Patents

Literature

169results about How to "Low raw material requirement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Super plastic forming method for plate type heat converter special titanium plate

InactiveCN101121178AHigh yield strengthEasy to processRoll mill control devicesFurnace typesPlate heat exchangerTitanium

The present invention relates to a superplastic forming method for the titanium plate specially used for the plate type heat exchanger, which belongs to the field of mechanical processing technology. The present invention comprises the following steps that spongy titanium is chosen to be the melted raw material; the spongy titanium is placed in a vacuum plasma smelting furnace to be directly cast into plate base; the plate base forms a plate of a thickness of 2.0 to 2.4 mm after the process of heating, hot rolling, acid and alkali washing; second heating, hot rolling and acid and alkali washing and annealing; the plate of a thickness of 2.0 to 2.4 mm after the annealing in the vacuum smelting furnace forms a titanium plate of a thickness of 0.5 to 0.6 mm after the process of cold rolling, cleaning, second annealing and cold rolling, acid and alkali washing and third annealing. The present invention adopts the process that the spongy titanium which contains oxygen, iron and nitrogen of comparatively high content is directly processed into the titanium plate base in the plasma smelting furnace and directly rolled into the plate without forging and pressing.

Owner:上海桦厦实业有限公司

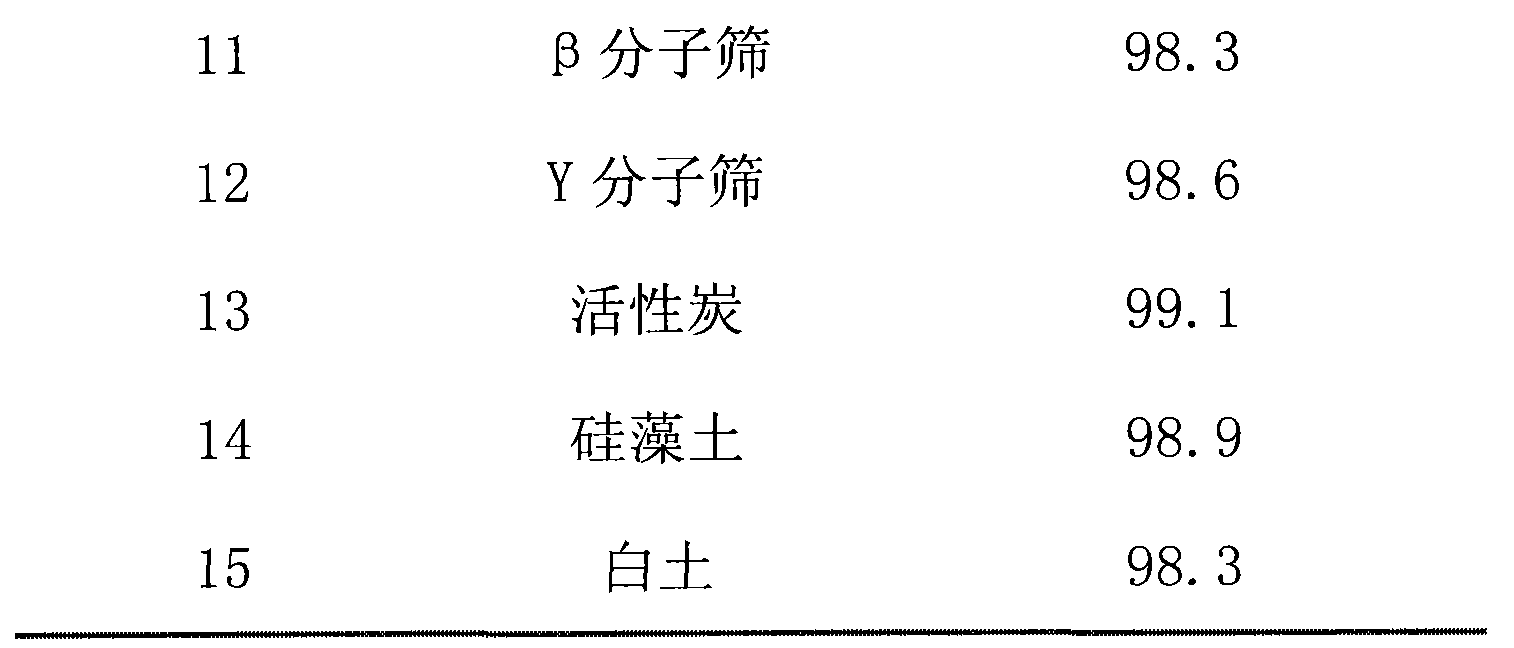

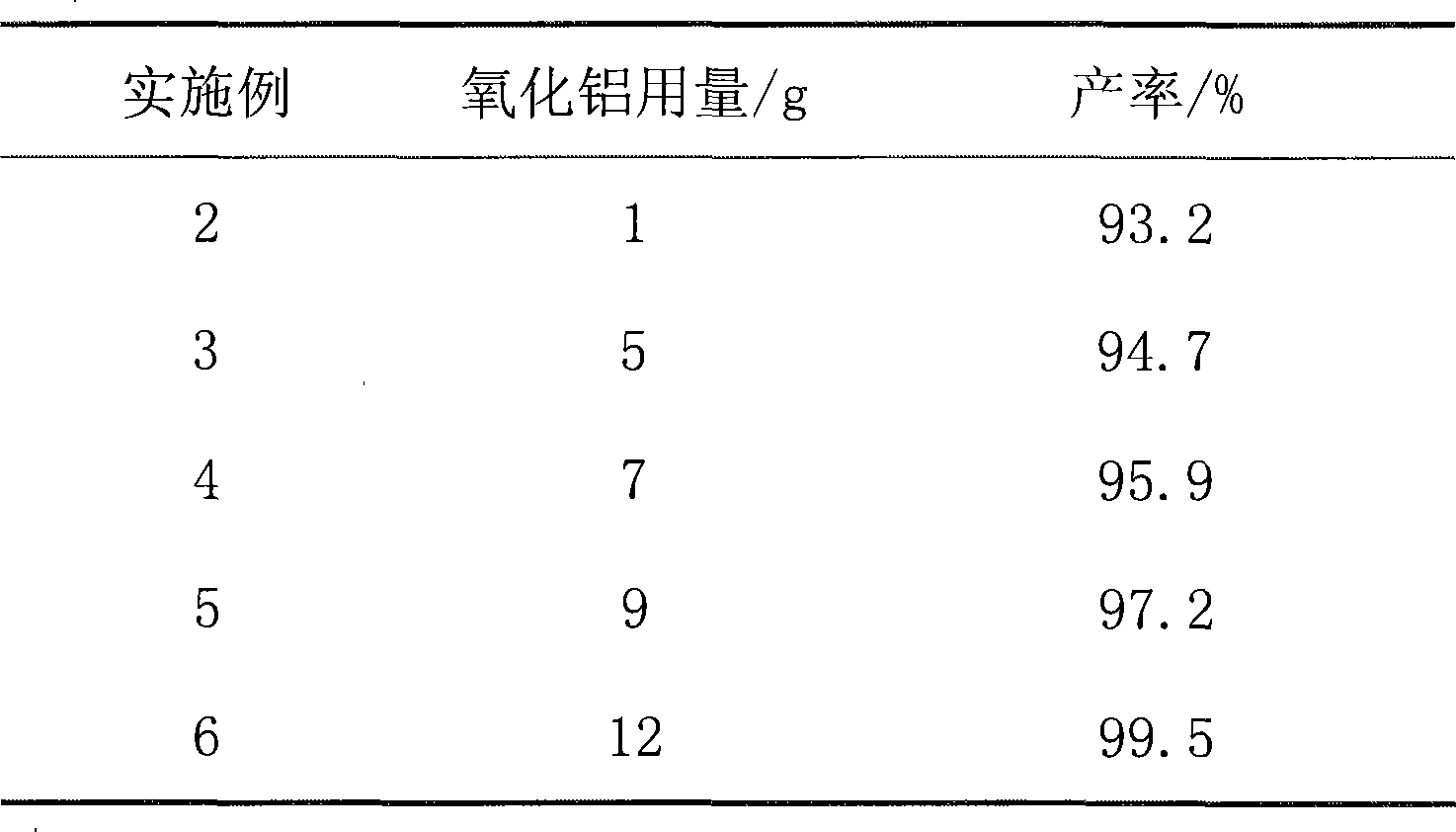

Novel solid body base catalyst and applications for biological diesel oil synthesizing

InactiveCN101249449AEasy to makeReduce energy consumptionMolecular sieve catalystsBiofuelsOil and greaseActivated carbon

The invention discloses a novel solid base catalyst and application thereof in the preparation of biodiesel oil. The catalyst is prepared by loading potassium fluoride as an active component on carriers; and calcining at a high temperature. The carrier is alumina, activated carbon or diatomite. The biodiesel oil is prepared by transesterification including adding oil and fat, low carbon alcohol and the solid base catalyst into a three-neck container; refluxing under heating and stirring; filtering to remove the catalyst; demixing the filtrate; separating glycerol at the lower layer, adding NaHCO3 solution into the mixture at the upper layer; washing until a neutral condition; drying with anhydrous MgSO4; and reduced pressure distilling. The application of the catalyst in the preparation of biodiesel oil has the advantages of high yield, cheap catalyst, small catalyst consumption, mild reaction conditions, short reaction time, reutilization of catalyst, environment friendliness and low requirement to raw material.

Owner:EAST CHINA NORMAL UNIV

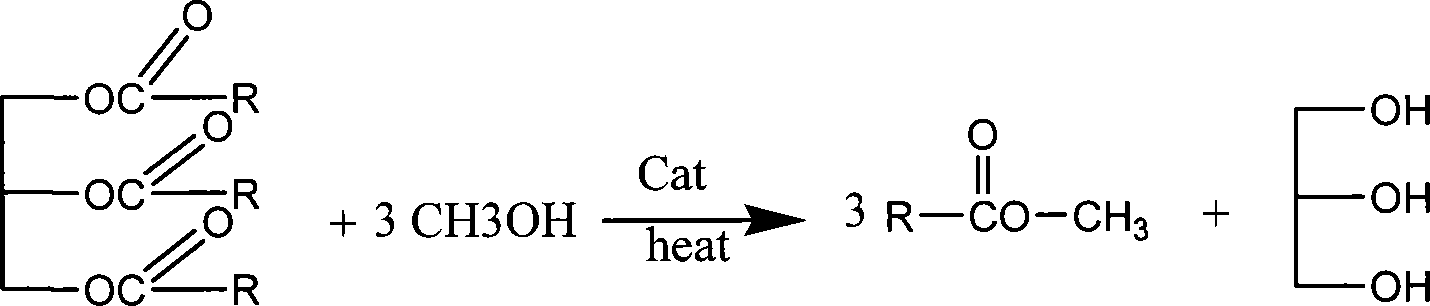

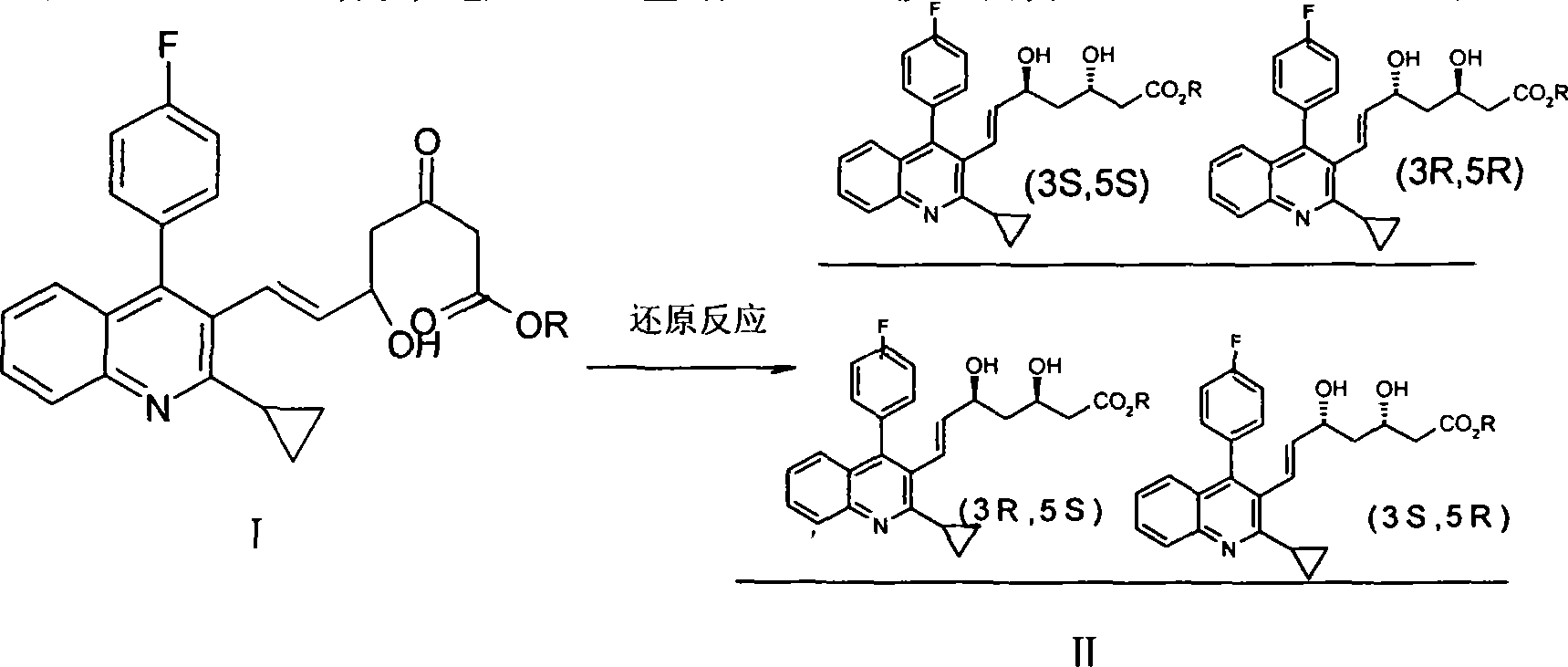

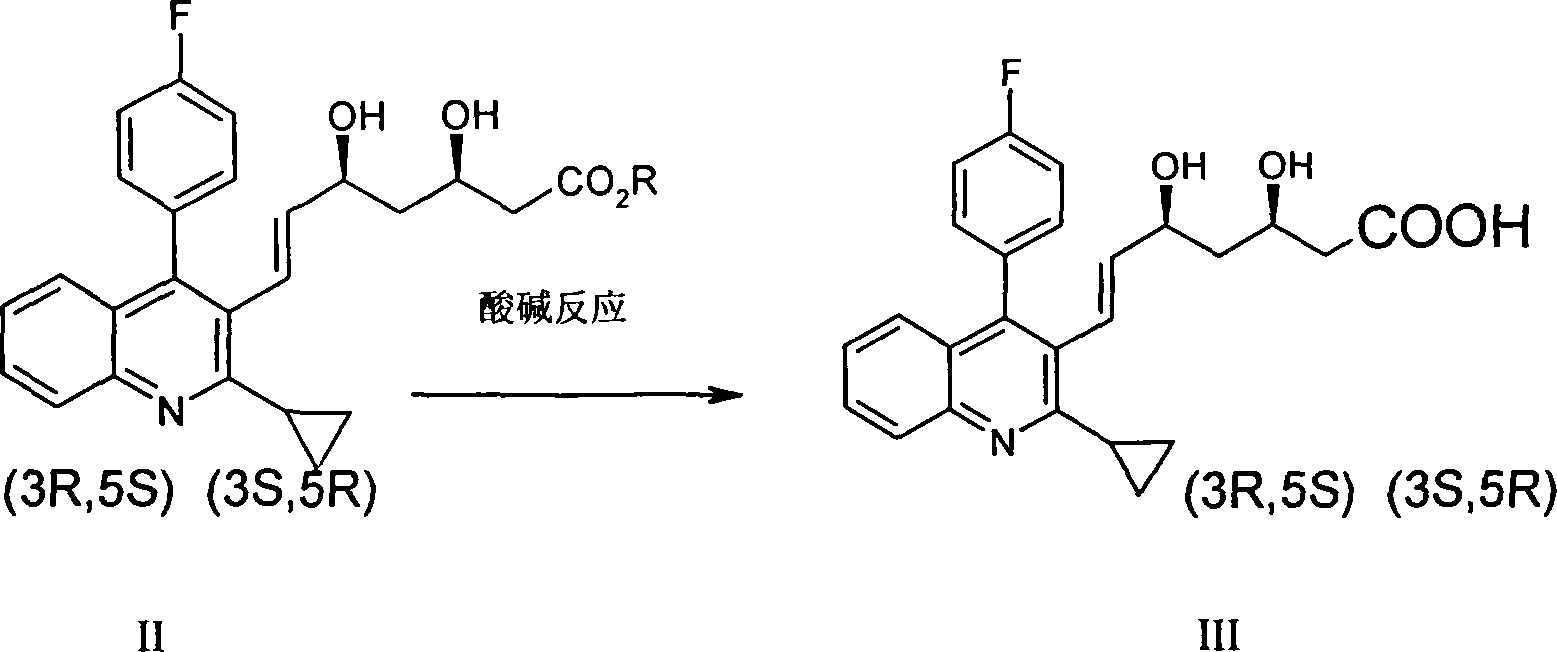

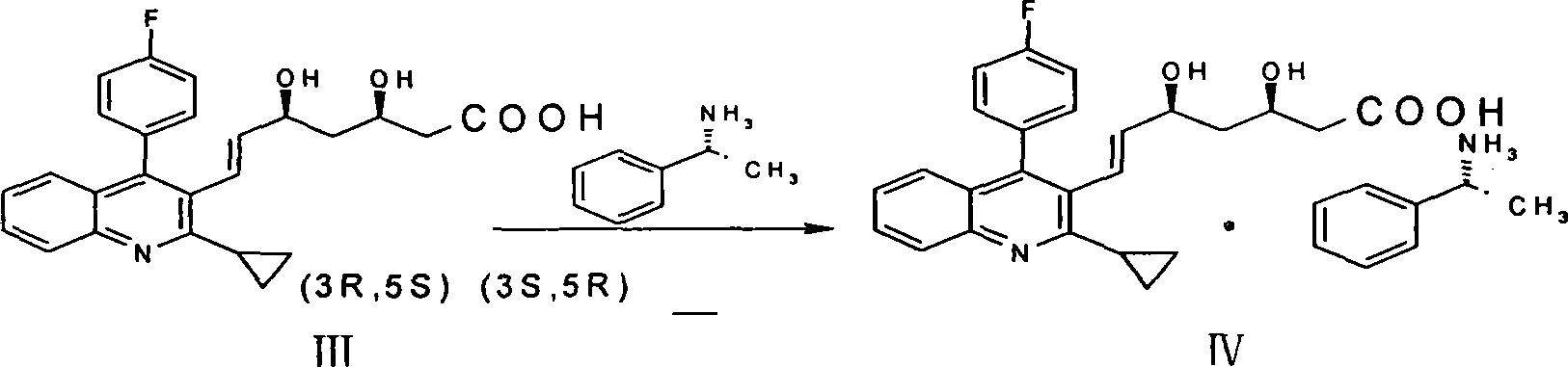

Method for producing pitavastatin calcium raw material

InactiveCN101219991ASimple preparation processLow raw material requirementOrganic chemistryChemistryCarbonyl group

The invention relates to a method for preparing the raw materials of pitavastatin calcium, which uses an (E)-7-[2-cyclopropyl-4-(4-fluorophenyl)-3-quinolyl]-5-hydroxyl-3- carbonyl-6-heptene acid ester as a beginning raw material to generate a heptenoic acid through being reduced and reacted by adding an alkali and an acid; a D-(+) benzyl methylamine is added to generate a mixture of a benzyl methylamine salt, and crystallize to separate out a (3R, 5S)-dihydroxy-7-[2-cyclopropyl-4-(4-fluorophenyl)-3-quinolyl]-6- heptenoic acid D-(+) benzyl methylamine through the different solubility of the mixtures in a separating agent, and the separating agent is a mixed liquid of a methyl isobutyl ketone and an acetone or an ethanol; finally adds lye to hydrolyze and prepare the pitavastatin calcium salt. The method of the invention is selectively reduced to a pair of isomers by using a determined reduction agent, generates salt by reacting with the D-(+) benzyl methylamine and effectively separates a needed isomer by utilizing the different solubility of various isomers to the separating agent. The invention has the advantages of simple preparing technique, low requirements for the raw materials and high conversion rate of the obtained products.

Owner:JIANGSU WANBANG BIOPHARMLS

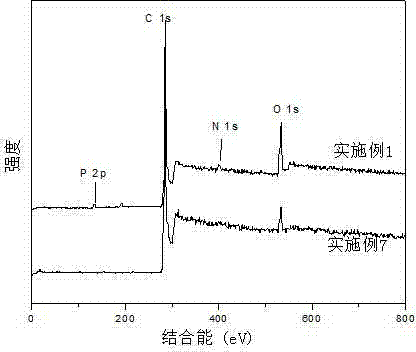

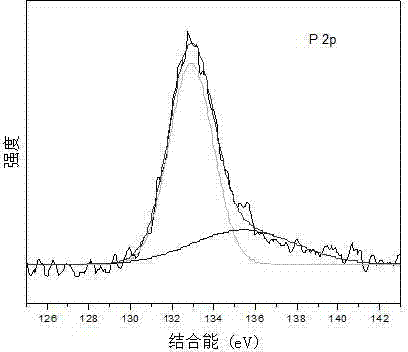

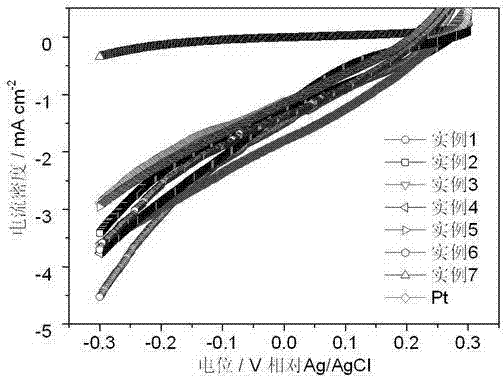

Preparation method and application of nitrogen and phosphorus codoped carbon oxygen reduction catalyst for microbial fuel cell

InactiveCN103794803ALow raw material requirementSimple preparation processCell electrodesCelluloseFiltration

The invention discloses a preparation method and application of a nitrogen and phosphorus codoped carbon oxygen reduction catalyst for a microbial fuel cell. The preparation method comprises the following steps: soaking cellulose by an ammonium phosphate compound brine solution, carrying out suction filtration, drying, and carbonizing under the protection of high-purity nitrogen, thereby obtaining nitrogen and phosphorus codoped carbon which serves as a cathode catalyst of the microbial fuel cell. The preparation method provided by the invention has the advantages that the catalyst is prepared by taking natural cellulose which is recyclable and is wide in source as a carbon source and taking cheap and nontoxic ammonium phosphate compound salt as a nitrogen source and a phosphorus source via a direct carbonization method, and can greatly improve the output power of the cell as the catalyst of the microbial fuel cell; the method is simple in preparation, is low in cost, and provides possibility for the scale production of the microbial fuel cells.

