Method for preparing powdery electrolytic manganese dioxide (EMD)

An electrolytic manganese dioxide, powdered technology, applied in the electrolysis process, electrolysis components and other directions, can solve the problems of difficult control of product quality, particle size and morphology, difficult removal of sulfate ions, affecting material properties, etc. Low, low raw material requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Before electrolysis, treat the anode plate with acid to activate its surface: prepare a sulfuric acid solution with a concentration of 0.1mol / L, use a lead-silver alloy plate for the anode, and a graphite plate for the cathode, place the anode and cathode plates in the acid solution, / m 2 Electrolyze at room temperature for 5 minutes at a current density of 100%; lightly polish the anode plate after electrolysis with fine sandpaper to make its surface smooth.

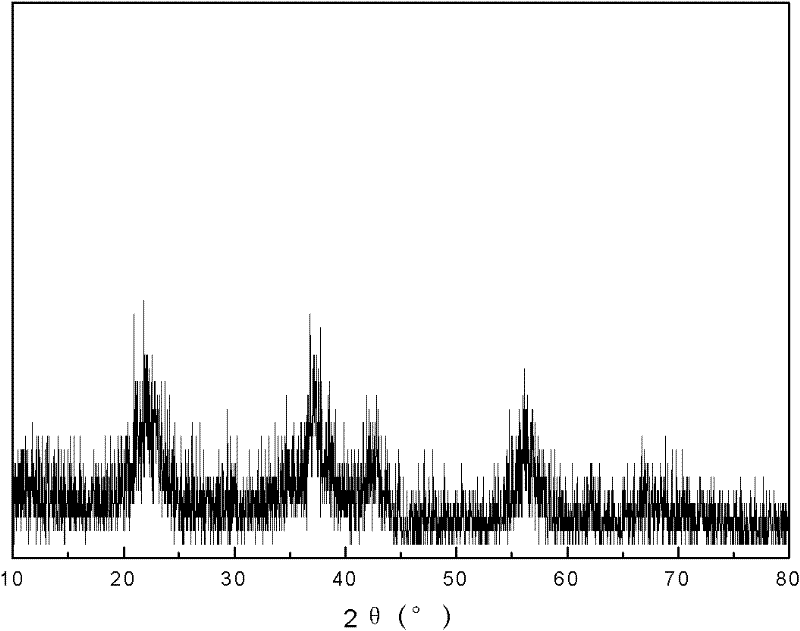

[0032] Weigh 17g of chemically pure manganese sulfate and 75g of concentrated sulfuric acid, dissolve them in 250mL of water, add polyethylene glycol accounting for 0.01% of the mass of manganese sulfate as an active agent, and prepare an electrolytic solution, using a diaphragm electrolyzer, constant current electrolysis, and setting the current density at 1A / m 2 , Electrolyzed at 30°C for 60 minutes, the particulate manganese dioxide was suspended in the solution, the solution was filtered, the anode area afte...

Embodiment 2

[0034] Before electrolysis, carry out acid treatment on the anode plate to activate its surface: prepare an acid solution with a concentration of 0.5mol / L, use a lead-silver alloy plate for the anode, and use a stainless steel plate for the cathode, place the anode and cathode plates in the acid solution, at 0.01A / m 2 Electrolyze at room temperature for 30 minutes at a current density of 100%; lightly polish the anode plate after electrolysis with fine sandpaper to make its surface smooth.

[0035] Weigh 42g of chemically pure manganese sulfate, 75g of concentrated sulfuric acid, dissolve them in 250mL of water, add ethanol accounting for 10% of the mass of manganese sulfate as an active agent, and prepare an electrolytic solution, adopt a diaphragm electrolyzer, conduct constant current electrolysis, and set the current density at 5000A / m 2 , electrolysis at 30°C for 240min, particulate manganese dioxide was suspended in the solution, the solution was filtered, the anode a...

Embodiment 3

[0037] Before electrolysis, treat the anode plate with acid to activate its surface: prepare an acid solution with a concentration of 0.5mol / L; use a titanium-manganese alloy plate for the anode, and a graphite plate for the cathode. / m 2 Electrolyze at room temperature for 10 minutes at a current density of 100 min; slightly polish the anode plate after electrolysis with fine sandpaper to make its surface smooth.

[0038]Weigh 34g of chemically pure manganese sulfate, 25g of concentrated sulfuric acid, dissolve them in 250mL of water, add polysorbate accounting for 10% of the mass of manganese sulfate as an active agent, and prepare an electrolytic solution, using a diaphragm electrolyzer, constant current electrolysis, and the current density is set at 1A / m 2 , electrolyze at 90°C for 240 minutes, suspend particulate manganese dioxide in the solution, filter the solution, the anode area after filtration is paste, and the precipitate is washed several times. Alcohol is used...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com