Patents

Literature

79results about How to "Easy to implement industrial production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

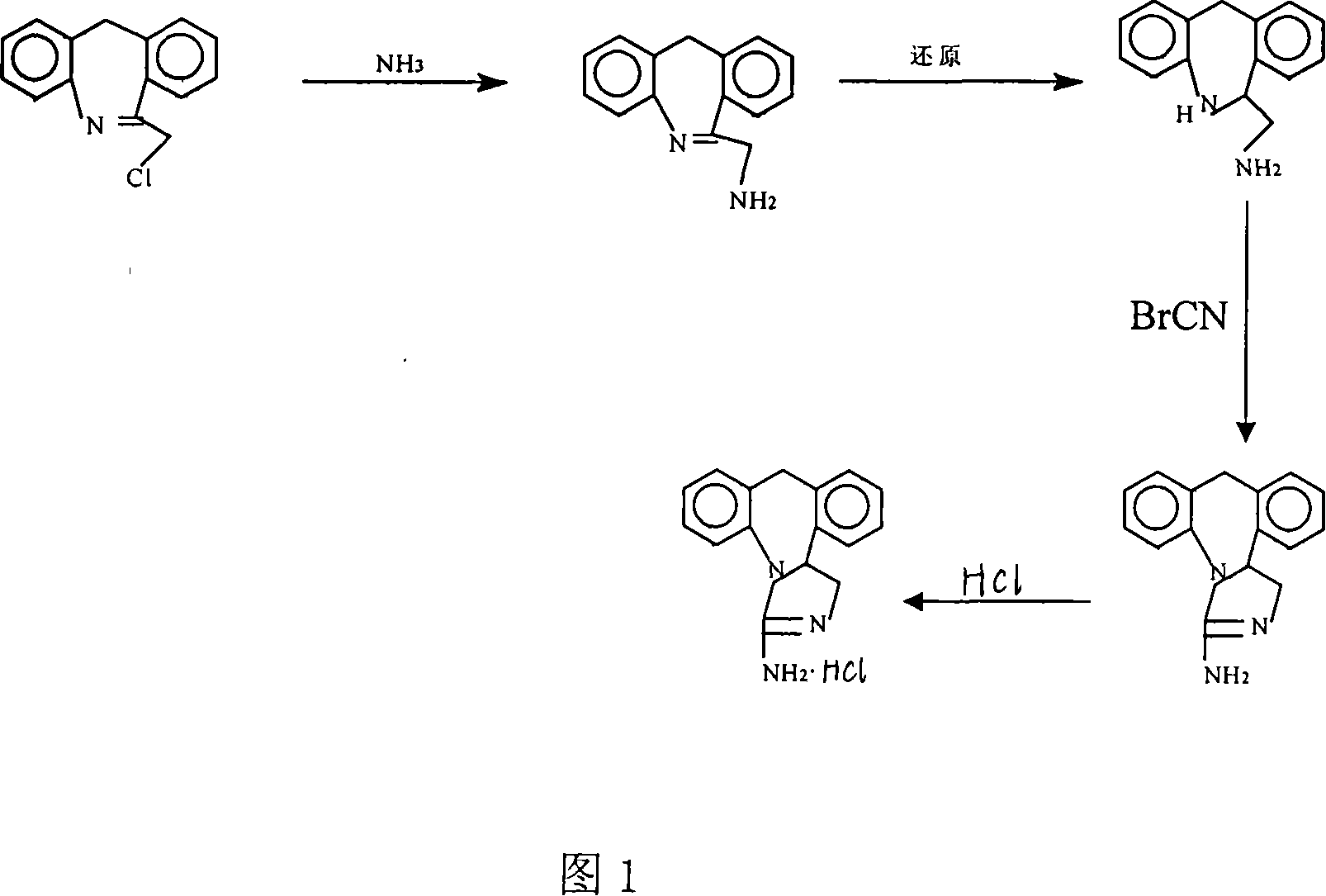

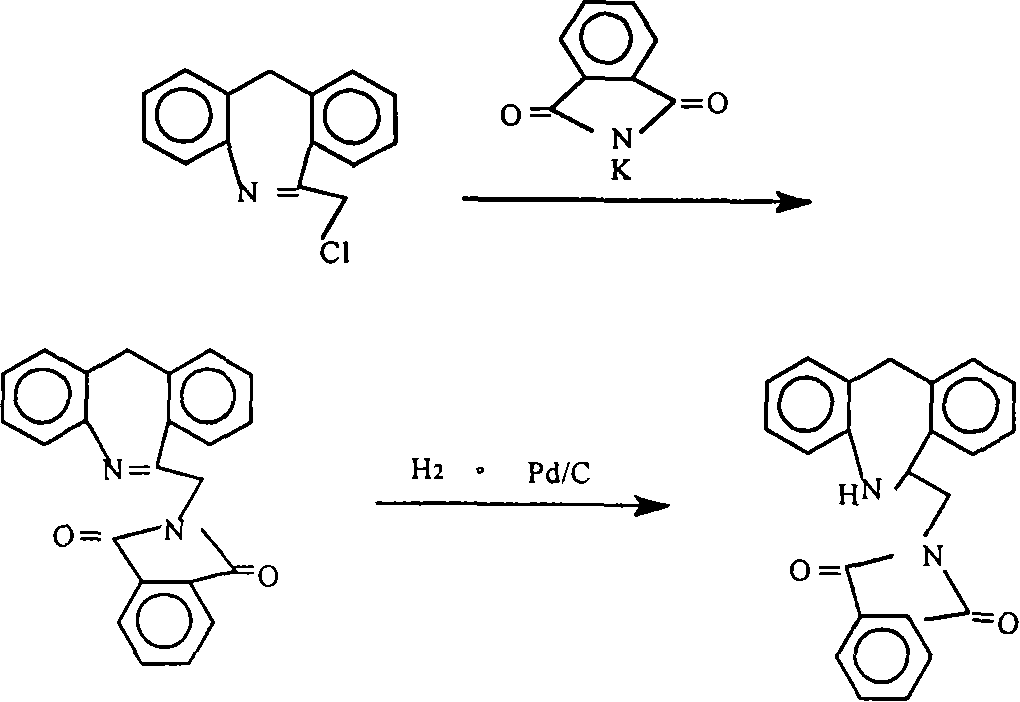

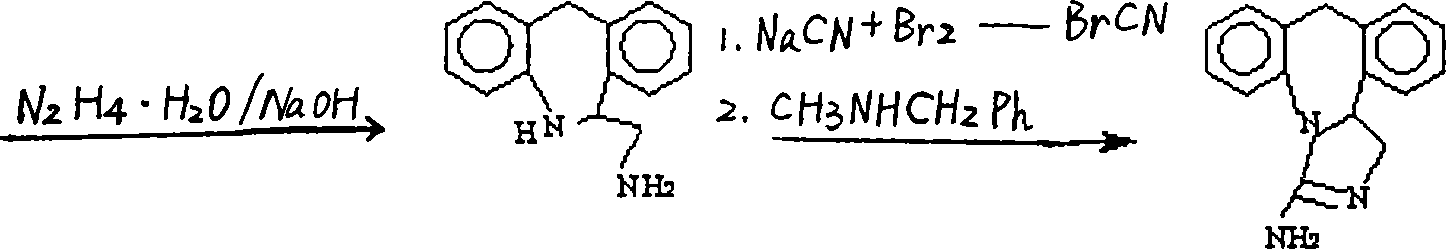

Chemical synthesis method for epinastine

InactiveCN101130544AHigh purityEasy to makeOrganic chemistryImmunological disordersChemical synthesisCyanogen bromide

The invention discloses a new chemical synthesizing method of yipisidin, which comprises the following steps: ammonifying 6-chloromethyl-11-dihyrogen-dibenz [b,e] aza to generate 6-aminomethyl-11-dihydrogen-dibenz [b,e] aza; reducing the 6-aminomethyl-11-dihydrogen-dibenz [b,e] aza into 6-aminomethyl-6,11-dihydrogen-5H-dibenz [b,e] aza; generating the product through cyanogen bromide to loop. The invention simplifies the making method with little by-product, which improves the receiving rate by 69% with high purity (HPLC. 99. 0%) for industrial manufacturing.

Owner:HANGZHOU LONGSHAN CHEM CO LTD

Method for producing preserved meat

InactiveCN101467705APerfect natural muscle fibersImprove textureFood preparationFiberAdditive ingredient

The invention provides a preparation method for preserved meat, relating to the preparation method for healthcare food, which is characterized in that the food is prepared by the steps of selecting materials, washing, crushing, boiling, pickling with ingredients, loading into a die, slicing, roasting, dehydrating, packing and sterilizing. The preparation method for the preserved meat has the beneficial effects that, the food is a pure natural green food, which has general equilibrium nutritionally; the preparation agrees with the nation-specified sanitary standards; the food fully utilizes the raw material, which is easy for industrial production; and the preserved meat prepared by the method has perfect natural muscle fiber, favorable texture and taste, which is not only suitable for the life rhythm of modern people, but also leads to better absorption of human body.

Owner:TIANJIN ZHONGYING HEALTH FOOD

Microbial particle preparation for aquacultural water quality purification and preparation method

ActiveCN102864137AImprove water qualityReduce morbiditySeawater treatmentMicroorganism based processesSeawaterChemistry

Disclosed are a microbial particle preparation for aquacultural water quality purification and a preparation method. The preparation is characterized by including utilizing zeolite as a core after steps of activation of bacillus subtilis by strains, seed liquid preparation, fermenting culturing, concentrating and the like, and then wrapping the bacillus subtilis outside the zeolite by a bacterium absorption medium to prepare gray white irregular particles with a structure of an inner layer and an outer layer. The microbial particle preparation is low in production cost, easy to store and transport and widely applicable to water quality purification of fresh water and sea water and contains more than or equal to 2X1010 / g of live bacterium counts. The microbial particle preparation can be quickly sunk to water bottom after being thrown into water, the bacillus subtilises can be massively bred in water and function in water purification together with the zeolite, organic substances such as residual baits and corrosive substances can be disintegrated quickly, and water quality can be further purified by means of nitrate and nitrite in the water, diseases of bred animals can be reduced while quality and output can be improved. Further, the microbial particle preparation is simple to prepare, low in cost, stable in preparation method and convenient to produce industrially, can be stored at room temperature without refrigerating and has excellent social benefits and economic benefits.

Owner:OCEAN UNIV OF CHINA +1

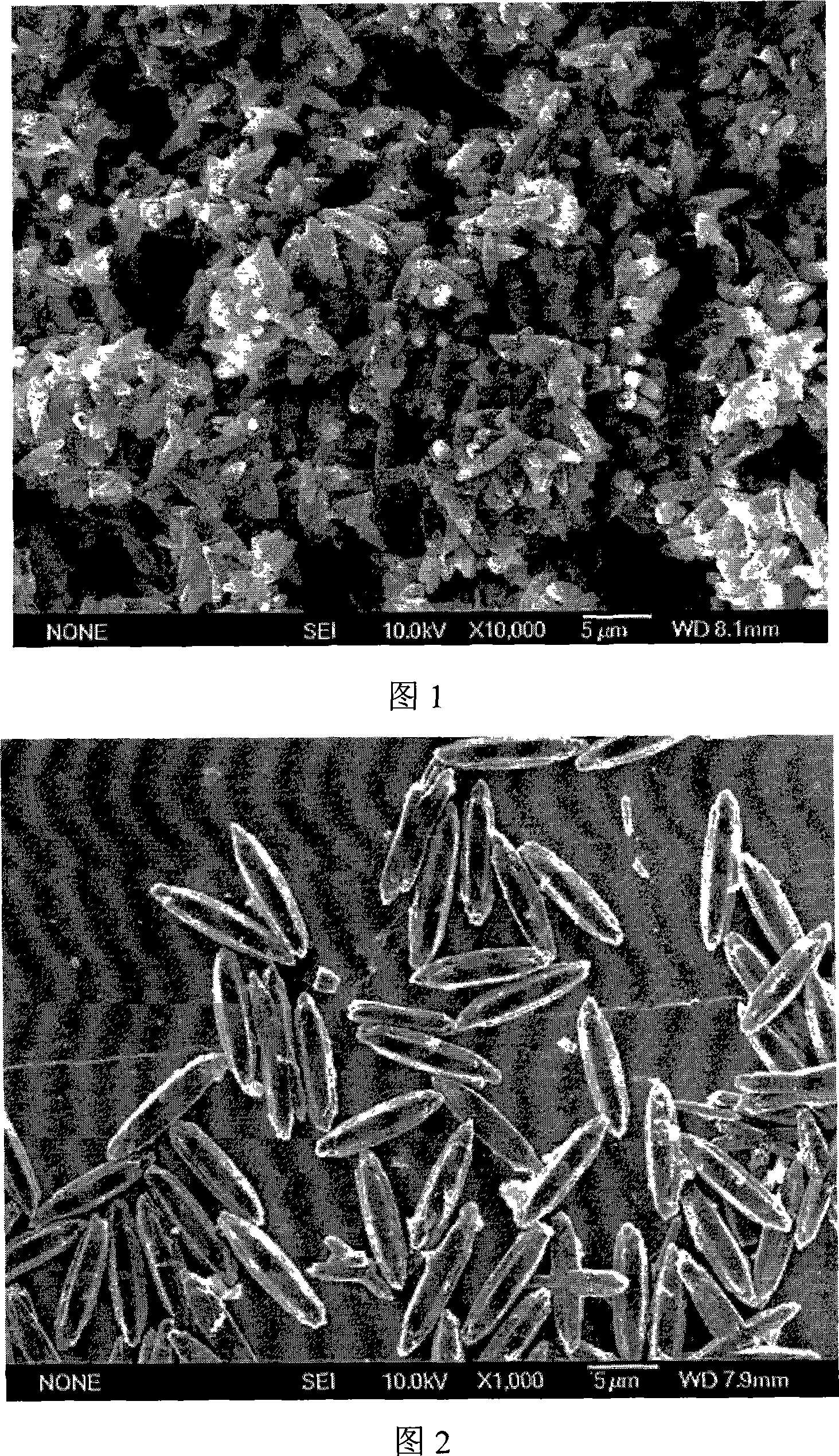

Method for manufacturing rice-shaped precipitated calcium carbonate

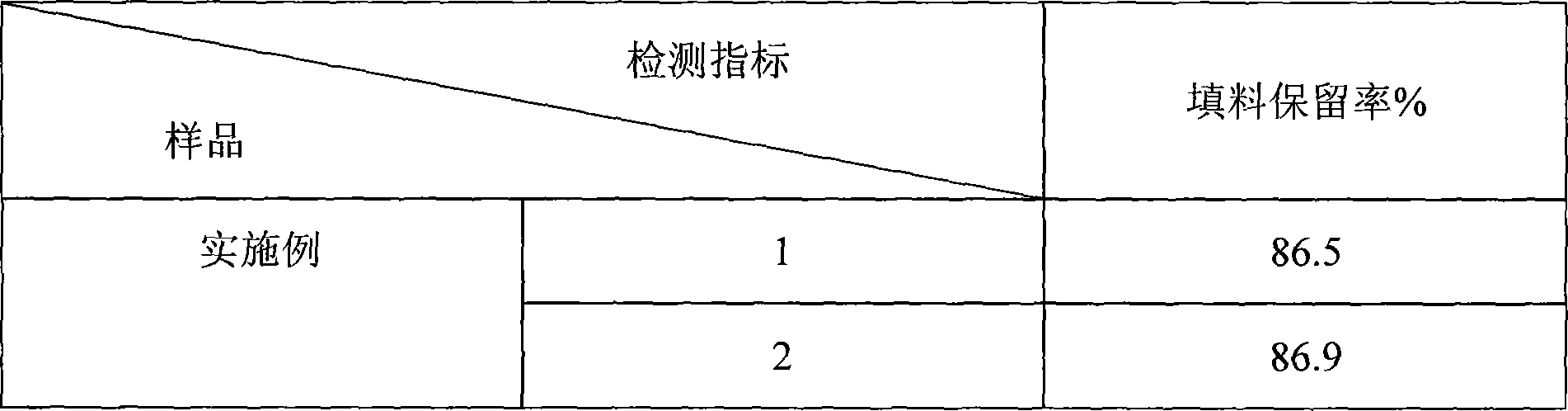

InactiveCN101209851AImprove smoothnessReduce smoothnessCalcium/strontium/barium carbonatesCoatings with pigmentsFiberCarbonization

