System and method for preparing battery-grade lithium carbonate

A lithium carbonate, battery-grade technology, applied in the field of resource recovery and utilization, can solve the problem that waste resources cannot be recycled and reused, and achieve the effects of efficient recovery, avoidance of waste resources, and high preparation purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

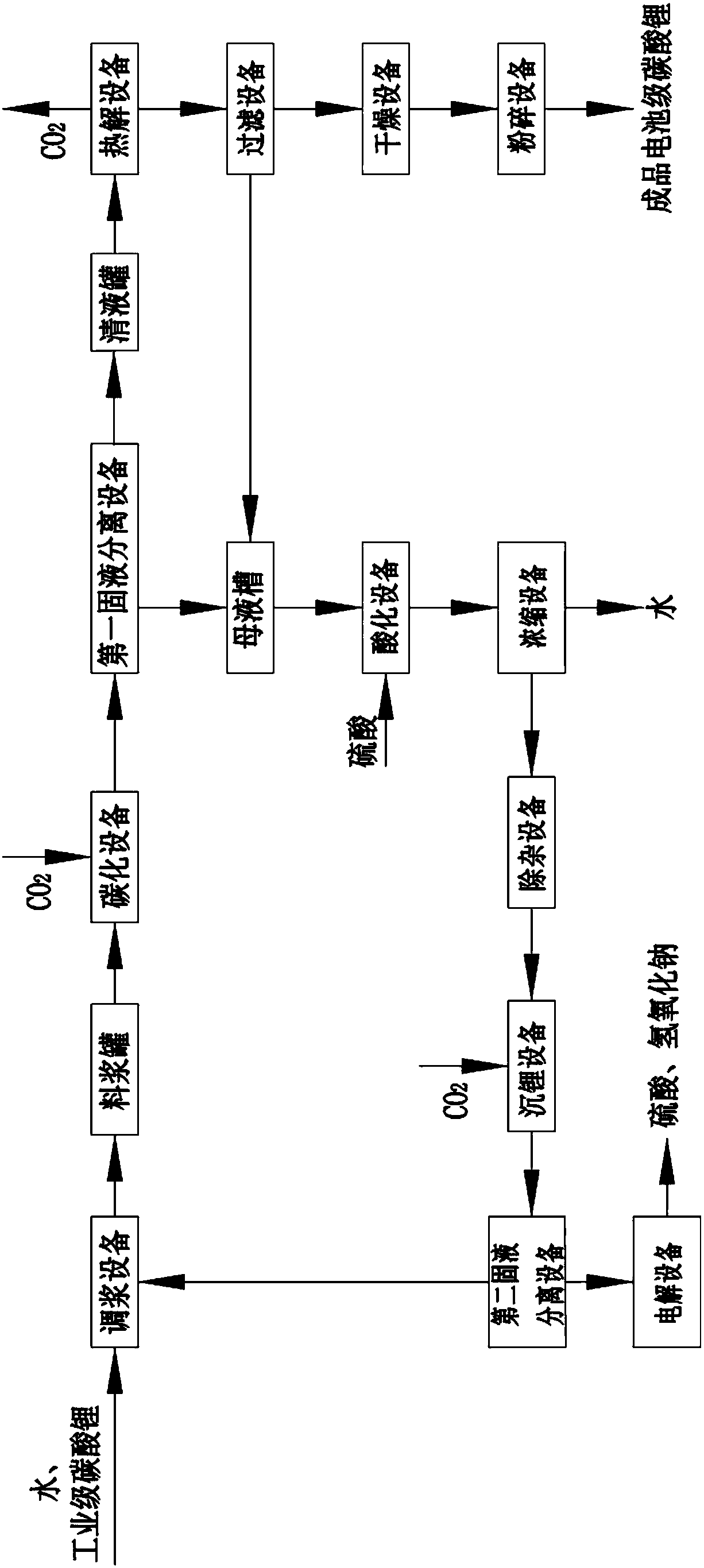

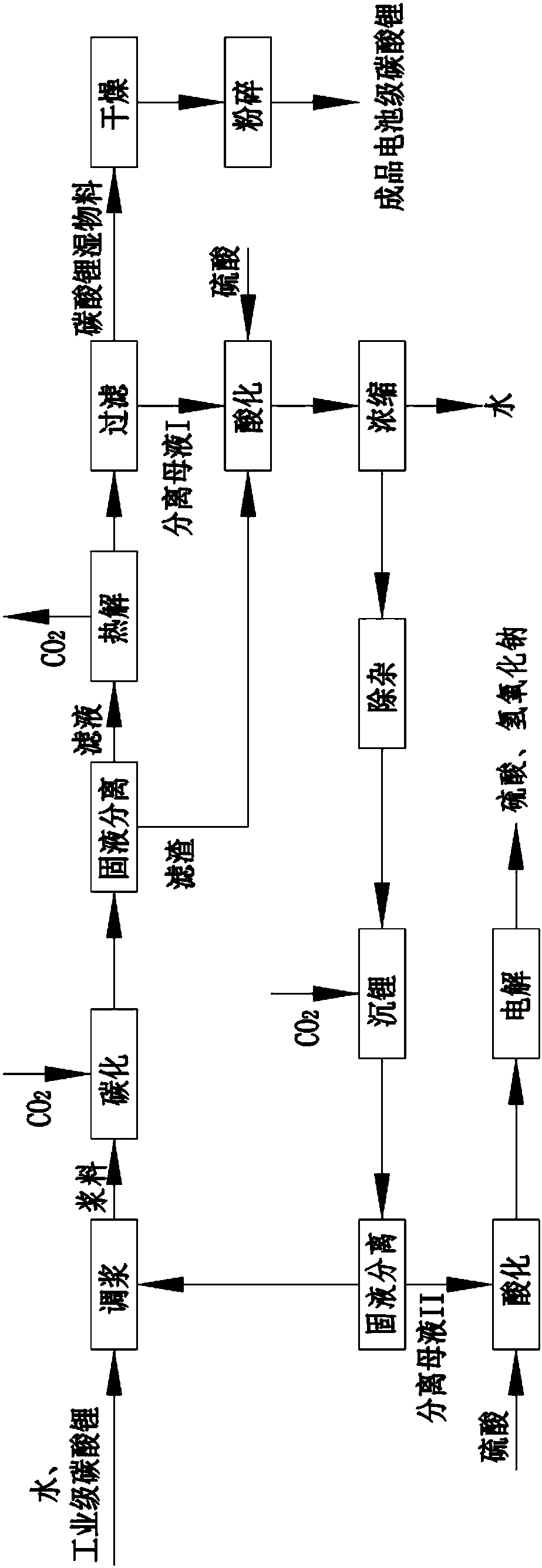

[0052] Such as figure 1 As shown, the system for preparing battery-grade lithium carbonate in this embodiment includes pulping equipment, carbonization equipment, pyrolysis equipment, filtration equipment, acidification equipment, concentration equipment, impurity removal equipment, lithium sinking equipment and electrolysis equipment;

[0053]The slurry mixing equipment, the carbonization equipment, the pyrolysis equipment and the filtering equipment are connected in sequence to perform slurry mixing, carbonization, pyrolysis and filtration respectively, and the slurry mixing equipment is provided with a raw material inlet; the carbonization equipment After passing through the first solid-liquid separation equipment, it is respectively connected with the pyrolysis equipment and the acidification equipment for pyrolysis and acidification, and the carbonization equipment performs solid-liquid separation through the first solid-liquid separation equipment; Acidification equipmen...

Embodiment 2

[0060] Such as figure 1 Shown, the system for preparing battery-grade lithium carbonate of the present embodiment, on the basis of embodiment 1,

