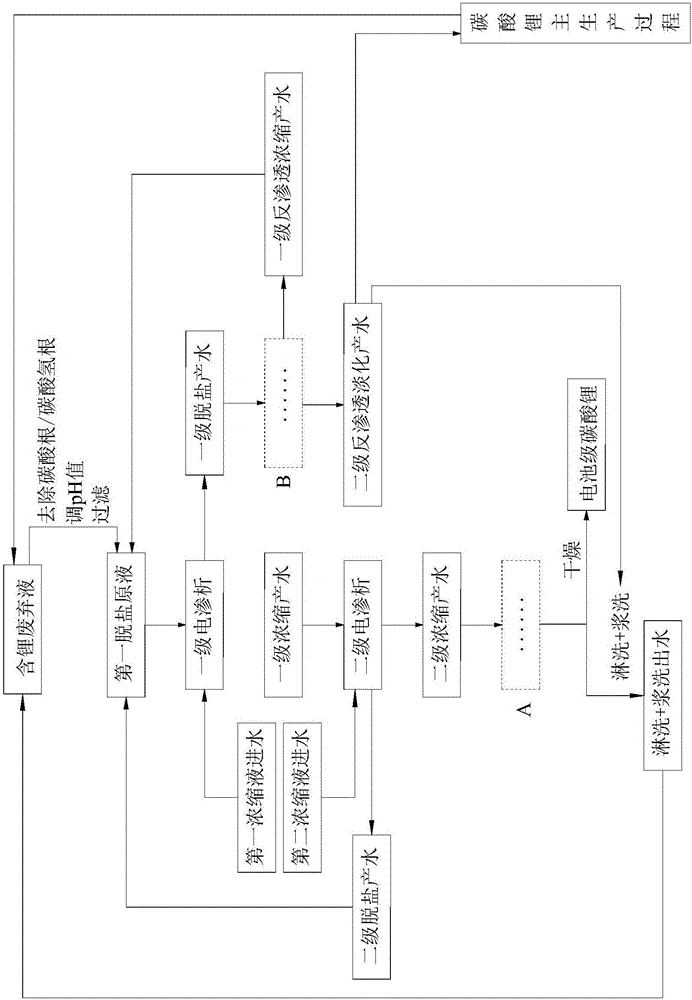

Comprehensive utilization method of lithium-containing waste fluids

A waste liquid, first-class technology, applied in the direction of lithium halide, lithium carbonate; / acid carbonate, etc., can solve the problem of fresh water or deionized water, unable to achieve synchronous recovery, high salt content in desalination solution , to achieve the effect of small footprint, low cost and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

