A kind of inorganic flame-retardant straw fiberboard for furniture and production method thereof

A technology of straw fiber and inorganic flame retardant, which is applied in the field of inorganic flame retardant straw fiber board for furniture and its production field, can solve the problems of restricting the production and application of fiber board, easy to wear mechanical processing performance, disordered surface texture of fiber board, etc., and achieves high production efficiency. , the effect of improving machinability, improving overall strength and machinability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

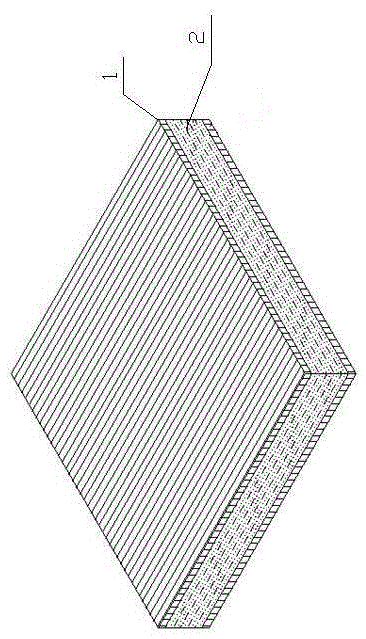

[0023] Embodiment 1, with reference to figure 1 , an inorganic flame-retardant straw fiber board for furniture, comprising a straw fiber core board 2, a bamboo veneer 1 is laid on the inner and outer surfaces of the straw fiber core board 2, and the bamboo veneer 1 is bonded with the straw fiber through an inorganic flame-retardant adhesive material layer. The core board 2 is bonded, and the straw fiber core board 2 is a plate-shaped material made of straw fiber and an inorganic flame-retardant adhesive.

Embodiment 2

[0024] Example 2, in the inorganic flame-retardant straw fiberboard for furniture described in Example 1: the thickness of the straw fiber core board 2 is 3mm, the thickness of the bamboo veneer 1 is 3mm, and the thickness of the straw fiberboard is 9mm .

Embodiment 3

[0025] Example 3, in the inorganic flame-retardant straw fiberboard for furniture described in Example 1: the thickness of the straw fiber core board 2 is 18mm, the thickness of the bamboo veneer 1 is 5mm, and the thickness of the straw fiberboard is 28mm .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com