Catechol-modified mesoporous silicon adsorbent, preparation method and use thereof

A technology of catechol and mesoporous silicon, which is applied in the field of preparation of mesoporous silicon adsorbent, can solve the problems of high energy consumption, high toxicity, and unsatisfactory effect, and achieve the effect of improving boron removal efficiency and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

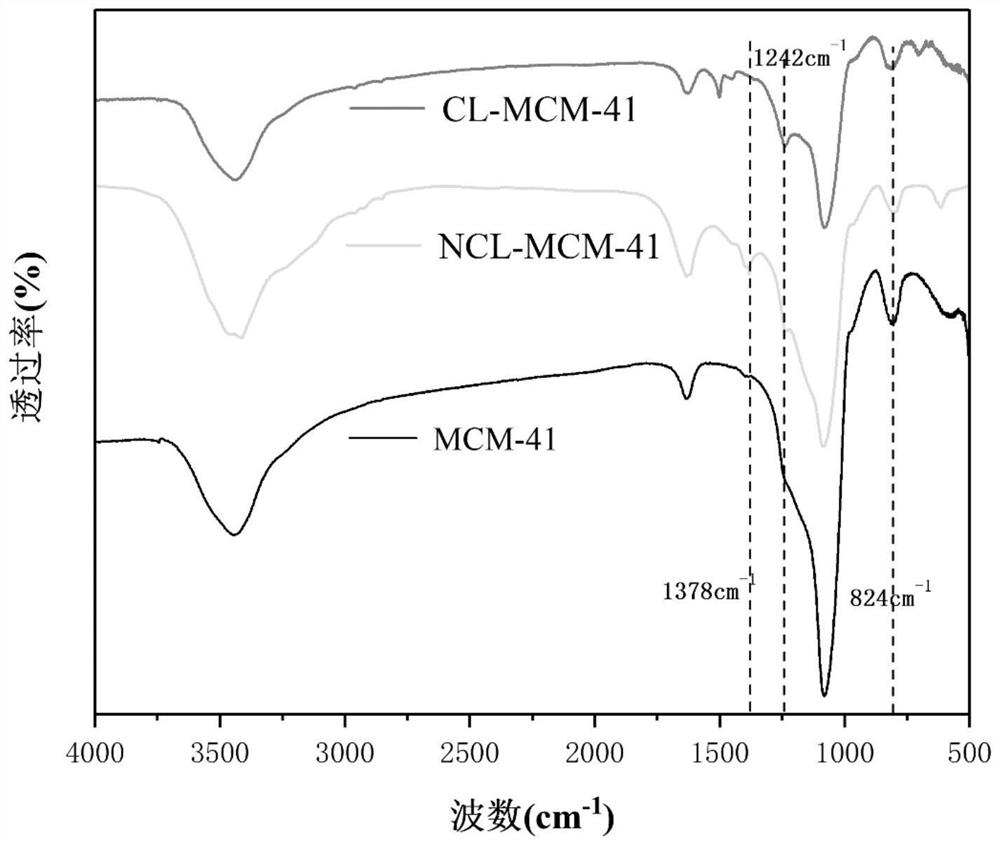

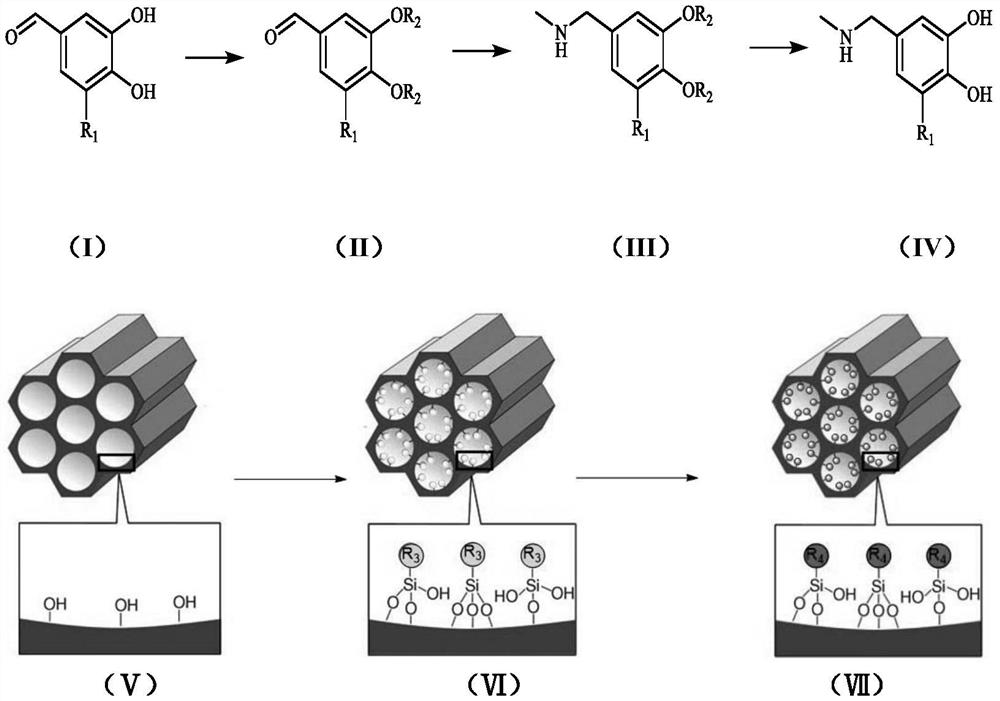

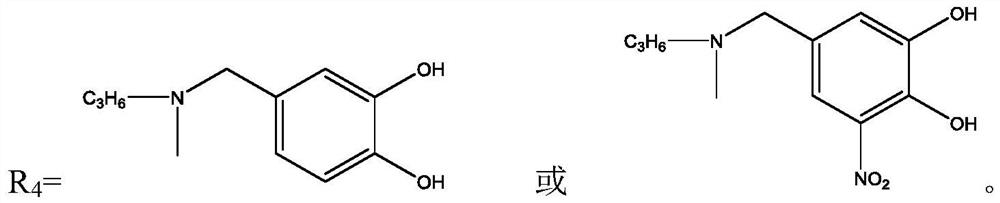

[0039] The preparation method of the mesoporous silicon adsorption material modified by catechol comprises the following steps:

[0040] (1) 50 mmol of the compound of formula (I) (R 1 =H), 250mmol potassium carbonate, 10mmol potassium iodide and 250mL N,N-dimethylformamide were stirred and mixed, stirred at room temperature for 1h under the protection of inert gas, then added 115mmol benzyl chloride, stirred at 70 ° C for 12h, the reaction ended Then, the product was extracted three times with ethyl acetate and saturated sodium chloride solution, the aqueous layer was taken out and extracted three times with ethyl acetate, the organic phases were combined, and then extracted three times with saturated sodium chloride solution, and the organic phase was extracted with anhydrous sulfuric acid. After the sodium is dried, the solvent is removed by rotary evaporation, and the compound of formula (II) is obtained by recrystallization with absolute ethanol;

[0041] (2) 10 mmol of ...

Embodiment 2

[0046] The preparation method of the mesoporous silicon adsorption material modified by catechol comprises the following steps:

