Method for manufacturing plates from waste fibers

A technology of waste fibers and boards, which is applied in the field of waste materials manufacturing boards, can solve the problems of high raw material requirements, high recycling costs, and increased costs, and achieve the effect of wide fiber range, small raw material requirements, and improved contact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

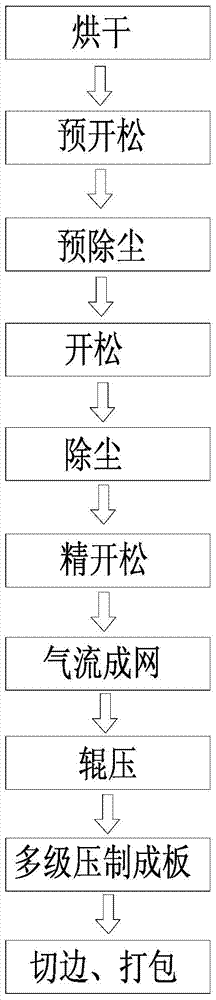

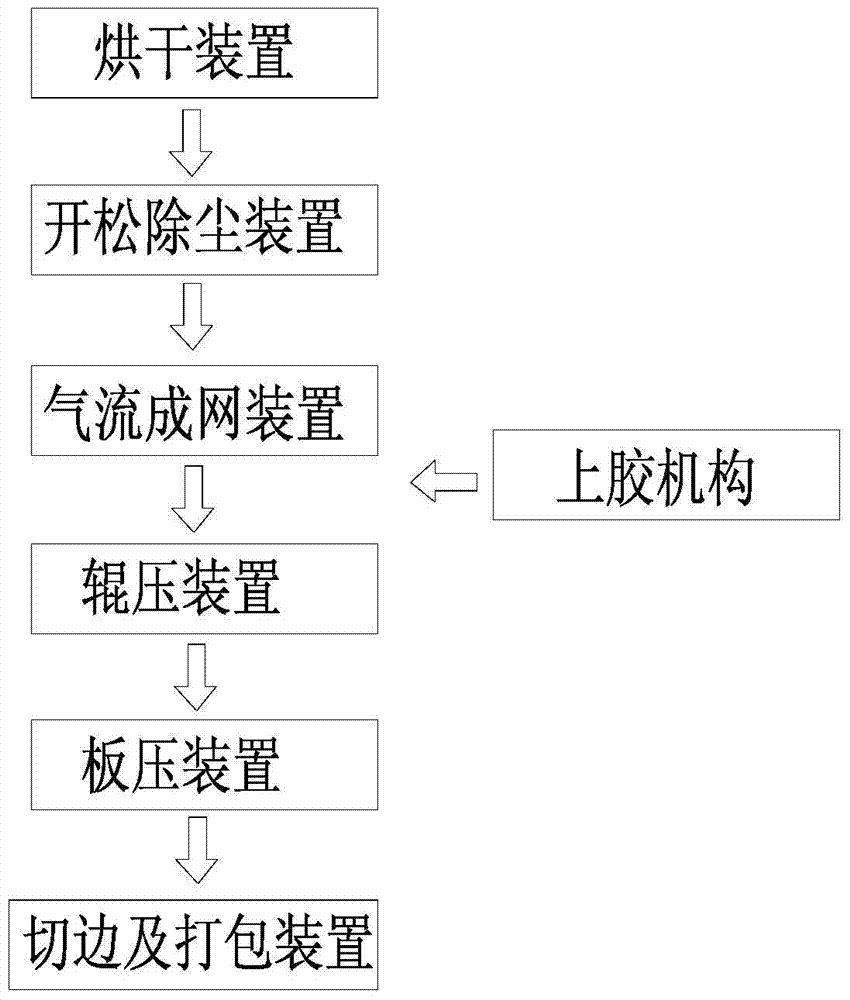

[0047] Example 1: According to the above steps, the waste filter bags are recycled, followed by steel ring removal, drying, pre-opening, pre-dust removal, opening, dust removal, fine opening, air-laid, roll pressing, and multi-stage pressing into a board , Trimming and packing. In the multi-stage web forming step, the amount of low-melting fiber mixed is 5wt% of the fiber obtained after opening and dust removal, and the amount of rubber powder sprayed is 10wt% of the total weight of the fiber web. In the step of pressing into a plate, the time of the fiber mesh in the multi-polar plate pressing box is 12 minutes, and it is pressed by four upper pressing plates from the inlet to the outlet, and the density is 650kg / m 3 Above, the board of predetermined thickness and strength.

Embodiment 2

[0048] Example 2: The difference between this example and Example 1 is that in the multi-stage web forming step, the amount of low-melting fiber mixed is 10wt% of the fiber obtained after opening and dust removal, and the amount of sprayed rubber powder is the total weight of the fiber web In the step of multi-stage pressing, the time of the fiber mesh in the multi-polar plate press box is 12 minutes, and the four upper press plates are pressed from the inlet to the outlet, and the density is 650kg / m 3 Above, the predetermined thickness and strength of the board.

Embodiment 3

[0049] Example 3: The difference between this example and Example 1 is that in the multi-stage web forming step, the amount of low-melting fiber mixed is 5wt% of the fiber obtained after opening and dust removal, and the amount of sprayed rubber powder is the total weight of the fiber web In the step of multi-stage pressing, the time of the fiber mesh in the multi-polar plate press box is 10 minutes, and the four upper press plates are pressed from the inlet to the outlet, and the density is 650kg / m 3 Above, the board of predetermined thickness and strength.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com