Owner:JIANGXI NORMAL UNIV

New process for preparing modified melamine polyphosphate

The invention discloses a new process for preparing modified melamine polyphosphate, which comprises the following steps: (1) adding water, phosphoric acid and a modifier into a reaction kettle, and heating to 20-70 DEG C; (2) adding melamine, heating to 90-100 DEG C, and reacting for 2-5 hours; (3) cooling the product obtained after the reaction in the step (2), filtering, and drying; and (4) carrying out polymerization reaction on the product, which is subjected to the step (3), at 300-450 DEG C for 10-120 minutes. The synthesis and modification of the melamine polyphosphate are carried out synchronously, so that the invention has the advantages of short reaction time, low requirements for raw materials, simple and convenient technical operation, and low environmental pollution; the prepared melamine polyphosphate has the advantages of favorable compatibility with resin, low solubility in water, and excellent thermal stability, and the temperature can reach about 360 DEG C when the weight loss is 2%, so that the modified melamine polyphosphate can satisfy the processing requirements of no halogen and flame retardancy for glass fiber reinforced nylon and polyester.

Owner:ZHEJIANG RES INST OF CHEM IND CO LTD +2

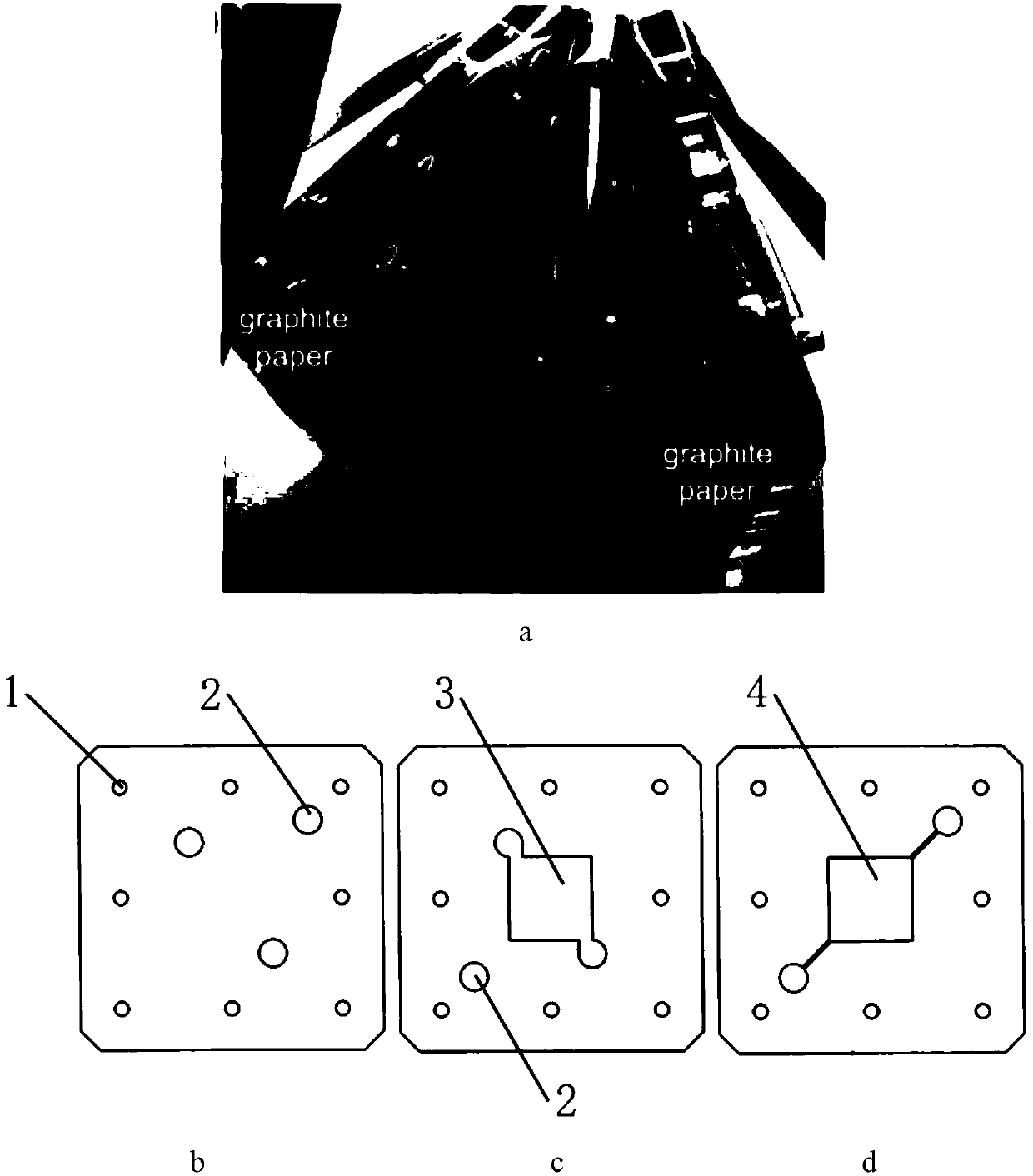

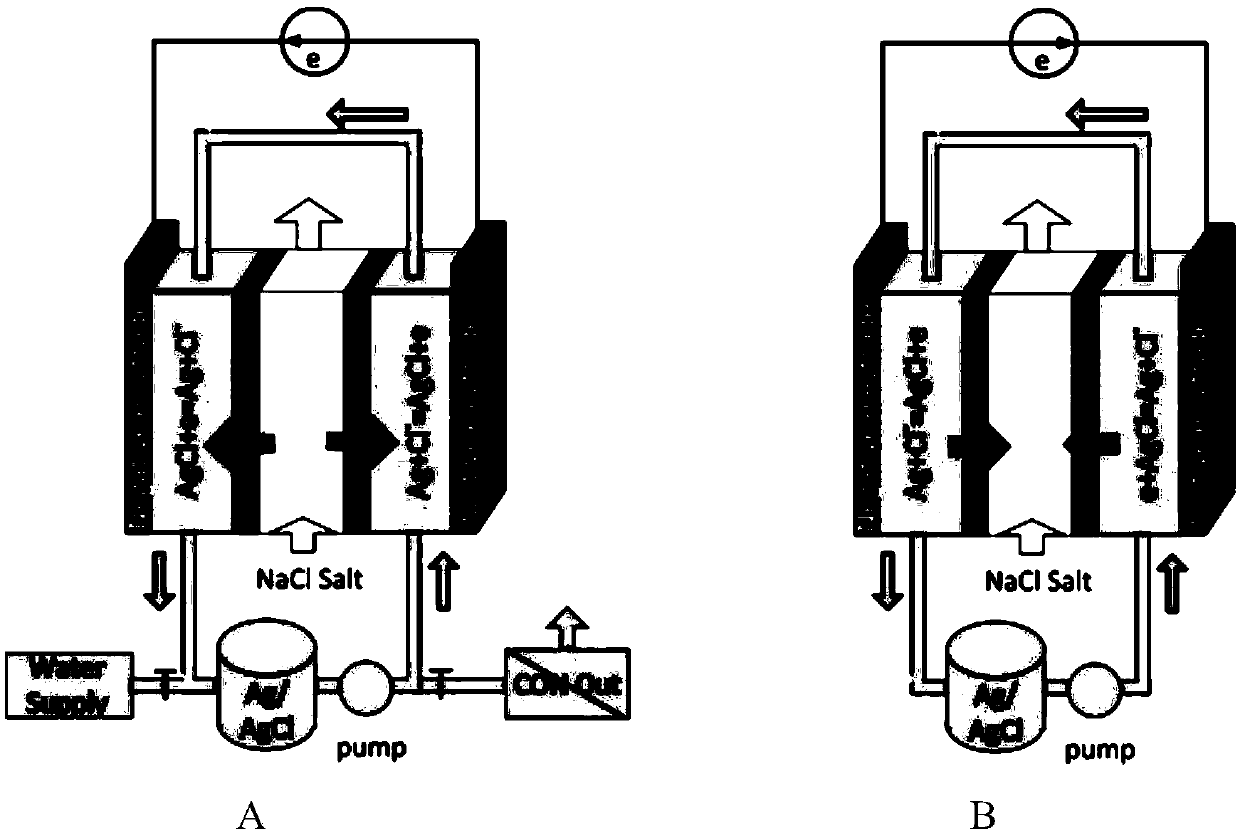

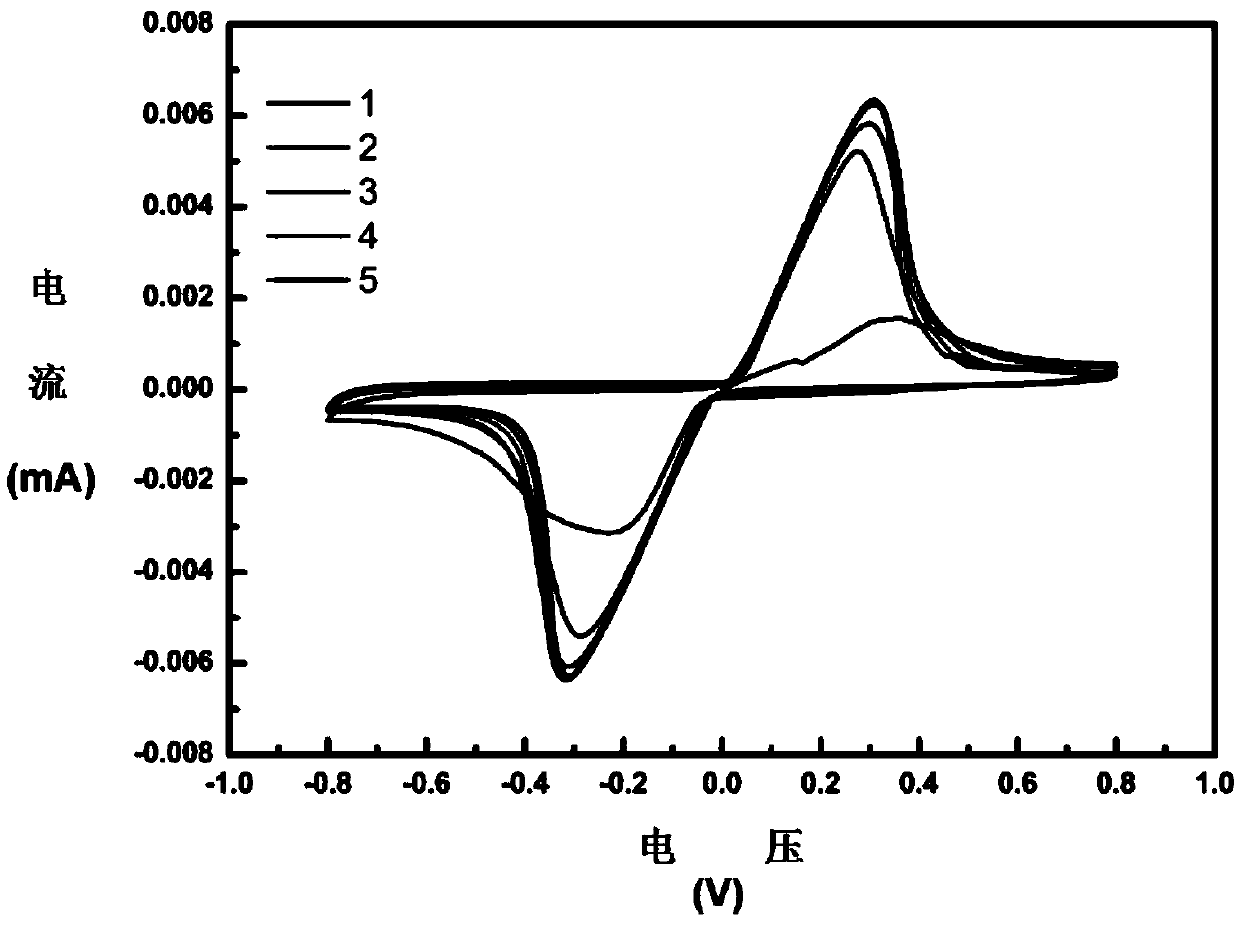

Method for performing continuous low-energy-consumption salt removal by utilizing flow battery redox reaction as well as application thereof

ActiveCN108675404AEvenly dispersedHigh specific capacitySeawater treatmentWater/sewage treatmentElectrical batteryEnvironmental engineering

The invention discloses Method for performing continuous low-energy-consumption salt removal by utilizing flow battery redox reaction as well as application thereof. The method comprises the step of removing salt through a salt-removing flow battery device, wherein the salt-removing flow battery device takes positive and negative electrode active flow materials as the positive and negative electrodes of the flow battery as well as takes a salt solution as electrolyte of the flow battery; and the salt-removing flow battery device also comprises an isolating device for isolating the salt solution from the positive and negative electrode active flow materials as well as also comprises an anion exchange membrane and a cation exchange membrane. The salt-removing flow battery device is low in flow electrode salt-removing work voltage, extremely low in energy consumption, high in specific capacity and high in cycle performance, and the positive and negative electrode materials can be reused,so that the true salt-removing aim can be achieved. The method provided by the invention is low in low energy consumption, can continuously perform electrochemical redox reaction and environment-friendly novel seawater desalination technology, and can be used for solving the problem of insufficient supply of fresh water resources.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Preparation method of three-dimensional micrometer level porous copper thin film

InactiveCN103132111AUniform pore size distributionWide range of aperture adjustmentElectroforming processesPorosityMicrometer

A preparation method of a three-dimensional micrometer level porous copper thin film comprises: a metal substrate is offered and serves as a negative electrode and a red copper sheet is offered and serves as a positive electrode; electroplating liquid is prepared, the content of Cu2+ in the electroplating liquid is 0.08mol / L to 0.2mol / L, the content of H2SO4 is 1.50mol / L to 3.00mol / L, the total content of a surface active agent is 0.5 mmol / L to 4.0mmol / L and the content of Cl- is 1.5mmol / L to 3.0mmol / L; and the three-dimensional porous copper thin film is formed on the metal substrate by using the electroplating liquid, the negative electrode and the positive electrode and adoption of a hydrogen bubble dynamic formwork electrodeposition method. The three-dimensional micrometer level porous copper thin film manufactured through the preparation method is even and small in hole diameter and high in porosity.

Owner:CHONGQING UNIV

Method for extracting gold from cyanidation tailings

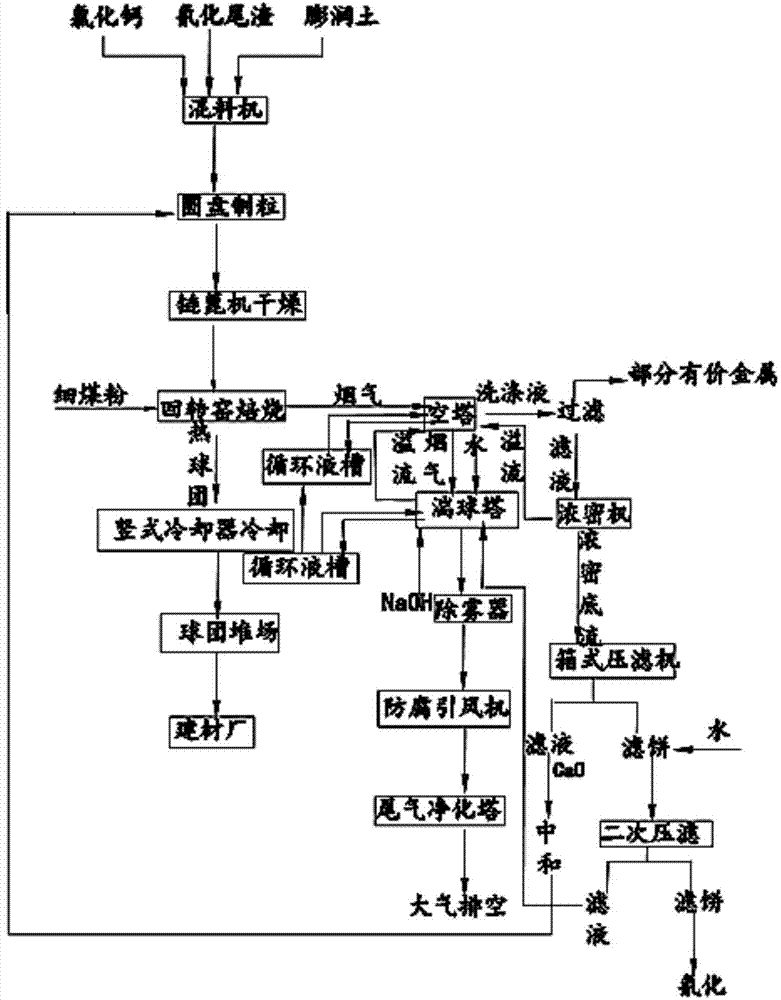

InactiveCN104726716AHigh recovery rateHigh strengthProcess efficiency improvementSodium BentoniteResource utilization

The invention belongs to the technical field of metallurgy, and particularly relates to a method for extracting gold from cyanidation tailings. The method comprises the following steps that the cyanidation tailings, bentonite and calcium chloride are proportionally mixed, pelletized, dried and roasted; metal gold and chlorine form a chemical compound; the chemical compound is volatilized in a form of smoke; the smoke is subjected to spray washing and concentrated by a thickener; ore pulp is subjected to filter pressing; an obtained filter cake is cyanidation leaching; and the gold is extracted. The method is simple in process, low in raw material requirement and high in gold recovery rate; the pellet strength is high; the phenomenon of rotary kiln accretion is avoided; the gold in the cyanidation tailings is recovered with lower production cost; in addition, 'zero waste emission' is realized in a whole production flow; environmental pollution is reduced; and a resource utilization rate is increased.

Owner:ZHAOJIN MINING +1

Foodstuff of pet dog and preparation method thereof

The invention provides food for a pet dog. The food is characterized in that the food mainly comprises the following raw materials by weight: 30 to 70 portions of edible meat or animal skin and 30 to 70 portions of puffed rice flour. The food which has cheap and easily obtained raw materials and high nutritive value can serve as the snack food for the pet dog for a long period. The invention also provides a preparation method for the food for the pet dog.

Owner:CHONGQING MAOYUAN IND

Separation process of natural free radical scavenger in Saxifraga tangutica and application of natural free radical scavenger

ActiveCN111187159ALow costHigh purityOrganic active ingredientsSugar derivativesPhysical chemistryFree radicals scavenger

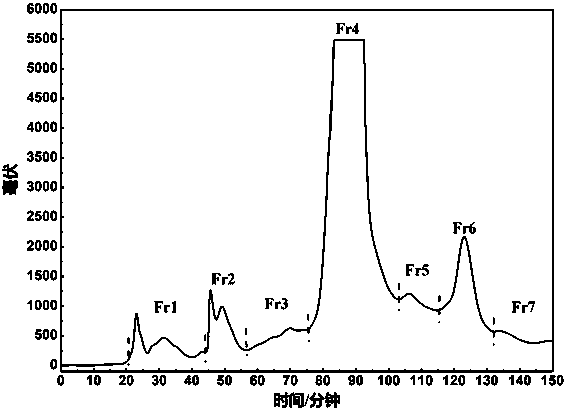

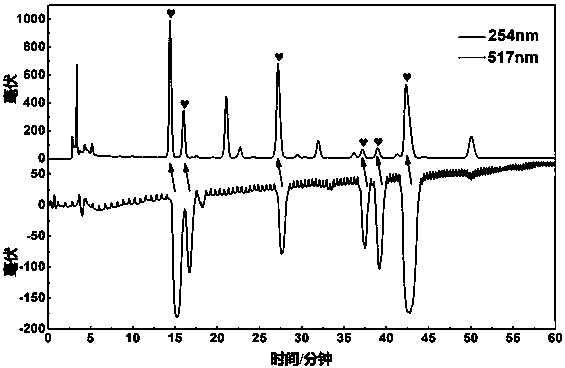

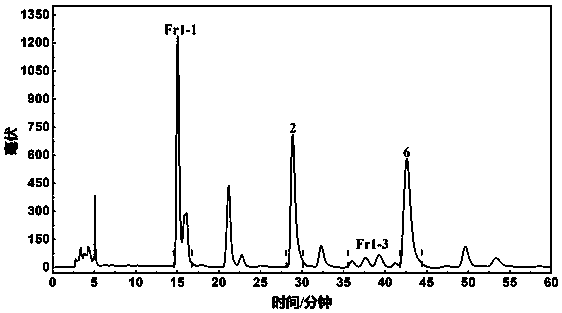

The invention relates to the technical field of separation of natural free radical scavengers in Saxifraga tangutica, in particular to a separation process of a natural free radical scavenger in Saxifraga tangutica and application of the natural free radical scavenger. The separation process comprises the following six steps: extraction, coarse separation via a microporous resin column, online free radical scavenger component screening, preparation via a reversed-phase preparative column, reversed-phase preparative liquid chromatographic purification of Fr1-1and hydrophilic / reversed-phase two-dimensional liquid chromatographic purification of Fr1-3. The method is low in cost, and product purity is greater than 95%; a technical means adopted by the invention can realize large-scale production: requirements on raw materials are not high, cost is low, and batch preparation is easy; room-temperature cold leaching extraction with methanol is adopted, so operation is easy; the microporous resin column is adopted for coarse separation, and a microporous resin separation material can be loaded in a medium-pressure column chromatography system, so large-scale production can be easily realized; and reversed-phase preparative liquid chromatography or hydrophilic preparative liquid chromatography used in separation and purification is a rapid isocratic method.