[0047] (1) 50 mmol of the compound of formula (I) (R 1 =H), 250mmol potassium carbonate, 10mmol potassium iodide and 250mL N,N-dimethylformamide were stirred and mixed, stirred at room temperature for 1h under the protection of inert gas, then added 115mmol benzyl chloride, stirred at 70 ° C for 12h, the reaction ended Then, the product was extracted three times with ethyl acetate and saturated sodium chloride solution, the aqueous layer was taken out and extracted three times with ethyl acetate, the organic phases were combined, and then extracted three times with saturated sodium chloride solution, and the organic phase was extracted with anhydrous sulfuric acid. After the sodium is dried, the solvent is removed by rotary evaporation, and the compound of formula (II) is obtained by recrystallization with absolute ethanol;

[0048] (2) 10 mmol of ...

Embodiment 3

[0053] The preparation method of the mesoporous silicon adsorption material modified by catechol comprises the following steps:

[0054] (1) 20 mmol of the compound of formula (I) (R 1 =NO 2 ), 100mmol of potassium carbonate, 2mmol of tetrabutylammonium iodide and 250mL of N,N-dimethylformamide were stirred and mixed, stirred at room temperature for 1h under the protection of inert gas, then added 46mmol of benzyl chloride, and stirred for 12h at 70°C, After the reaction, the product was extracted three times with ethyl acetate and saturated sodium chloride solution, the aqueous layer was taken out and extracted three times with ethyl acetate, the organic phases were combined, and then extracted three times with saturated sodium chloride solution. After drying with sodium sulfate, the solvent is removed by rotary evaporation, and the compound of formula (II) is obtained by recrystallization with absolute ethanol;

[0055] (2) 10 mmol of the compound of formula (II), 4 mL of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| separation factor | aaaaa | aaaaa |

| separation factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com