[0061] The slurry mixing equipment is a slurry mixing tank, the carbonization equipment is a carbonization tower, and a slurry tank is arranged between the slurry mixing tank and the carbonization tower; the first solid-liquid separation equipment is a centrifuge; the pyrolysis equipment is Decomposition tower, a clear liquid tank is provided between the first solid-liquid separation equipment and the pyrolysis equipment; the filtration equipment is an ultrafiltration membrane machine or a reverse osmosis membrane machine, and the filtration equipment passes through drying equipment and crushing equipment The lithium carbonate wet material produced by the filter equipment can be dried and pulverized to produce the finished battery grade lithium carbonate.

[0062] In this embodiment, a slurry tank is provided between the slurry tan...

Embodiment 3

[0064] Such as figure 1 As shown, the system for preparing battery-grade lithium carbonate of the present embodiment, on the basis of embodiment 1 or 2, the drying equipment is a disc dryer or a belt dryer, and the pulverizing equipment is a jet mill or a hammer The grinding process of these two machines does not require any solid grinding media, which can ensure the purity of lithium carbonate. Among them, the jet mill can automatically classify lithium carbonate solid particles, so that the particle size of lithium carbonate solid particles is relatively uniform; The filtration equipment and the first solid-liquid separation equipment are connected to the acidification equipment through a mother liquor tank; The concentration equipment is a combination of ultrafiltration membrane machine and reverse osmosis membrane machine. The principle is to use ultrafiltration membrane machine to remove macromolecular impurities first, and then use reverse osmosis membrane machine to pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com