Owner:CHINA ACAD OF SCI NORTHWEST HIGHLAND BIOLOGY INST

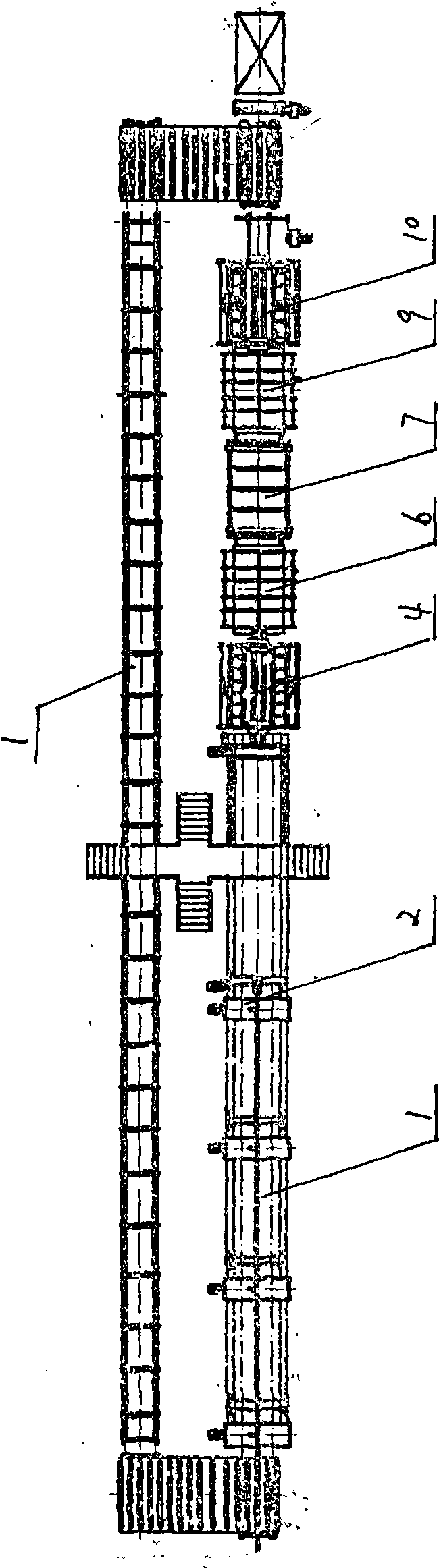

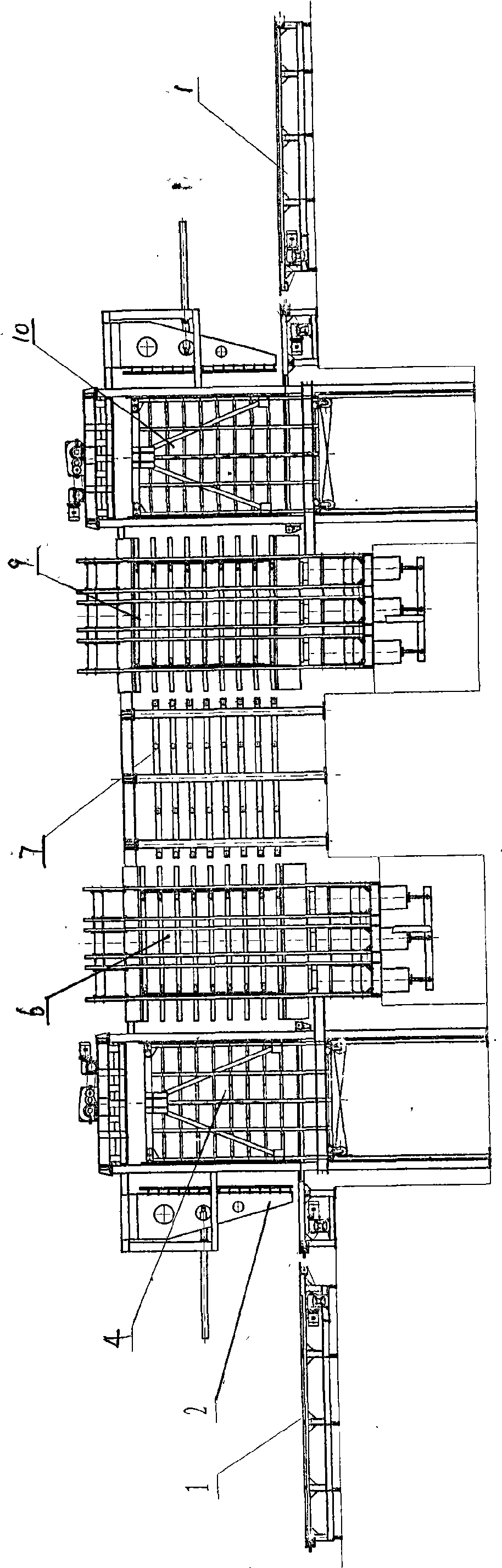

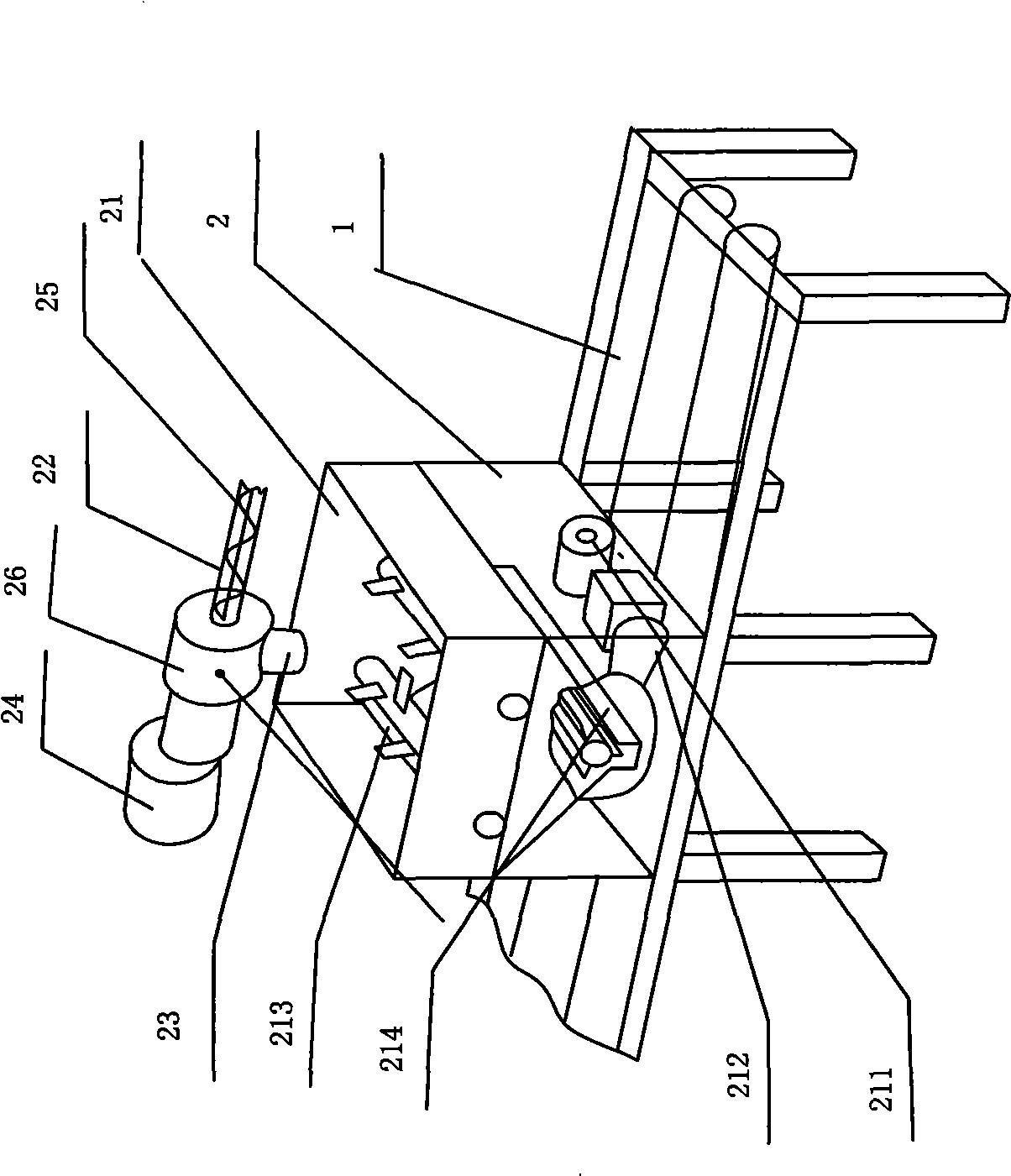

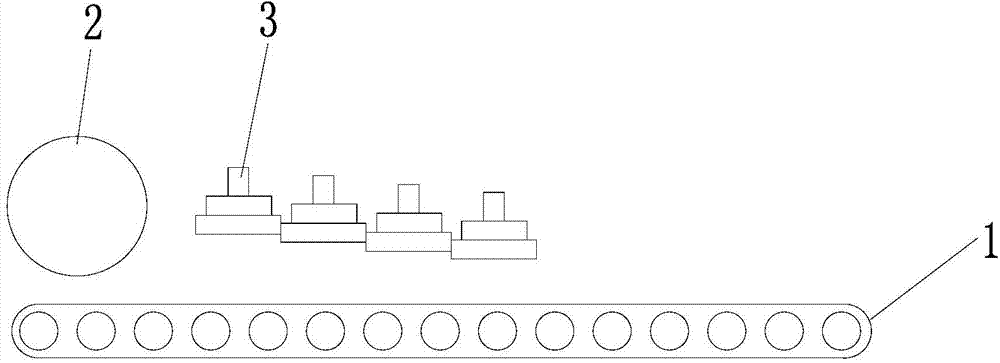

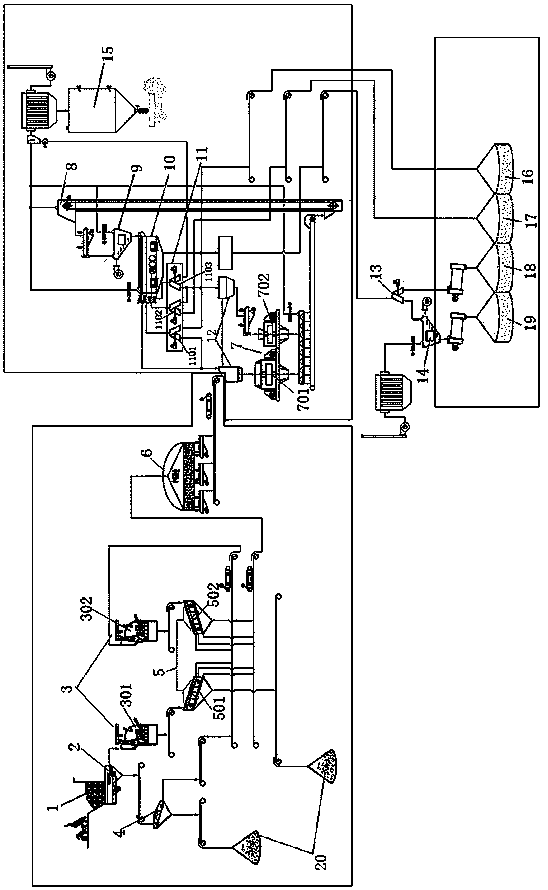

Production equipment for large-sized plastic-wood board

InactiveCN101531022ARealize automated productionIncrease productionWood working apparatusDomestic articlesPush and pullPush pull

The invention discloses production equipment for large-sized plastic-wood boards, which is characterized by consisting of a transmission device (1), a feeding device (2), a material heating device (3), a thermal pressure lifting device (4), a thermal pressure push-pull device (5), a hot press (6), a passing board lifter (7), a passing board push and pull machine(8), a cold press (9), an outgoing plate lifter (10), an outgoing plate push and pull machine(11), a separating device and an automatic cutting device (12), as well as realization of automatic production, high yield, an annual large-sized plastic-wood board production capacity of 8,000 to 20,000 cubic meters of a single set, stable product quality, realization of 1 to 30 layer production scale, customized product specifications ranging from 80*80*0.3to 350*350*6 centimeters according to requirements, low requirements on raw materials, low product cost, and wide application range.

Owner:杨孝干

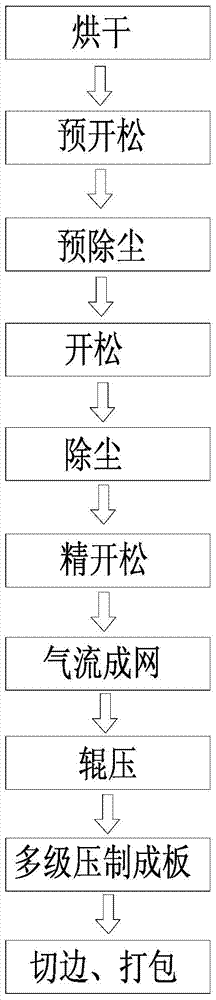

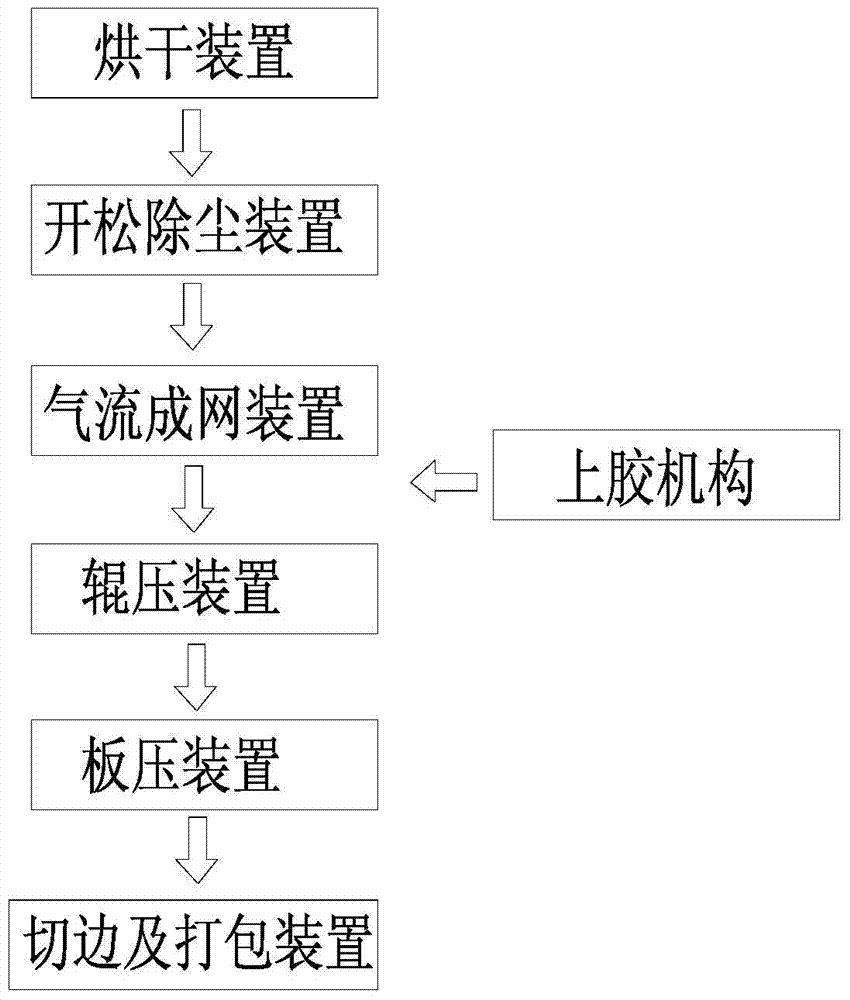

Method for manufacturing plates from waste fibers

The invention provides a method for manufacturing plates from waste fibers of waste filtering bags, waste textiles and the like. The method comprises the steps of drying, loosening, dedusting, air laying, rolling, multi-stage compressing to form plates, trimming and packaging. An air laying technology is selected, so that fibers are arranged in a fiber net without directivity, and the horizontal and longitudinal ratio of the plates is approximate to 1:1, and the method is suitable for various fibers with different lengths and wide varieties, requires less on raw materials, and is suitable for a wide range of fibers; compared with a scheme that the required thickness of plates is reached by laying for multiple layers in a traditional carding method, the air-laying can obtain the required thickness of plates by directly controlling the output speed.

