Battery-grade lithium carbonate preparation method

A lithium carbonate, battery-grade technology, applied in the direction of lithium carbonate;/acid carbonate, etc., to achieve the effect of easy industrial production, short process flow and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

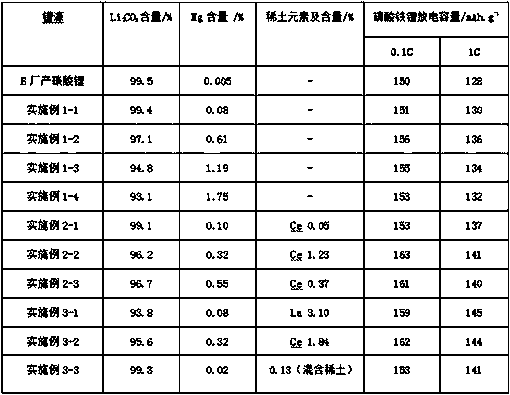

[0030] Example 1 (including Example 1-1, 1-2, 1-3, 1-4)

[0031] with 1 # Lithium sulfate purification solution was used as raw material to prepare battery-grade lithium carbonate with Mg contents of 0.08%, 0.61%, 1.19%, and 1.74%, respectively. In this example, lithium carbonate is synthesized by adding lithium sulfate purification solution to soda ash solution.

Embodiment 1-1

[0033] Take Na 2 CO 3 Solution 0.73L (wherein, Na 2 CO 3 content of 298g / L, Mg content of 20mg / L, Ca content of 3mg / L; Na 2 CO 3 The dosage is 1.17 times of the stoichiometric amount, dissolved with 0.09g EDTA, 0.25g polyethylene glycol), added to the reaction kettle, and heated to 80°C; 1 # Add 1.5L of lithium sulfate purification solution into the reactor, the solution temperature is 20°C, add 0.36g of magnesium sulfate (containing 35mg of Mg), stir and dissolve. Then add the lithium sulfate purification solution to Na under stirring condition 2 CO 3 solution. After adding the lithium sulfate purification solution, raise the temperature to 85°C, continue to stir and react for 60 minutes, filter, and then fully wash the filter cake with 900mL of pure water at a temperature of 85°C, and then place the obtained lithium carbonate filter cake (containing 15% attached water) in Dry at 200°C to obtain 101.6g of battery-grade lithium carbonate product.

[0034] Li of the pr...

Embodiment 1-2

[0037] Take Na 2 CO 3 Solution 0.76L (wherein, Na 2 CO 3 content of 298g / L, Mg content of 20mg / L, Ca content of 3mg / L; Na 2 CO 3 The dosage is 1.20 times of the stoichiometric amount, dissolved with 0.13g EDTA, 0.30g polyethylene glycol), added to the reaction kettle, and heated to 90°C; 1 # Add 1.5L of lithium sulfate purification solution into the reactor, raise the temperature to 40°C, add 6.3g of magnesium sulfate (containing 0.61g of Mg), and stir to dissolve. Then add the lithium sulfate purification solution to Na under stirring condition 2 CO 3 solution. After adding the lithium sulfate purification solution, raise the temperature to 90°C, continue to stir and react for 50 minutes, filter, then fully wash the filter cake with 980mL of pure water at a temperature of 90°C, and then place the obtained lithium carbonate filter cake (containing 14% attached water) in Dry at 150°C to obtain 105.2g of battery-grade lithium carbonate product.

[0038] Li of the produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com