The invention provides rice-shaped precipitation calcium carbonate, a preparation method and the application thereof. The preparation method comprises the steps that: (1) crystal control agent is added into calcium hydroxide aqueous suspension to obtain mixture; (2) the mixture of the first step is communicated with carbon dioxide for carbonization reaction until the pH value of the mixture reaches 6.5-8.5 and the rice-shape calcium carbonate is collected from the reaction products; the crystal control agent is soluble carbonate. The rice-shape calcium carbonate of the invention has moderate length diameter ratio, which is easier to be maintained in paper fiber than ordinary light calcium carbonate, and increases the smoothness of the paper at the same time; furthermore, the invention not only preserves the printing quality of the paper, but also reduces the consumption of filler and increases retention rate, meanwhile, the manufactured paper has superior characteristics of high stiffness and high smoothness and has no problems of alkali recycling and discharging, being easy for implementing industrialized production.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

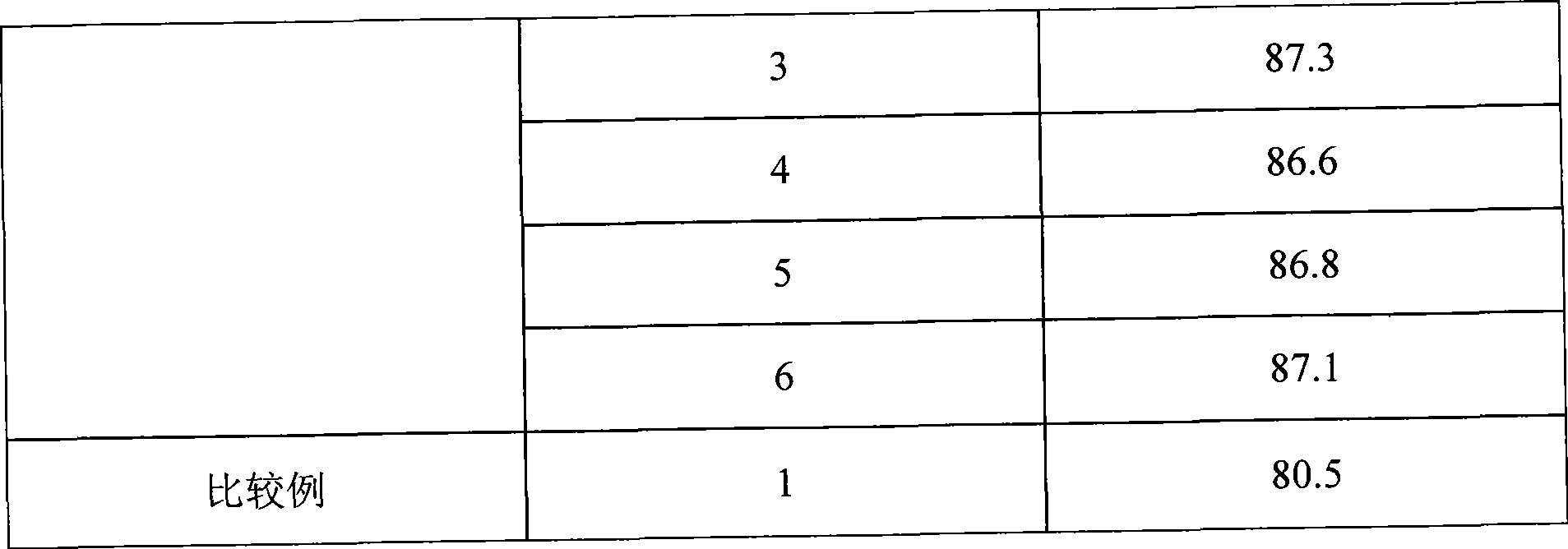

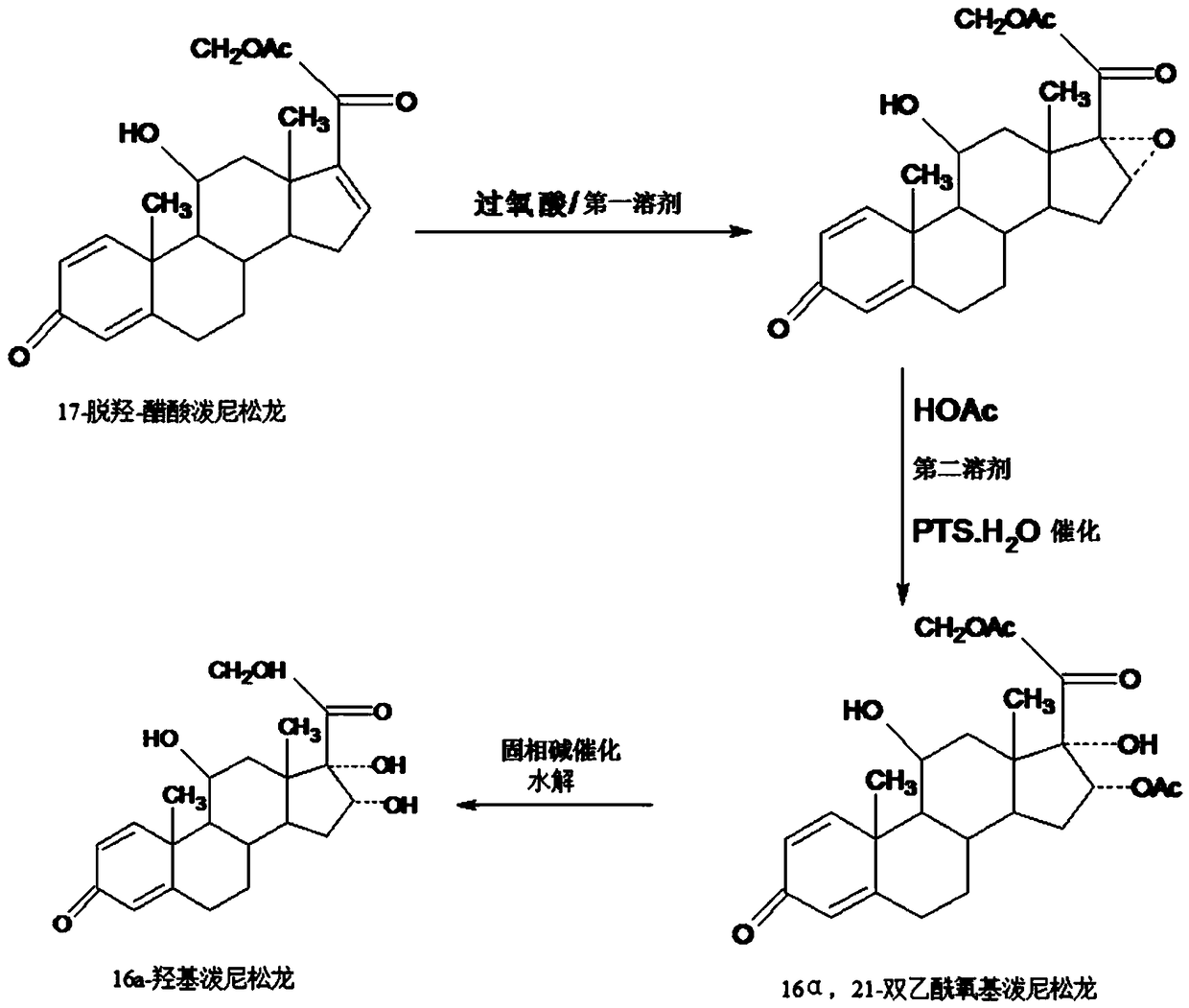

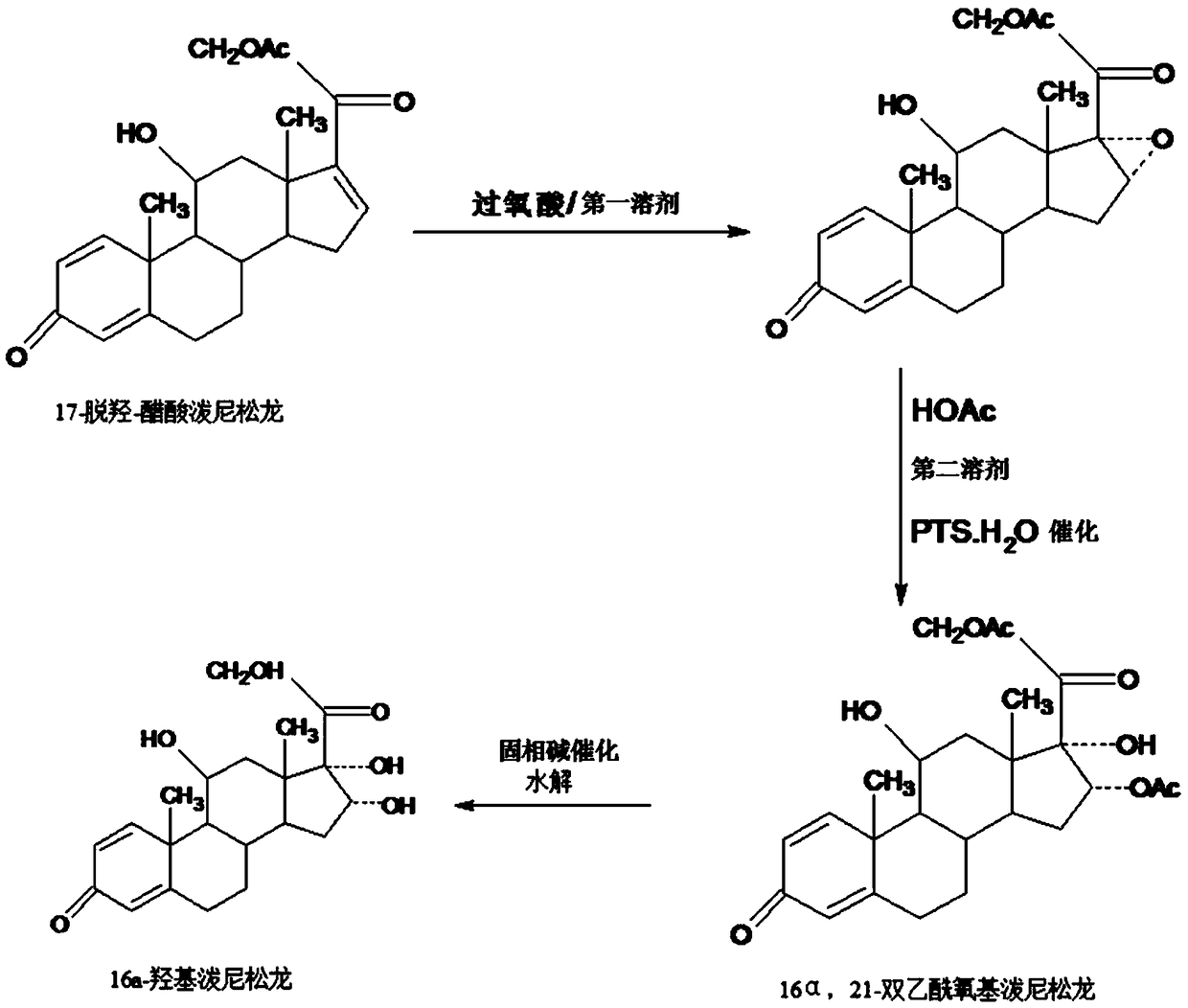

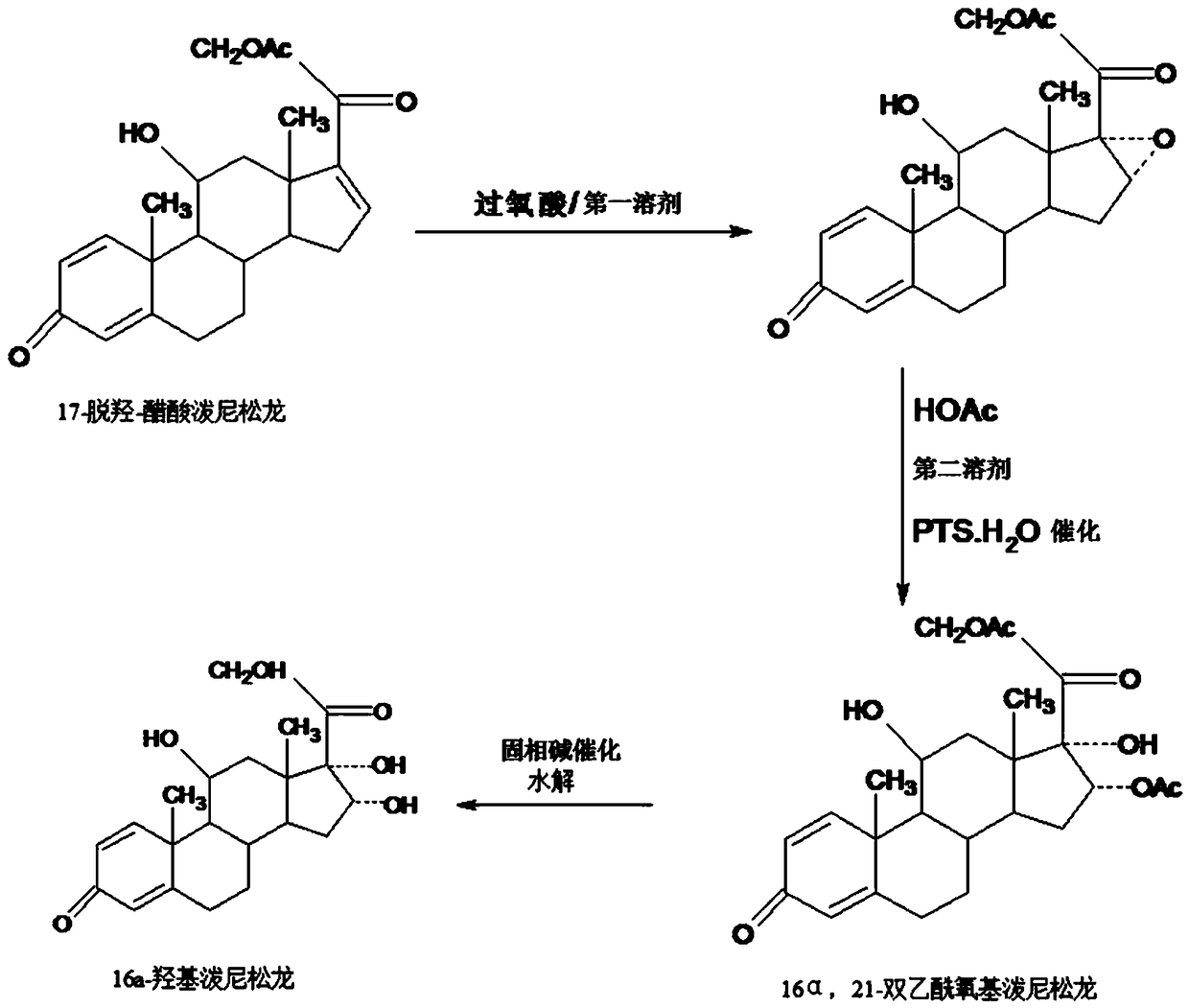

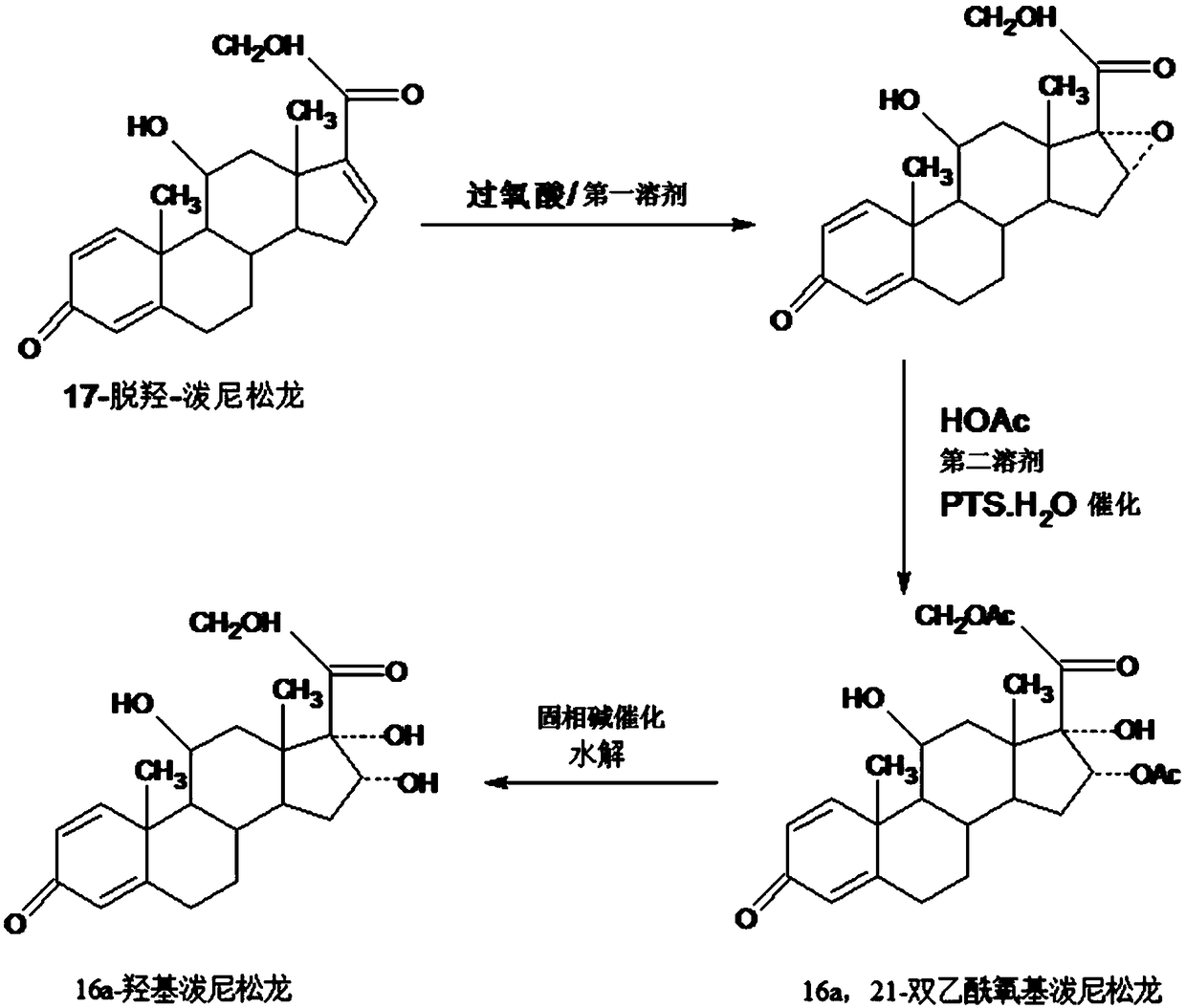

Method for preparing 16a-hydroxyl prednisolone product

InactiveCN109232696AAvoid many difficulties such as difficult purificationEasy to operateSteroidsAcetic acidOrganic solvent

The invention provides a method for preparing a 16a-hydroxyl prednisolone product. The method comprises the steps: firstly, subjecting 17a-deshydroxy prednisolone acetate, which serves as a starting raw material, and organic peroxy acid to an epoxidation reaction at 16,17 sites in a first organic solvent, so as to prepare epoxide; subjecting the epoxide and glacial acetic acid to a ring-opening reaction under the catalysis of an acid catalyst in a second organic solvent, so as to prepare 16a,21-diacetoxyl prednisolone; then, dissolving the 16a,21-diacetoxyl prednisolone in a third organic solvent, and hydrolyzing acetate of two positions under the catalysis of a solid-phase alkali catalyst, so as to prepare 16a-hydroxyl prednisolone; finally, subjecting the crude 16a-hydroxyl prednisoloneobtained through solid-phase alkali-catalyzed hydrolysis to heated refluxing, decoloring and recrystallization by low carbon alcohols of C4 or less, thereby obtaining the 16a-hydroxyl prednisolone product. The 16a-hydroxyl prednisolone is prepared by the efficient, environment-friendly and cheap method.

Owner:HUNAN KEREY BIOTECH

Preparation method of 16alpha-hydroxy prednisolone

InactiveCN109081861AAvoid many difficulties such as difficult purificationEasy to operateSteroidsSodium carbonatePrednisolone acetate