Owner:福建鑫华股份有限公司 +2

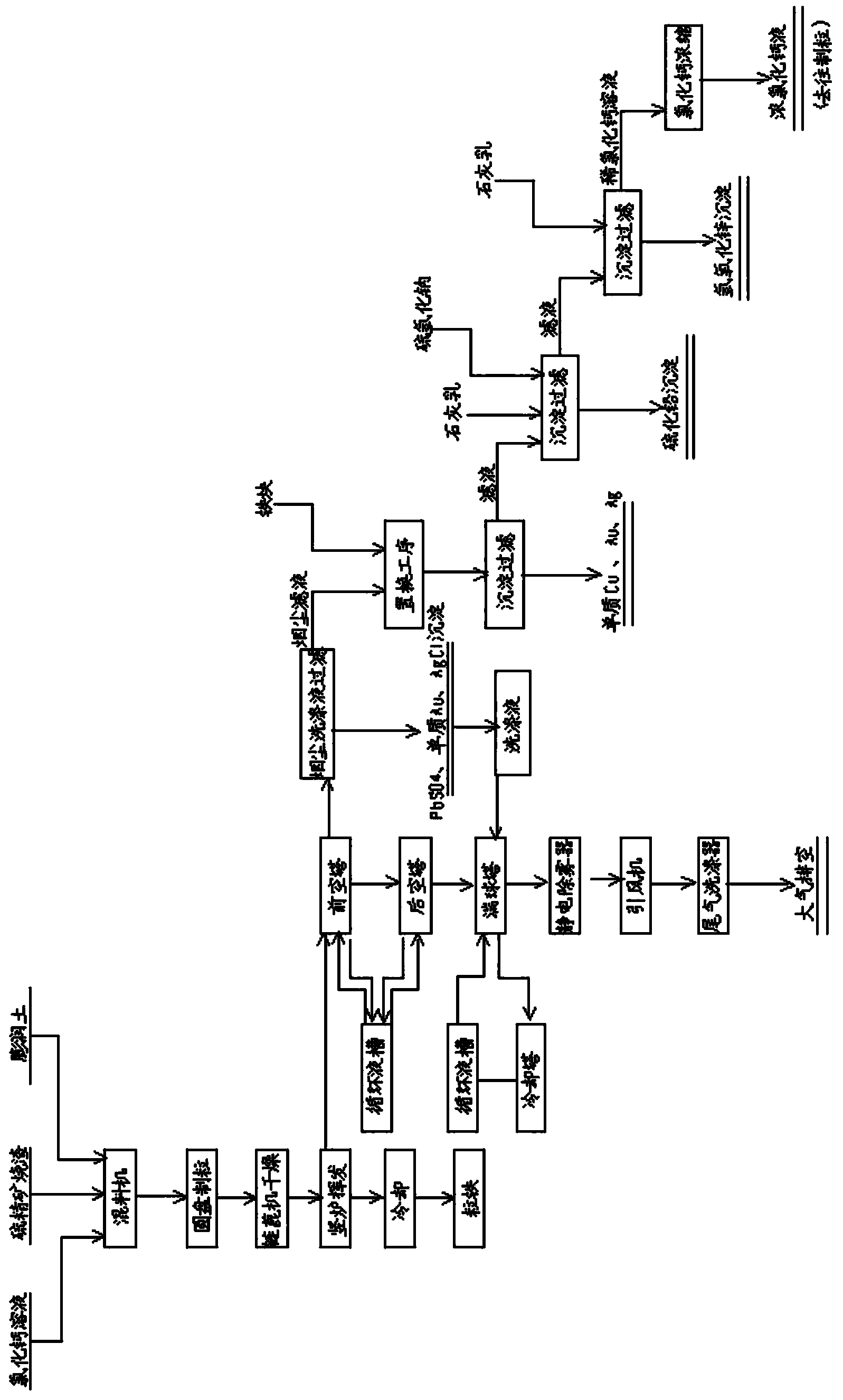

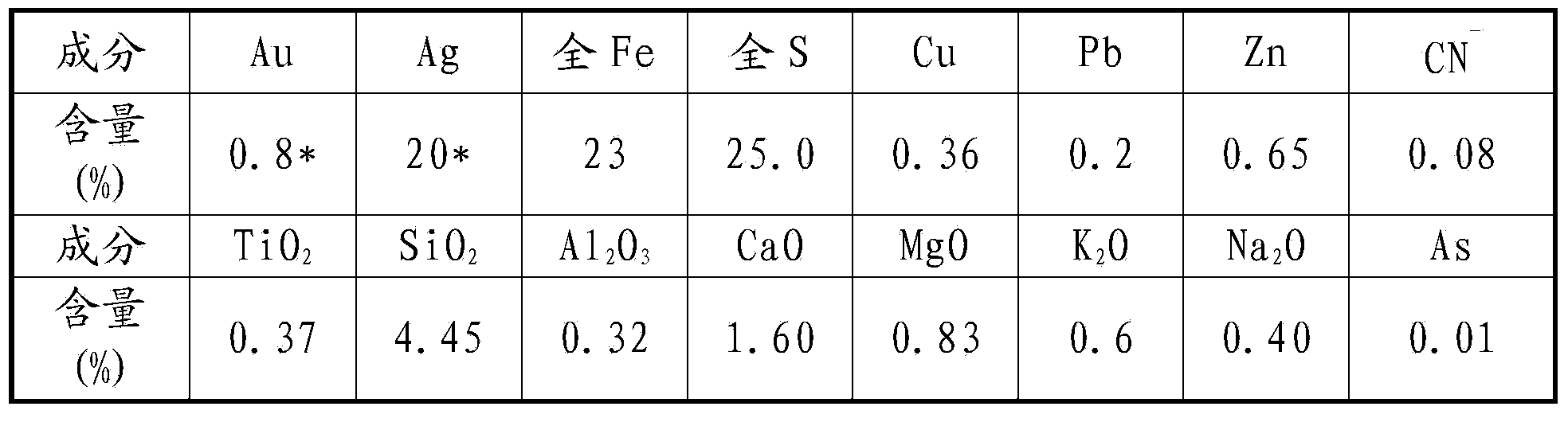

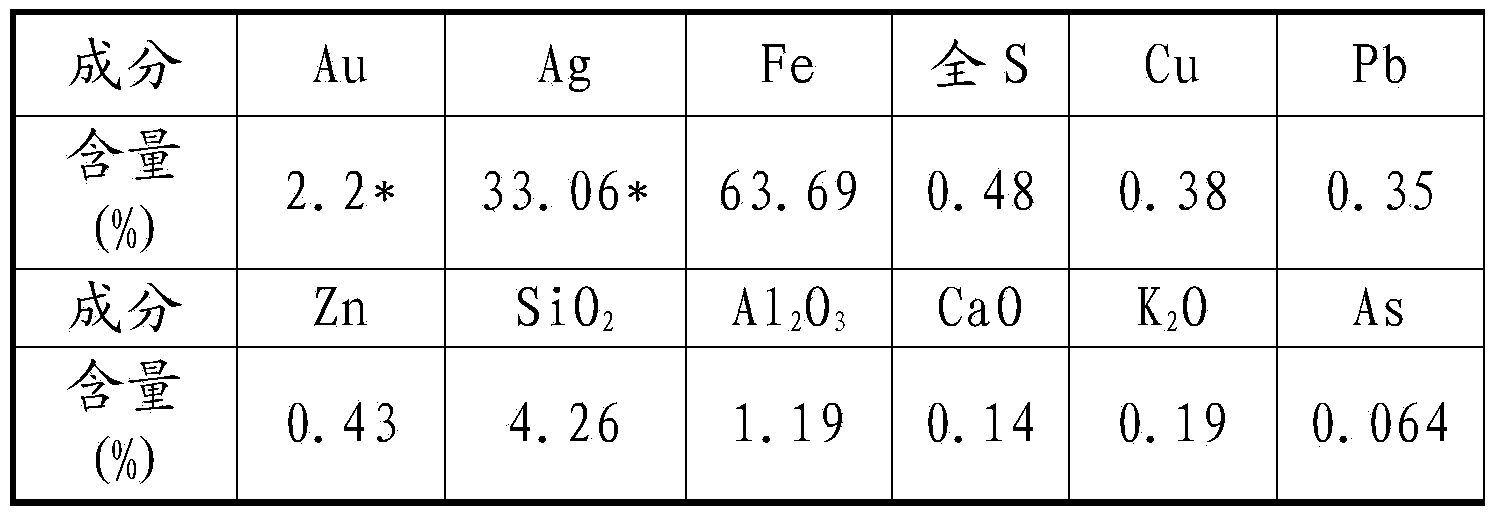

Method for recycling valuable metal from sulfur concentrate cinders

ActiveCN103805787AHigh recovery rateAdjust pHProcess efficiency improvementSingle substanceSodium hydrosulfide

The invention belongs to the technical field of mineral separation and metallurgy and particularly relates to a method for recycling valuable metal from sulfur concentrate cinders. The method comprises the following steps: sequentially adding bentonite and a calcium chloride solution into the sulfur concentrate cinders to form a mixed material; wetly grinding the mixed material; spraying water into the wetly-grinded mixed material to generate raw grains, and drying; roasting the dried grains by using natural gas to obtain iron grains and smoke; washing the smoke and filtering to obtain PbSO4 sediment, AgCl sediment and a single substance Au; adding iron blocks into a filtering solution to displace the single substances Cu, Au and Ag; filtering again and adding a sodium hydrosulfide solution into the filtering solution; adjusting the pH by using lime milk; filtering to obtain lead; and adding the lime milk into the filtering solution to adjust the pH, and filtering and drying to obtain Zn(OH)2. The method provided by the invention is simple in process and is efficient and environmental friendly; the requirements on raw materials are low and the recycling rate of the valuable metal is high; the valuable metal in the sulfur concentrate cinders is recycled by using a low production cost.

Owner:ZHAOJIN MINING +1

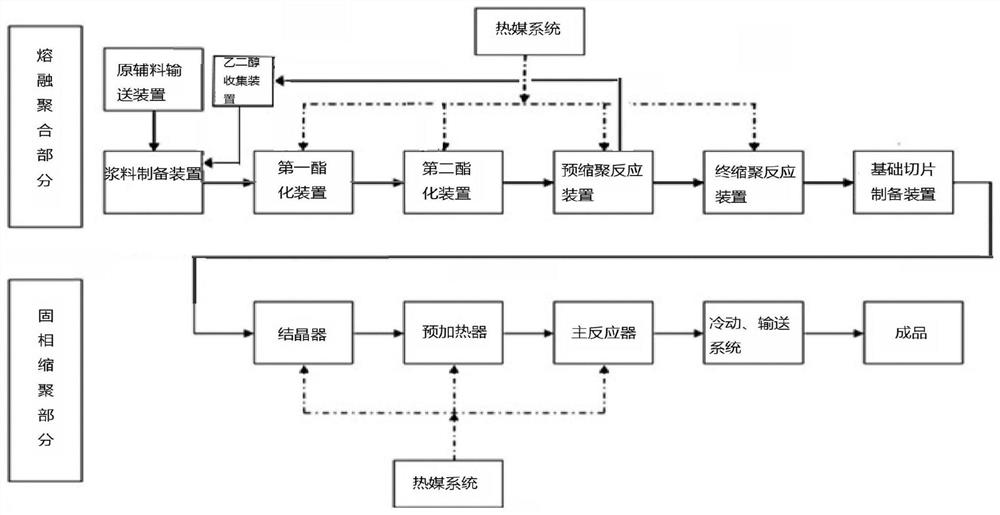

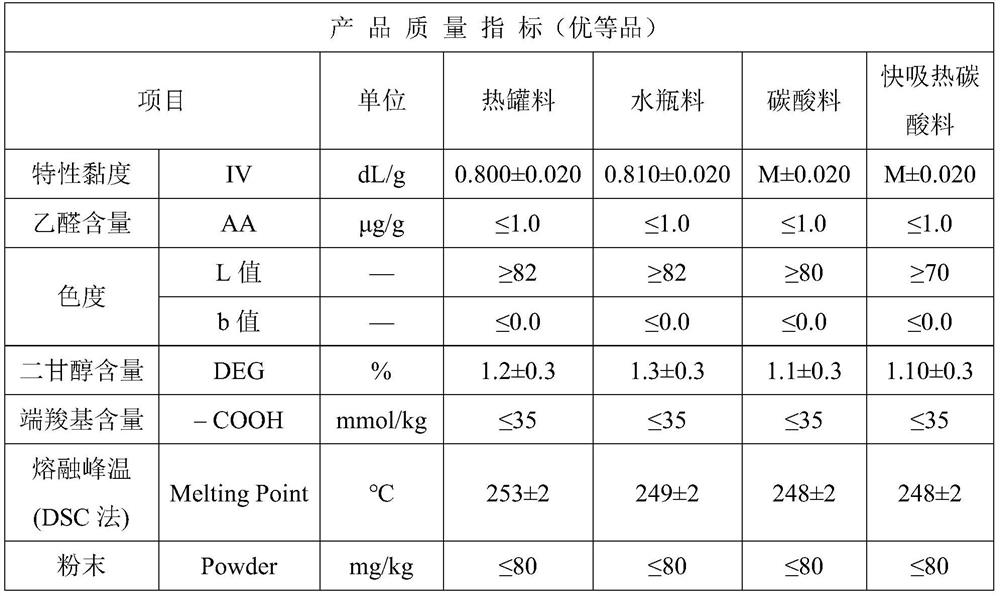

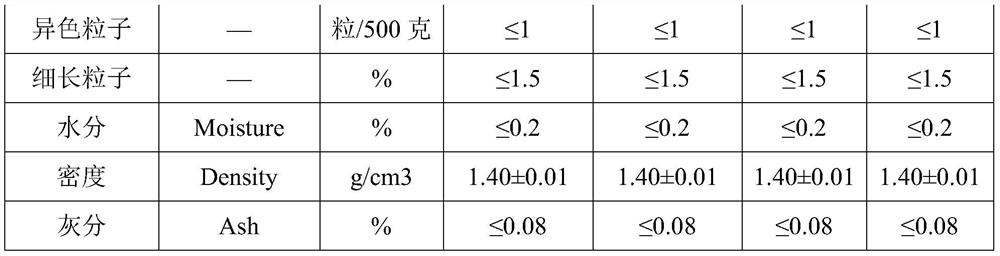

Method and system for producing rPET bottle-grade polyester chips

PendingCN111849026AAccurate removalExcellent indicatorsPlastic recyclingDistillation separationPolymer scienceEsterification reaction

The invention discloses a method and a system for producing rPET bottle-grade polyester chips. The method comprises the following steps: an esterification step, a pre-polycondensation step, a final polycondensation step and a solid-phase polycondensation step, in the esterification step, raw materials including waste PET polyester bottle fragments, terephthalic acid and ethylene glycol are added into an esterification device, the waste PET polyester bottle fragments are subjected to an alcoholysis reaction, and meanwhile, terephthalic acid and ethylene glycol are subjected to an esterificationreaction. The method is low in investment, simple in technical route, low in raw material requirement and good in product quality; an original polyester bottle chip production device is adopted, thewaste polyester bottle fragments are subjected to alcoholysis by utilizing ethylene glycol which is one of polyester bottle production raw materials, so that the closed circulation of the ethylene glycol is realized, the esterification reaction kettle has a dual-purpose function, and the PET polyester chips meeting the national standard level of raw materials can be produced by utilizing the wastePET polyester bottles.

Owner:CHINA RESOURCES PACKAGING MATERIALS CO LTD

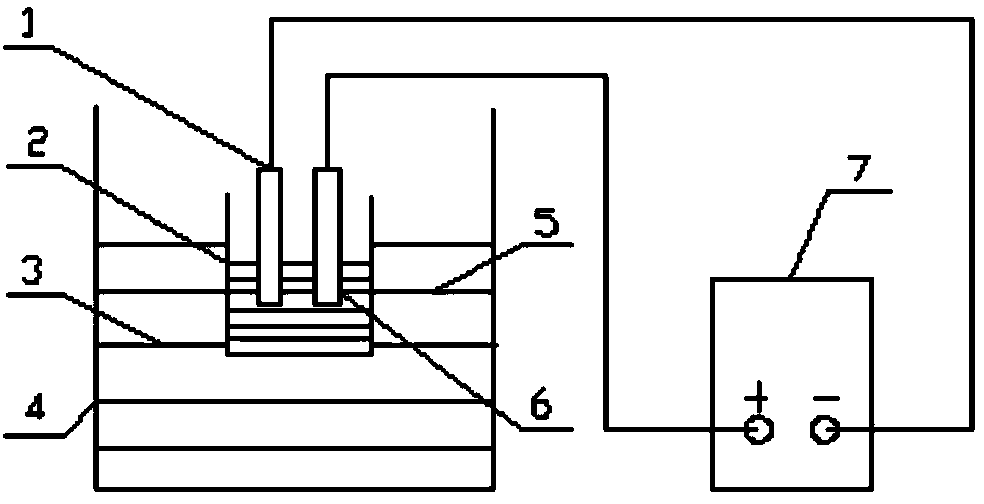

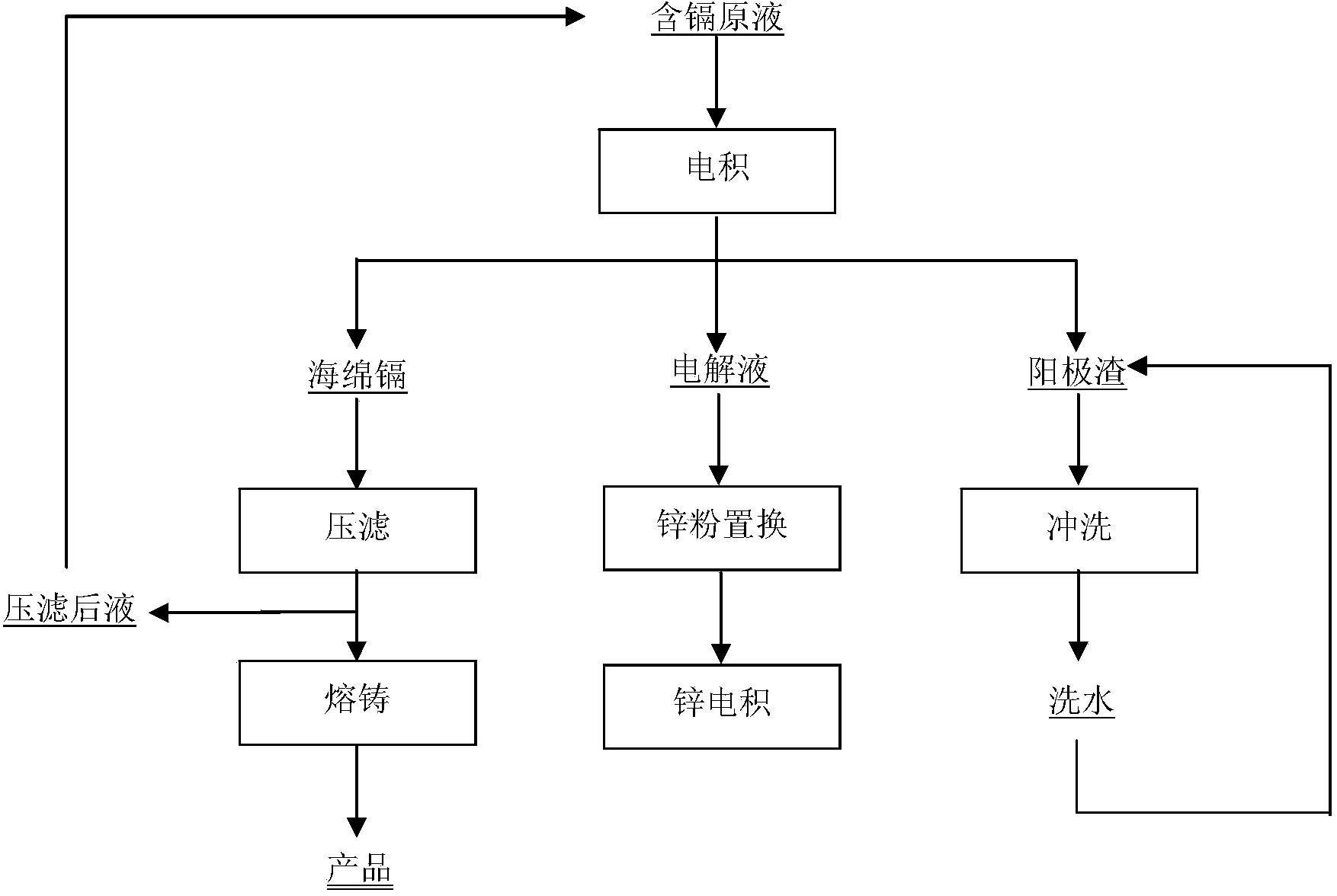

Method for manufacturing sponge cadmium under effect of micro currents

Disclosed is a method for manufacturing sponge cadmium under the effect of micro currents. The method specifically comprises the steps that a zinc plate or a zinc sheet is used as the anode, a titanium mesh or a titanium plate or an aluminum mesh or an aluminum plate or a copper mesh or a copper plate is used as the cathode, a solution containing 10-100g / L of cadmium and over 30g / L of zinc is used as a reaction stock solution, zinc plate replacement is conducted under the effect of the micro currents with the current density being 20-80A / m<2>, and the branch-shaped sponge cadmium is obtained. In the sponge cadmium manufactured through the method, the purity of cadmium is high and the impurity content is low. The zinc plate in the method is obtained in the zinc smelting electro-deposition process, the residual reacted solution can be directly returned to the zinc electro-deposition process, and raw material cyclic utilization in the whole technological process is realized. The method for manufacturing the sponge cadmium under the effect of the micro currents is simple in technological operation and equipment, reduces the cost, is tightly combined with an existing zinc smelting process, and enables industrial production to be realized easily.

Owner:CENT SOUTH UNIV

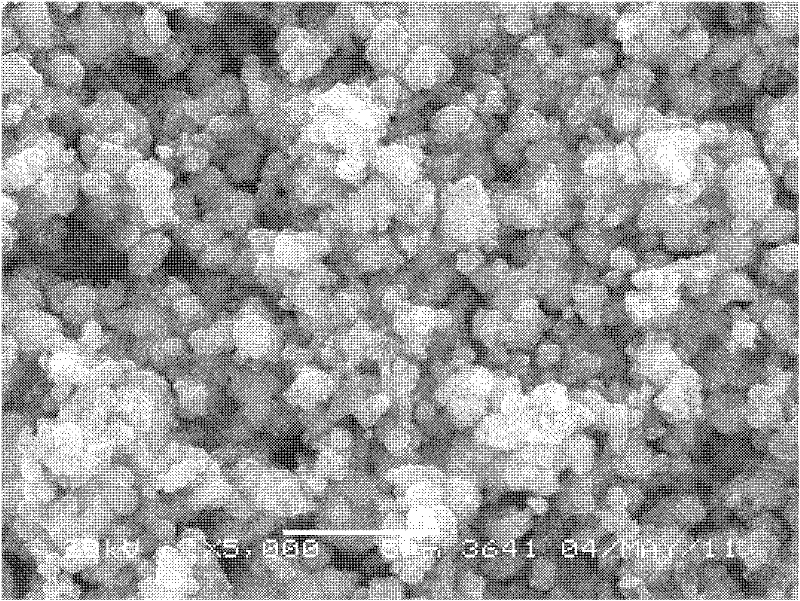

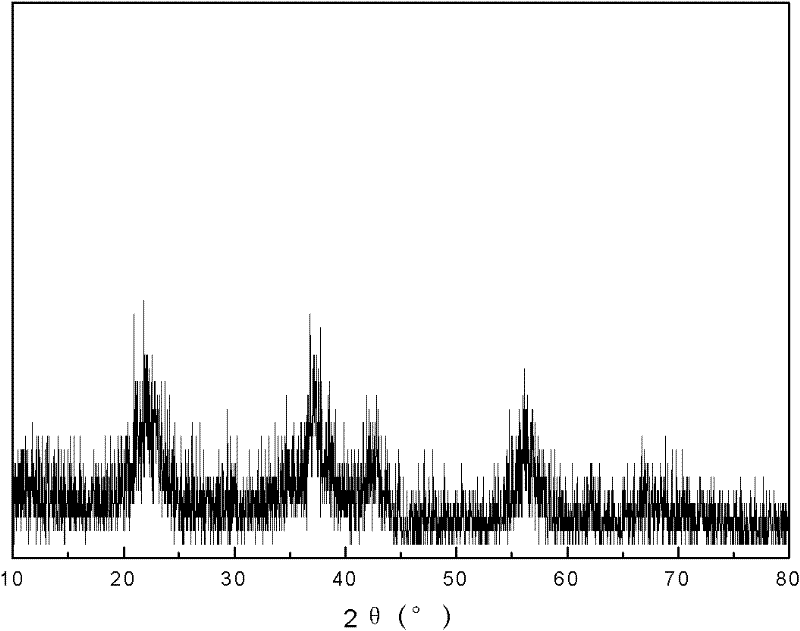

Method for preparing powdery electrolytic manganese dioxide (EMD)

ActiveCN102242373ALow raw material requirementLow costElectrolysis componentsUltrasound - actionActive agent

The invention discloses a method for preparing powdery electrolytic manganese dioxide (EMD). In the method, the powdery EMD is directly obtained from solution by improving the electrolytic process and controlling the electrolytic condition; and during electrolysis, a diaphragm electrolytic cell is adopted, a lead silver alloy plate or a titanium manganese alloy plate subjected to acid treatment is taken as an anode, and a graphite plate or a stainless steel plate is taken as a cathode. The method comprises the following steps of: preparing electrolyte with 0.1 to 10.0mol / L sulfuric acid and 0.4 to 1.2mol / L manganese sulfate, adding an active agent into the electrolyte, electrolyzing at the temperature of between 20 and 100 DEG C under the action of ultrasonic waves, and filtering to obtain the powdery EMD; and washing the powdery EMD for multiple times, adding a dispersing agent into solution when the powdery EMD is washed for the last time, and drying to obtain the powdery EMD. The method has the characteristics that: the process flow is simple, energy consumption and cost are low, product particles are uniform and have good appearance, and the like.

