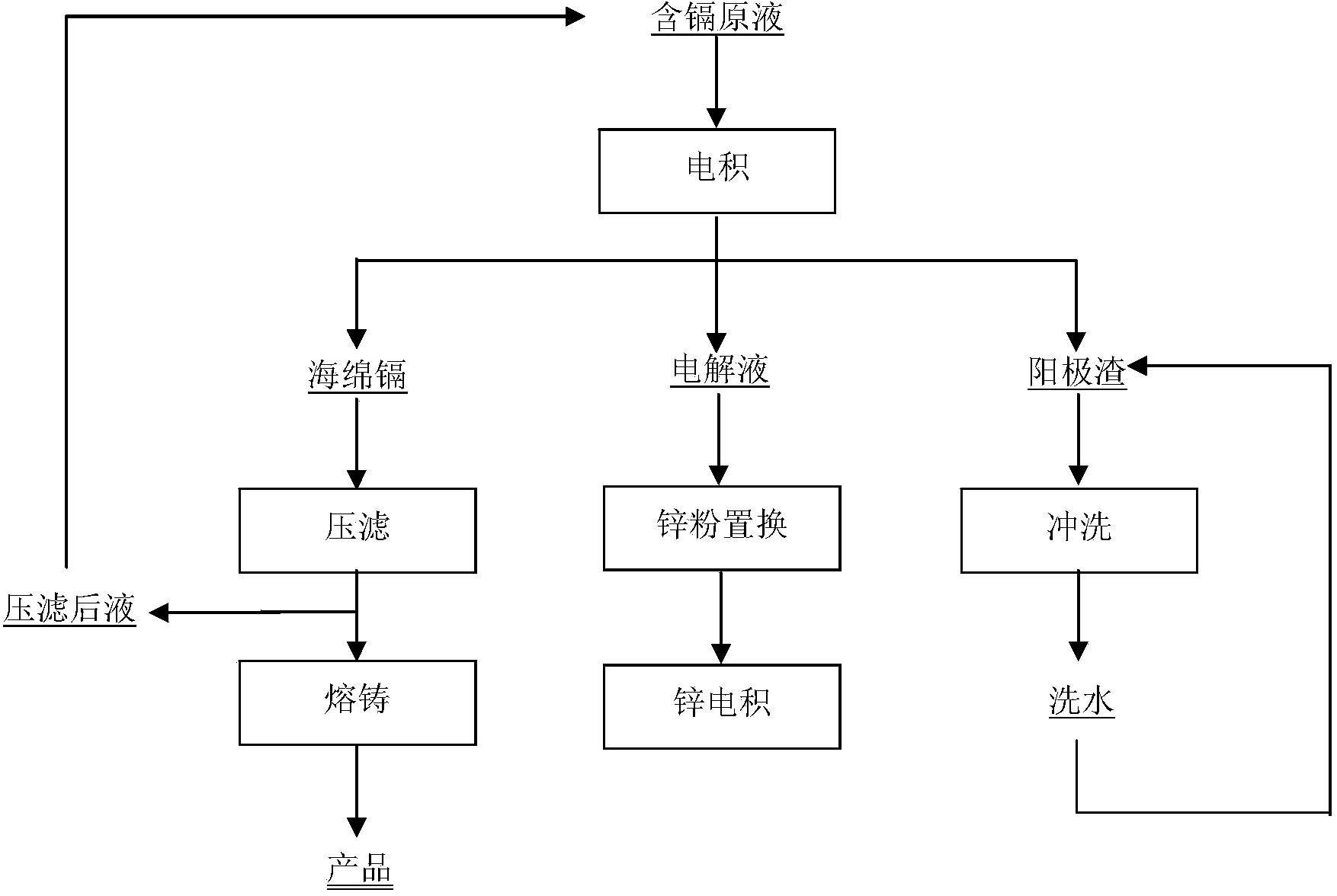

Method for manufacturing sponge cadmium under effect of micro currents

A micro-current, sponge cadmium technology, applied in the direction of cells, etc., can solve the problems of large consumption of zinc powder, low product purity and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Sponge cadmium heap leaching oxidation solution is used as raw material, and its elemental composition is shown in Table 2.

