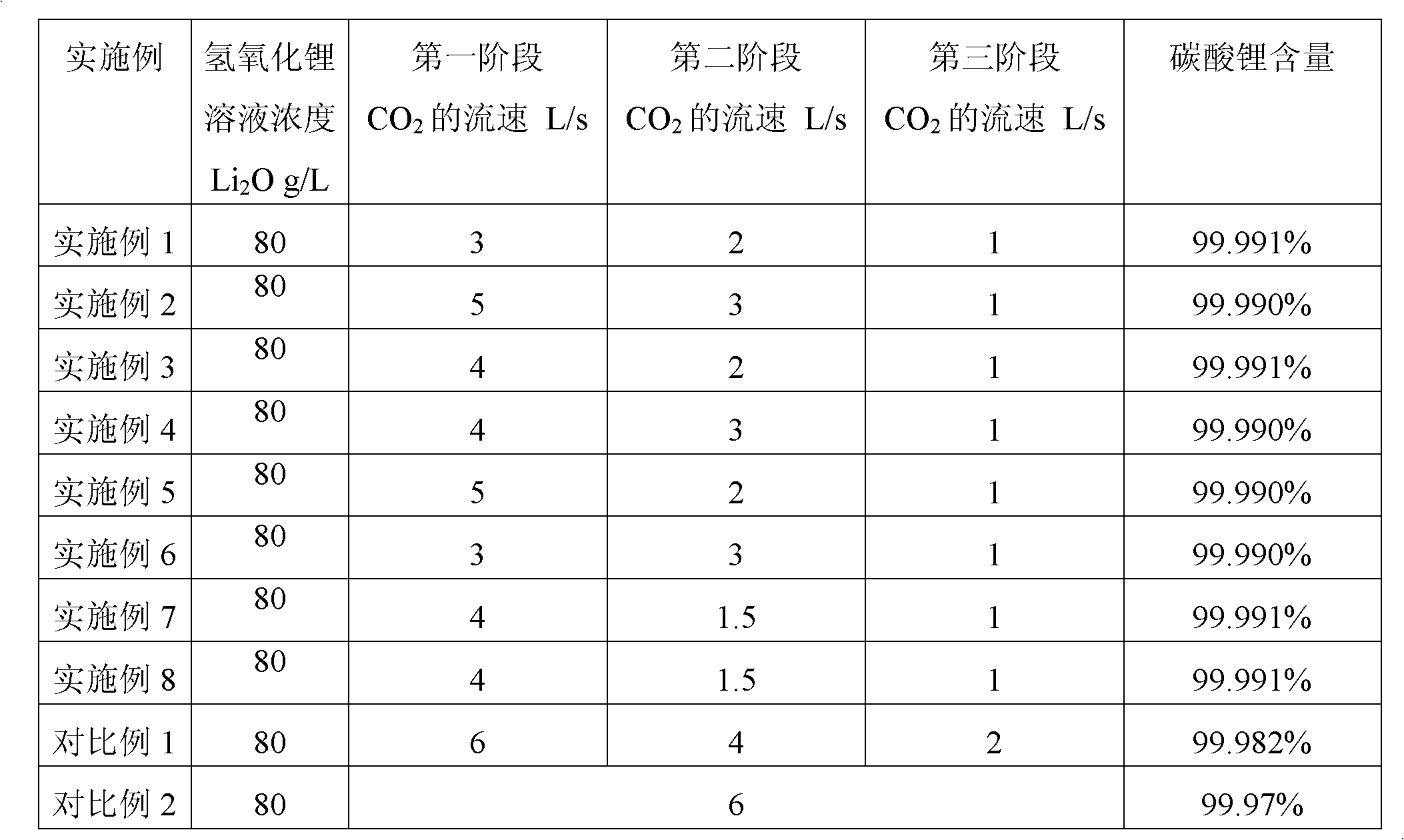

[0051] Embodiment 2-8 adopts the inventive method to prepare high-purity lithium carbonate

[0052] Embodiment 2-8 method is the same as embodiment 1, only difference is CO 2 The specific results are shown in Table 1.

[0053]

[0054] As can be seen from Table 2, the present invention is passing through CO 2 , by controlling the CO 2 The flow rate can realize high-purity lithium carbonate with a lithium carbonate content of 99.99% in one step without further purification.

[0055] The inventor of the present invention is by adjusting lithium hydroxide solution concentration, in Li 2 Within the range of O concentration of 50-90g / L, high-purity lithium carbonate with lithium carbonate content of 99.99% can be obtained. And lithium hydroxide solution concentration is too low, when 45g / L, because the mother liquor amount increases, lithium yield reduces, and equipment utilization rate reduces. And when higher than 90g / L, because lithium hydroxide can not dissolve complete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com