Owner:CENT SOUTH UNIV

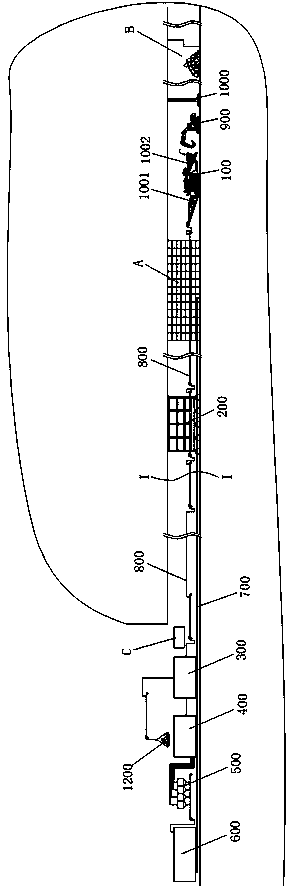

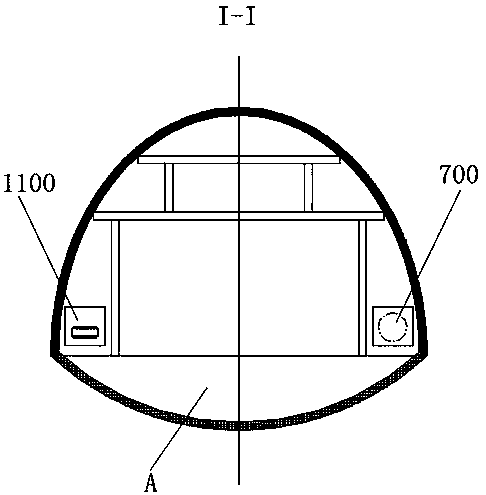

Tunnel slag tapping, sand and gravel processing and concrete processing and conveying integrated equipment and process

PendingCN110130920ASolve the transportation problemReduce in quantityTunnelsMixing operation plantSlagMaterial resources

The invention discloses a tunnel slag tapping, sand and gravel processing and concrete processing and conveying integrated equipment and process. The tunnel slag tapping, sand and gravel processing and concrete processing and conveying integrated equipment comprises mobile crushing equipment, wherein a discharging port of the mobile crushing equipment is sequentially connected with a material pre-sorting system, an aggregate processing system and a concrete processing system through a telescopic conveying belt group, and a discharging port of the concrete processing system is connected with aconcrete belt conveying system; after materials in a tunnel blasting area B are preliminarily crushed by the moving crushing equipment, the materials are transported into the pre-sorting system and the aggregate processing system to prepare fine aggregates and fine sand with different gradations, finally transported into the concrete processing system to prepare concrete, and transported to a tunnel construction area through the concrete belt conveying system for concrete construction after penetrating through a lining trolley. The manpower and material resources are reasonably utilized and distributed, the automatic construction of a tunnel is achieved, high flexibility and good safety performance are achieved, and the construction efficiency and quality of the tunnel are greatly improved.

Owner:GUIZHOU CHENGZHI HEAVY IND SCI TECH

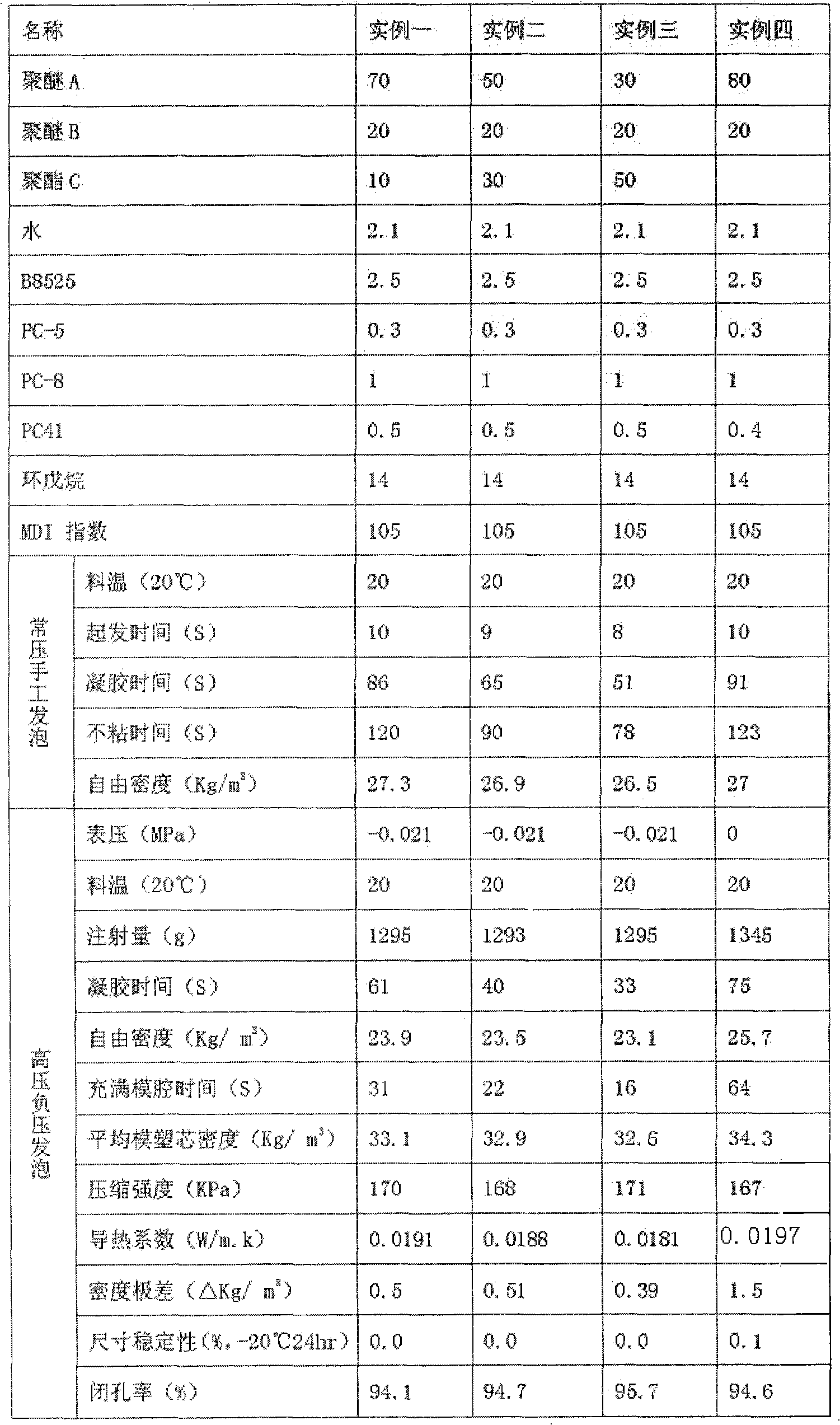

Hard polyurethane molding foam negative pressure foaming raw material formula and hard polyurethane molding foam negative pressure foaming production method

The invention relates to a formula of a hard polyurethane molding foam negative pressure foaming raw material, wherein the raw material is prepared by mixing polyether polyol, a polyester polyol, a foam stabilizer, a catalyst and water, and a weight ratio of the polyether polyol to the polyester polyol to the foam stabilizer to the catalyst to the water is 50-90:10-50:2-3:2-3:1-2.5. The hard polyurethane molding foam negative pressure foaming production method comprises carrying out hard polyurethane foaming under a state with a negative pressure of 0 to -0.025 MPa, wherein polyurethane foaming is performed under the negative pressure state so as to reduce polyurethane raw material requirements. In addition, a high functionality polyester polyol can be adopted as a main polyol to prepare a combination polyether so as to carry out foaming, such that a mold cavity can be filled in a short time, and the prepared foam has characteristics of thin cell, high strength and good size stability.

Owner:绍兴广佳庄鑫建材制造有限公司

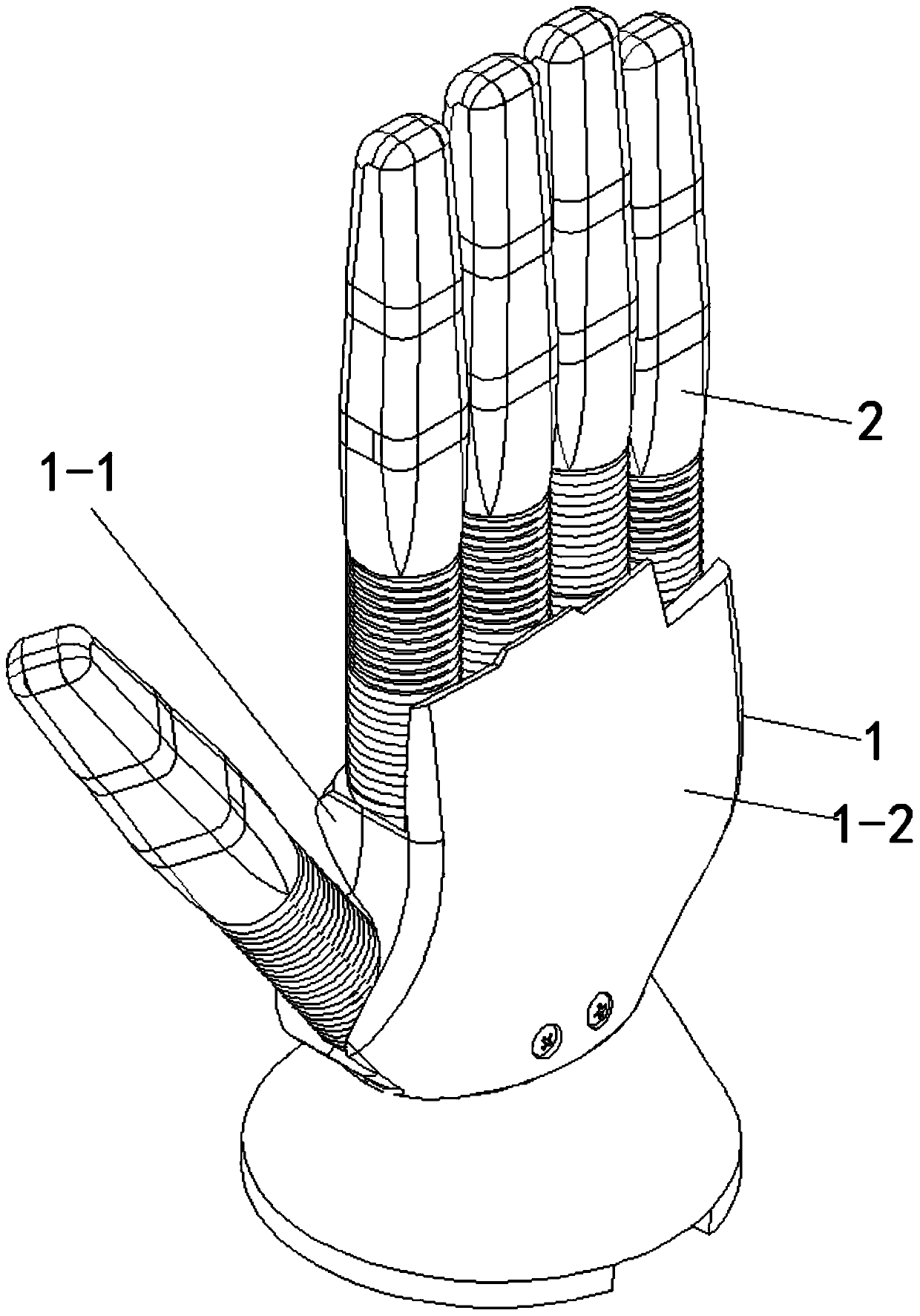

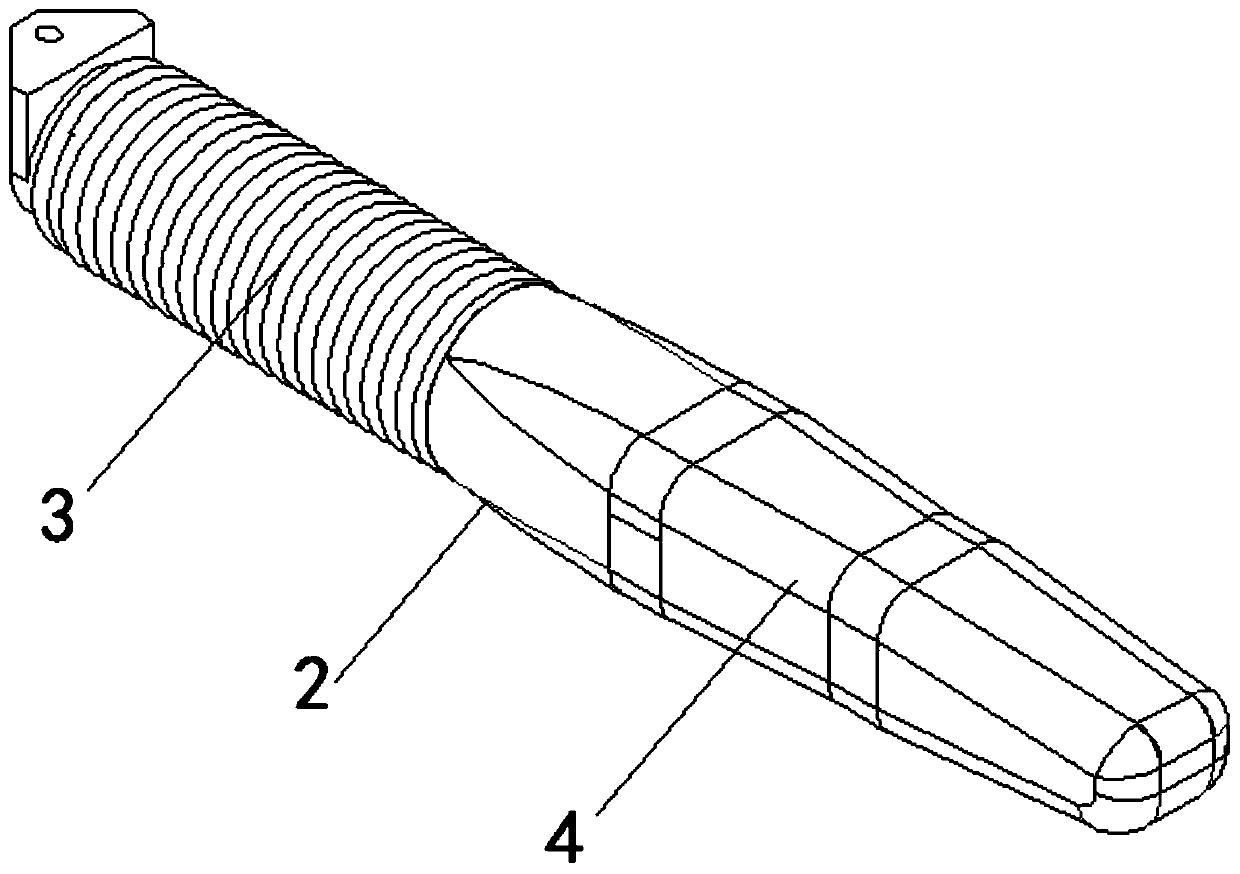

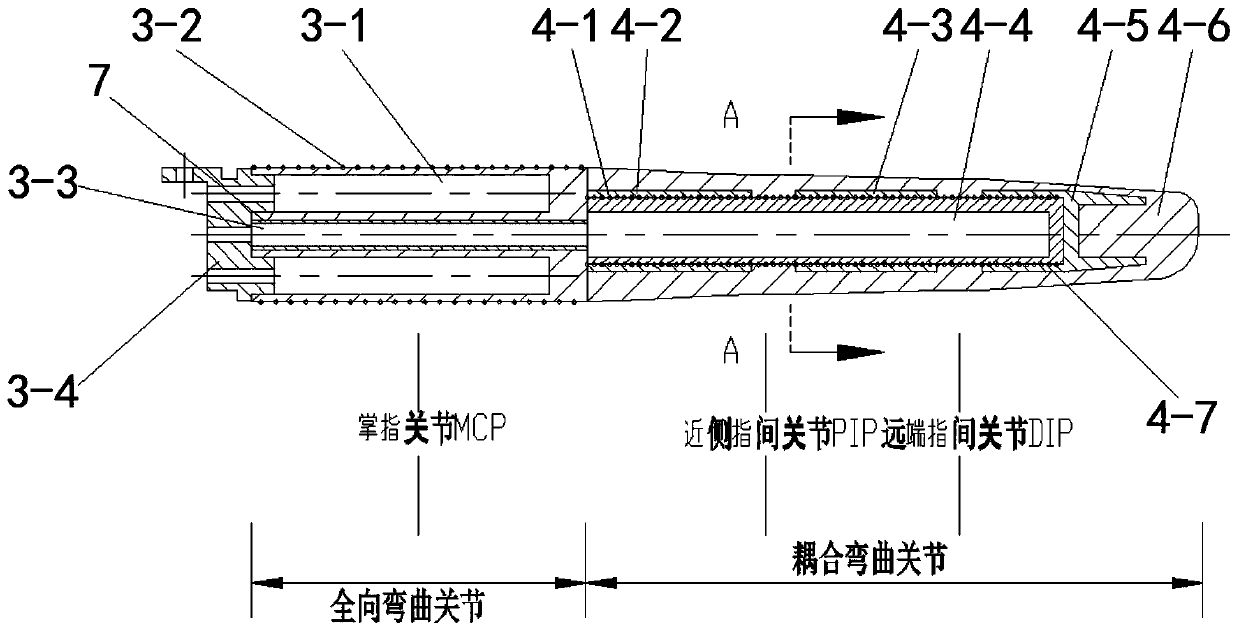

Multi-degree of freedom human-simulated rigid-flexible mixing hand and manufacturing technology thereof

The invention discloses a multi-degree of freedom human-simulated rigid-flexible mixing hand and a manufacturing technology thereof, and belongs to the technical field of robots. Each soft finger includes metacarpophalangeal joints and interphalangeal joints, wherein a central air flue communicates with a central air cavity. A plurality of metacarpophalangeal joint air cavities surround the central air flues. A layer of fiber limiting threaded pipes are wound around the metacarpophalangeal joint air cavities. The central air flues and the tail ends of the multiple metacarpophalangeal joint aircavities are inserted into a finger base. A ventilating cavity is formed inside the body of a hard palm, and the hard palm fix the soft fingers through screws. Each central air flue, each metacarpophalangeal joint cavity and each central air cavity achieve air inflow through capillary silica gel hoses. The active degree of freedom is multiple, the human hand joint structure is simulated, and thejoint angle and motion relations are close to human hand parameters. Due to the joint type structure, compared with a continuous bent soft claw, the hand has the larger enveloping space, the grabbingperformance is better, the flexibility is good, and the hand has the good adaptability for soft and fragile objects and unstructured environment.

