Boron-free high-performance glass fiber and preparation method thereof

A glass fiber, high-performance technology, applied in the field of materials, can solve the problems of inapplicability and high raw material requirements, and achieve the effect of low cost and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

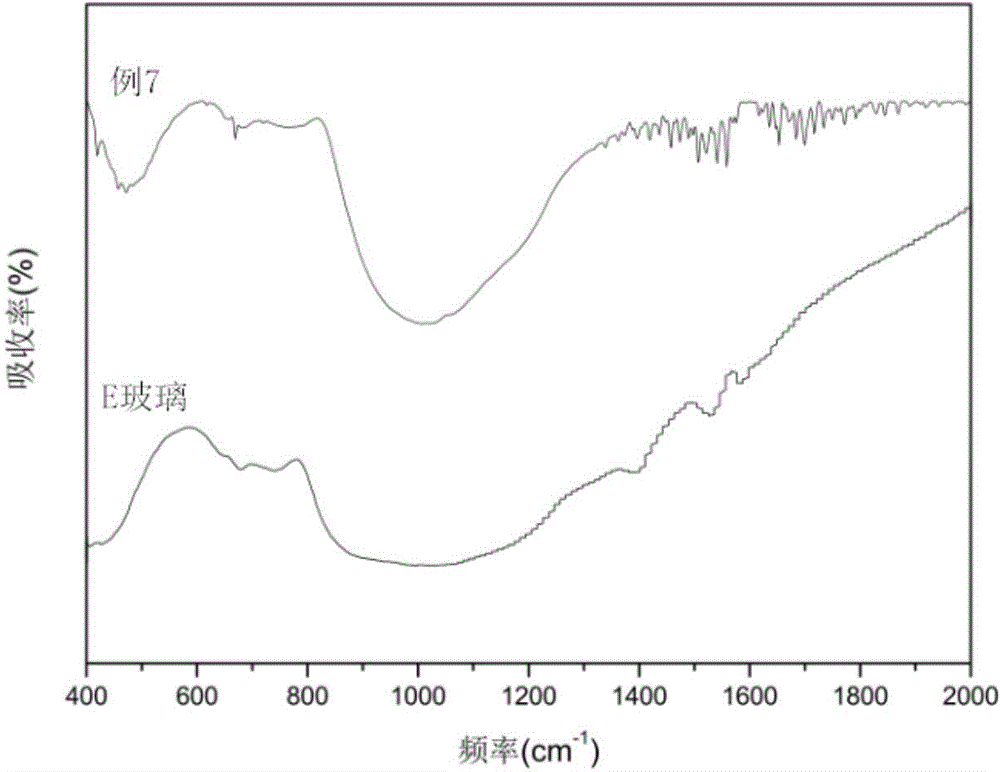

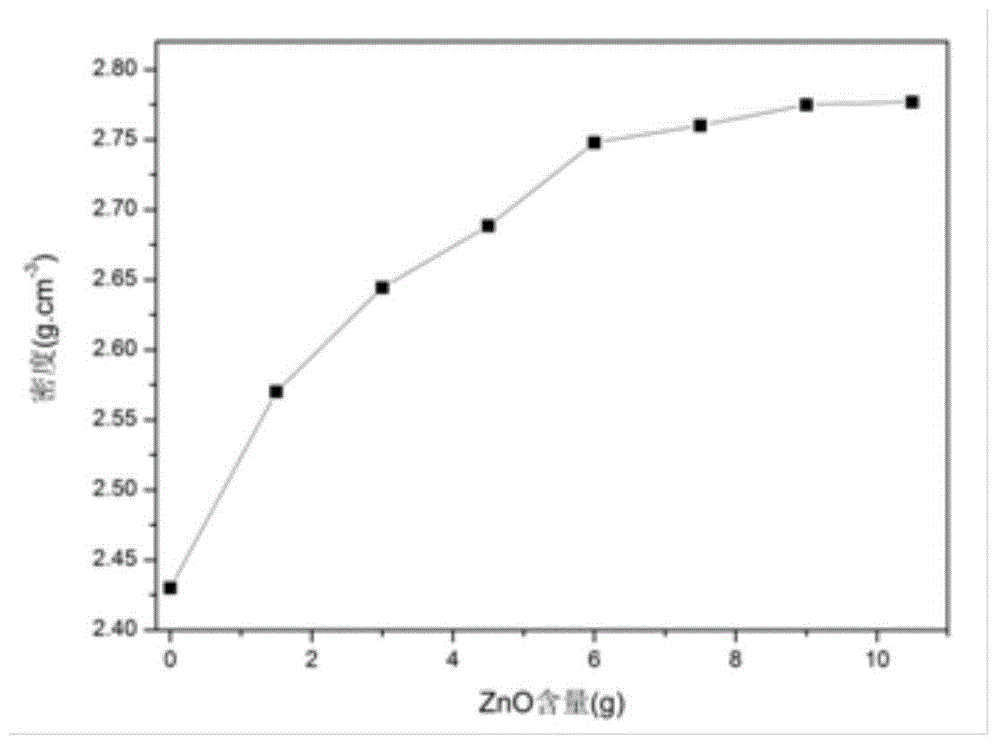

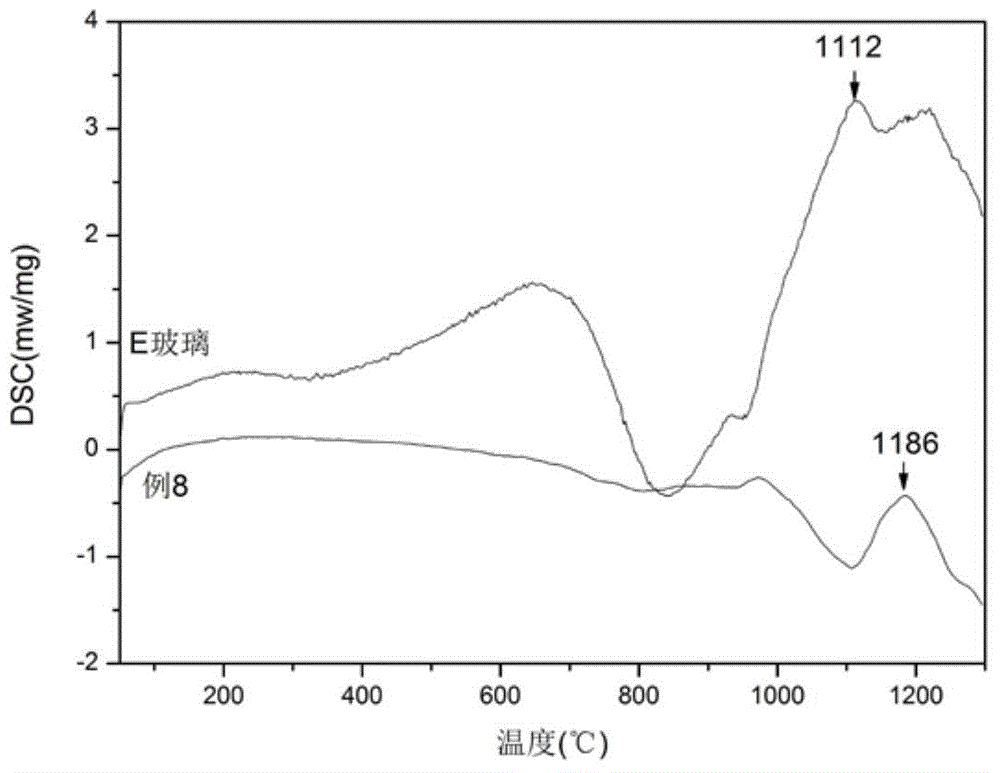

Embodiment 1

[0059] The raw material of the present invention can be prepared into glass or glass fiber, and the standard for judging whether it can be drawn is the analysis of the thermal properties of the glass. The method of preparing glass is to cast and anneal the molten glass formed by melting raw materials; the method of preparing glass fiber is to draw the molten glass formed by melting raw materials at the drawing temperature according to the conventional process. The present invention tests the relevant technical parameters of the glass fiber, which has nothing to do with the mechanical properties, so it only needs to be made into a glass sample for testing.

[0060] Weigh the raw materials according to the raw material formula in Table 2 below, and prepare them into glass samples. In the lifting crucible electric furnace, melt at 1500°C for 3 hours and pour it into the graphite mold, and then send it into the lifting crucible electric furnace for annealing (cast the glass liquid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com