Salt lake lithium extraction system and method based on membrane separation

A membrane separation and preparation system technology, which is applied in the field of salt chemical industry, can solve the problems of high cost of membrane separation technology, low adsorption capacity of adsorbent, corrosion equipment, etc., and achieve the effect of improving boron removal efficiency, low production cost and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

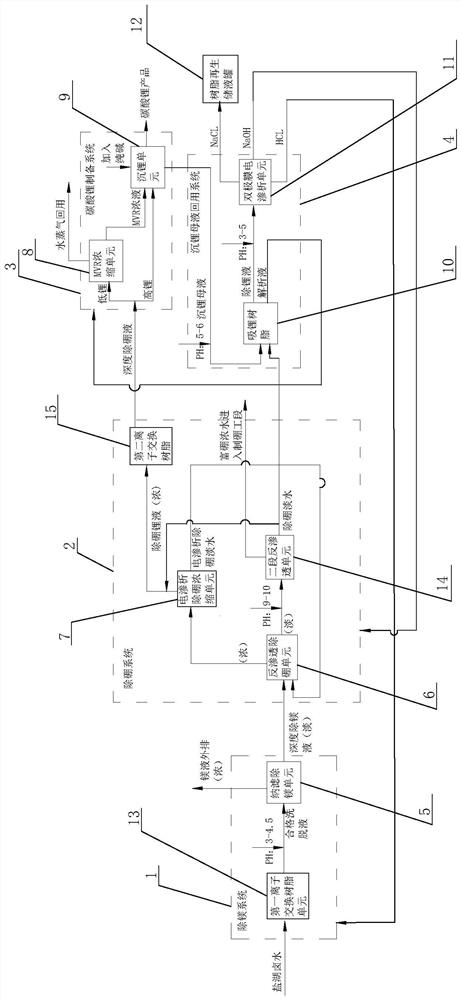

[0035] A salt lake lithium extraction system based on membrane separation, such as attached figure 1 As shown, it includes sequentially connected magnesium removal system 1, boron removal system 2, lithium carbonate preparation system 3, lithium sinking mother liquor recycling system 4, and the magnesium removal system 1 includes first ion exchange resin 13 and nano The magnesium filter unit 5, the boron removal system 2 includes a reverse osmosis boron removal unit 6, an electrodialysis boron removal concentration unit 7, and a lithium carbonate preparation system 3 includes a sequentially connected MVR concentration unit 8, a lithium precipitation unit 9, and a lithium precipitation unit 9. The mother liquor reuse system 4 includes a lithium-absorbing resin 10 and a bipolar membrane electrodialysis unit 11 connected in sequence, wherein the concentrated water end of the reverse osmosis boron removal unit 6 is connected to the water inlet end of the electrodialysis boron remov...

Embodiment 2

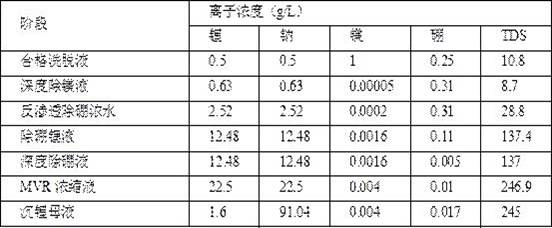

[0051] A kind of salt lake extracting lithium system based on membrane separation of the present embodiment and method rest are identical with embodiment 1, and difference is:

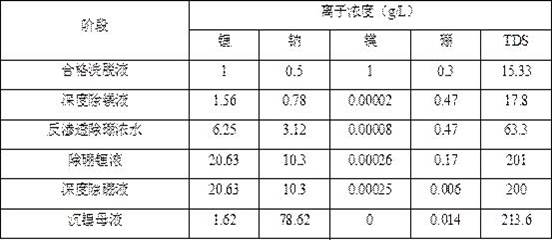

[0052] The lithium ion content in the qualified eluent is 1 g / L, the sodium ion content is 0.5 g / L, the magnesium ion content is 1 g / L, and the B ion content is 0.3 g / L;

[0053] Before the qualified eluent enters the nanofiltration magnesium removal unit 5, the pH is adjusted to 3, the removal rate of magnesium in each stage of nanofiltration is greater than 80%, the lithium ion content in the deep magnesium removal solution is 1.56 g / L, and the magnesium ion content is 0.02 mg / L;

[0054] The recovery rate of produced water in reverse osmosis boron removal unit 6 is 75%, the removal rate of boron is 50%, the removal rate of boron by electrodialysis is 63%, the lithium ion content in the deep boron removal solution is 20.63 g / L, and the boron ion content is 6 mg / L, the total solid content of the solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com