Calcium carbide smelting process by oxygen heating method

An oxygen-thermal method and calcium carbide technology are applied in the field of smelting to achieve good reaction kinetic conditions, reduce production energy consumption, and broaden the source of raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

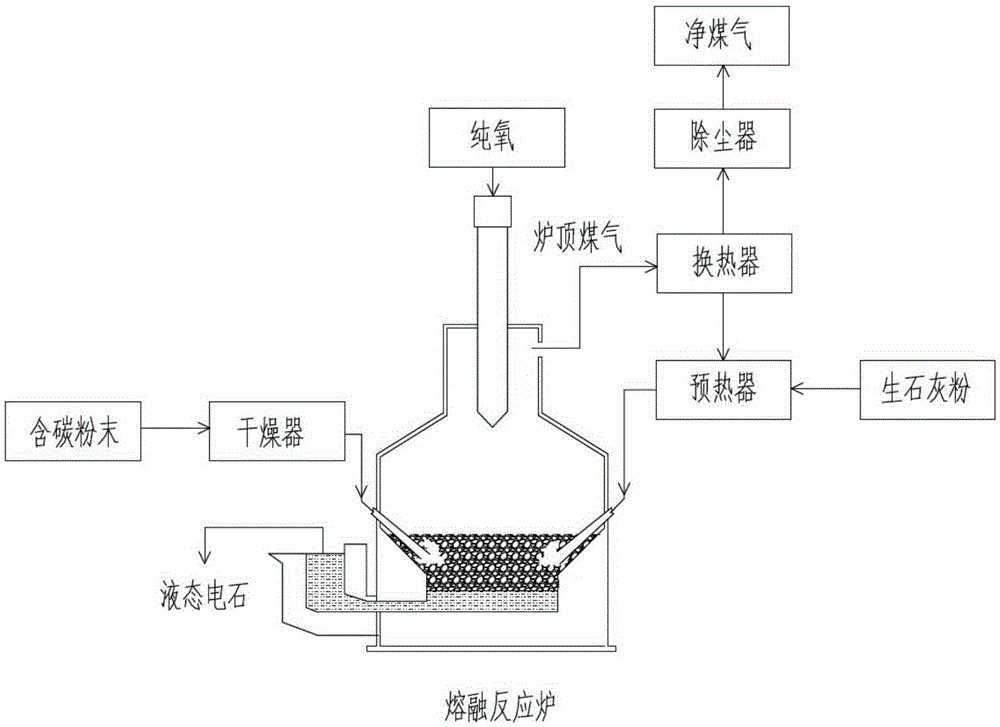

Image

Examples

Embodiment 1

[0021] 1. Use a preheater to preheat quicklime powder with a particle size of 0-3mm to 950°C, so that the remaining limestone (CaCO 3 ) is fully decomposed into quicklime (CaO);

[0022] 2. Use a dryer to preheat the coke powder with a particle size of 0-3mm to 200°C to reduce the moisture content of the coke powder to below 1%;

[0023] 3. Spray the preheated quicklime powder and coke powder into the melting reaction furnace respectively;

[0024] 4. Control the mass ratio of coke powder and quicklime powder sprayed into the melting reactor to 1.5:1;

[0025] 5. The amount of pure oxygen injected into the top of the furnace is 600Nm 3 / t(coke powder);

[0026] 6. Part of the coke powder and pure oxygen burn to release heat. The temperature in the melting reaction furnace reaches 1500 ° C. Quick lime powder and coke powder react rapidly in the melting reaction furnace. After producing liquid calcium carbide, it is discharged from the lower part of the melting reaction furna...

Embodiment 2

[0029] 1. Use a preheater to preheat quicklime powder with a particle size of 0-2mm to 1000°C, so that the remaining limestone (CaCO 3 ) is fully decomposed into quicklime (CaO);

[0030] 2. Use a dryer to preheat the blue charcoal powder with a particle size of 0-1mm to 250°C to reduce the moisture content of the blue charcoal powder to below 1%;

[0031] 3. Spray the preheated quicklime powder and blue charcoal powder into the melting reaction furnace respectively;

[0032] 4. Control the mass ratio of blue charcoal powder and quicklime powder sprayed into the melting reactor to be 1.8:1;

[0033] 5. The amount of pure oxygen injected into the top of the furnace is 800Nm 3 / t (blue charcoal powder);

[0034] 6. Part of the blue charcoal powder and pure oxygen burn to release heat, the temperature in the melting reaction furnace reaches 1800 ℃, quicklime powder and blue charcoal powder react rapidly in the melting reaction furnace, and after producing liquid calcium carbid...

Embodiment 3

[0037] 1. Use a preheater to preheat quicklime powder with a particle size of 0-1mm to 1100°C, so that the remaining limestone (CaCO3 ) is fully decomposed into quicklime (CaO);

[0038] 2. Use a dryer to preheat the pulverized coal with a particle size of 0-0.5mm to 300°C to reduce the moisture content of the pulverized coal to below 1%;

[0039] 3. Spray the preheated quicklime powder and coal powder into the melting reaction furnace respectively;

[0040] 4. Control the mass ratio of coal powder and quicklime powder sprayed into the melting reactor to 2.2:1;

[0041] 5. The amount of pure oxygen injected into the top of the furnace is 1000Nm 3 / t(coal powder);

[0042] 6. Part of the coal powder and pure oxygen combust to release heat, the temperature in the melting reaction furnace reaches 2200 ℃, quick lime powder and coal powder react rapidly in the melting reaction furnace, and after producing liquid calcium carbide, it is discharged from the lower part of the melting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com