The invention provides a preparation method of 16alpha-hydroxy prednisolone, comprising: subjecting 17alpha-deshydroxy prednisolone acetate as an initial material to 16,17-epoxidation with an organicperoxy acid in a first organic solvent to obtain an epoxide; subjecting the epoxide, in a second organic solvent, to ring-opening reaction with glacial acetic acid under the catalysis of an acid catalyst to obtain 16alpha,21-diacetoxy prednisolone; dissolving 16alpha,21-diacetoxy prednisolone in a third organic solvent, and hydrolyzing acetates in two positions under the catalysis of a solid alkaline catalyst, wherein the solid alkaline catalyst is made by adsorbing sodium carbon or sodium hydroxide to aluminum oxide, silicone or calcium carbonate as a support. The 16alpha-hydroxy prednisoloneis prepared via the method which is efficient, environmentally and fair in cost.

Owner:HUNAN KEREY BIOTECH

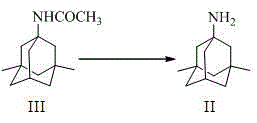

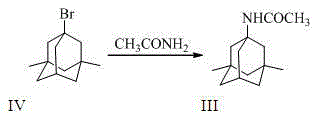

Method for preparing memantine hydrochloride

ActiveCN104557567ARaw materials are easy to obtainEasy to operateOrganic compound preparationCarboxylic acid amides preparationKetone solventsMemantine hcl

The invention discloses a method for preparing memantine hydrochloride. The method is characterized in that the method provided by the invention uses 1-bromo-3,5-dimethyladamantane (represented by a general formula IV in the description) as a starting material which is subjected to an amination reaction with acetamine to obtain a key intermediate 1-actamido-3,5-dimethyladmantane (represented by a general formula III in the description); the compound represented by the general formula III is subjected to alcoholysis in a mixture system of inorganic base and n-butyl alcohol for deacetylated to obtain memantine; memantine is treated using hydrochloric acid in a ketone solvent to obtain memantine hydrochloride. The method provided by the invention overcomes deficiencies in the prior art and has the advantages that the raw materials are simple and readily available, the reaction steps are simple and short, and the operations are convenient and fast, therefore, the method is suitable for industrial production.

Owner:CHONGQING PHARMA RES INST

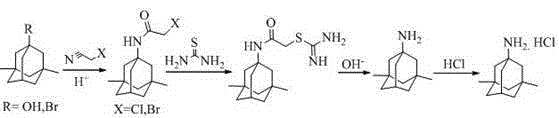

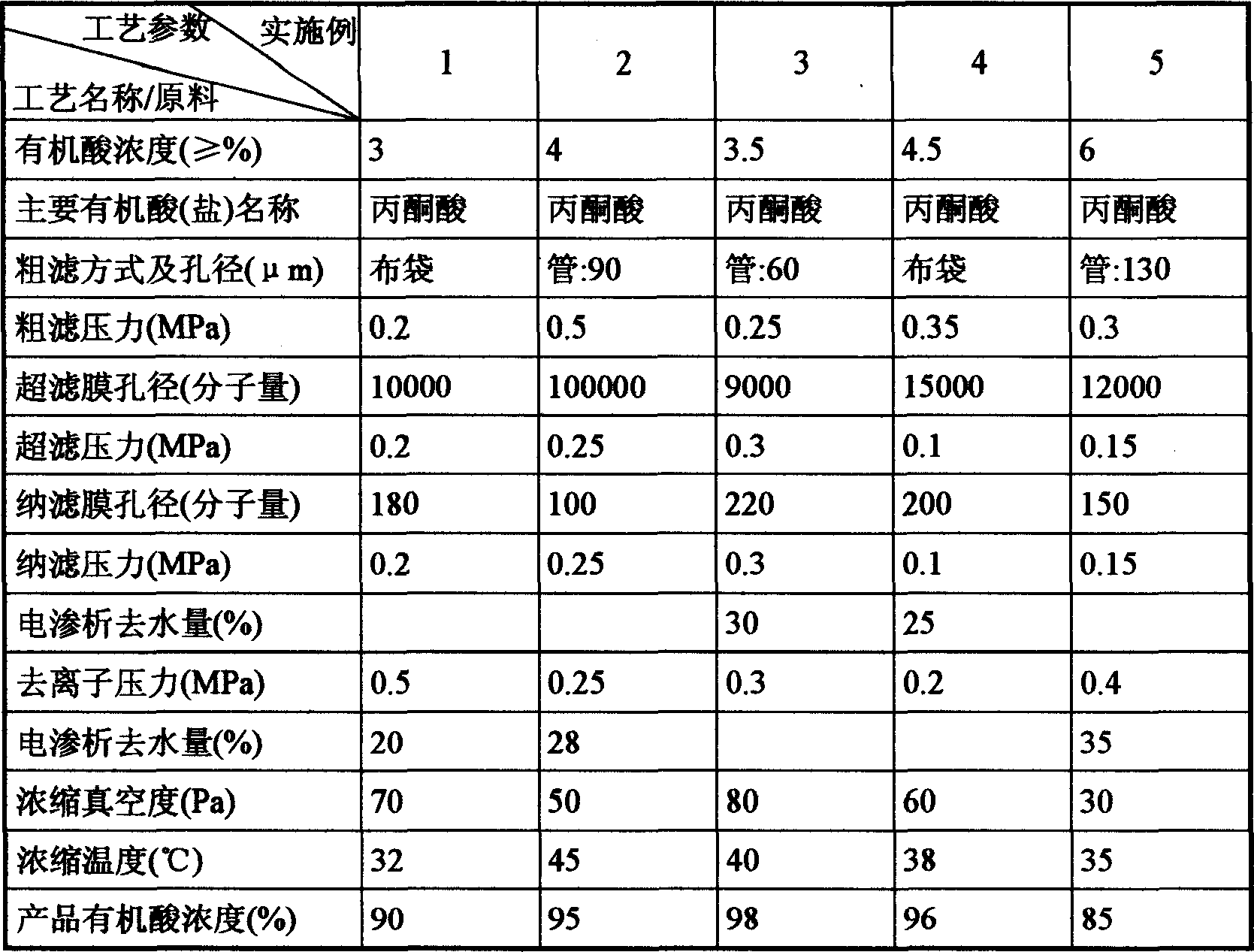

Process for organic acid extraction from fermentation liquid using membrane method

InactiveCN1730457AEasy to operateEasy to implement industrial productionUltrafiltrationCarboxylic compound separation/purificationOrganic acidMembrane method

The invention discloses a process for extracting organic acid from fermentation liquor through film method, which consists of the steps of fermentation liquor preparation, ultrafiltration, nano filtration, deionization and concentration. The invention has the advantages of simple operational process, low cost of production, high yield, and complete de-sugaring.

