Battery-grade lithium carbonate preparation method based on phase transformation

A technology of phase transformation and lithium carbonate, which is applied in the direction of lithium carbonate;/acid carbonate, etc., can solve the problems of inability to process heterogeneous lithium carbonate raw materials, restricting the development of large-scale technology industries, and requiring high purity of raw materials, etc. , to achieve the effect of ensuring high purity and quality, fast speed and slow speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

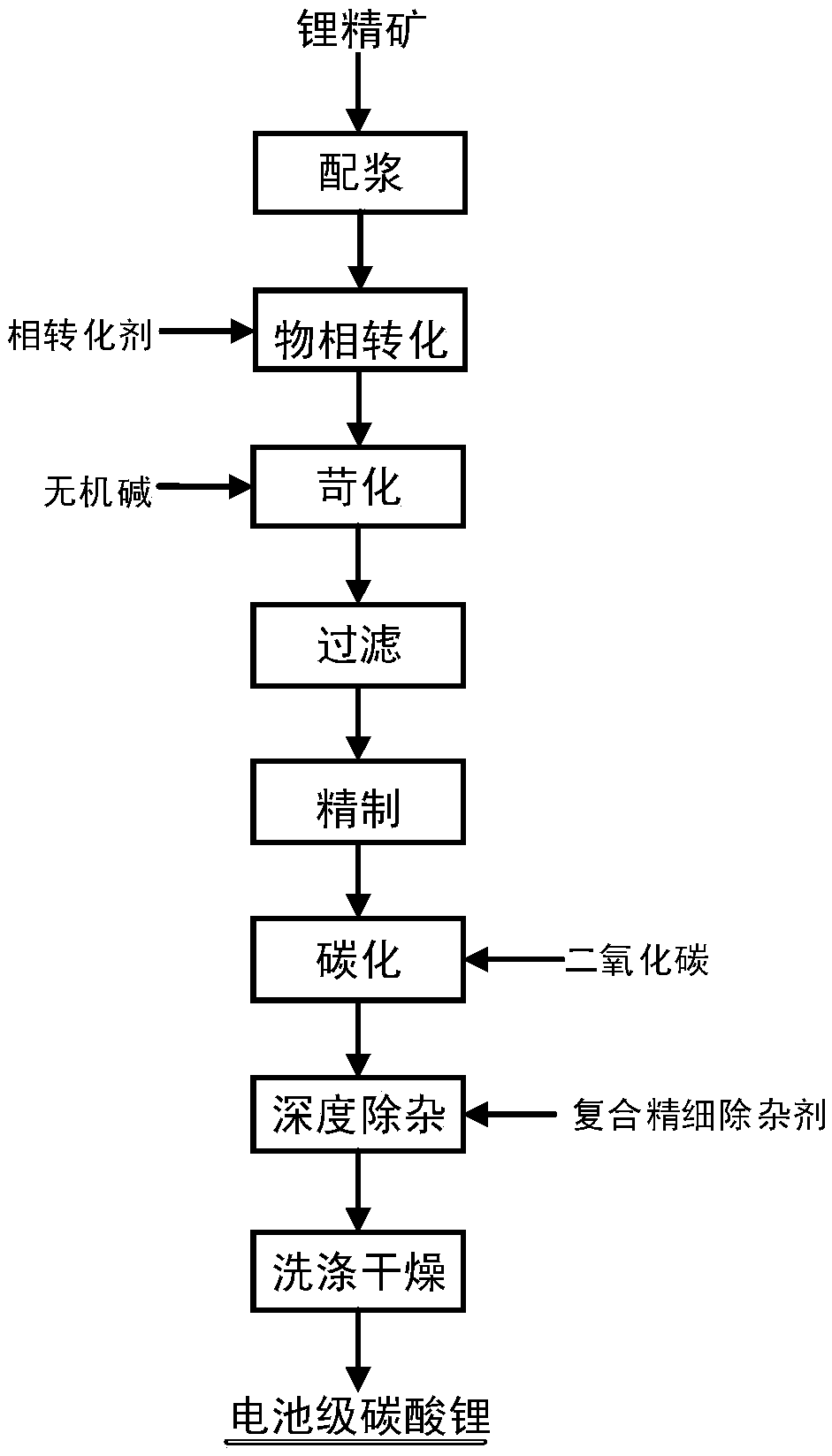

[0030] The invention provides a method for preparing battery-grade lithium carbonate based on phase transformation. The method uses heterogeneous lithium carbonate as a raw material, and uses water washing-phase transformation-causticization-carbonization-fine impurity removal method to prepare battery-grade lithium carbonate. Specific steps are as follows:

[0031] 1) Phase transformation: the lithium concentrate with a lithium carbonate content of 50-95wt% is mixed with water to make a 10-50wt% slurry, and then a phase transformation agent is added to control the mol ratio of lithium carbonate and the phase transformation agent to be 1: 1-5, stir (50-500 rpm) at 10-100°C for 0.5-5 hours, filter to obtain the lithium content (in the form of Li 2 O meter) 2.0-6.0wt% high-concentration lithium salt solution;

[0032] 2) Causticization: mix the lithium salt solution and the inorganic base in a molar ratio of 1:1-4, stir at 10-100°C (50-500 rpm) and react for 0.5-5 hours, filter...

Embodiment 1

[0039] Weigh 100 grams of lithium concentrate with a lithium carbonate content of 50wt%, mix it with water to make a 15wt% slurry, then add hydrochloric acid, control the molar ratio of lithium carbonate to hydrochloric acid to be 1:1, and stir (500 rpm) at 10°C for reaction 0.5 hour, filter, obtain lithium content (with Li 2 O meter) 2.0wt% lithium salt solution; Lithium salt solution and sodium hydroxide were mixed in a molar ratio of 1:1, stirred at 10°C (500 rpm) and reacted for 5 hours, filtered to obtain lithium content (in Li 2 (O) 2.0wt% causticizing solution; the causticizing solution is continuously passed through an ion exchange column filled with equal amounts of styrene cation exchange resin D-61 and acrylic acid cation resin D113 to obtain a refined causticizing solution; 40 liters of causticizing solution at the standard (0°C, 1 atm) carbon dioxide ratio, feed carbon dioxide into the refined causticizing solution, stir at 60°C (50 rpm) and react for 0.5 hours, s...

Embodiment 2

[0041] Weigh 100 grams of lithium concentrate with a lithium carbonate content of 95wt%, mix it with water to make a 50wt% slurry, then add sulfuric acid, control the molar ratio of lithium carbonate to sulfuric acid to be 1:3, and stir (50 rpm) at 100°C for reaction 5 hours, filter, obtain lithium content (with Li 2 O meter) 5.0wt% lithium salt solution; Lithium salt solution and potassium hydroxide were mixed in a molar ratio of 1:4, stirred at 100°C (50 rpm) and reacted for 0.5 hour, filtered to obtain lithium content (in Li 2 O meter) 5.0wt% causticizing solution; The causticizing solution is continuously passed through the ion exchange column filled with styrene cation exchange resin 734, D001 and quaternary ammonium type cation resin D254 (three weight ratios 10:2:1), Obtain refined causticizing solution; according to the ratio of 200 liters of standard (0°C, 1 atm) carbon dioxide per liter of refined causticizing solution, feed carbon dioxide into the refined causticizi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com