Method for reducing iron by smelting reduction in electrometallurgy

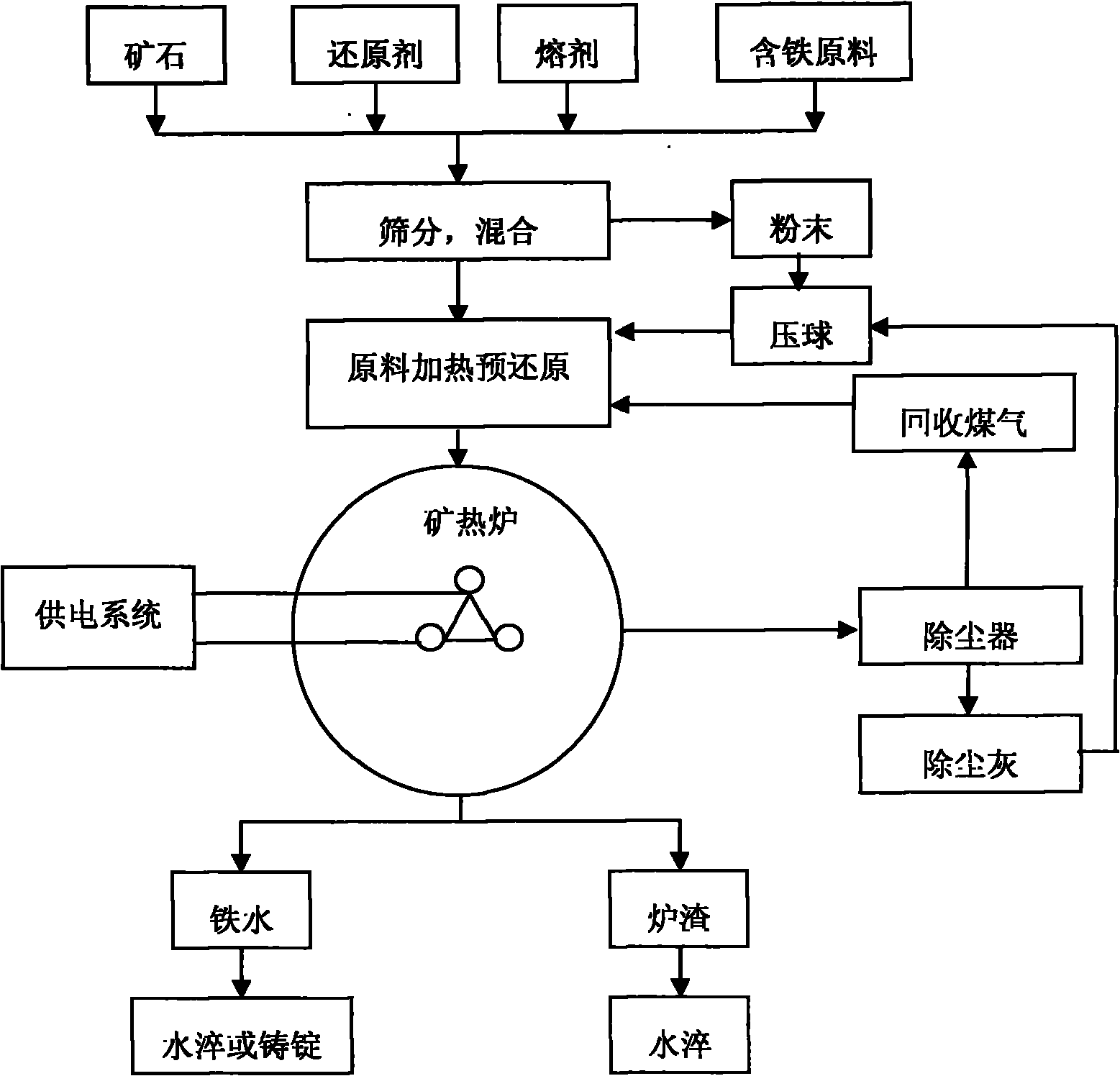

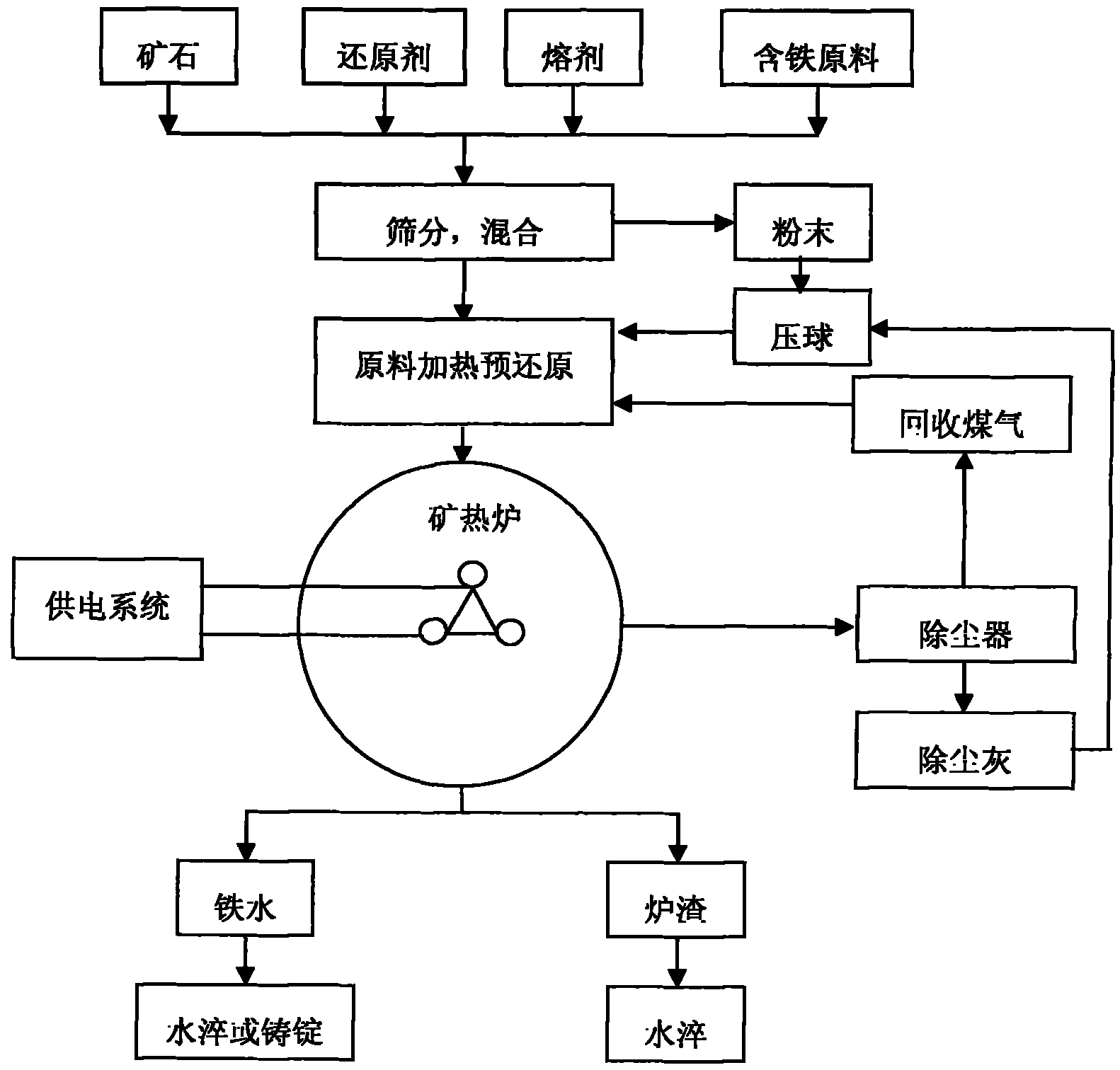

A technology of reducing iron and electrosmelting, applied in the direction of improving process efficiency, can solve the problems of lack of high-grade and high-quality iron ore resources, lack of competitiveness, and high labor productivity, and achieve compact layout of process equipment, wide application range, and occupation. Small area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