Owner:韩清秀

Instant pork skin crystal

The invention provides an instant pork skin crystal, relating to a preparation method for healthcare food, which is characterized in that the food is prepared by the steps of selecting materials, washing, undergoing acid and alkali treatment, boiling, chopping, puffing, drying, preparing into product, packing and sterilizing. The instant pork skin crystal has the beneficial effect that, the method for preparing the edible pork skin crystal has the advantages of high temperature and long term infusion saving, simple technology, time and labor saving, full utilization of large amount of pork skin resources, and industrial treatment. The product has nutritionally general equilibrium, full utilization of raw materials and easy industrial production, and the preparation of which agrees with the nation-specified sanitary standards. The pork skin crystal prepared by the method has perfect natural muscle fiber, favorable texture and taste, which is not only suitable for the life rhythm of modern people, but also leads to better absorption of human body.

Owner:TIANJIN ZHONGYING HEALTH FOOD

Moulding sand additive suitable for iron casting piece

The invention relates to the field of industrial casting, in particular to a moulding sand additive suitable for an iron casting piece. The moulding sand additive suitable for the iron casting piece is prepared from mixing the following raw materials in percentage by mass: 20 to 40 percent of aluminosilicate powder, 10 to 19 percent of graphite powder, and 50 to 70 percent of bentonite, wherein the aluminosilicate powder is prepared from mixing the following raw materials in percentage by mass: 55 to 80 percent of SiO2, 7 to 40 percent of Al2O3, 0.5 to 6 percent of Na2O, 0.5 to 6 percent of K2O and 0.5 to 9 percent of Fe2O3. The additive is prepared from inorganic composite materials, is incombustible so as not to produce toxic and hazardous waste gas during a production process, and is green and environmental-friendly. The moulding sand additive mainly replaces pulverized coal in wet type clay sand, has excellent clay sand resistance, and is used for the iron casting piece, so that the wettability of a casting mould and a metal liquid is reduced, the casting piece cannot stick sand, and the occurrence of the defects such as scab of the casting piece is reduced.

Owner:云南衡纬科技有限公司

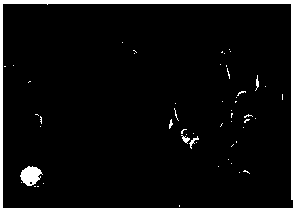

Tin dioxide/polypyrrole nanocomposite and preparation method thereof

InactiveCN103275317AGuaranteed electrical contactThe synthesis process is simpleTin dioxidePolypyrrole

The invention discloses a tin dioxide / polypyrrole nanocomposite. A tin tetrachloride solution and urea are taken as raw materials, and nano tin dioxide is prepared through a hydrothermal method in a microemulsion system including CTAB (cegtyl trimethyl ammonium bromide), n-pentanol and n-hexane; and then in the microemulsion system, ferric trichloride is taken as an oxidizing agent, and the material is prepared through microemulsionin situ polymerization to a pyrrole monomer. According to the composite material, nano tin dioxide is dispersed in loose conductive polypyrrole matrix, so that electrical contact between tin dioxide particles can be guaranteed effectively, and the nanocomposite is enabled to combine advantages of polypyrrole and tin dioxide, is expected to be an excellent Lithium-ion battery material, and is widely applied to the fields of micro-electronics, sensing, energy and the like. Meanwhile, the preparation method combines the advantages of the hydrothermal method and the microemulsion method, and has the advantages of easily obtained synthesis raw materials, simple synthesis and low cost.

Owner:SHANDONG UNIV

Monomers and intermediates of AB type hydroxyl modified high polymer and preparation methods of monomers and intermediates

InactiveCN103664622AHigh yieldHigh purityOrganic compound preparationCarboxylic acid esters preparationFormate EstersAxial pressure

The invention discloses monomers and intermediates of an AB type hydroxyl modified high polymer, and preparation methods of the monomers and the intermediates. The intermediates include methyl o-hydroxyl p-carboxyl benzoate (I) and m-hydroxyl p-methoxycarbonyl benzoyl chloride (I'). The monomers of the AB type hydroxyl modified high polymer include a monomer (IV) of AB type hydroxyl modified PPTA (Poly-p-Phenylene Terephthamide) and a monomer (VIII) of AB type hydroxyl modified PBO (Poly-p-phenylenebenzobisthiazole), wherein R1 is H, R2 is OH, or R1 is OH and R2 is OH, and R is CH3 or C2H5. Due to introduction of hydroxyl in the AB type monomer, the light resistance, the composite cohesiveness and the axial pressure resistance of a high polymer prepared from the AB type hydroxyl modified high polymer can be improved, and moreover the preparation methods of the intermediate and the monomer have the characteristics of high yield, high selectivity and industrial production accordance.

Owner:ZHEJIANG UNIV OF TECH +1

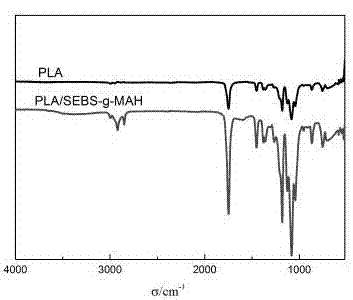

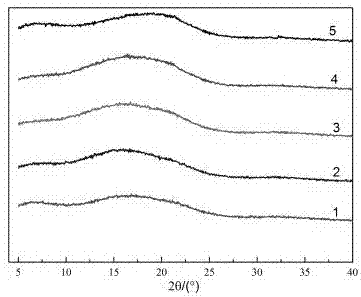

High-toughness polylactic acid in-situ maleic anhydride grafted thermoplastic elastomer composite material

InactiveCN107163522AGood compatibilityEasy to implement industrial productionMaleic anhydridePolylactic acid

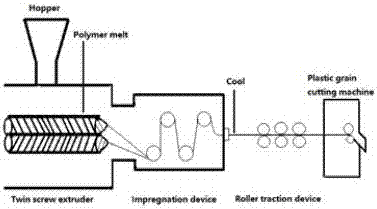

The invention discloses a high-toughness polylactic acid in-situ maleic anhydride grafted thermoplastic elastomer composite material. The composite material is prepared from polylactic acid and maleic anhydride grafted thermoplastic elastomer. The preparation method comprises the following steps: respectively drying the polylactic acid and maleic anhydride grafted thermoplastic elastomer; mixing the polylactic acid and maleic anhydride grafted thermoplastic elastomer according to a proportion, shaking for simple physical mixing to enable the polylactic acid and the maleic anhydride grafted thermoplastic elastomer to be sufficiently mixed, and feeding at a high speed; melting and extruding in a twin-screw extruder, and performing high traction rate and quick cooling curing, sufficiently cooling the extruded strips in cold water, and feeding to a granulator for granulating; and drying the granular material, and sufficiently and uniformly dispersing the mixture by adopting high-pressure high-shearing-flow-field injection molding equipment to prepare the high toughness composite material. The composite material has the characteristics of simple preparation process, relatively low energy consumption, low cost, elastomer maleic anhydride grafted thermoplastic elastomer SEBS recycling.

Owner:GUIZHOU UNIV

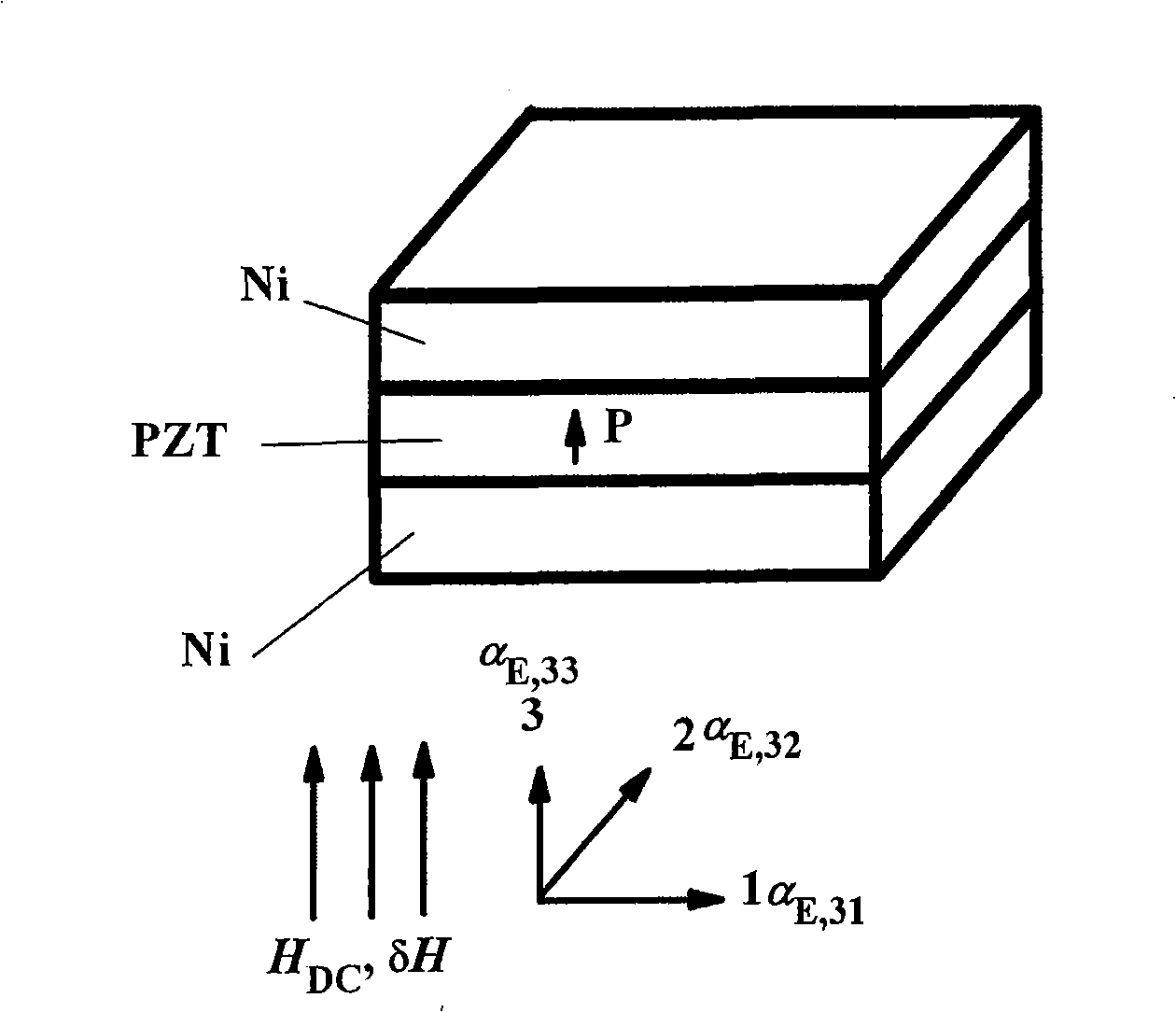

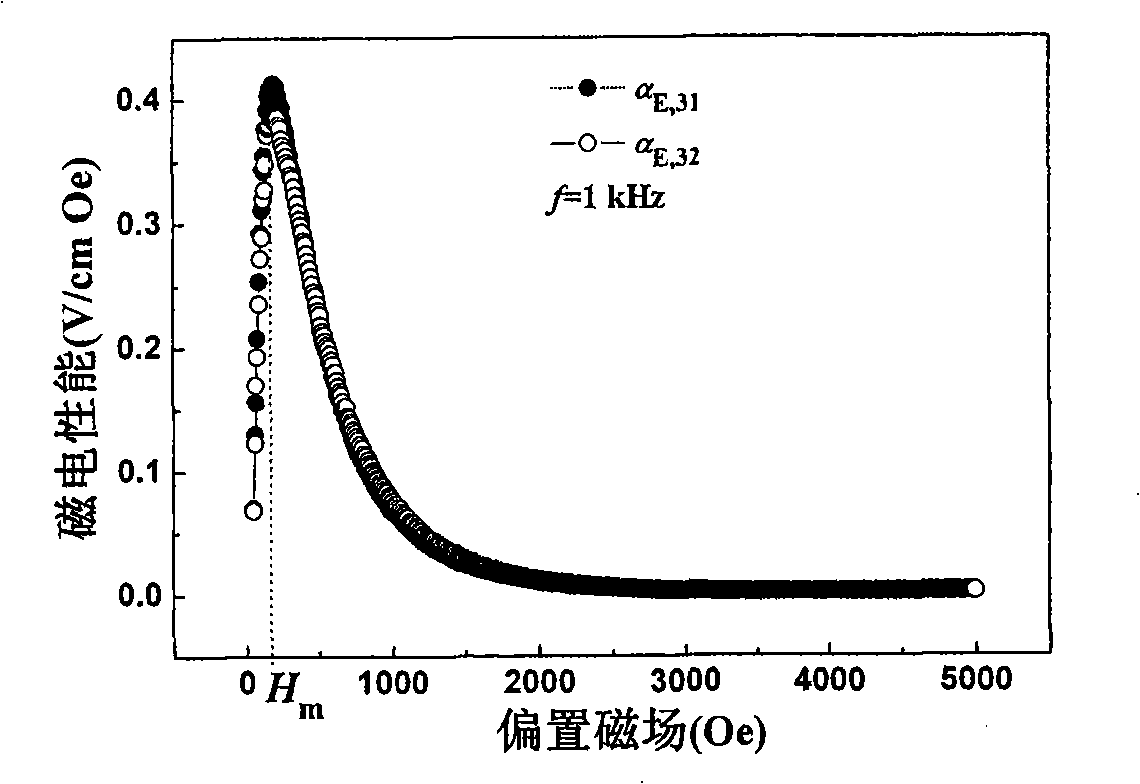

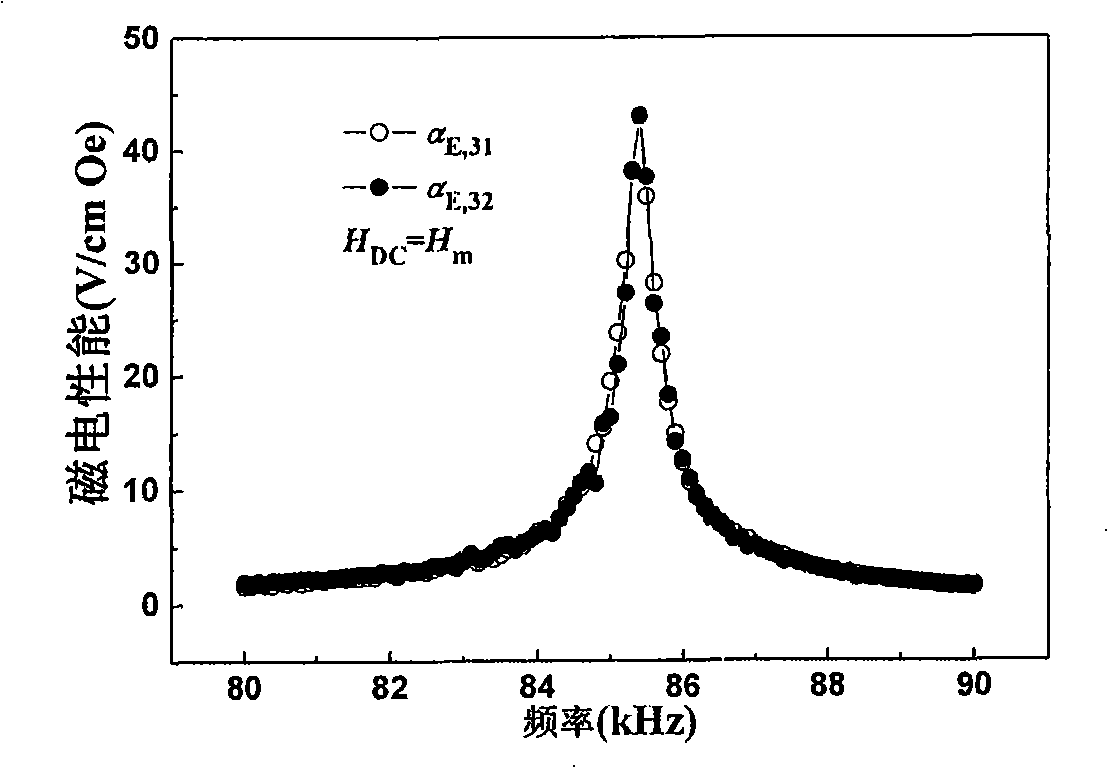

Method for designing and preparing spherical shell layered magnetoelectric composite material structure

