Hard polyurethane molding foam negative pressure foaming raw material formula and hard polyurethane molding foam negative pressure foaming production method

A rigid polyurethane and molded foam technology, which is applied in the field of raw material formulation of rigid polyurethane molded foam negative pressure foaming, can solve the problem of easy formation of surface or internal voids, influence of foam thermal insulation and appearance, and excessive growth of raw material viscosity, etc. problems, to achieve the effect of saving raw material injection, good dimensional stability, and fine pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

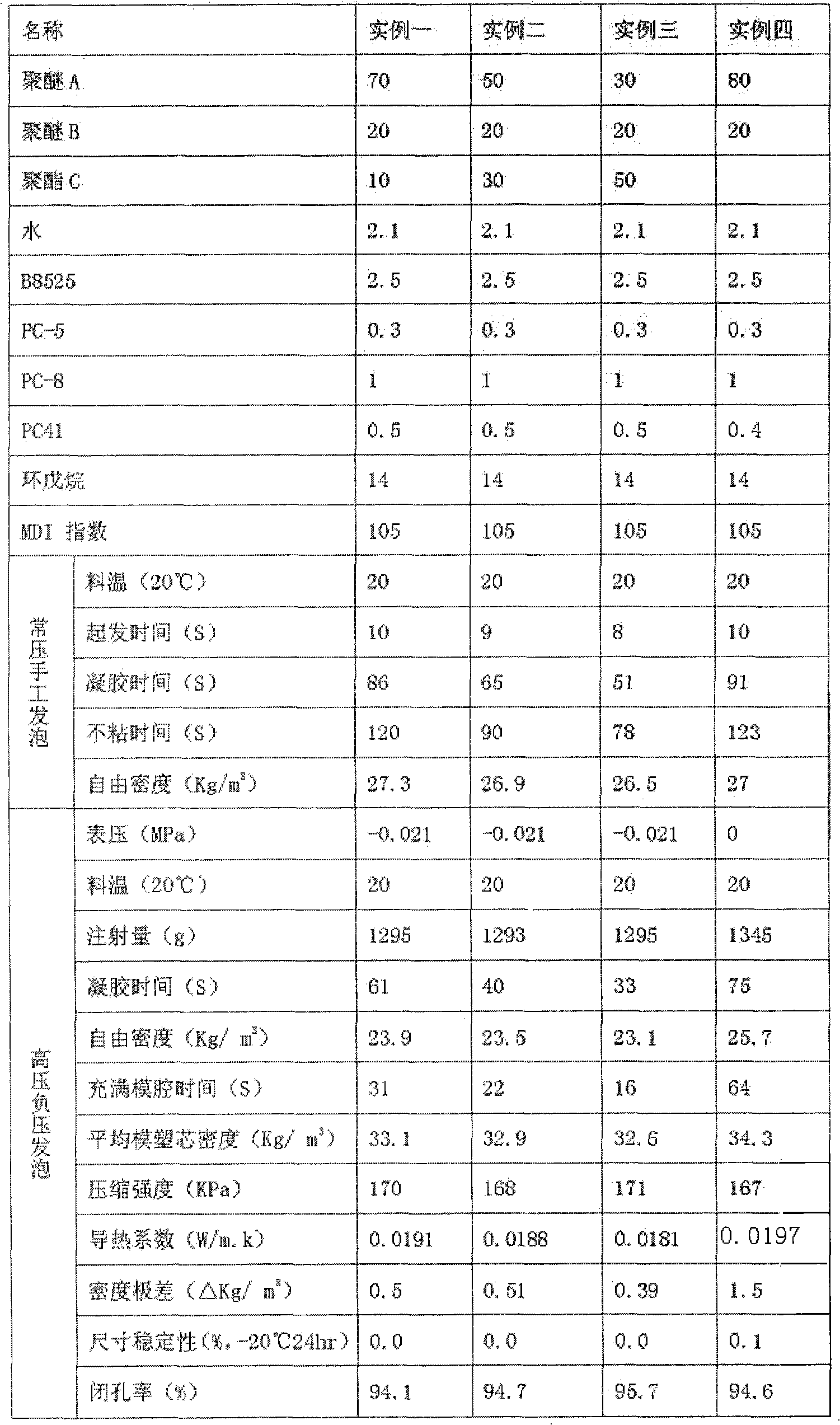

[0016] Embodiment: Rigid polyurethane molded foam negative pressure foaming raw material formula is formed by mixing polyether polyol, polyester polyol, foam stabilizer, catalyst, and water. The proportion of each component by weight is: polyether polyol Polyol: polyester polyol: foam stabilizer: catalyst: water=50~90:10~50:2~3:2~3:1~2.5;

[0017] The polyether polyol can be prepared by polymerization of toluenediamine, sucrose, sorbitol, glycerin, glycol initiator, or two or more co-initiators wherein and epoxide;

[0018] The polyester polyol is a polyfunctional polyol containing aromatics with a functionality of 2-4, and the catalyst is a quaternary ammonium salt, hexahydrotriazine, dimethylcyclohexylamine, pentamethyldiethylenetriamine Any two or more amine catalysts, and the foam stabilizer is a surfactant containing Si-C bonds.

[0019] The production method of negative pressure foaming of rigid polyurethane molded foam is to carry out rigid polyurethane foaming under t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com