Production equipment for large-sized plastic-wood board

A board production equipment, plastic wood technology, applied in the processing and production of plastic wood board, large-scale plastic wood board production equipment field, can solve the problems of high raw material requirements, low output, limited product specifications, etc., to achieve low raw material requirements, output High, stable product quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

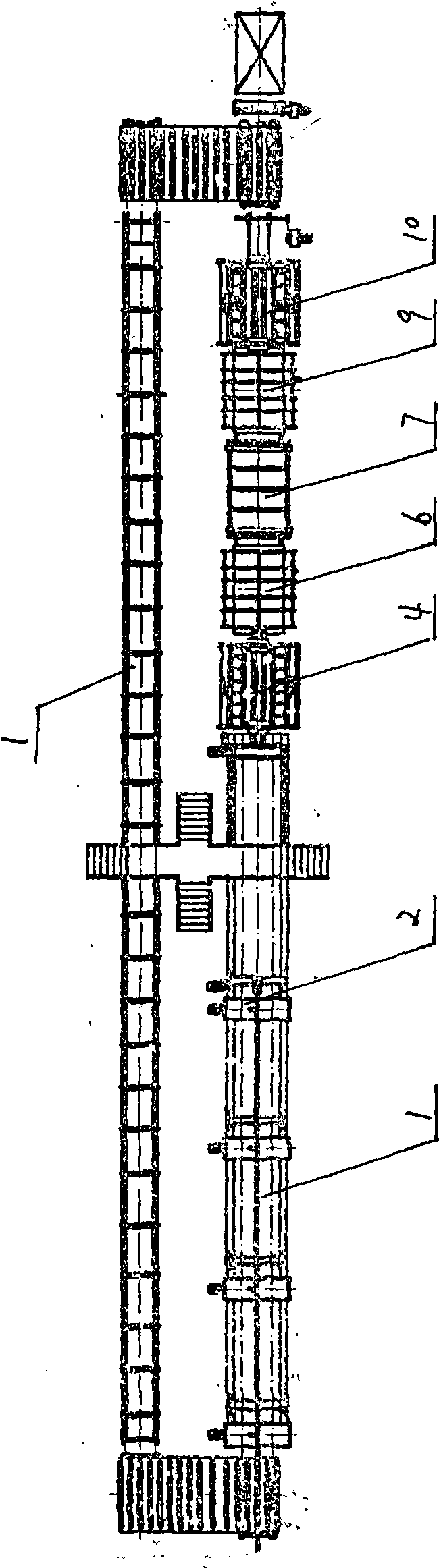

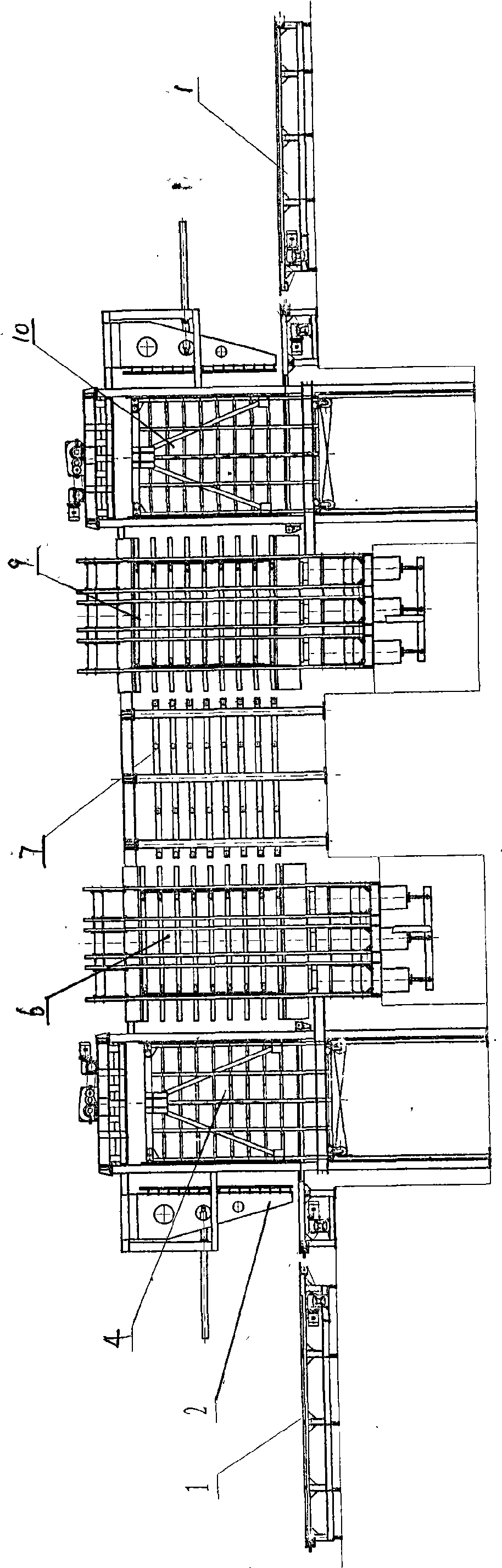

[0053] Example 1, see Figure 1-14 , the processing and assembling transmission device 1 is installed on the production line bracket and runs through the entire production line. There are template protrusions 16, the template protrusions 16 block the mold frame 13 and cannot be pulled out from the mold frame handle 14, the transmission device 1 is a chain drive, and can also be a conveyor belt drive;

