Method for preparing low-magnetism high-purity lithium carbonate by using saline lithium salt

A technology of high-purity lithium carbonate and lithium carbonate, applied in the direction of lithium carbonate;/acid carbonate, etc., can solve the problem of high content of lithium carbonate impurities and magnetic substances, lithium carbonate industry does not have international competitiveness, and application value It is not as good as high-purity lithium carbonate and other problems, and achieves the effects of less magnetic substance content, low production cost, and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

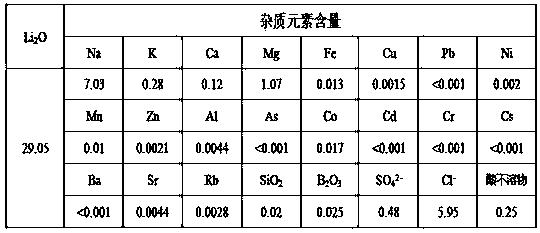

Image

Examples

Embodiment 1

[0028] A method for preparing low-magnetic high-purity lithium carbonate with salt lake lithium salt, comprising the following steps:

[0029] (1) Slurry: Weigh a certain amount of salt lake lithium salt, add it into a slurry container filled with tap water at 60°C according to the liquid-solid mass ratio of 2:1, and carry out stirring slurry;

[0030] (2) Counter-current washing: Put the salt lake lithium salt slurry obtained in step (1) into a constant temperature water bath for counter-current washing, using a single step-by-step washing, the mass ratio of washing liquid to solid is 3:1, and the washing temperature is 60°C. The time is 30 minutes, the number of washings is 2 times, and the total washing water volume to liquid-solid mass ratio is 4:1;

[0031] (3) Bicarbonation: Add the salt lake lithium salt washed in step (2) into tap water and put it into a beaker to stir, the liquid-solid mass ratio is 20:1, the reaction temperature is 20°C, the hydrogenation reaction ti...

Embodiment 2

[0040] A method for preparing low-magnetic high-purity lithium carbonate with salt lake lithium salt, comprising the following steps:

[0041] (1) Slurry: Weigh a certain amount of salt lake lithium salt, add it into a slurry container filled with 90°C tap water at a liquid-to-solid mass ratio of 6:1, and carry out stirring and slurrying;

[0042] (2) Countercurrent washing: Put the salt lake lithium salt slurry obtained in step (1) into a constant temperature water bath for countercurrent washing, using a single step-by-step washing, the mass ratio of washing liquid to solid is 8:1, and the washing temperature is 90 ° C. The time is 60 minutes, the number of washings is 8 times, and the total washing water volume and liquid-solid mass ratio are 7:1;

[0043] (3) Bicarbonation: Add the salt lake lithium salt washed in step (2) into tap water and put it into a beaker to stir, the liquid-solid mass ratio is 27:1, the reaction temperature is 40°C, the hydrogenation reaction time ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetism | aaaaa | aaaaa |

| magnetism | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com