InactiveCN101330124AHigh modulus of elasticityImprove magnetoelectric propertiesPiezoelectric/electrostrictive device manufacture/assemblyMagnetostrictive device manufacture/assemblyCompression moldingChemical plating

The invention discloses a spherical shell laminar magneto-electric composite material structure and a manufacturing method, and relates to the design and manufacture method of an isotropic magneto-electric effect laminar magneto-electric composite material structure. The method comprises the following steps: hemispherical shell piezoelectric ceramic is achieved through compression molding and sintering, after the high-temperature polarizing is performed, metallizing is performed by adopting the chemical plating method, two metallized piezoelectric ceramic hemispherical shells are bonded into a complete piezoelectric ceramic hemispherical shell through the strong glue, and then the shell is laid in the prepared electroplating solution to be electroplated till a magnetic layer with the required thickness is electroplated, thereby the spherical shell laminar magneto-electric composite material is achieved. Compared with the prior simple laminar composite material, such as a flat plate, because the dimensions of the structure in the three-dimensional direction are identical, the magneto-electric performances of the structure in all directions are identical, and by adopting the isotropic magneto-electric performance, the spherical shell laminar magneto-electric composite material can be applied to the magnetic field detection in the unknown directions.

Owner:UNIV OF SCI & TECH BEIJING

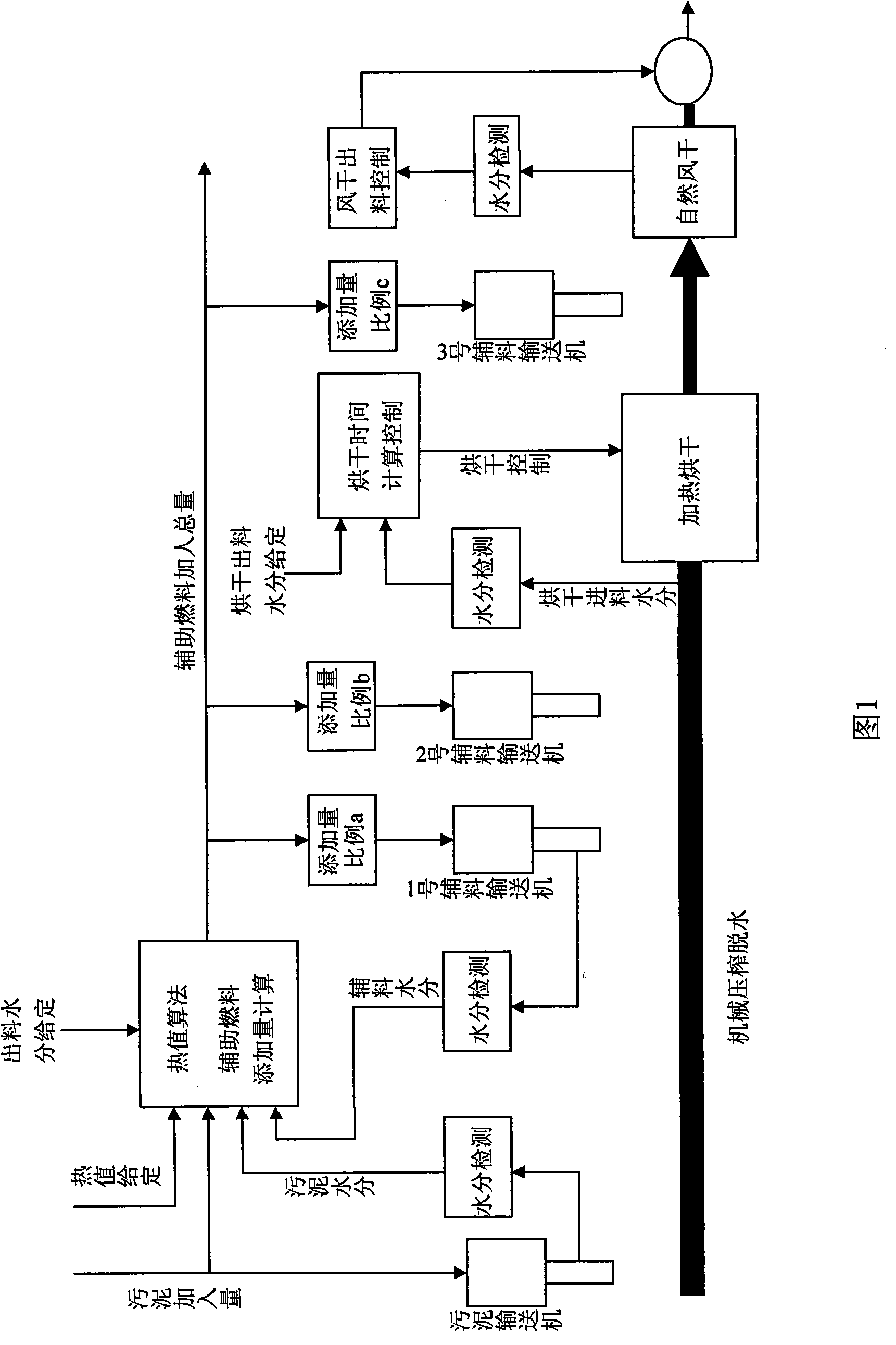

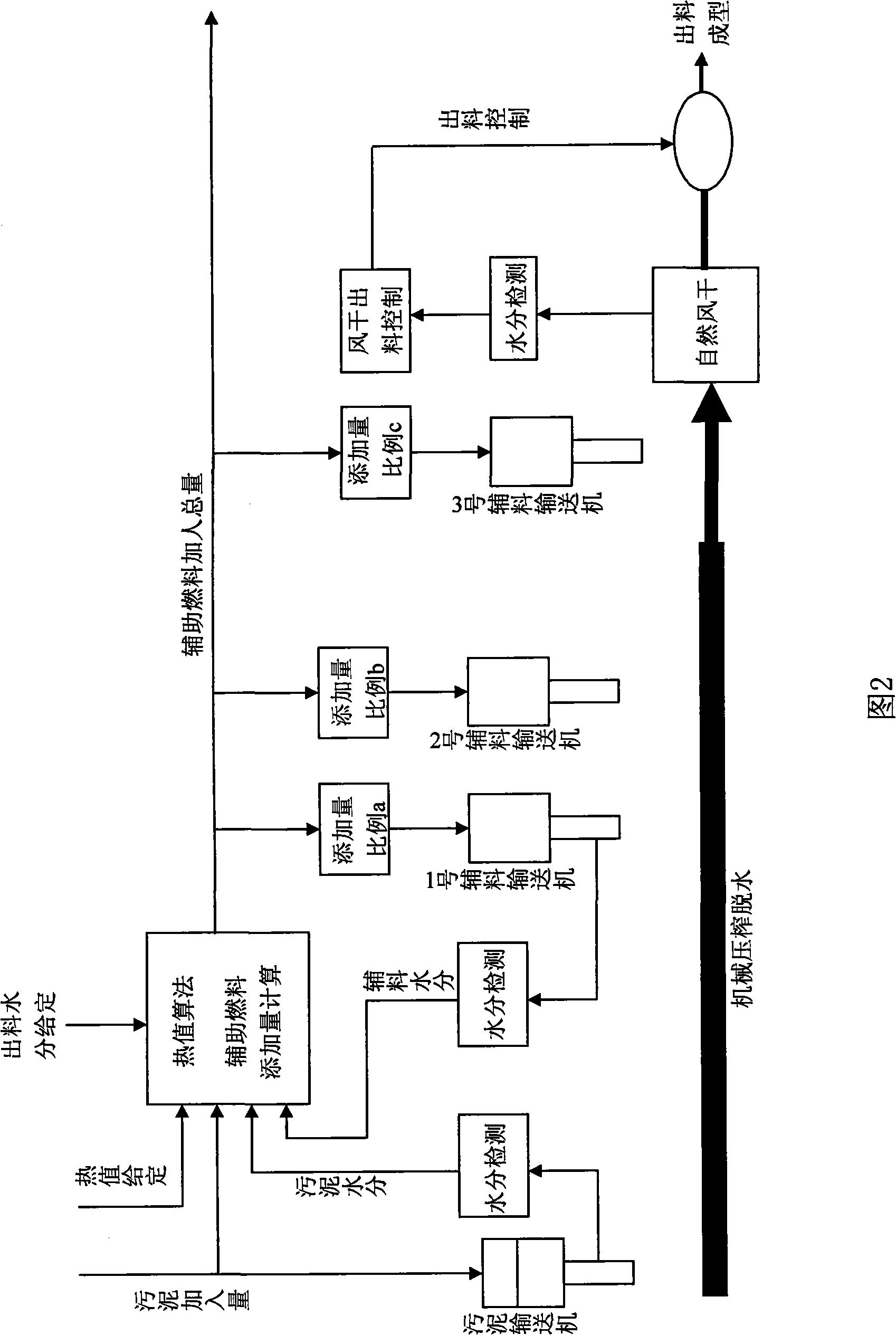

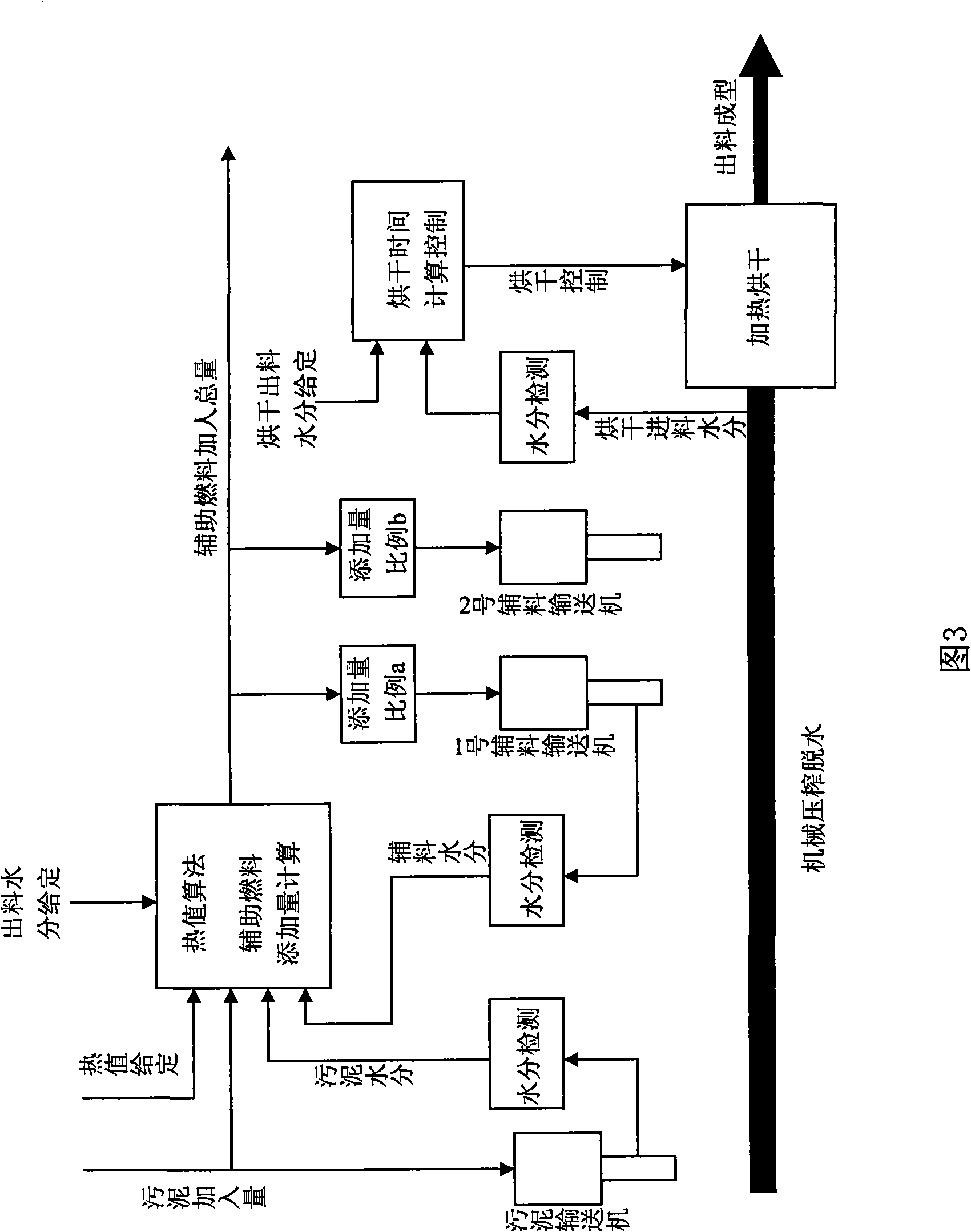

Sludge calorific value control method

InactiveCN101314514ACalorific value control method scienceCalorific value control method is reasonableSludge treatment by de-watering/drying/thickeningFilter mediaPulp and paper industry

The invention discloses a method for controlling a sludge calorific value. The method comprises the following steps that: auxiliary fuel is added into a sludge in preliminary condensation and dehydration and subject to dehydration drying to control the calorific value; according to the calorific power and the dryness of the sludge which is needed to be dried, the addition amount of the auxiliary fuel is subject to the specific calculation of the calorific value based on the influences of the auxiliary fuel, pure sludge and moisture of the sludge after the addition of auxiliary fuel, dehydration and drying on the calorific value; the dehydration drying adopts a method of mechanical compression dehydration and drying dehydration; the auxiliary fuel is added into the sludge in the process of mechanical compression dehydration and drying dehydration; when the sludge is subject to mechanical compression dehydration, the auxiliary fuel is added into the sludge by adopting a mode of paving the auxiliary fuel on a filtering medium of dehydration equipment. Based on that the calorific value of the sludge of the same kind is mainly determined by two parameters of the water ratio of the sludge and the relative content of the auxiliary fuel, the method adopts the technical proposal of dehydrating and drying the sludge and controlling the addition amount of the auxiliary fuel, is scientific and reasonable, has strong maneuverability and can effectively solve the technical difficult problems of the calorific value control of the sludge energy utilization.

