Method for extracting gold from cyanidation tailings

A technology of cyaniding tailings and calcium chloride, which is applied in the field of mineral processing and metallurgy, can solve the problems of low gold recovery rate, achieve high gold recovery rate, improve resource utilization rate, and high pellet strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

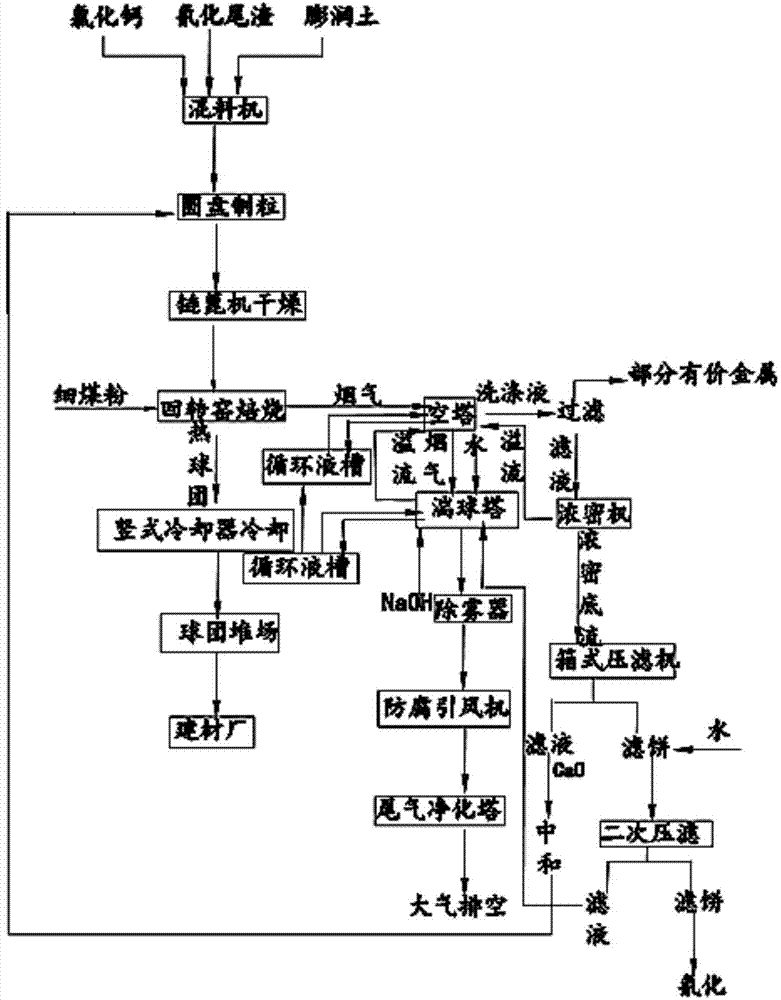

Image

Examples

Embodiment 1

[0037] (1) Get 10kg of cyanide tailings, 200g of bentonite, and 100g of calcium chloride and add them to the mixer to form a mixture, and then moisten and grind the mixture so that the fineness of the mixture—200 mesh particle size accounts for more than 80% of the mass ratio ;

[0038] (2) sending the mixed material after moistening into a disc granulator with a diameter of 5 cm to granulate, spraying the calcium chloride solution obtained in 1.2L step (7) during the granulation process;

[0039] (3) The prepared pellets are sent to the grate machine for drying. The grate machine is divided into five drying sections. At 220°C, dry the pellets until the water content is less than 0.5wt%;

[0040] (4) The dried pellets enter the rotary kiln through the grate chute for roasting. In the rotary kiln, the fine coal powder sprayed from the coal injection pipe of the kiln head provides heat to control the temperature at 1050°C, and the roasting is completed for 4 hours to obtain hot...

Embodiment 2

[0046] (1) Get 10kg of cyanide tailings, 200g of bentonite, and 500g of calcium chloride and add them to the mixer to form a mixture, and then moisten and grind the mixture so that the fineness of the mixture—200 mesh particle size accounts for more than 80% of the mass ratio ;

[0047] (2) sending the mixed material after moistening into a disc granulator with a diameter of 5 cm to granulate, spraying the calcium chloride solution gained in the step (7) of 1.5L during the granulation process;

[0048] (3) The prepared pellets are sent to the grate machine for drying. The grate machine is divided into five drying sections. At 235°C, dry the pellets until the water content is less than 0.5wt%;

[0049] (4) The dried pellets enter the rotary kiln through the grate chute for roasting. In the rotary kiln, the fine coal powder sprayed from the coal injection pipe of the kiln head provides heat to control the temperature at 1150°C, and the roasting is completed for 4 hours to obtain ...

Embodiment 3

[0055] (1) Get 10kg of cyanide tailings, 200g of bentonite, and 1000g of calcium chloride and add them to the mixer to form a mixture, and then grind the mixture so that the fineness of the mixture -200 mesh particle size accounts for more than 80% of the mass ratio ;

[0056] (2) sending the mixed material after moistening and grinding into a disc granulator with a diameter of 5 cm to granulate, and spray the calcium chloride solution obtained in the step (7) of 1L in the granulation process;

[0057] (3) The prepared pellets are sent to the grate machine for drying. The grate machine is divided into five sections of drying area. At 250°C, dry the pellets until the water content is less than 0.5wt%;

[0058] (4) The dried pellets go through the grate chute into the rotary kiln for roasting. In the rotary kiln, the heat is provided by the fine coal powder sprayed from the coal injection pipe of the kiln head to control the temperature at 1200°C, and the roasting is completed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com