Owner:HARBIN INST OF TECH

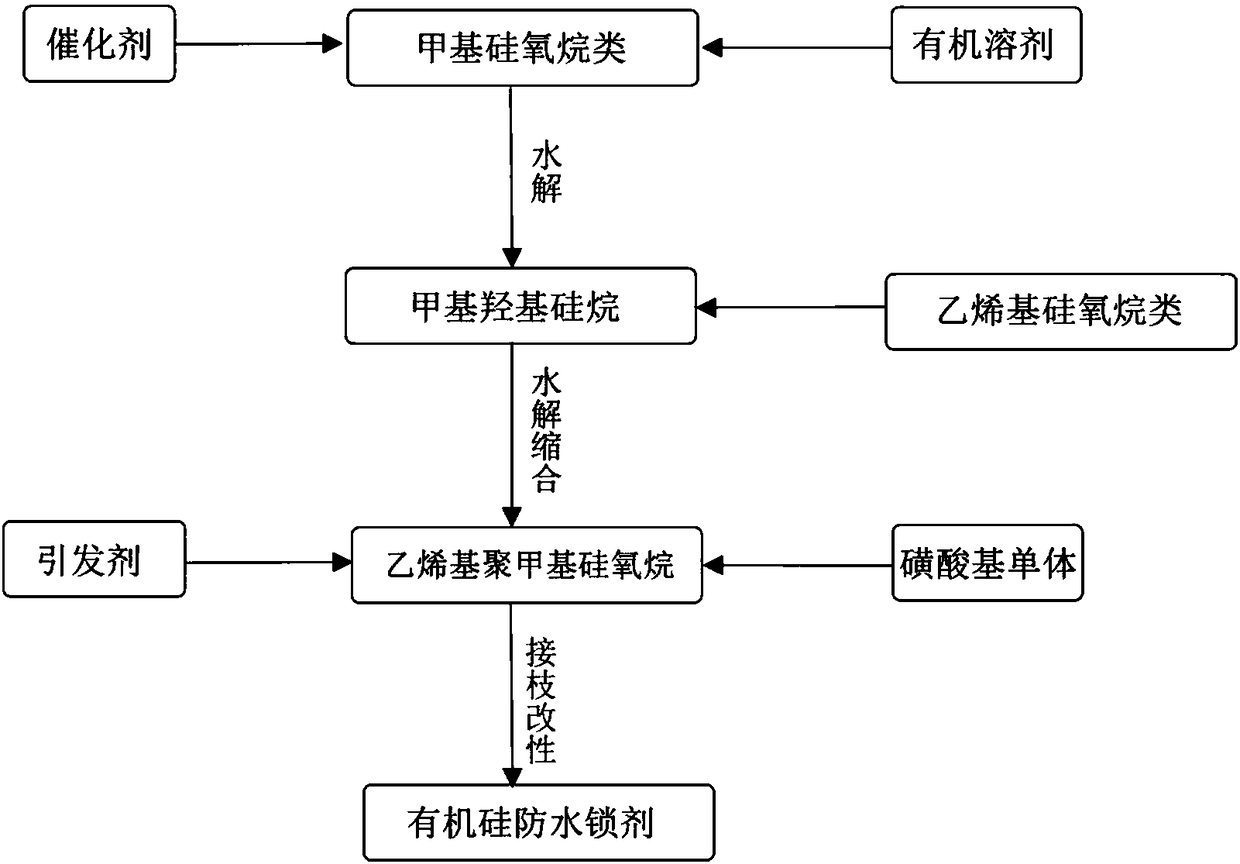

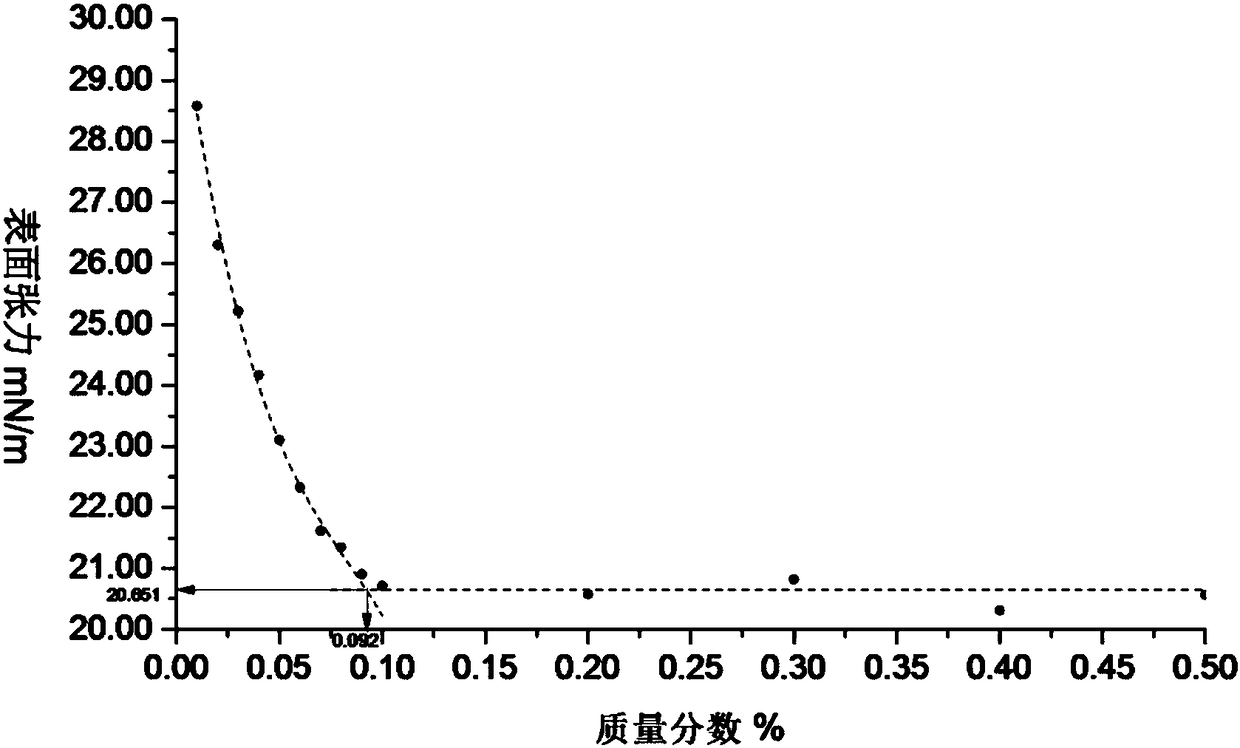

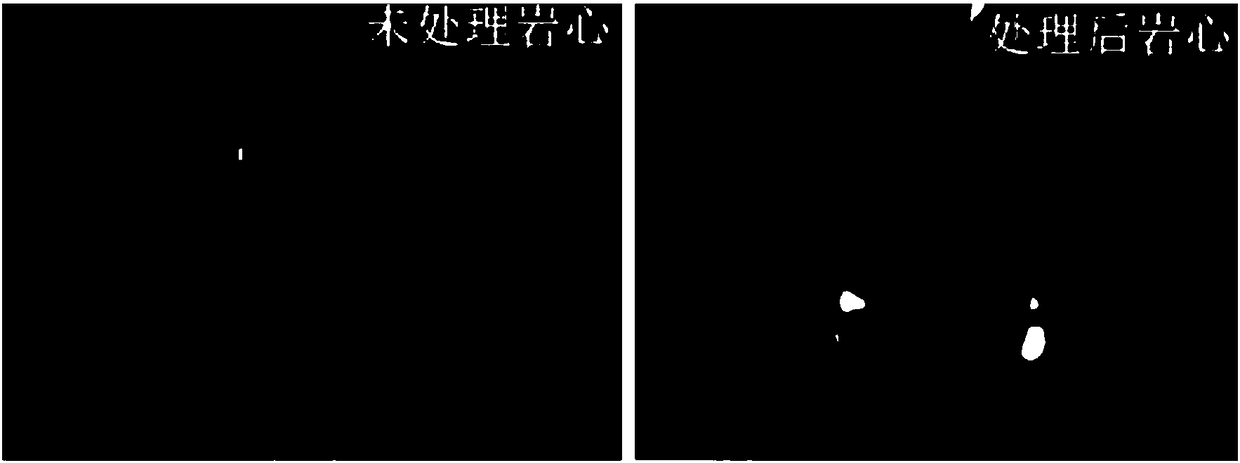

Environmental-friendly organic silicon water blocking prevention agent for drilling fluid and preparation method and application thereof

The invention provides an environmental-friendly organic silicon water blocking prevention agent for a drilling fluid and a preparation method and application thereof. The organic silicon water blocking prevention agent comprises a hydrophobic group and a hydrophilic group, wherein the hydrophobic group is a polymethyl hydrosiloxane chain; the hydrophilic group is a sulfonic acid group and hydroxyl. The organic silicon water blocking prevention agent is prepared from methylsiloxane and vinyl siloxane through hydrolytic condensation reactions and grafting reactions with sulfonic acid group monomers. By adopting the organic silicon water blocking prevention agent provided by the invention, surface tension can be relatively well reduced, water wetting on the surfaces of pores can be turned into vapor wetting, flow-back of filtrate can be improved, gas permeability can be improved, and water blocking damage caused by a reservoir can be remarkably reduced; in addition, the organic silicon water blocking prevention agent is low in foaming rate, good in foam inhibition and elimination property, easy in preparation raw material obtaining, safe and feasible in reaction condition and easy inindustrial production.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

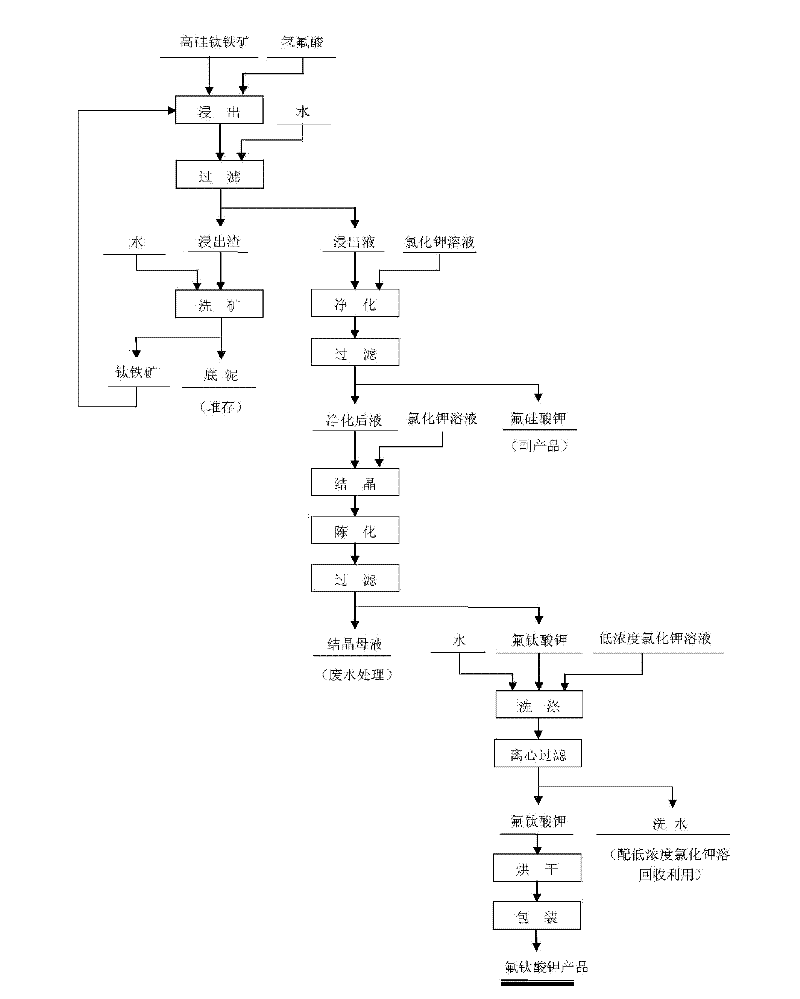

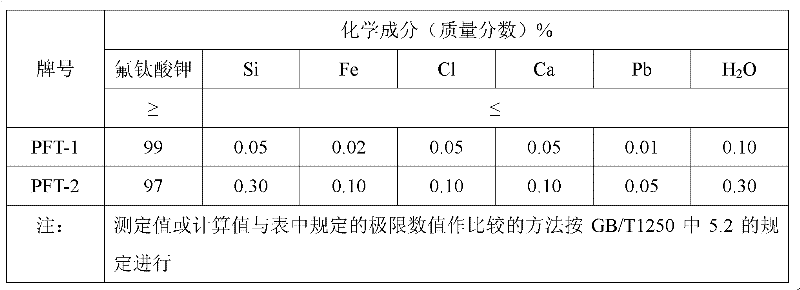

Method for preparing grade-adjustable potassium fluotitanate through using high-silicon-titanium iron ore

The invention which belongs to a metallurgical technology concretely provides a method for preparing grade-adjustable potassium fluotitanate through using high-silicon-titanium iron ore. The method comprises three steps of leaching, silicon removal and potassium fluotitanate synthesis. According to the method, the iron ore with high contents of silicon and titanium is directly used as a raw material, the raw material can be directly used for production without preprocessing, and hydrofluoric acid can be directly used without refining; the impurity silicon is processed into high purity potassium fluosilicate, and potassium fluosilicate can be sold in the market and causes no wastes; and additionally, the potassium fluotitanate prepared through the method of the invention, which has the characteristics of adjustable grade and production cost saving, can satisfy demands of different clients.