Owner:ZHEJIANG HUAZHANG TECH

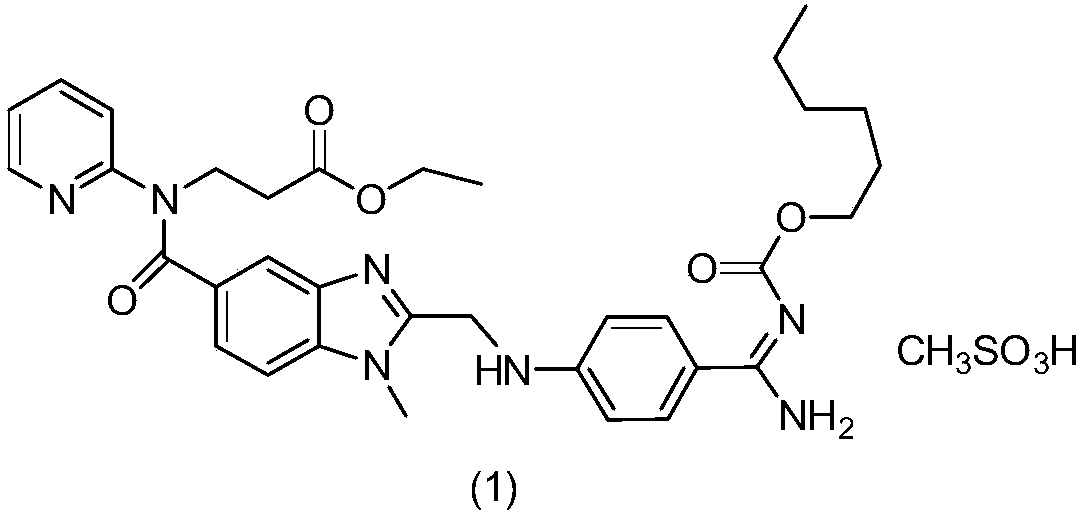

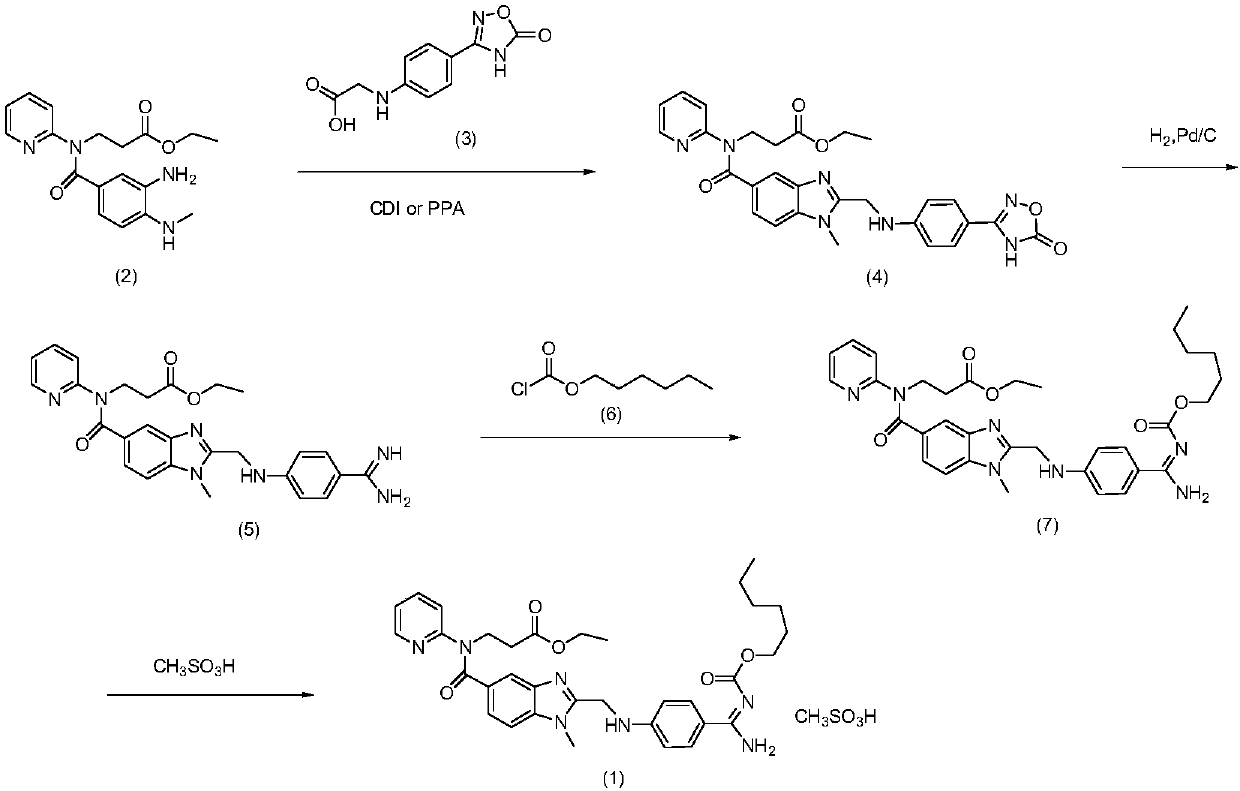

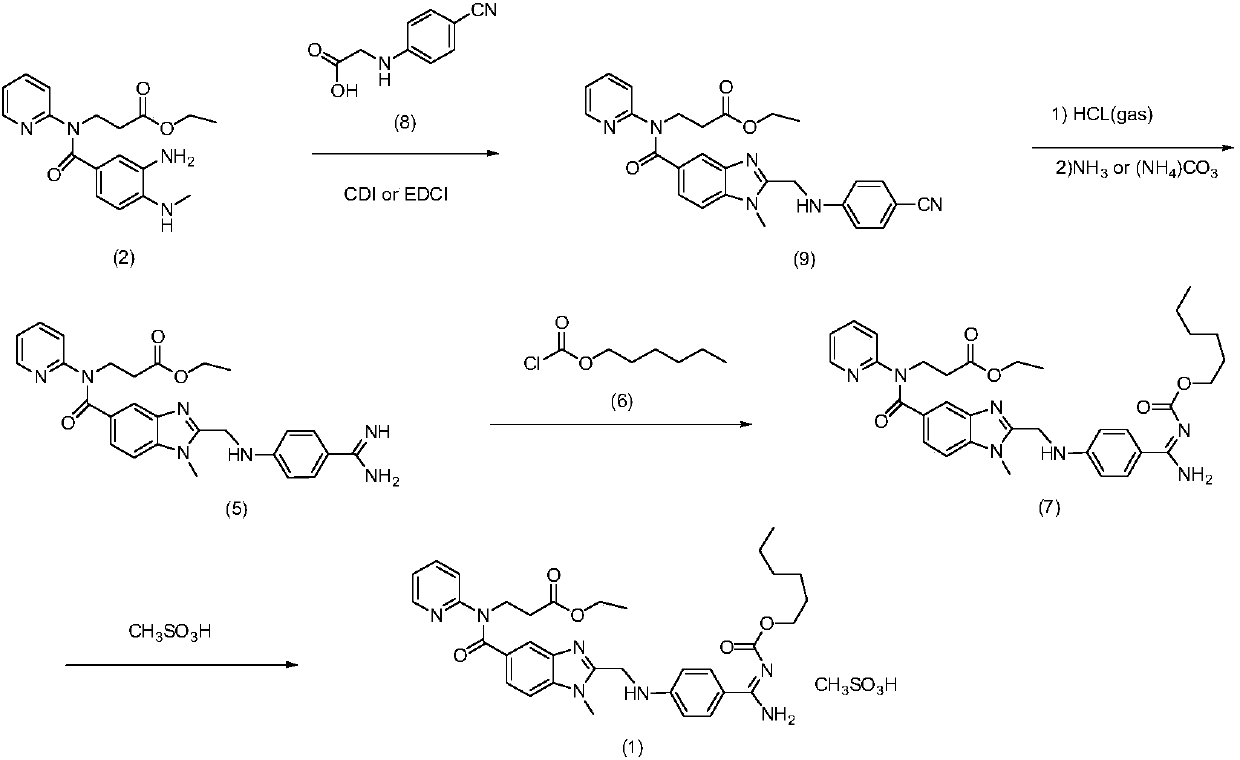

Dabigatran etexilate mesylate preparation method

The invention belongs to the field of pharmaceutical synthesis, and provides a dabigatran etexilate mesylate preparation method, which comprises: carrying out a ring closure reaction on 3-[(3-amino-4-methylaminobenzoyl)(pyridine-2-yl)amino] ethyl propionate and chloroacetic anhydride to generate N-[[2-(chloromethyl)-1-methyl-1H-benzimidazole-5-yl]carbonyl]-N-2-pyridyl-beta-alanine ethyl ester, carrying out a condensation reaction on the N-[[2-(chloromethyl)-1-methyl-1H-benzimidazole-5-yl]carbonyl]-N-2-pyridyl-beta-alanine ethyl ester and 4-aminobenzamidine dihydrochloride to obtain 3-({2-[(4-amidino-phenylimino)-methylene]-1-methylene-1H-benzimidazole-5-carbonyl}-pyridine-2-imine)-ethyl propionate, carrying out ester forming on the 3-({2-[(4-amidino-phenylimino)-methylene]-1-methylene-1H-benzimidazole-5-carbonyl}-pyridine-2-imine)-ethyl propionate and hexyl chloroformate to obtain dabigatran etexilate, and carrying out salt forming on the dabigatran etexilate and methanesulfonic acid to obtain dabigatran etexilate mesylate. According to the present invention, the route of the method has characteristics of high yield, mild condition and convenient intermediate purification, and meets the requirements of industrial production.

Owner:辽宁博美医药科技有限公司

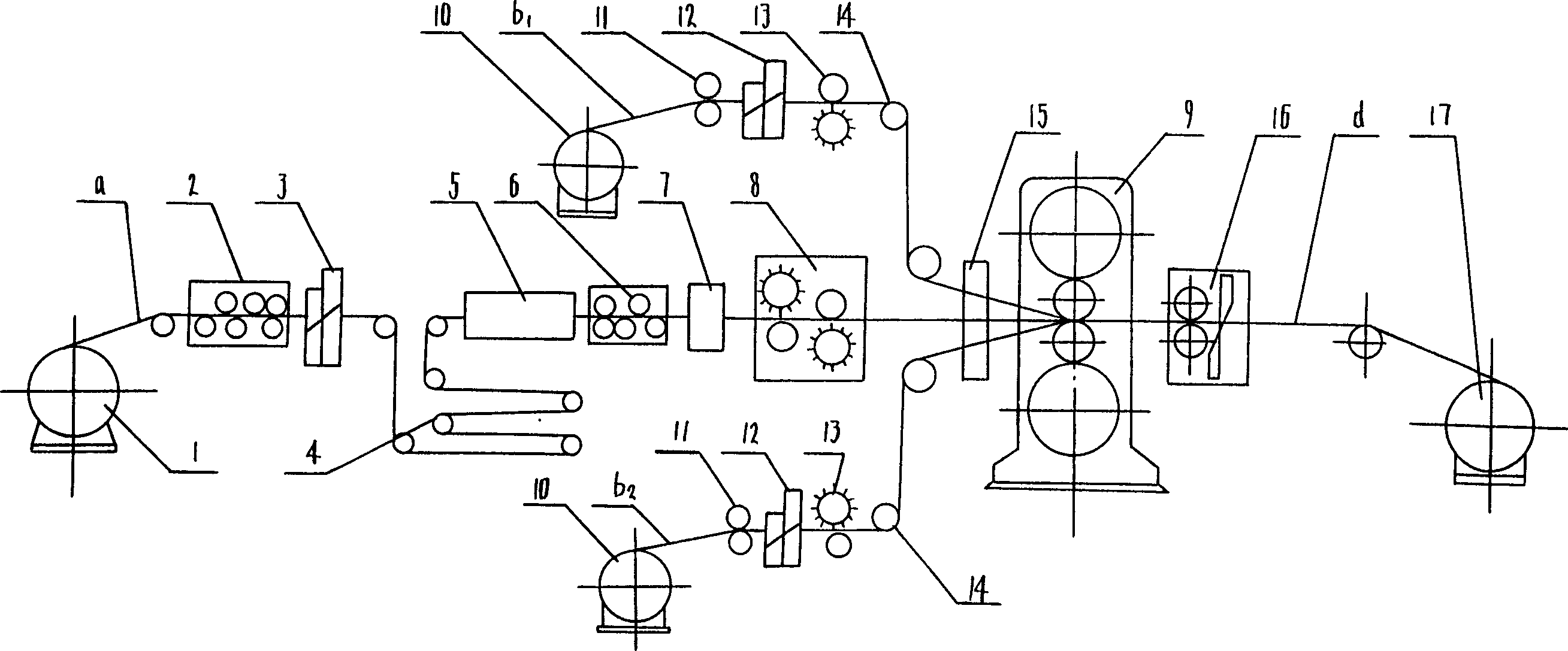

Producing method of double-metal composite band

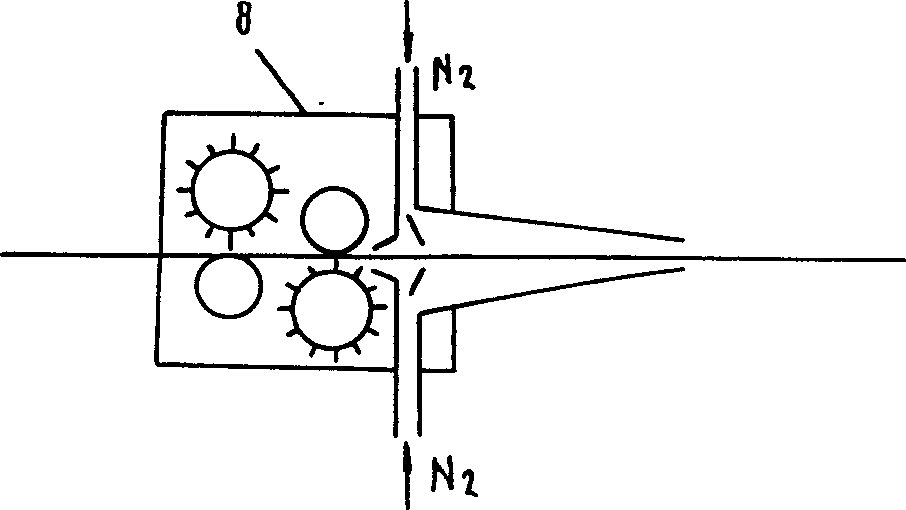

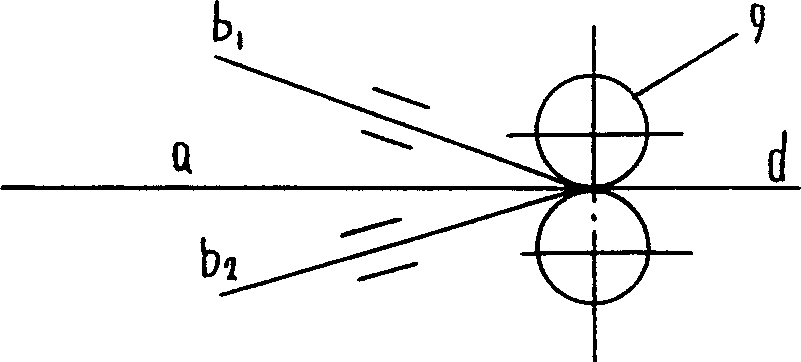

InactiveCN1126616CImprove performanceEasy to implement industrial productionWork treatment devicesAuxillary arrangementsComposite strengthNitrogen

