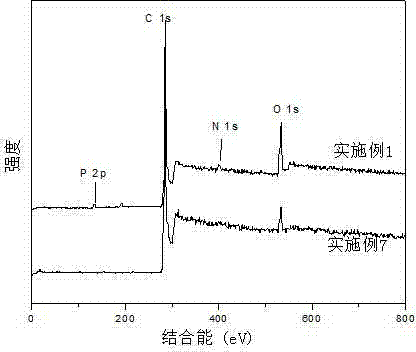

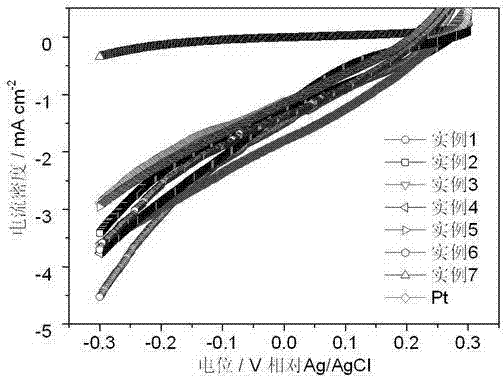

Preparation method and application of nitrogen and phosphorus codoped carbon oxygen reduction catalyst for microbial fuel cell

A fuel cell and co-doping technology, applied in the direction of electrical components, battery electrodes, circuits, etc., to achieve the effects of simple preparation process, increased output power, and easy expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

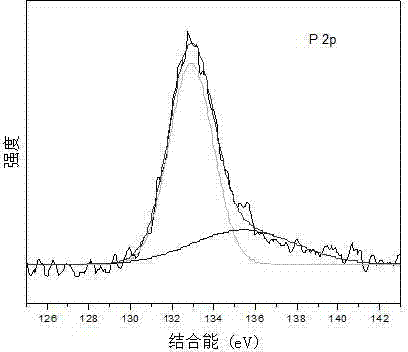

[0026] Step 1: Catalyst Preparation

[0027] Soak 10 g of microcrystalline cellulose in 100 mL of 1 M (NH 4 ) 3 PO 4 The solution was stirred for 24 h and then filtered with suction. The filter cake was dried in an oven at 80 °C. After it was taken out and ground evenly, it was put into a porcelain boat and placed in a quartz tube in a tube furnace. Under the protection of high-purity nitrogen with a flow rate of 100 mL / min, the tube furnace was heated to 900 °C, kept at a constant temperature for 1 h, and cooled naturally. , to obtain black powder. After washing with distilled water for 3 times, dry it to obtain the catalyst.

[0028] Step 2: Fabrication of air cathode and electrochemical performance test

[0029] Ultrasonically disperse conductive carbon black in ethanol, and dropwise add PTFE emulsion equivalent to 7 / 3 mass of conductive carbon black. Continue to exceed

[0030] Squeeze and stir until an elastic, dough-like mass forms. Take it out and roll it into ...

Embodiment 2

[0035] Step 1: Catalyst Preparation

[0036] Soak 10 g of microcrystalline cellulose in 100 mL of 1 M (NH 4 ) 3 PO 4 The solution was stirred for 24 h and then filtered with suction. The filter cake was dried in an oven at 80 °C. After it was taken out and ground evenly, it was put into a porcelain boat and placed in a quartz tube in a tube furnace. Under the protection of high-purity nitrogen with a flow rate of 100 mL / min, the tube furnace was heated to 1000 °C, kept at a constant temperature for 1 h, and cooled naturally. , to obtain black powder. After washing with distilled water for 3 times, dry it to obtain the catalyst.

[0037] Step 2: Fabrication of air cathode and electrochemical performance test

[0038] The second step of embodiment 2 is as described in the second step of embodiment 1.

[0039] The third step: MFC assembly and performance testing

Embodiment 3

[0040]The third step of embodiment 3 is as described in the third step of embodiment 1.

[0041] Example 3

[0042] Step 1: Catalyst Preparation

[0043] Soak 10 g of microcrystalline cellulose in 100 mL of 1 M NH 4 PO 3 (Ammonium metaphosphate) solution, after stirring for 24 h, suction filtration. The filter cake was dried in an oven at 80 °C. After it was taken out and ground evenly, it was put into a porcelain boat and placed in a quartz tube in a tube furnace. Under the protection of high-purity nitrogen with a flow rate of 100 mL / min, the tube furnace was heated to 900 °C, kept at a constant temperature for 1 h, and cooled naturally. , to obtain black powder. After washing with distilled water for 3 times, dry it to obtain the catalyst.

[0044] Step 2: Fabrication of air cathode and electrochemical performance test

[0045] The second step of embodiment 3 is as described in the second step of embodiment 1.

[0046] The third step: MFC assembly and performance te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com