Owner:HUNAN RES INST FOR NONFERROUS METALS

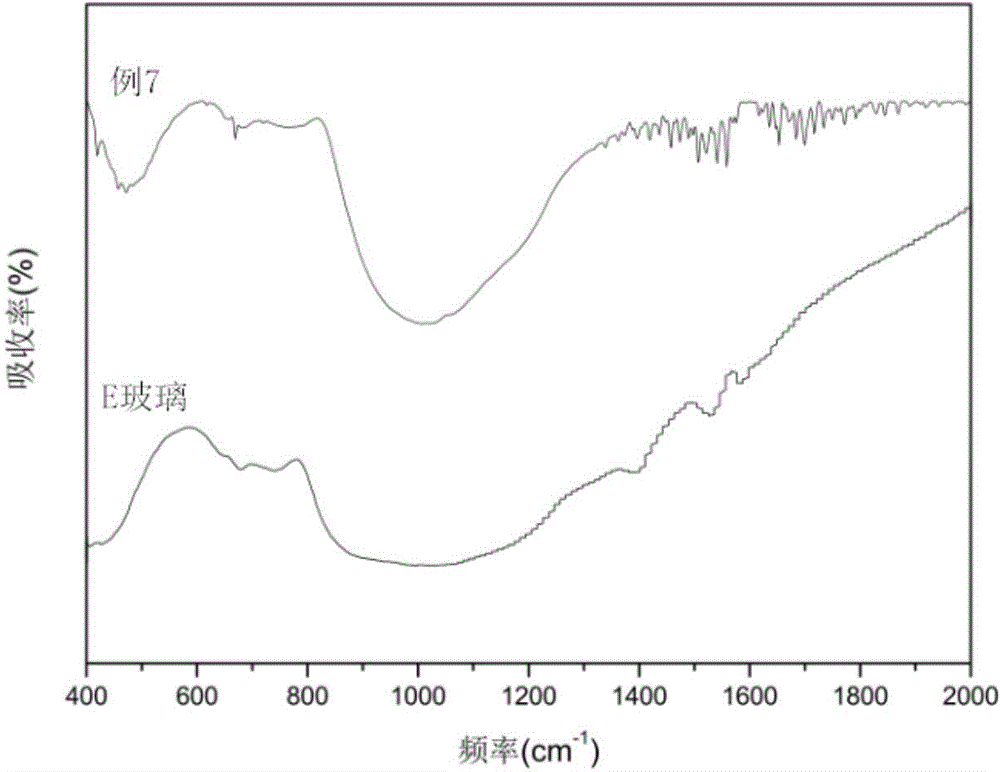

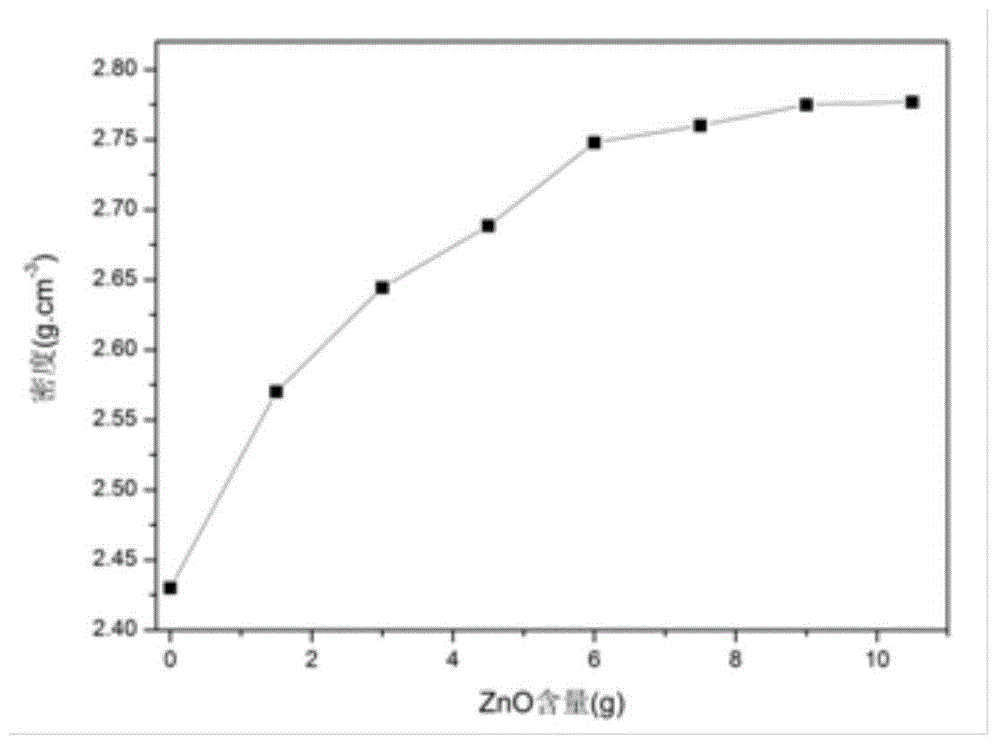

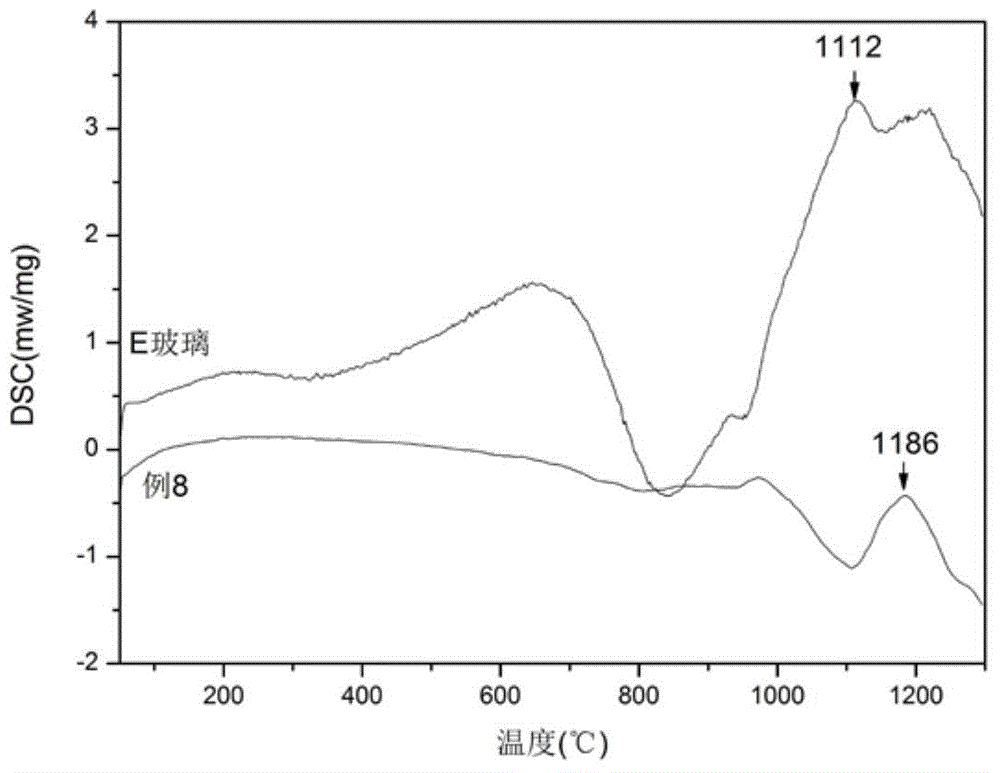

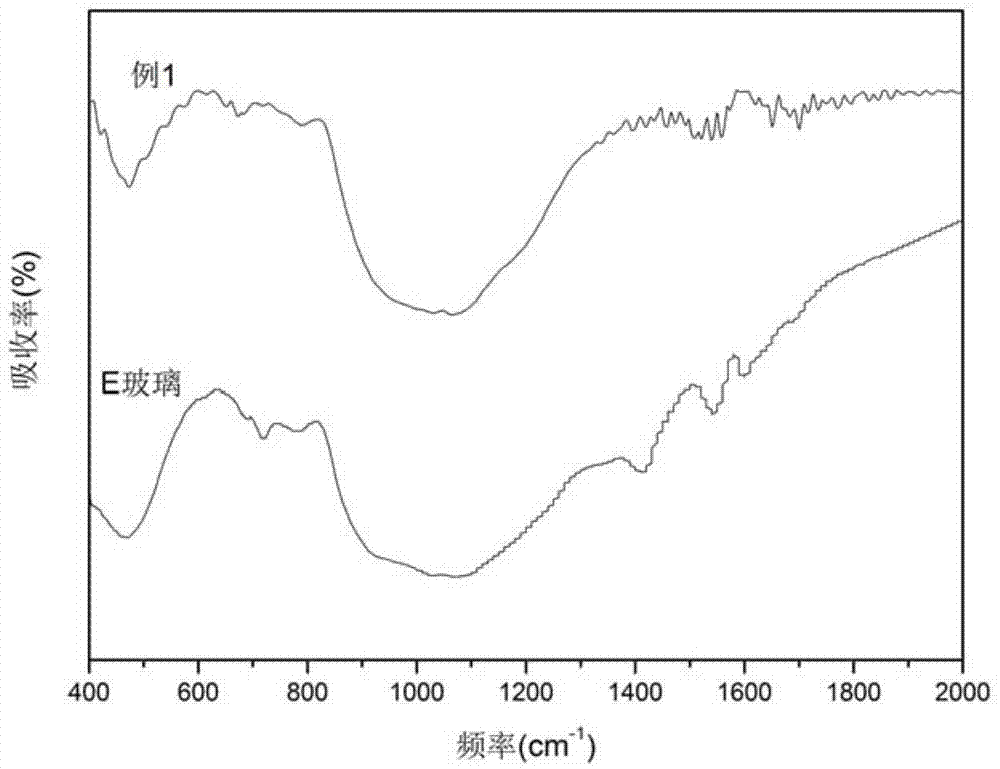

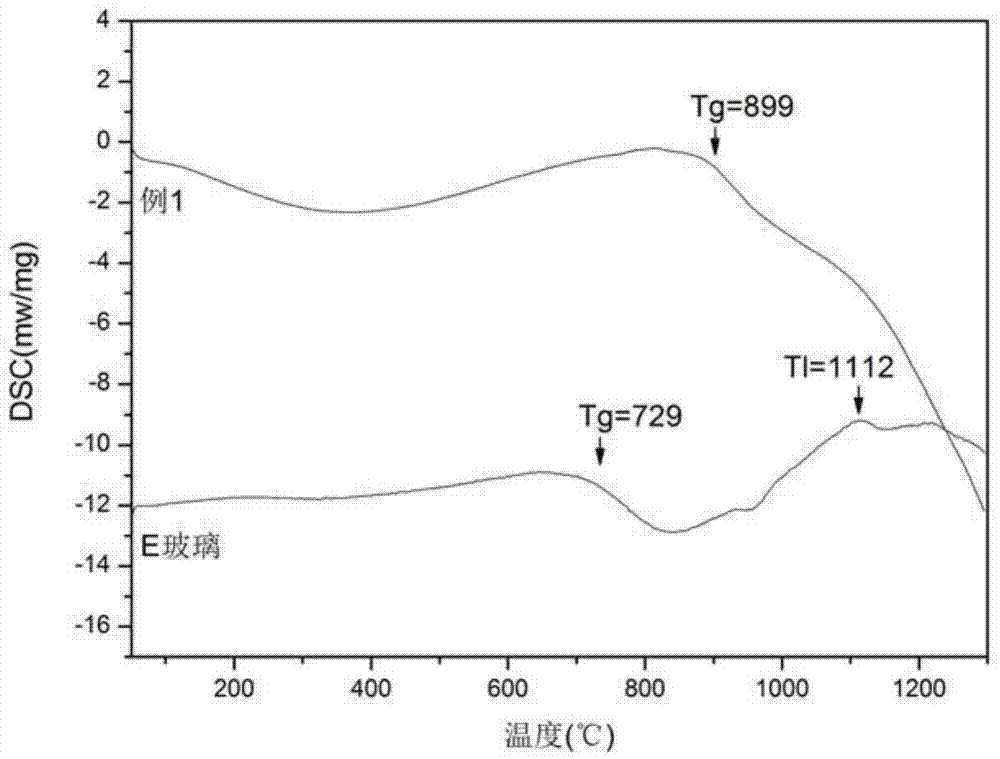

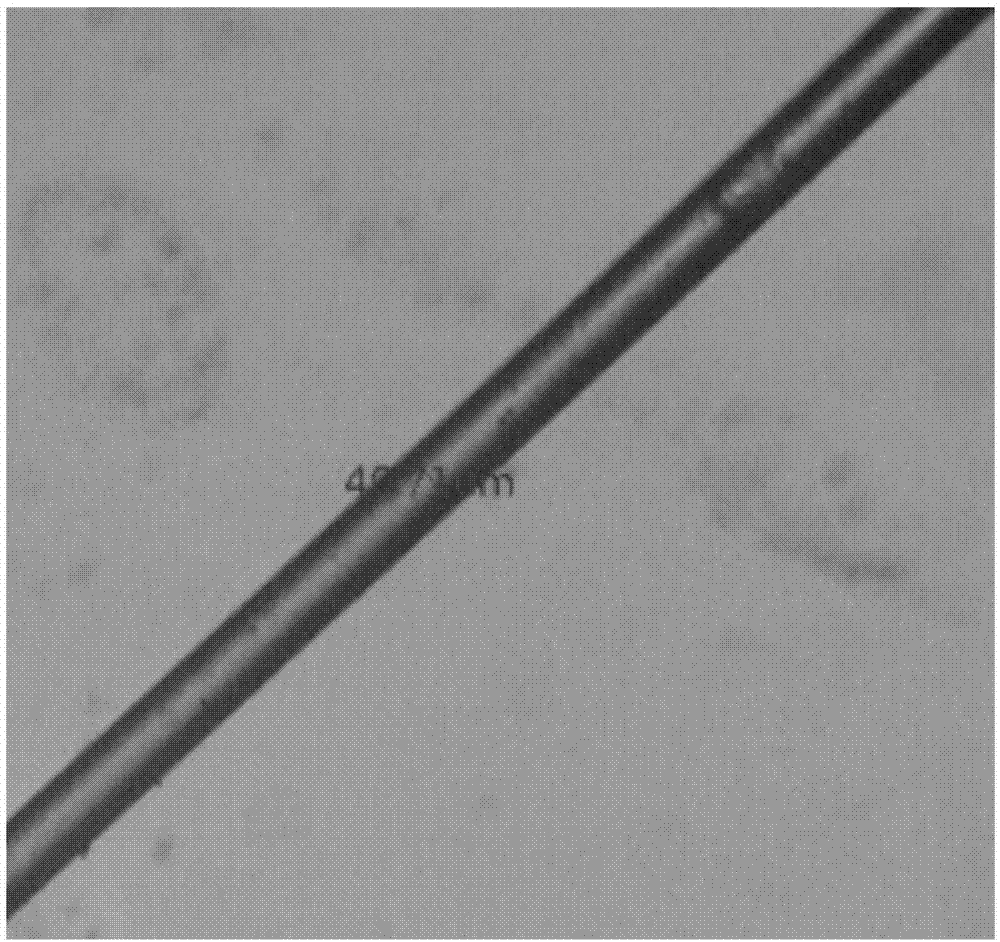

Boron-free high-performance glass fiber and preparation method thereof

The invention discloses a boron-free high-performance glass fiber and a preparation method thereof and belongs to the technical field of materials. The boron-free high-performance glass fiber is prepared from the following raw materials in percentage by weight: 30-55% of blast furnace slag, 1-15% of fly ash, 42-50% of quartz sand, 0-15% of zinc oxide, 0-2% of magnesium oxide and 0-3.5% of calcium oxide. According to the boron-free high-performance glass fiber, the adversely effects of the volatilization of boron on a kiln, the environment and the production cost are avoided, and the boron-free high-performance glass fiber has the advantages of excellent performance, reasonable process parameters, low production cost and environmental friendliness and furthermore, the raw materials can directly adopt industrial-grade raw materials and the effect is not affected.

Owner:UNIV OF JINAN

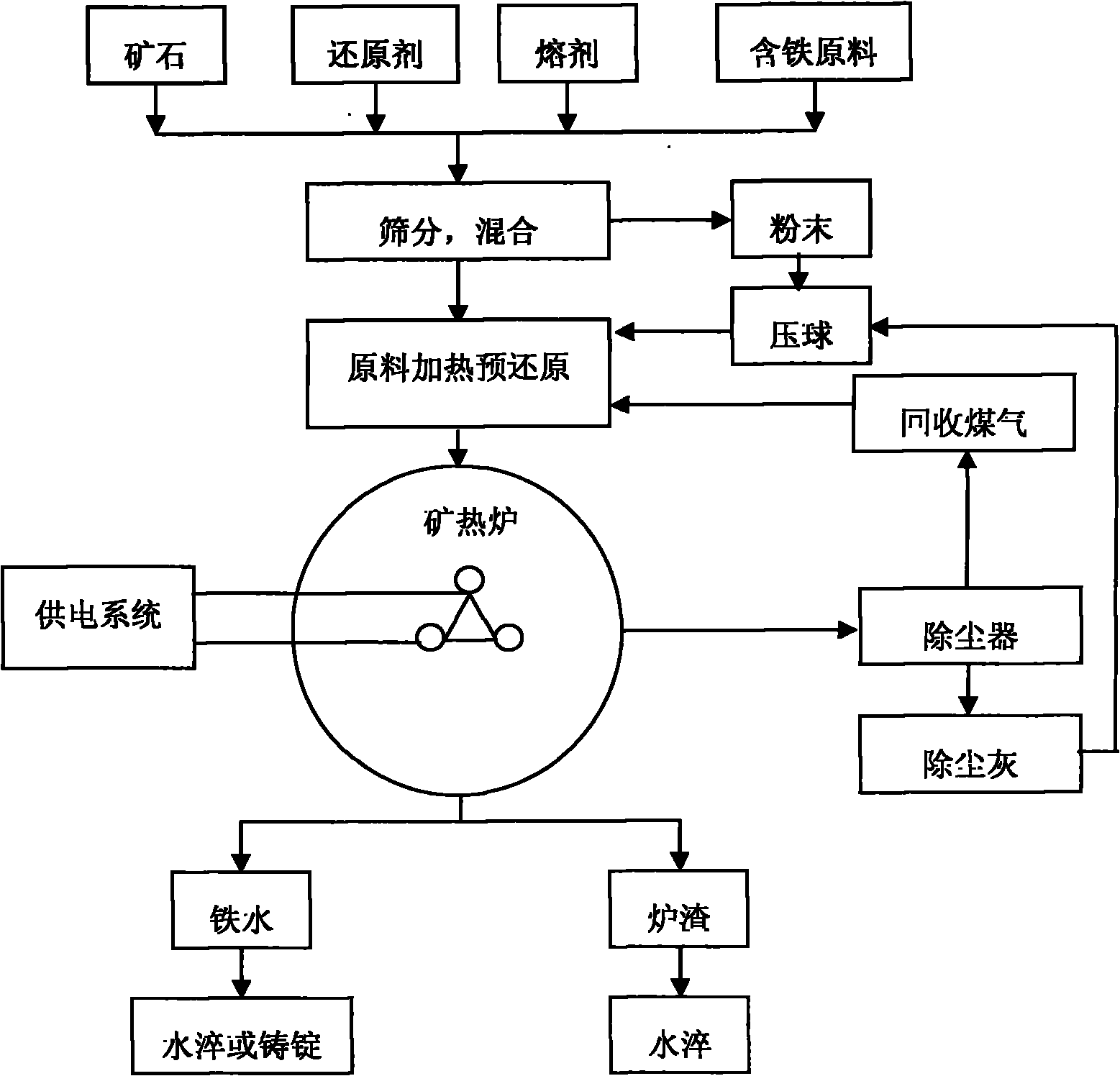

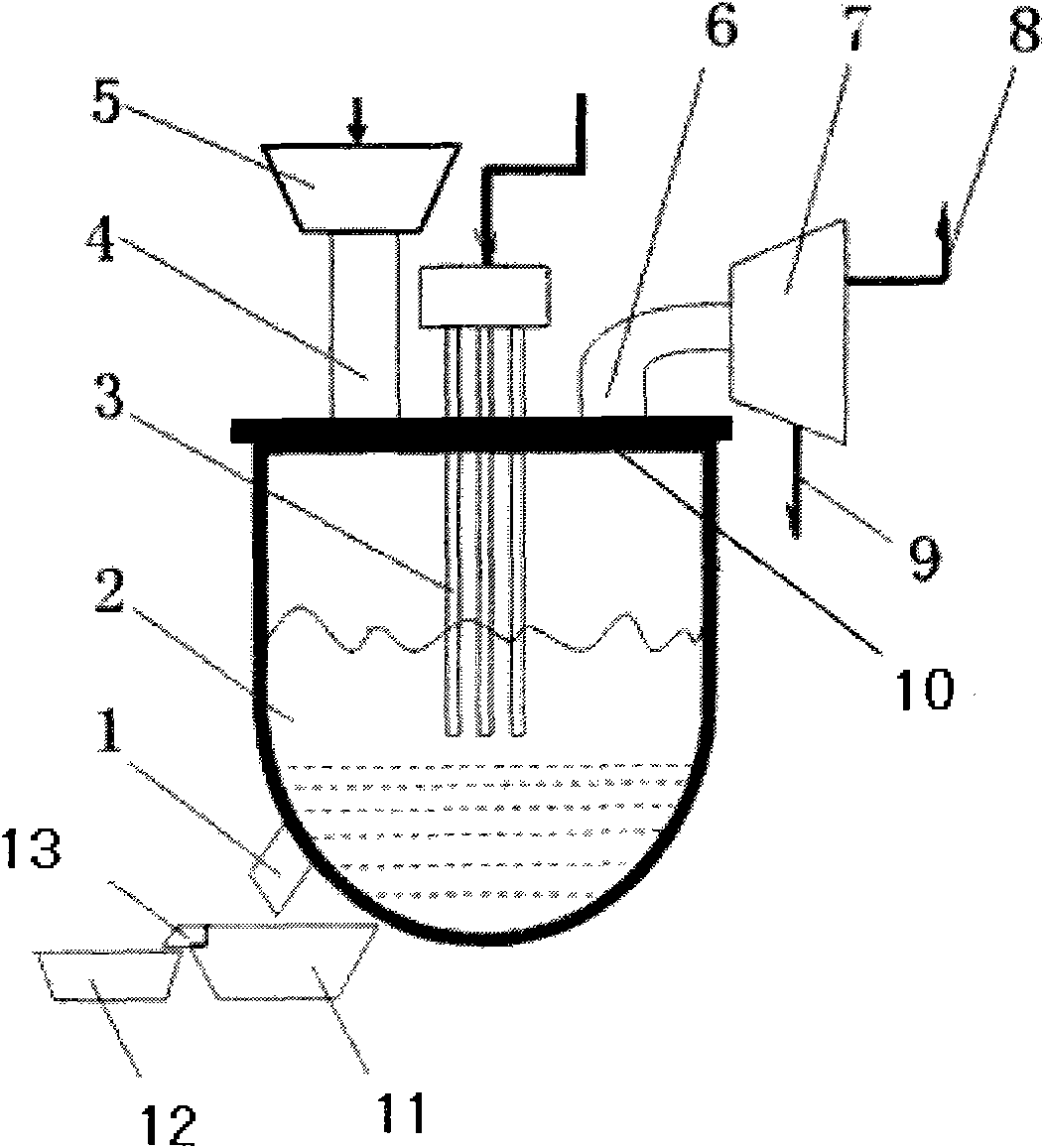

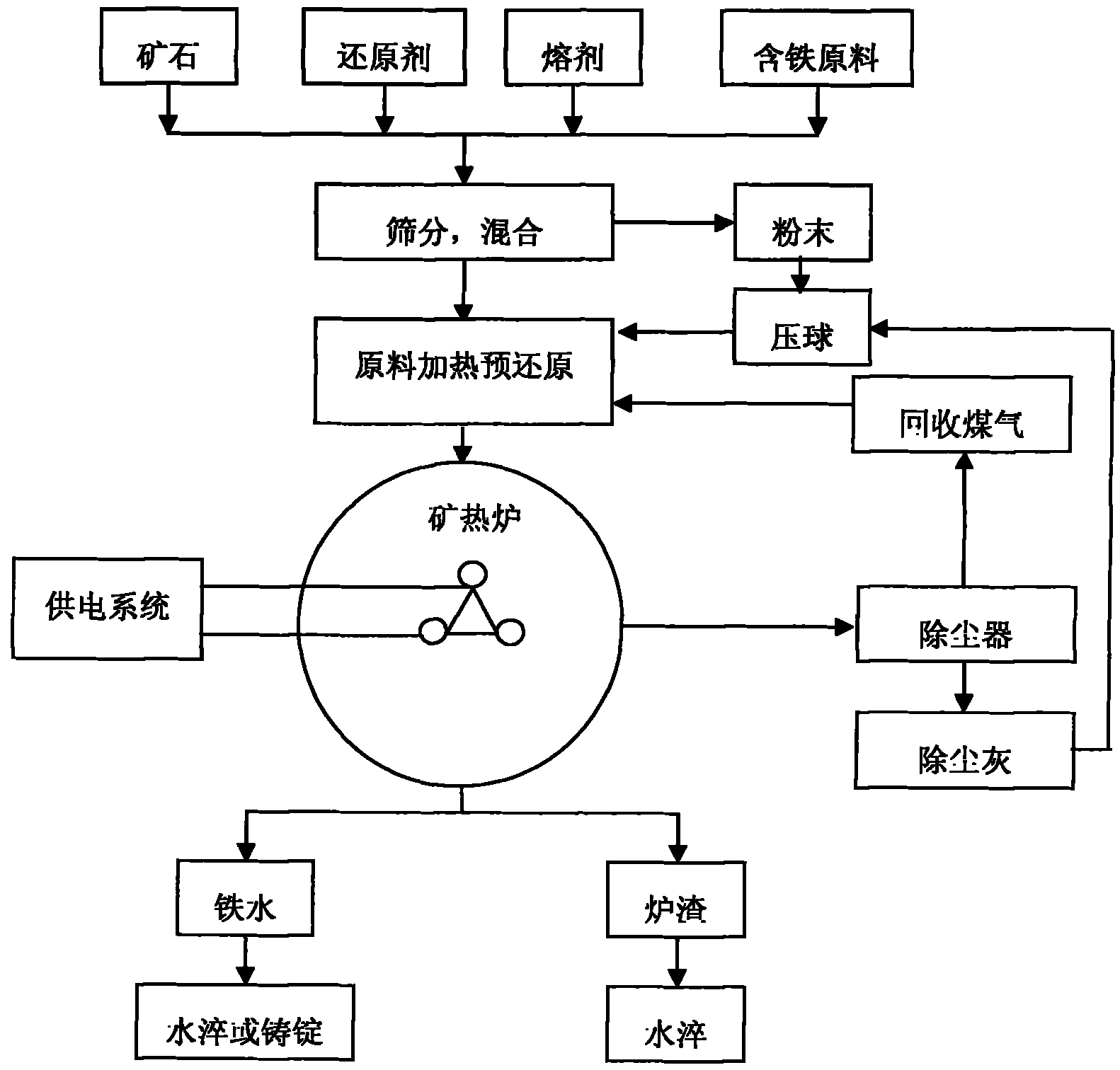

Method for reducing iron by smelting reduction in electrometallurgy

The invention provides a method for reducing iron by smelting reduction in electrometallurgy. The method is characterized by taking electric energy as a heat source and natural ore or artificial ore, carbonaceous reducing agent and solvent as raw materials and comprising the following steps: pre-reducing the raw materials at the temperature of 700 to 900 DEG C for 4 to 6 h; heating to 1,400 to 1,700 DEG C in an electric furnace so as to smelt the furnace burden and reduce into molten iron and slag, and discharging the molten iron and slag to a foundry ladle; meanwhile, dedusting the smoke dust during the smelting, wherein the smoke is returned to a pre-reducing device and used as reducing gas; the smoke dust is used for manual granulation and recycled; the molten iron is cast and formed or directly used for steelmaking; and the slag is processed for other purposes. The method has the advantages of simple process and equipment, little occupation, low requirements on raw materials, wide applicable range, low sulphur load of produced molten iron compared with molten iron of a blast furnace and good product quality, while saving investment and resources without needing equipment for coking, sintering and the like or using coke as fuel.

Owner:KUNMING IRON & STEEL GRP CO LTD

Fine purification method for sterol

The invention relates to a refining method of high content natural plant sterol, the natural plant crude sterol with the weight percentage of 35 percent to 80 percent weight content is selected and added in petroleum ether or other mixed solvents for stirring and filtration, a solid phase I is selected, the solid phase I is added in the petroleum ether or other mixed solvents for evenly stirring and filtration, a solid phase II is taken and added in ethanol solution for heating and stirring, activated carbon is added, the heating temperature is 60 to 80 DEG C, the holding time is 0.5 to 2 hours, heat filtration is carried out, then slow stirring and slow cold separation crystallization are carried out, the solution is subject to constant temperature filtration after cold separation, and the filtrate is dried by constant temperature air blow to obtain refined plant sterol. The technique has short route, simple operation, wide processing range of the crude sterol, small energy consumption and low cost, yield and purity both achieve higher standards, thus providing a certain degree of protection for increasing the economic benefit of enterprises.

Owner:NINGBO DAHONGYING BIO ENG

Boron-free high-performance glass fiber taking pulverized fuel ash and desalted river sand as raw materials, as well as preparation method thereof

The invention discloses a boron-free high-performance glass fiber taking pulverized fuel ash and desalted river sand as raw materials, as well as a preparation method thereof, belonging to the technical field of materials. The boron-free high-performance glass fiber is prepared from the following raw materials in percentage by weight: 30-55% of pulverized fuel ash, 0-15% of blast-furnace slag, 40-50% of desalted river sand, 0-12%of magnesium oxide, and 0-6% of calcium oxide. The high-performance glass fiber can be prepared in a common refractory material liner smelting furnace by pretreating the pulverized fuel ash and adding a less amount of blast furnace slag, magnesium oxide and calcium oxide through taking pulverized fuel ash and desalted river sand as raw materials, the strength and elastic modulus are obviously higher than those of the common E glass and ECR, Advantex boron-free glass and the like, the preparation processes are simple, the smelting temperature is at 1400-1420DEG C, a difference between the fiber forming temperature and liquid phase temperature is more than 70DEG C which is far higher than the lowest standard of the glass fiber industrial production being 50DEG C, the production cost is low, and the glass fiber industrial production standard can be met. The component glass has higher chemical corrosion resistance and high-temperature resistance properties compared with the traditional E glass.

Owner:UNIV OF JINAN

Preparation method of iron vanadium nitride

InactiveCN102976290ALow raw material requirementHigh recovery rateNitrogen compoundsProcess efficiency improvementIron powderVanadium nitride

The invention relates to the technical field of vanadium metallurgy, and especially relates to a method for preparing iron vanadium nitride. The method comprises the steps that: A, a vanadium-containing compound, a solid reducing agent, and reduced iron powder are uniformly mixed and molded; B, the material obtained in the step A is placed in a reactor in a nitrogen protective atmosphere, and is subjected to a reaction for 6-10h under a high temperature of 1300-1600 DEG C; and C, the product obtained by the step B is fetched and cooled, and the iron vanadium nitride product is obtained when a temperature is lower than 120 DEG C. The iron vanadium nitride preparation method provided by the invention is energy-saving and consumption-reducing, and has the advantages of simple and feasible technology, high operability, and low investment. With the method, production capacities of vanadium-nitrogen alloy products can be greatly improved.

Owner:ANYANG YUQIANXIN METALLURGY REFRACTORY

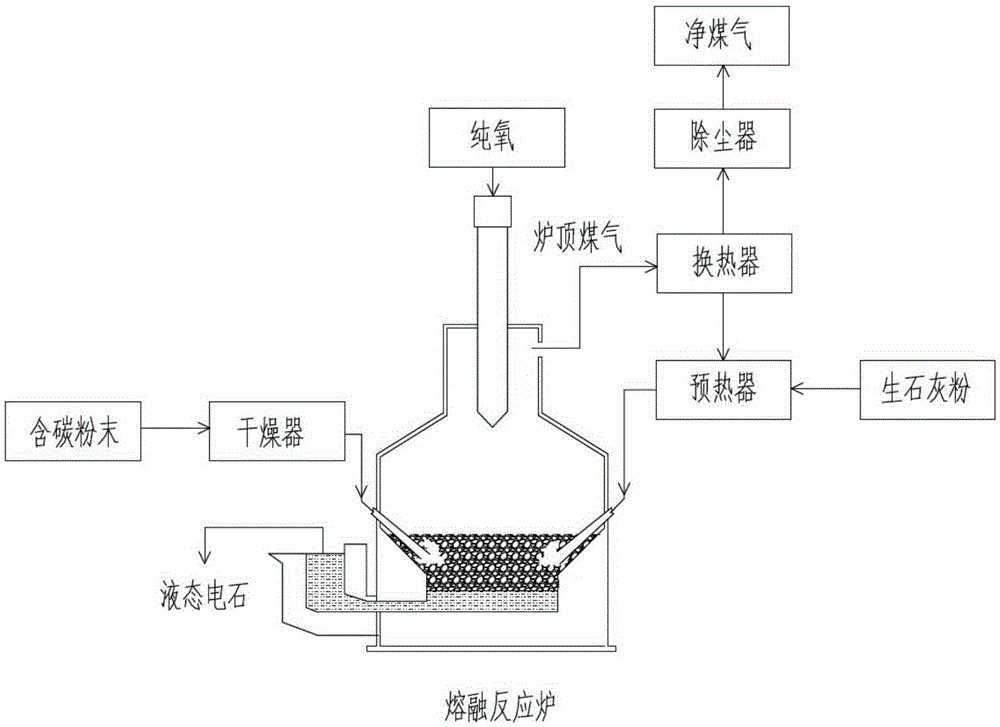

Calcium carbide smelting process by oxygen heating method

ActiveCN105293497AExpand sourceLow raw material requirementEnergy inputCalcium carbideCombustionSmelting process

The invention provides a calcium carbide smelting process by an oxygen heating method. The processing process is realized with supports of a fusion reacting furnace, a preheater, a drier, a heat exchanger, pure oxygen equipment and raw materials, wherein, pulverized quick lime is preheated to 950-1200 DEG C by the preheater; coke powder or semi-coke powder or coal dust or mixed carbonaceous powder are preheated to 200-400 DEG C by the drier, and the water content is reduced to less than 1%; preheated raw materials are injected into the fusion reacting furnace, the combustion temperature is 1500-2500 DEG C, liquid state calcium carbide generates in the condition, the liquid state calcium carbide is discharged from a calcium carbide outlet of the fusion reacting furnace, and gas generated in the fusion reacting furnace is discharged from a gas outlet at a furnace roof; the process solves the technology problem of the calcium carbide smelting process by the oxygen heating method, and environmental protection and energy saving effects are solved.