A method for manufacturing a bimetallic composite strip, comprising the steps of surface pretreatment, rolling composite, heat treatment of the composite strip, and the like. This method also adds surface initial adsorption after surface pretreatment, and nitrogen is sprayed on the clean metal surface to form a nitrogen adsorption film on the metal surface. The rolling compounding of this method adopts rapid electric heating and non-isothermal rolling compounding. This method has the advantages of simple process, convenient operation, significantly reduced cost, improved composite strength, favorable interface bonding, and improved reprocessing performance of the composite plate.

Owner:NORTHEASTERN UNIV

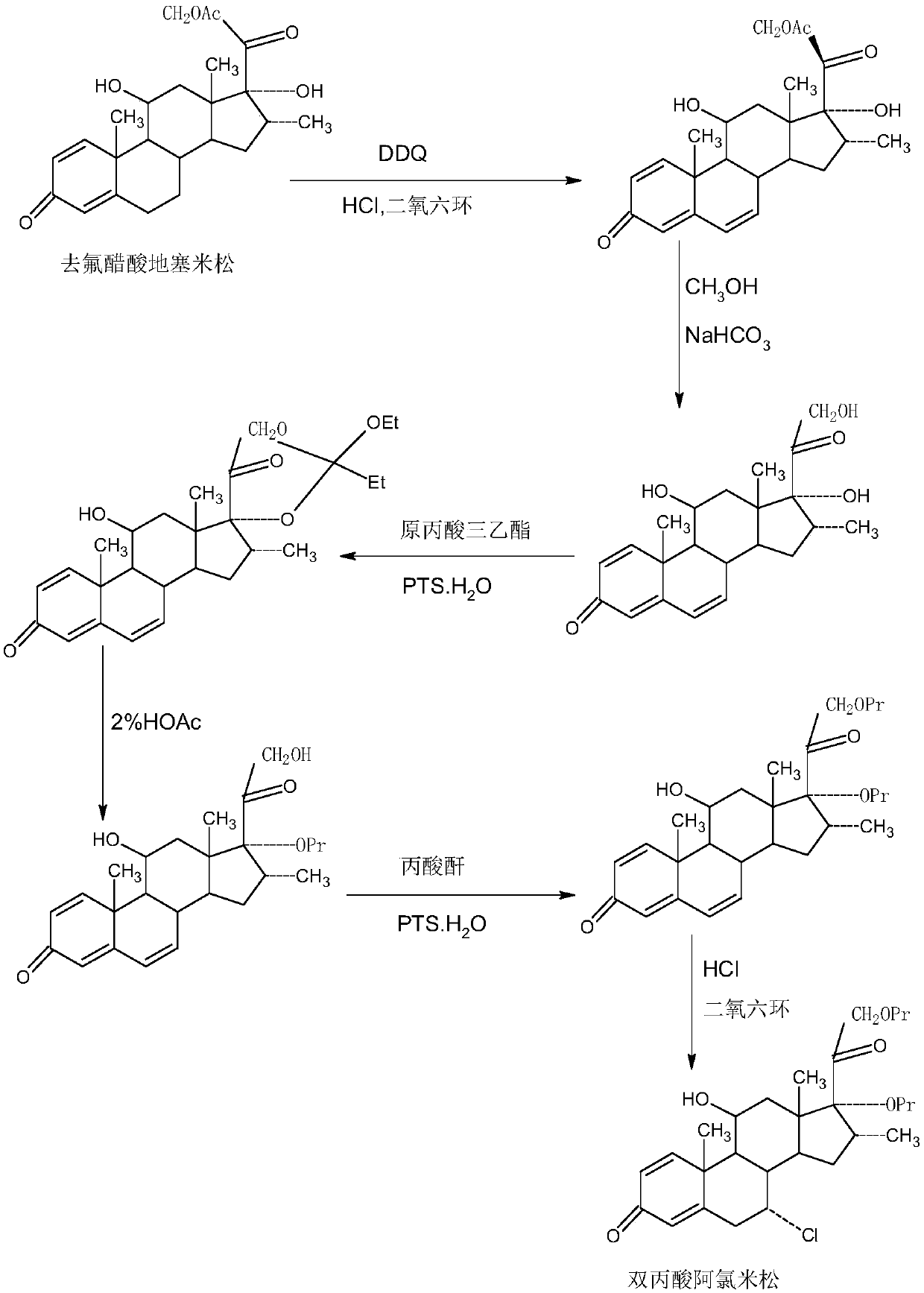

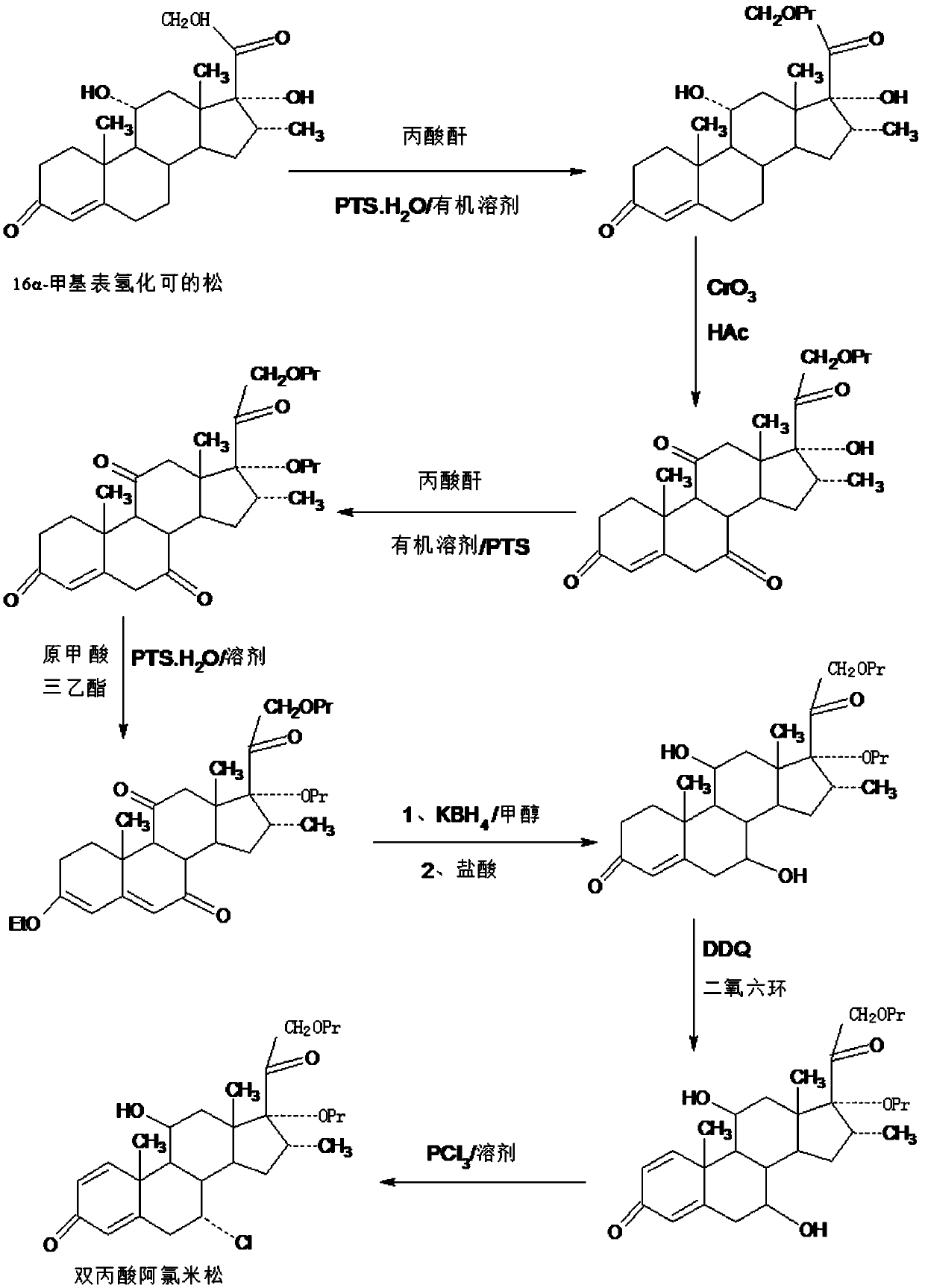

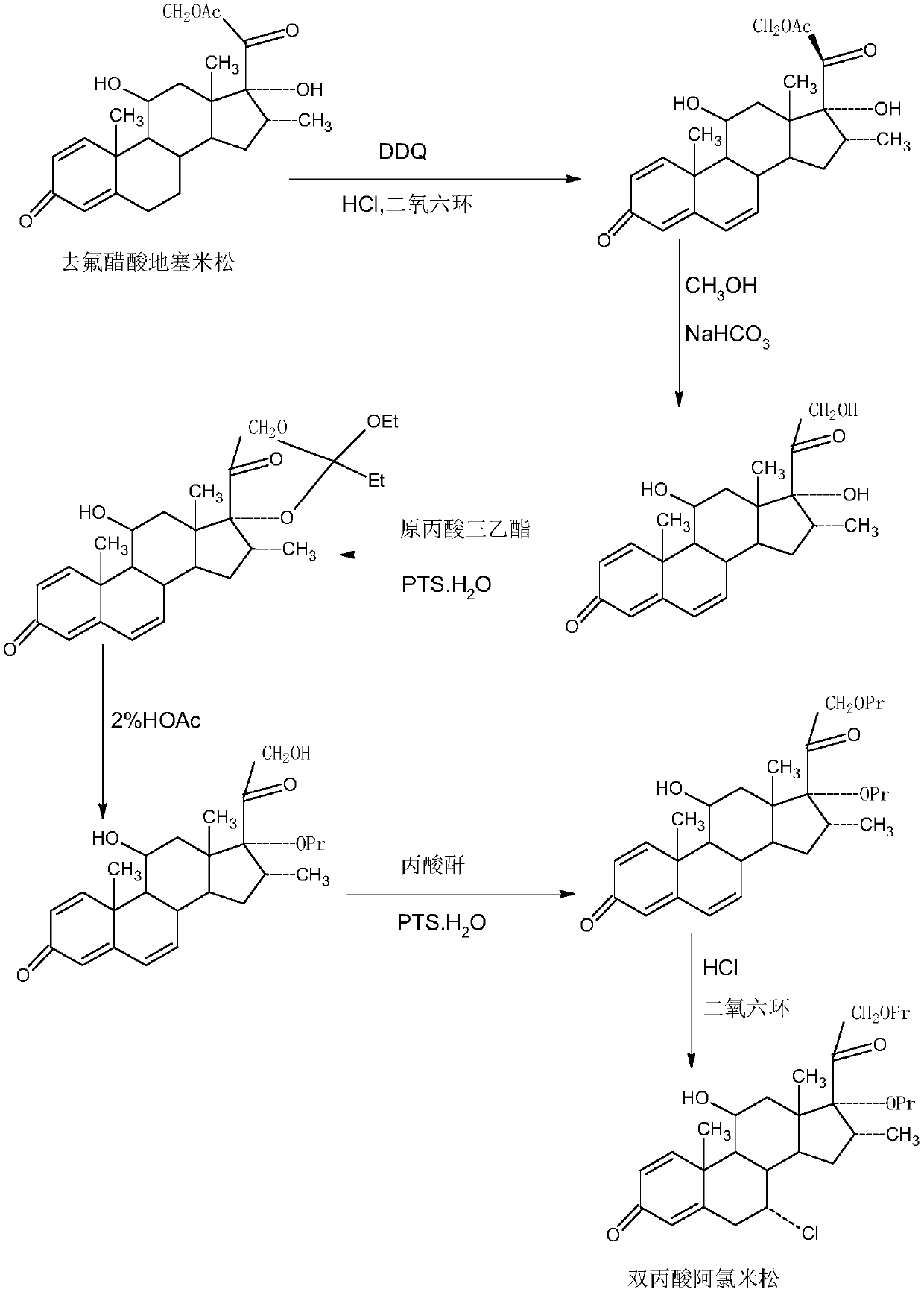

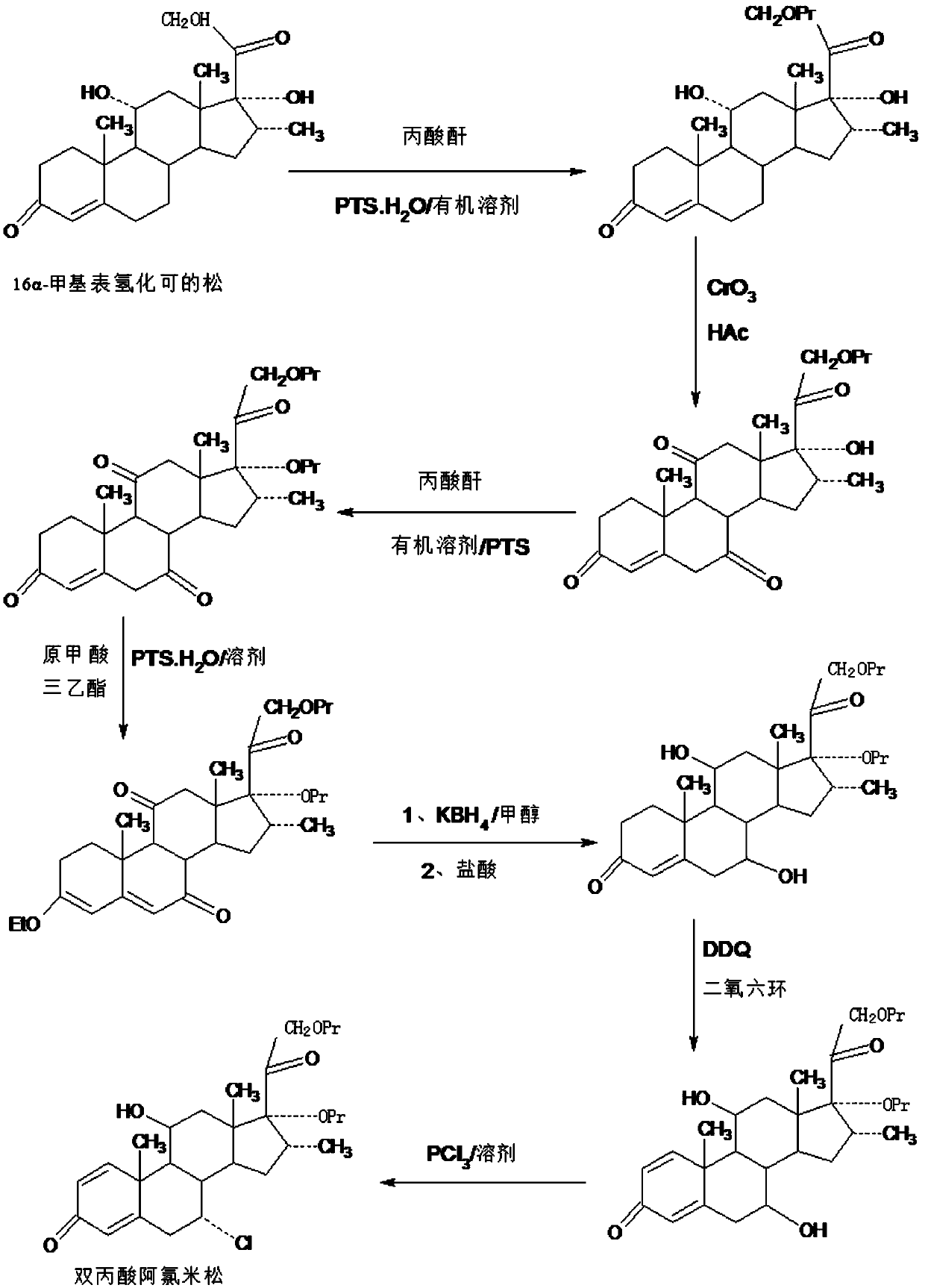

Method for preparing alclometasone dipropionate

ActiveCN109678920AShort synthetic routeProcess economy and environmental protectionSteroidsDexamethasonePropanoic acid

The invention provides a method for preparing alclometasone dipropionate. According to the method, alclometasone dipropionate is synthesized by the following seven reaction steps: esterification of 16a-methyl epihydrocortisone as a raw material with propionic acid at position 21; double-oxidization at positions 7 and 11 to obtain diketone; esterification with propionic acid at position 17; enolization and etherification protection at position 3; reduction and acid hydrolysis for deprotection with diketone at positions 7 and 11; dehydrogenation with DDQ (Dichlorodicyanobenzoquinone) at position1; and chlorine substitution at position 7. According to the method for preparing alclometasone dipropionate, the alclometasone dipropionate is synthesized by taking 16a-methyl epihydrocortisone as the raw material through seven steps; compared with a convention method with dexamethasone fluoroacetate as the raw material, the process has the advantages of short synthetic route and economy and environmental protection, simple production and operation, high product yield and the like; in the alclometasone dipropionate produced with the method, the total synthetic yield is increased from original 2.678% to 32-35%, the production cost is less than 20% of that of the traditional method; the solvent used in production can be recycled and reused; the industrial production is easy to implement.

Owner:HUNAN KEREY BIOTECH

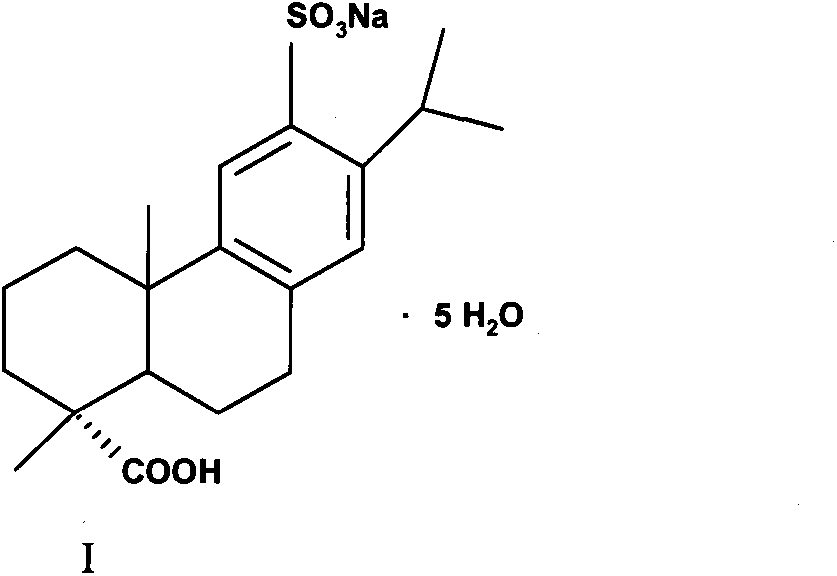

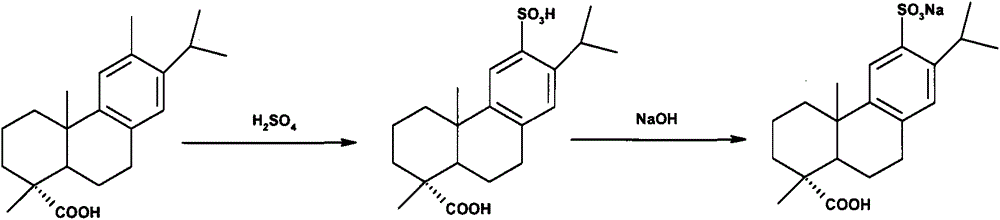

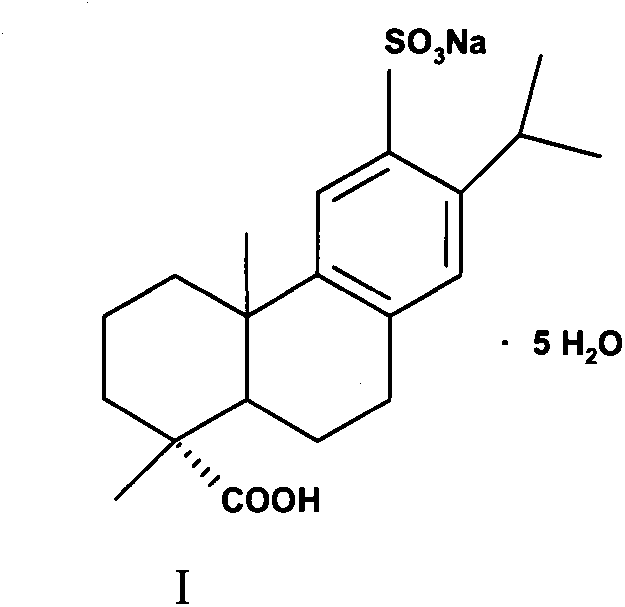

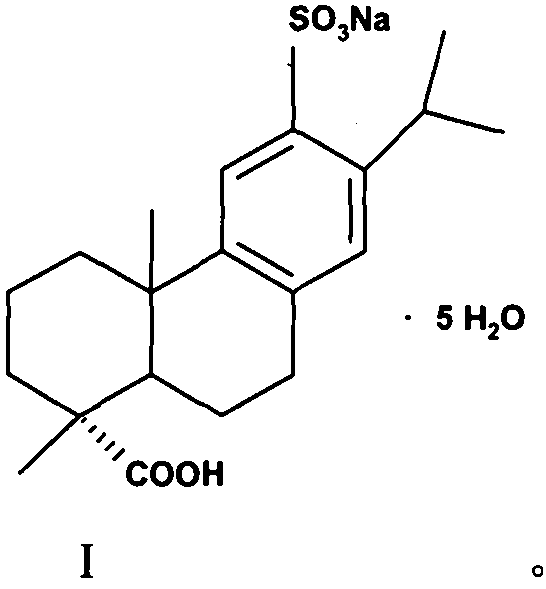

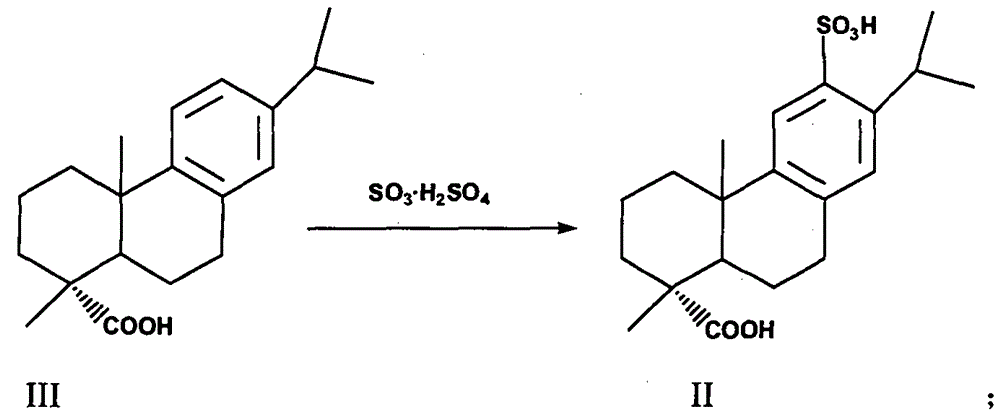

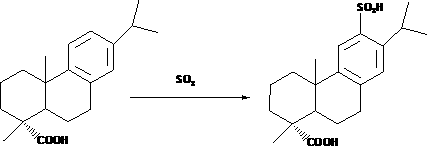

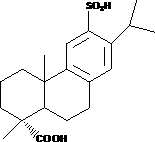

Method for preparing ecabet sodium