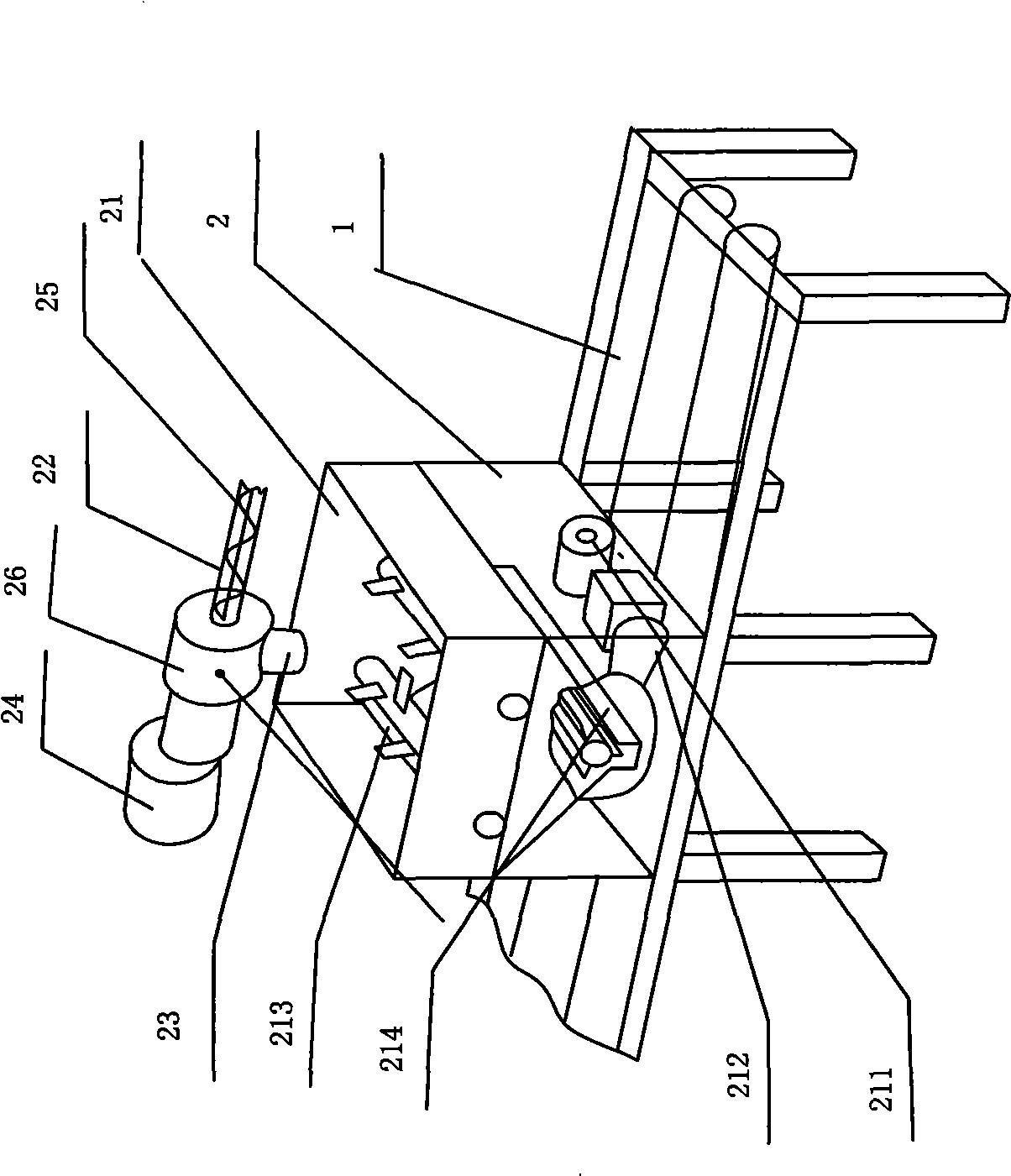

[0054] Feeding device 2 is installed at one end of transmission device 1, and it comprises feeder 21, and feeder pipe 22 is arranged above feeder 21, and screw rod is arranged in feeder pipe 22, is made by steel bar 25, and the end of feeder pipe 22 has motor 24, and The steel bar 25 is connected to drive the steel bar 25 to rotate, so that the material is sent to the top of the feeding hopper. There is a switch 26 on the feeding pipe 22. A feeding pipe 23 is installed on the feeding pipe 22. When the switch is turned on, the material enters from the feeding pipe 23. There are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com