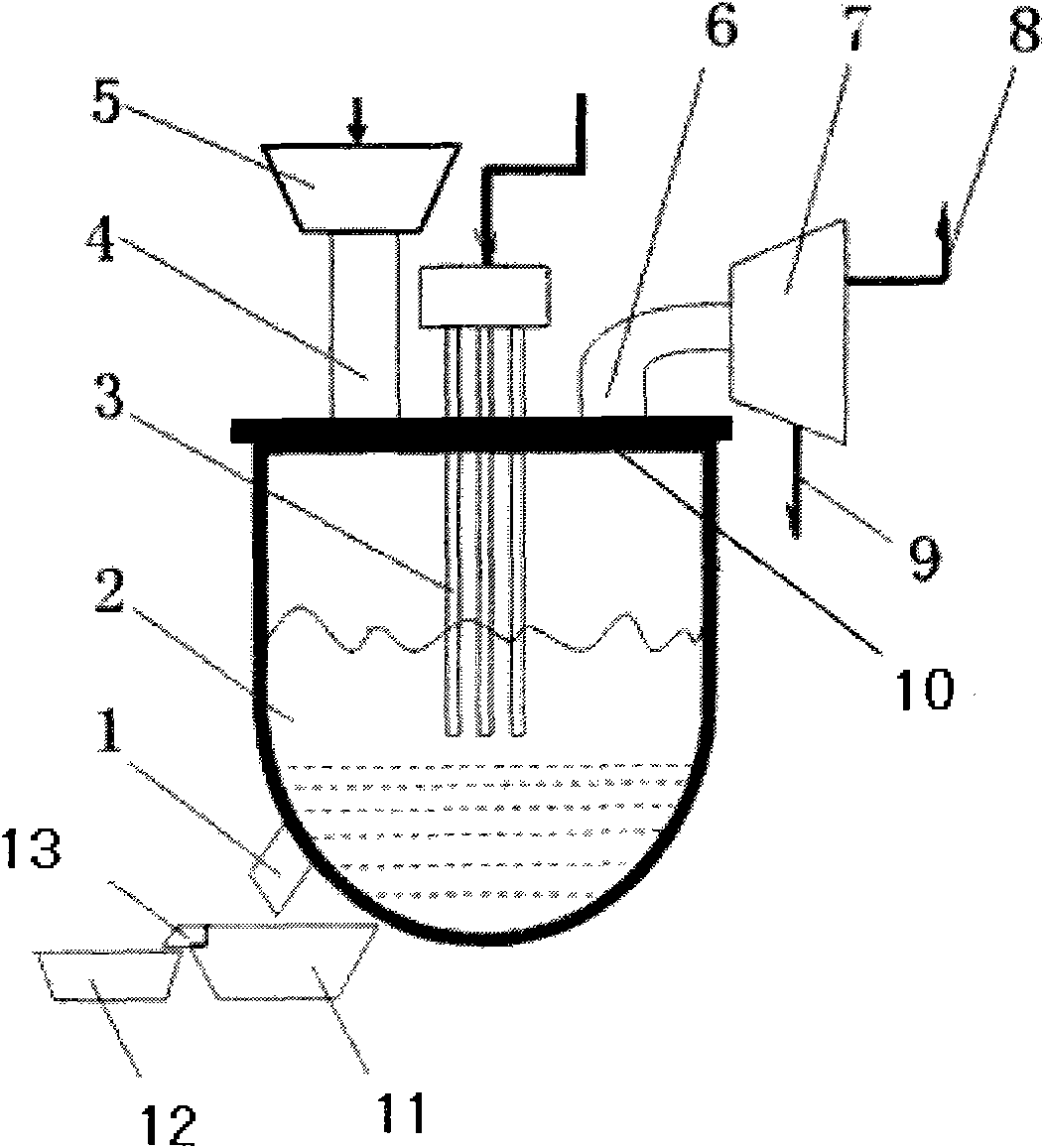

Method used

Image

Examples

Embodiment 1

[0027] A. After pulverizing and sieving the reducing agent—coke, the coke with a particle size of 3 to 25mm on the sieve is sent into the heating rotary kiln. The amount of feeding is 18% of the quality of the ore entering the kiln. ) is: C: 86, Af: 2.5, Vf: 15, H 2 O: 9.8, the coke under the sieve with a particle size of less than 3mm is pressed into balls by a conventional ball press machine, and then sent to the heating rotary kiln;

[0028] B. The chemical composition (Wt%) is: TFe: 43, P: 0.08, S: 0.20, As: 0.016, SiO 2 : 8.00, CaO+MgO: 8, H 2 O: The ore of 9.06 is crushed and screened. The ore with a particle size of 10-80mm on the sieve is sent to the heating rotary kiln. The ore with a particle size of less than 10mm under the sieve is pressed into balls by a conventional ball press machine, and then sent to the heating. in the rotary kiln;

[0029] C. After crushing and sieving the flux-lime, the lime with a particle size of 10-80mm on the sieve is sent to the heat...

Embodiment 2

[0034] A. After pulverizing and sieving the reducing agent—coal, the coal with a particle size of 3-25 mm on the screen is sent into the heating furnace, and the feeding amount is 25% of the ore mass, and the coal with a particle size of less than 3 mm under the screen is conventionally After being pressed into balls, it is sent into the heating furnace. The chemical composition (Wt%) of the coal is: C: 81, Af: 1.78, Vf: 13.5, H 2 O: 7.96;

[0035] B. The chemical composition (Wt%) is: TFe: 45, P: 0.07, S: 0.17, As: 0.012, SiO 2 : 6.55, CaO+MgO: 3, H 2 O: The ore of 7.86 is crushed and sieved. The ore with a particle size of 10-80mm on the sieve is sent to the heating furnace, and the fine ore with a particle size of less than 10mm under the sieve is pressed into balls according to the conventional method, and then sent to the heating furnace;

[0036] C. After crushing and sieving the flux—limestone and silica, the limestone and silica with a particle size of 10-80mm on the...

Embodiment 3

[0041] A. After pulverizing and sieving the reducing agent—coal and coke, the coal and coke with a particle size of 3-25mm on the sieve are sent into the heating rotary kiln, and the feeding amount is 15% of the ore mass. The 3mm coal and coke powder are pressed into balls according to the routine, and then sent to the heating rotary kiln. The chemical composition (Wt%) of the coal is: C: 81, Af: 1.78, Vf: 13.5, H 2 O: 7.96, the chemical composition of coke is: C: 85, Af: 1.6, Vf: 12, H 2 0:9.25;

[0042] B. The chemical composition (Wt%) is: TFe: 52, P: 0.09, S: 0.16, As: 0.015, SiO 2 : 7.87, CaO+MgO: 3.56, H 2 O: The ore of 7.56 is crushed and screened. The ore with a particle size of 10-80mm on the sieve is directly sent to the rotary kiln, and the fine ore with a particle size of less than 10mm under the sieve is pressed into balls according to the conventional method, and then sent to the heating rotary kiln;

[0043] C. After pulverizing and sieving the flux—lime, lim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com