Environmental-friendly organic silicon water blocking prevention agent for drilling fluid and preparation method and application thereof

A technology of waterproof locking agent and organosilicon, applied in the field of petroleum exploration, can solve the problems of high cost, unenvironmental protection and poor effect of waterproof locking agent, and achieve the effects of low foaming rate, improved permeability and safe preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

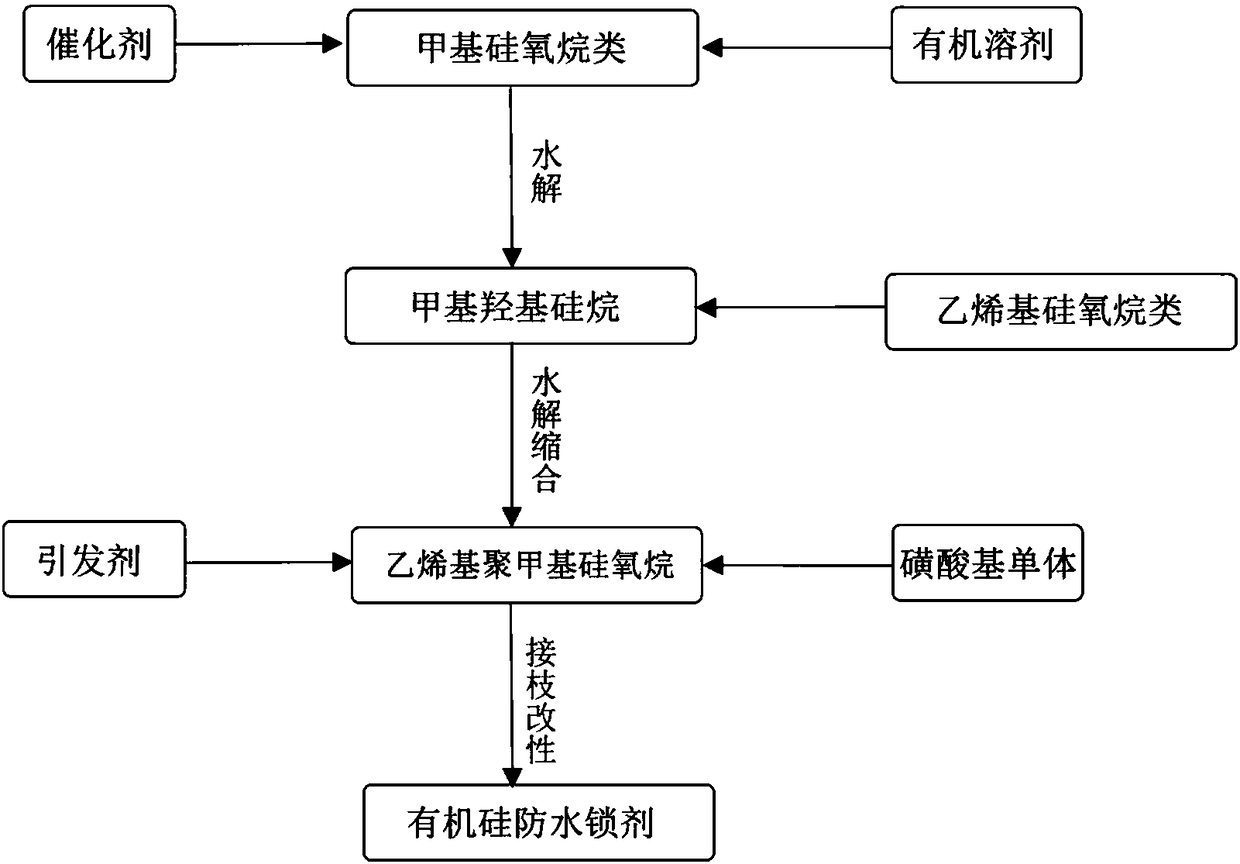

[0049] This example provides a method for preparing an environment-friendly silicone waterproof locking agent for drilling fluid. The preparation flow chart is as follows: figure 1 shown, including the following steps:

[0050] Step 1, add 20.0g ethanol, 20.0g dimethyldimethoxysilane, 10.0g dimethyldiethoxysilane, 5.0g methyltrimethoxysilane and 5.0g methyl Triethoxysilane was heated up to 50-60° C., stirred evenly, and then 8.4 g of 10% hydrochloric acid solution was added dropwise, and hydrolysis reaction was carried out for 1 h after the dropwise addition was completed for 5 minutes.

[0051] Step 2, dropwise add 0.5g of vinyltriethoxysilane, 0.5g of methylvinyldimethoxysilane and 1.0g of methylvinyldiethoxysilane, and perform hydrolysis after 0.5h dropwise Condensation reaction 1.5h;

[0052] Step 3, continue to heat up to 60-75 ° C, add dropwise 10 g of 14% 2-acrylamide-2-methylpropanesulfonic acid aqueous solution and 10 g of 0.1% azobisisobutyronitrile (AIBN ) ethano...

Embodiment 2

[0058] This example provides a method for preparing an environment-friendly silicone waterproof locking agent for drilling fluid. The preparation flow chart is as follows: figure 1 shown, including the following steps:

[0059] Step 1, add 20.0g of isopropanol, 20.0g of dimethyldimethoxysilane, 15.0g of dimethyldichlorosilane and 5.0g of diphenyldimethoxy in a 500mL stirred reactor Silane, heated up to 50-60°C, stirred evenly, then added dropwise 7.2g of sulfuric acid solution with a mass fraction of 10%, and carried out hydrolysis reaction for 1h after the dropwise addition was completed for 5 minutes.

[0060] Step 2, dropwise add 1.0g of vinyltriethoxysilane, 0.5g of vinyltris(2-methoxyethoxy)silane and 0.5g of vinyltriisopropoxysilane, add dropwise for 0.5h Carry out hydrolysis condensation reaction 2h after finishing;

[0061] Step 3, continue to heat up to 60-75°C, add dropwise 10g of 14% 2-hydroxy-3-allyloxy-1-propenesulfonic acid aqueous solution and 10g of 0.1% azob...

Embodiment 3

[0067] This example provides a method for preparing an environment-friendly silicone waterproof locking agent for drilling fluid. The preparation flow chart is as follows: figure 1 shown, including the following steps:

[0068] Step 1, add 20.0g toluene, 20.0g dimethyldimethoxysilane, 15.0g dimethyldiethoxysilane and 5.0g dodecyltrichlorosilane to a 500mL stirred reactor, and heat up to 50 -60°C, after stirring evenly, 8.0 g of hydrochloric acid solution with a mass fraction of 10% was added dropwise, and the hydrolysis reaction was carried out for 1 h after the dropwise addition was completed for 5 minutes.

[0069] Step 2: Add 0.4 g of vinyltrichlorosilane, 1.0 g of vinyltriethoxysilane and 1.0 g of vinyltrimethoxysilane dropwise, and carry out hydrolysis and condensation reaction for 1.5 h after the dropwise addition for 0.5 h;

[0070] Step 3, continue to heat up to 60-75°C, add 10g of 14% 2-acrylamide-2-methylpropanesulfonic acid (AMPS) solution and 10g of 0.1% lauryl pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| critical surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com