[0057] Table 1 The content of main elements in cadmium sponge heap leaching solution (unit: g / L)

[0058]

[0059] The pH of the reaction stock solution is 0.5; the size of the cathode is: 100mm×50mm; the size of the anode is: 100mm×50mm.

[0060] (1) Preparation before loading the tank: ①Weigh the cathode and anode plates first to obtain the composition content of the zinc plate; ②Measure the volume of the initial electrolyte volume, and take samples to analyze the Zn and Cd contents;

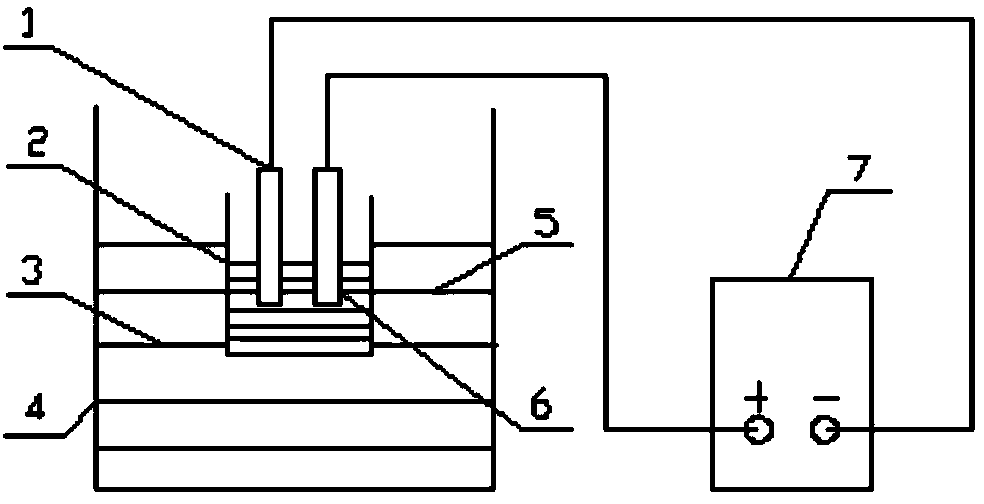

[0061] (2) Set the center distance between cathode and anode to be 3cm, one piece of cathode titanium mesh, the mesh aperture is 5mm, one piece of anode zinc plate is installed in the tank, the positive pole of the power supply is connected to the anode, and the negative pole is connected to the cathode;

[0062] (3) According to the current density of 50A / m ...

Embodiment 2

[0069] Sponge cadmium heap leaching oxidation solution is used as raw material, and its elemental composition is the same as Table 2.

[0070] Adjust the pH of the reaction stock solution to 1; the size of the cathode is: 80mm×50mm; the size of the anode is: 100mm×50mm.

[0071] (1) Preparation before loading the tank: ①Weigh the cathode and anode plates first to obtain the composition content of the zinc plate; ②Measure the volume of the initial electrolyte volume, and take samples to analyze the Zn and Cd contents;

[0072] (2) Set the center distance between cathode and anode as 5cm, one piece of cathode titanium plate, one piece of anode zinc plate in the tank, the positive pole of the power supply is connected to the anode, and the negative pole is connected to the cathode;

[0073] (3) According to the current density of 50A / m 2 The calculated current is 0.9A, the temperature of the electrolytic stock solution is 25°C, and the reaction time is 2 hours;

[0074] (4) Aft...

Embodiment 3

[0079] The leaching solution of copper cadmium slag is used as raw material, and its elemental composition is shown in Table 2.

[0080] Table 2 Elemental composition of copper cadmium slag leaching solution (unit: g / L)

[0081]

[0082] The pH of the reaction stock solution is 3; the size of the cathode is: 180mm×70mm; the size of the anode is: 180mm×80mm.

[0083] (1) Preparation before loading the tank: ①Weigh the cathode and anode plates first to obtain the composition content of the zinc plate; ②Measure the volume of the initial electrolyte volume, and take samples to analyze the Zn and Cd contents;

[0084] (2) Set the center distance between cathode and anode to be 9cm, 3 pieces of cathode aluminum mesh are connected in parallel, the mesh aperture is 15mm, and 4 pieces of anode zinc plates are connected in parallel to install the tank;

[0085] (3) According to the current density of 80A / m 2 The calculated current is 6.9A, the temperature of the electrolytic stock ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com