Method for preparing grade-adjustable potassium fluotitanate through using high-silicon-titanium iron ore

A technology of potassium fluorotitanate and ilmenite, which is applied in chemical instruments and methods, titanium compounds, inorganic chemistry, etc., to achieve the effects of saving production costs, simple operation and easy control, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

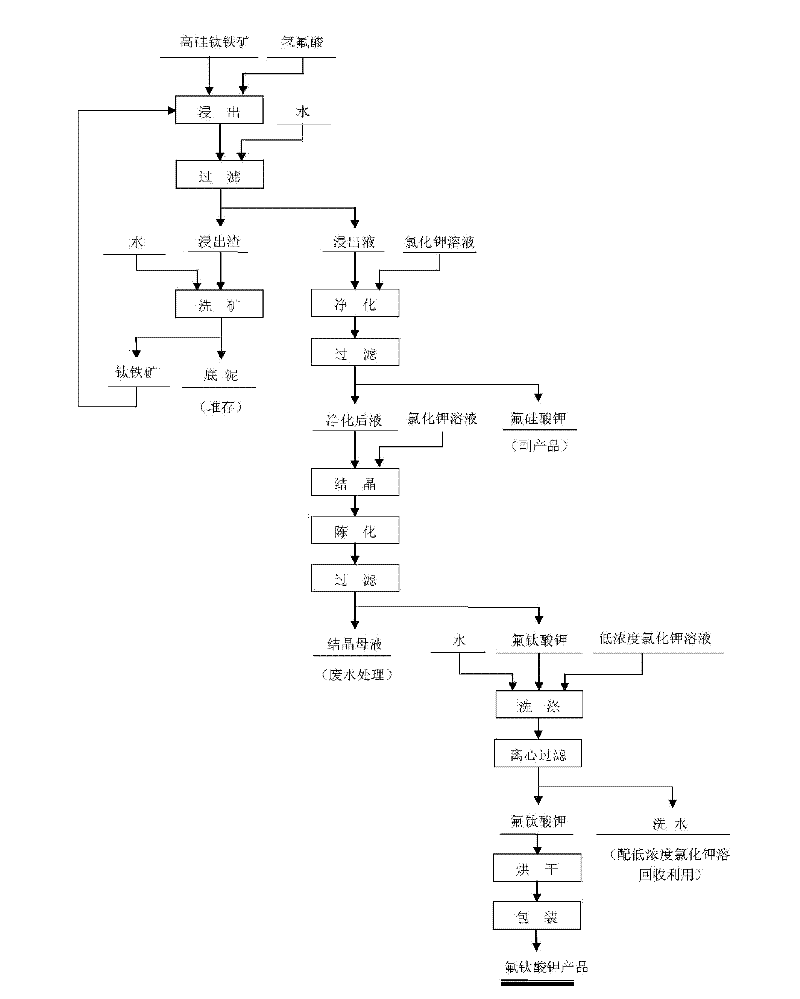

Method used

Image

Examples

Embodiment 1

[0056] Purification and removal of silicon: 3m 3 Add 0.44m3 (1.6 times the theoretical value) of potassium chloride solution with a concentration of 259g / L into the mixed leaching solution, add time for 1.8h, let stand for 3h, and filter;

[0057] Output: purification liquid 3.52m 3 , containing 141.21g / L of titanium dioxide and 1.12g / L of silicon dioxide,

[0058] Potassium fluorosilicate: 92.03kg, purity 98.7%;

[0059] Crystallization: The purification solution is 3.52m 3 Add 4.35m of potassium chloride solution with a concentration of 259g / L 3 (1.2 times the theoretical value), adding time 2h, standing for 3h, filtering;

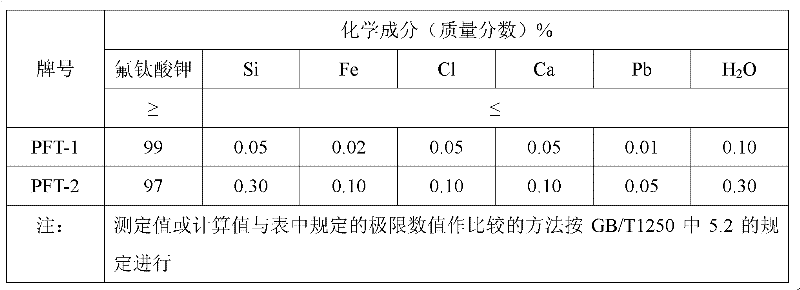

[0060] Output: potassium fluorotitanate: 1441 kg, purity 99.7%, silicon dioxide content 0.101% (Si0.05%).

Embodiment 2

[0062] Purification and removal of silicon: 3m 3 Add 0.45m potassium chloride solution with a concentration of 259g / L to the mixed leachate 3 (1.65 times of theoretical value), adding time 1.9h, standing for 2.83h, filtering,

[0063] Output: purification liquid 3.56m 3 , containing titanium dioxide 140.79g / L, containing silicon dioxide 0.88g / L, potassium fluorosilicate: 93.44kg, purity 99.0%;

[0064] Crystallization: The purification solution is 3.56m 3 Add 4.25m of potassium chloride solution with a concentration of 259g / L 3 (1.18 times the theoretical value), adding time 2.2h, standing for 3.5h, filtering;

[0065] Yield: potassium fluotitanate: 1438.85 kg, purity 99.8%, silicon dioxide content 0.09% (Si0.042%).

[0066] 4. Production of secondary products:

Embodiment 3

[0068] Purification and removal of silicon: 3m 3 Add 0.39m potassium chloride solution with a concentration of 259g / L to the mixed leachate 3 (1.4 times of theoretical value), adding time 1.6h, standing for 3h, filtering,

[0069] Output: purification liquid 3.44m 3 , containing titanium dioxide 146.81g / L, containing silicon dioxide 1.82g / L, potassium fluorosilicate: 84.08kg, purity 98.6%;

[0070] Crystallization: The purification solution is 3.44m 3 Add 4.35m of potassium chloride solution with a concentration of 259g / L 3 (1.2 times the theoretical value), adding time 2.1h, standing for 3h, filtering;

[0071] Output: Potassium fluotitanate: 1466.44kg, purity 98.6%, silicon dioxide content 0.42% (Si0.20%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com