Owner:WISDRI ENG & RES INC LTD

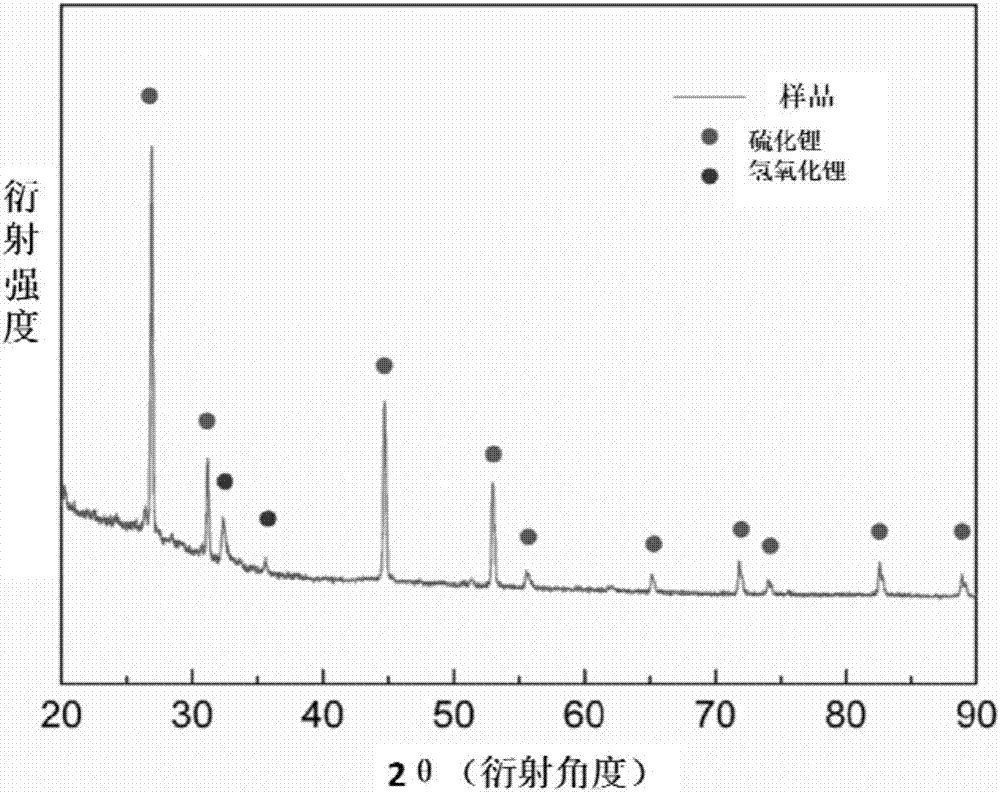

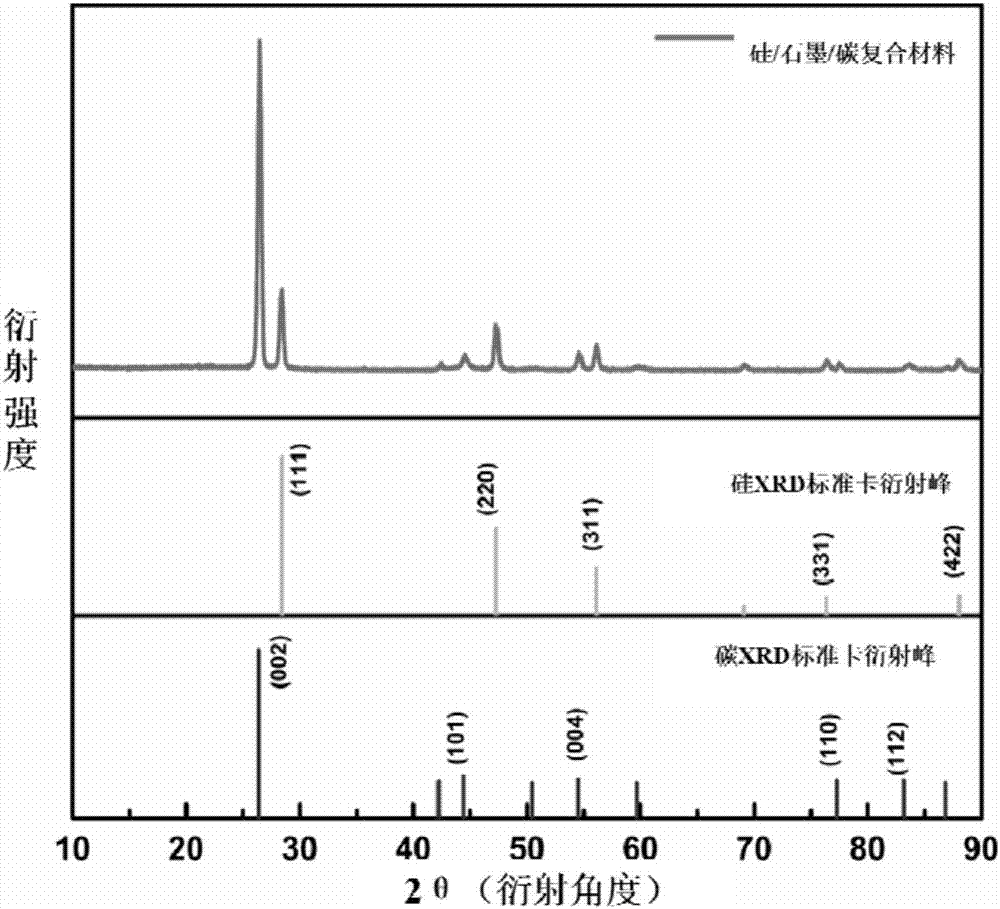

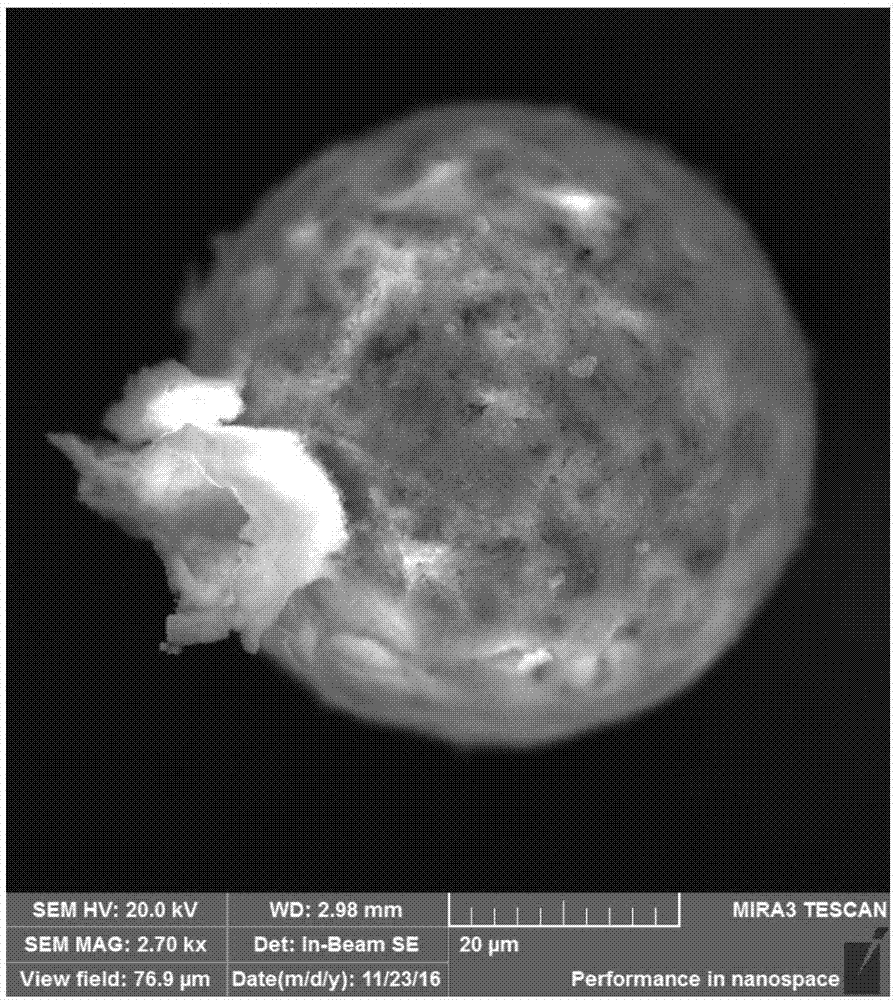

Lithium sulfide/nano silicon carbon whole battery and preparation method and application thereof

InactiveCN107275571AEvenly dispersedSimple stepsElectrode thermal treatmentFinal product manufactureCarbon compositesCarbon coated

The invention discloses a lithium sulfide / nano silicon carbon whole battery and a preparation method and application thereof. The preparation method includes following steps: dispersing lithium sulfate into water, dispersing an organic carbon source into an organic solvent, drying and granulating to prepare a composite precursor after sufficient mixing, and calcining at high temperature to obtain a carbon coated lithium sulfide composite anode material; respectively dispersing nano silicon, the organic carbon source and artificial graphite into the organic solvent, drying and granulating after sufficient mixing, and calcining at high temperature to obtain a carbon coated silicon carbon composite cathode material; assembling the carbon coated lithium sulfide composite anode material and the carbon coated silicon carbon composite cathode material to obtain the lithium sulfide / nano silicon carbon whole battery. The preparation method is simple in preparation process, simple and convenient to operate and suitable for large-scale production; the whole battery prepared by the method has the advantages of high first-time charging and discharging efficiency, high specific capacity and good circulating performance, can meet needs of high-capacity electronic equipment and is suitable for electromobiles or portable electronic products.

Owner:SOUTH CHINA NORMAL UNIVERSITY

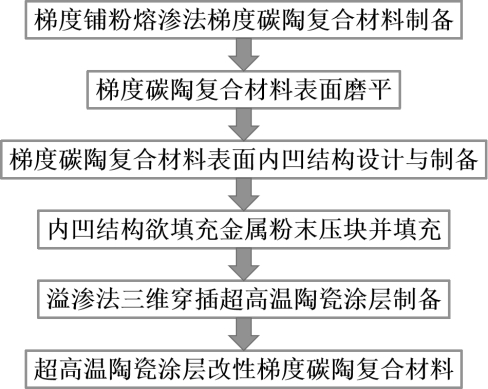

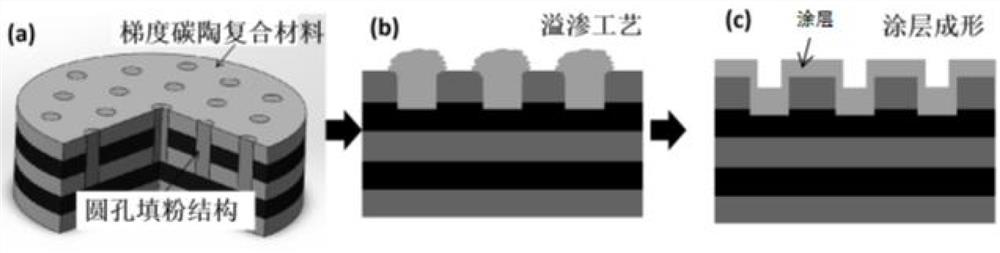

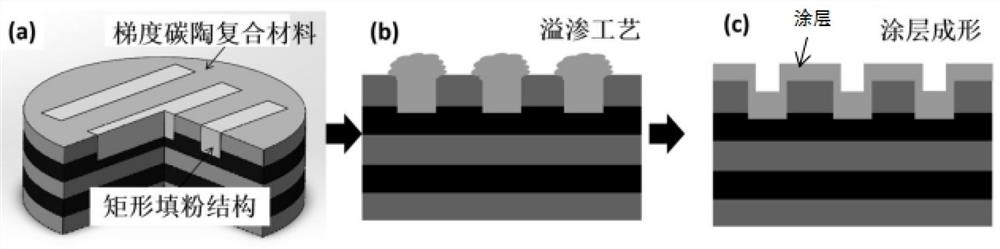

Ceramic coating protection gradient carbon-ceramic composite material and preparation method thereof

ActiveCN113582713AStable high temperature mechanical propertiesImprove high temperature mechanical propertiesCeramic compositeCarbide coating

The invention discloses a ceramic coating protection gradient carbon-ceramic composite material and a preparation method thereof. The ceramic coating protection gradient carbon-ceramic composite material comprises: a gradient carbon-ceramic composite material which is provided with a concave structure on the surface thereof and is a gradient C / C-ZrC-SiC composite material; and an ultrahigh-temperature ceramic coating which is continuously arranged along the surface of the gradient carbon-ceramic composite material and the inner wall surface of the concave structure. The ultrahigh-temperature ceramic coating is an indissolvable metal carbide coating formed by diffusing and infiltrating indissolvable metal along the surface of the gradient carbon-ceramic composite material and reacting the indissolvable metal with the surface of the gradient carbon-ceramic composite material. Therefore, the formed ceramic coating is a three-dimensional jack structure coating, the interfacial strength of the ceramic coating is far higher than that of a two-dimensional plane coating, the surface area of the coating is greatly increased due to the arrangement of the concave structure, meanwhile, the flow resistance of melt on the surface of the composite material can be improved, then the overall temperature resistance of the composite material can be improved, and the risk of coating stripping is reduced.

Owner:CENT SOUTH UNIV

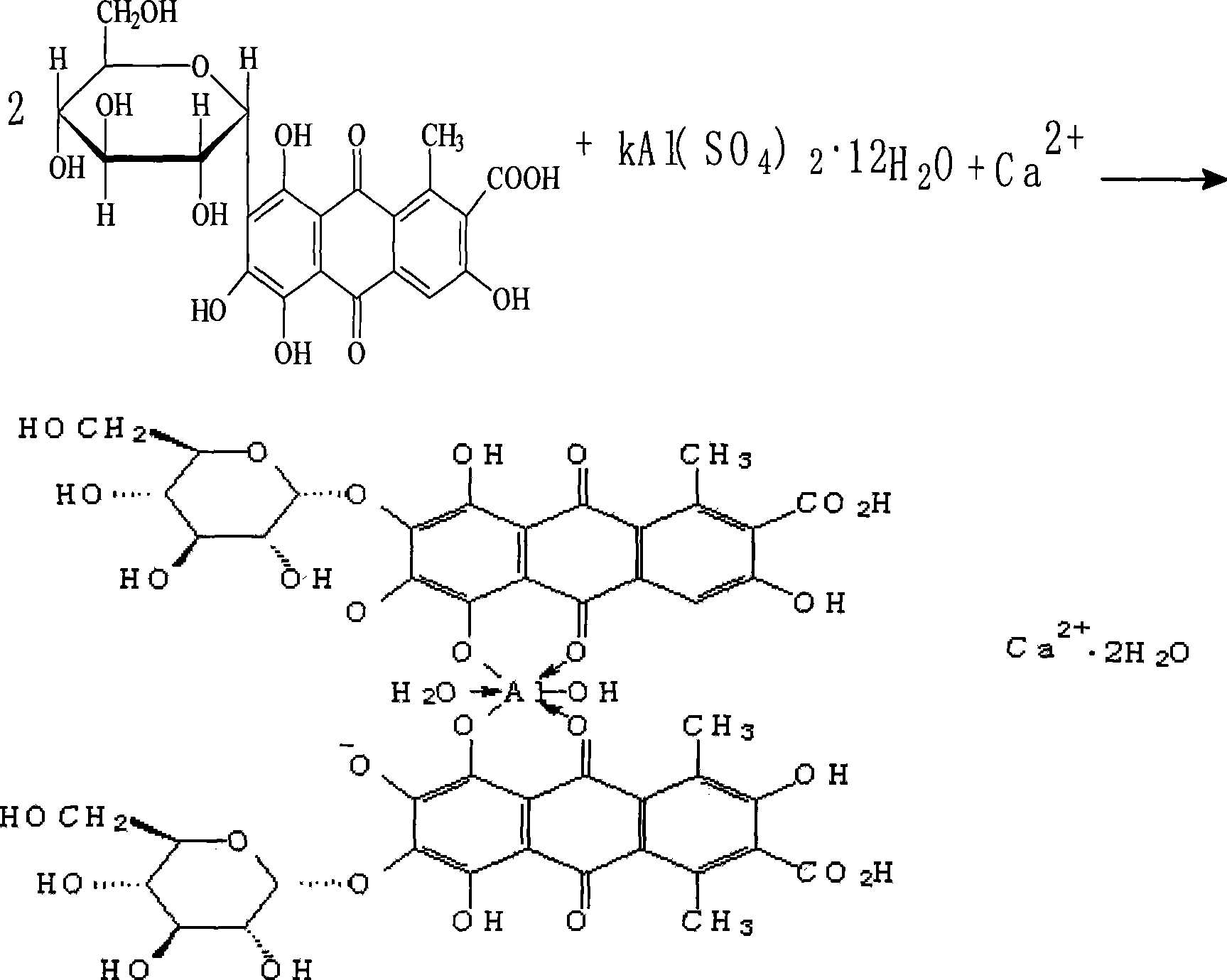

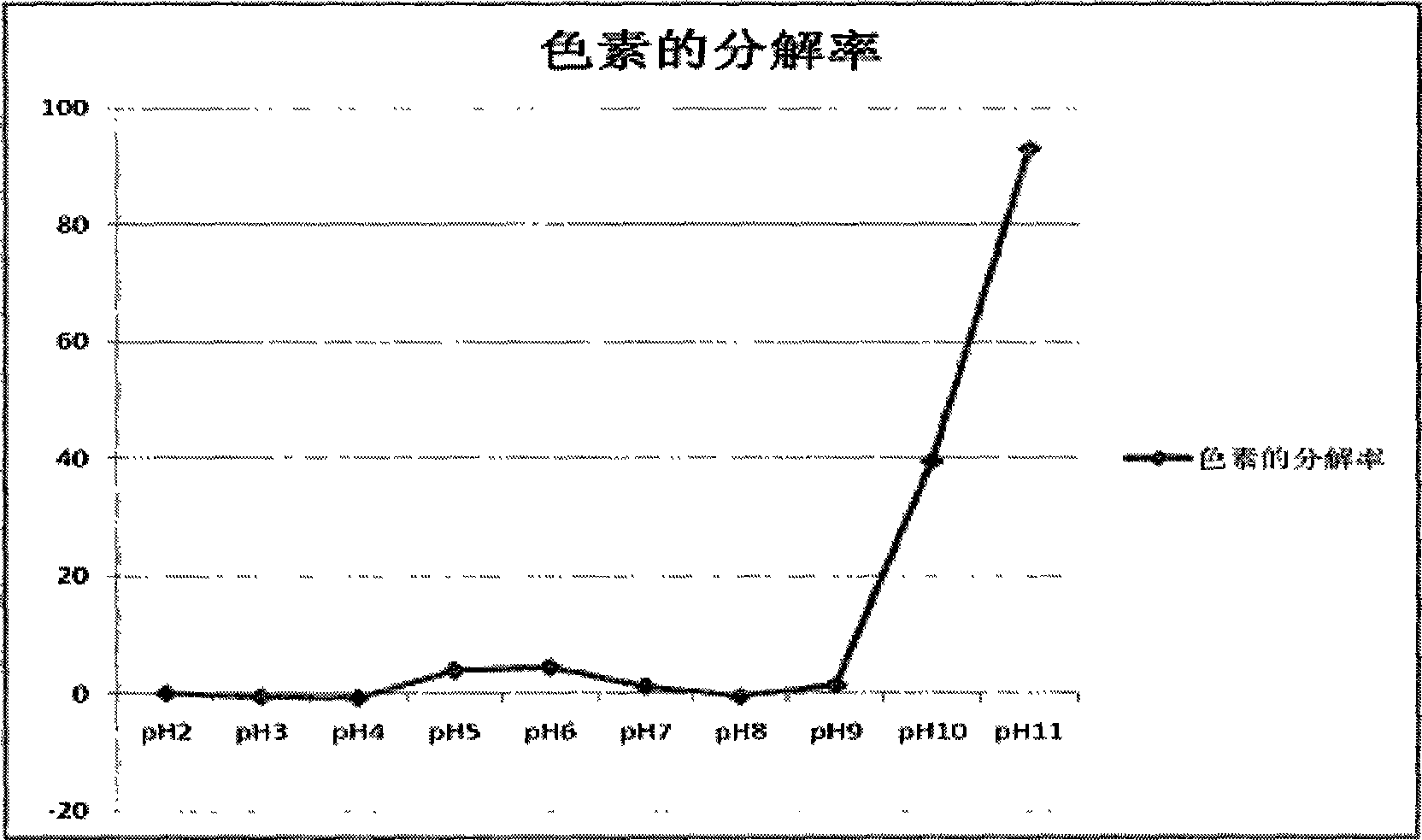

Method for preparing water-soluble cochinilin color lake

InactiveCN101461513AIncrease unit outputReduce the rising cost of purificationNatural dyesFood preparationCarminic acidWater soluble

The invention relates to a preparation of water soluble lake of carminic acid, including steps of: (1) preparation of cochineal color acid mother liquor; (2) laking; (3) generation of water soluble lake. The water soluble lake of carminic acid can be widely applied to food product, candy, beverage, medicament and cosmetics.

Owner:上海染料研究所有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com