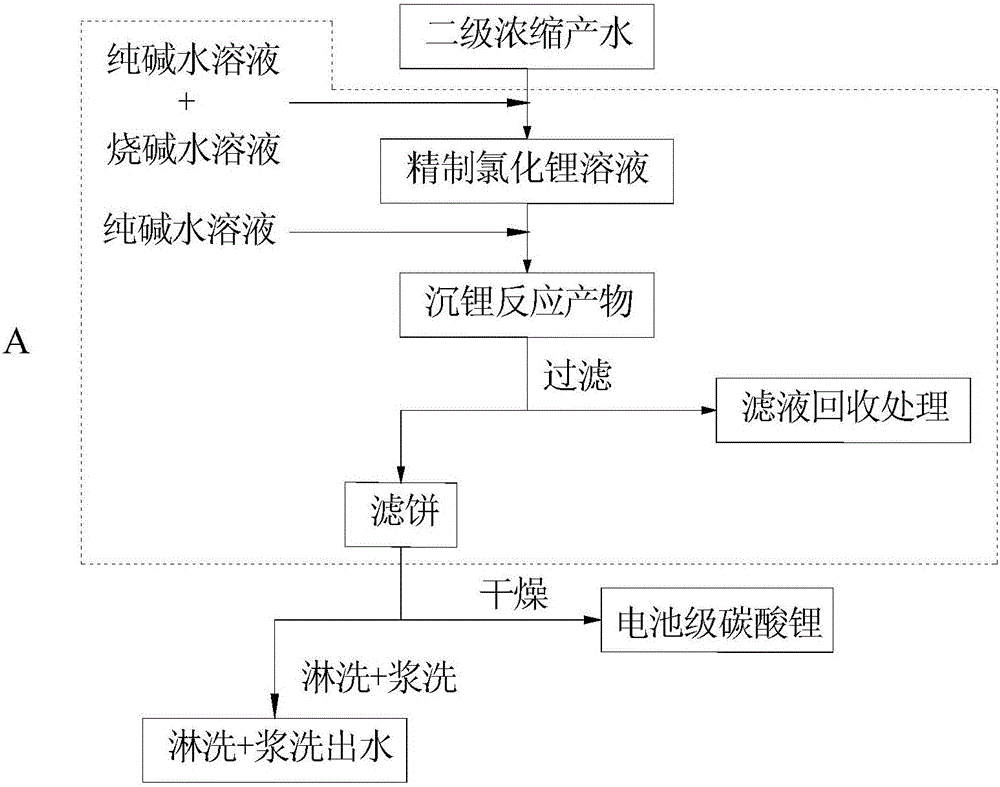

Examples

Embodiment 5

[0097] Li + The concentration drops to 1435mg / L, which is equivalent to the Li in the first desalted stock solution + 9% of the total amount can be returned to the first-stage electrodialysis, that is, combined with the first desalted stock solution in Example 4 and then entered into the first-stage electrodialysis step to form material coupling.

Embodiment 6

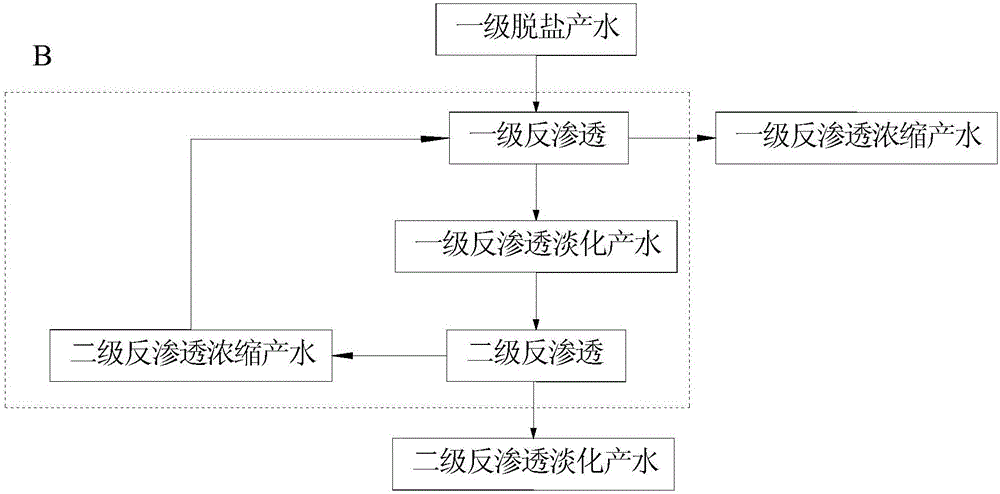

[0099] In this example, the primary desalination product water obtained in Example 4 is subjected to reverse osmosis treatment to obtain deionized water with higher purity (ie, reverse osmosis desalination product water).

[0100] Take 300L of the first-stage desalination product water obtained in Example 4, and the specific composition of the first-stage desalination product water is shown in Table 5; the U.S. Dow Chemical FILMTEC BW30-2540 membrane module is used to perform two-stage reverse osmosis treatment: a The first-stage desalination product water is used as the first-stage reverse osmosis feed water, and the first-stage reverse osmosis desalination product water and the first-stage reverse osmosis concentrated product water are obtained after the first-stage reverse osmosis treatment; the first-stage reverse osmosis desalination product water is used as the second-stage reverse osmosis feed water, After the two-stage reverse osmosis treatment, the two-stage reverse os...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com