ActiveCN104086465AWeak alkalineFast sulfonationSulfonic acids salts preparationState of artSodium salt

The invention discloses a method for preparing ecabet sodium. The method disclosed by the invention is characterized by comprising the following steps of carrying out sulfonation reaction on dehydroabietic acid (formula III) as a starting material and fuming sulfuric acid to obtain 12-sulfonic dehydroabietic acid (formula II) and enabling the compound shown as the formula II and a sodium-forming agent to form a sodium salt in a solvent system at least containing water to obtain ecabet sodium. By virtue of the method disclosed by the invention, the deficiencies of the prior art are overcome and the method has the advantage of high sulfonation yield and high selectivity in sodium salt forming, simple operation, safety and environment friendliness and is suitable for industrial production.

Owner:CHONGQING KANGLE PHARMA

A kind of preparation method of ecabet sodium

ActiveCN104086465BWeak alkalineFast sulfonationSulfonic acids salts preparationState of artSodium salt

The invention discloses a preparation method of ecabet sodium, which is characterized in that: the method of the invention uses dehydroabietic acid (formula III) as a starting material, and carries out sulfonation reaction with oleum to obtain 12-sulfonic acid Base dehydroabietic acid (formula II), the compound of formula II and a sodium forming agent form a sodium salt in at least an aqueous solvent system to obtain ecabet sodium. The method of the invention overcomes the disadvantages of the prior art, and has the advantages of high sulfonation yield, high selectivity for sodium salt formation, simple operation, safety and environmental protection, and is suitable for industrial production.

Owner:CHONGQING KANGLE PHARMA

A kind of method utilizing vacuum low temperature extraction to separate steviol glycosides

InactiveCN101671378BReduce the burden onLarge adsorption capacitySugar derivativesSugar derivatives preparationFlocculationVacuum extraction

The invention discloses a method for extracting and separating steviol glycosides by using vacuum low-temperature extraction. The steps are successively raw material crushing, vacuum low-temperature extraction, centrifugal filtration, secondary vacuum low-temperature extraction and centrifugal filtration, flocculation precipitation, filtration, gradient membrane separation, gradient Eluted, concentrated and dried to obtain the product. The steviol glycoside extracted by the invention has high purity and high activity, and the extraction method is easy to implement industrialized production, and the cost is greatly reduced, creating a new way for the production of stevioside.

Owner:安徽亚强生物工程股份有限公司

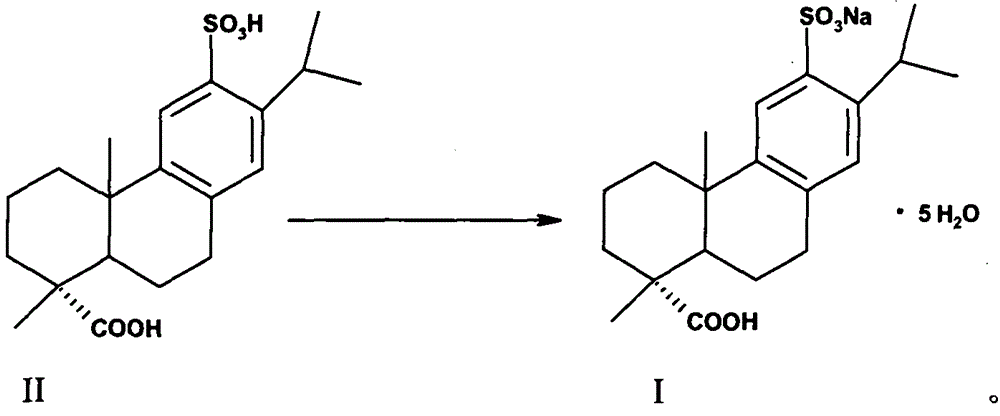

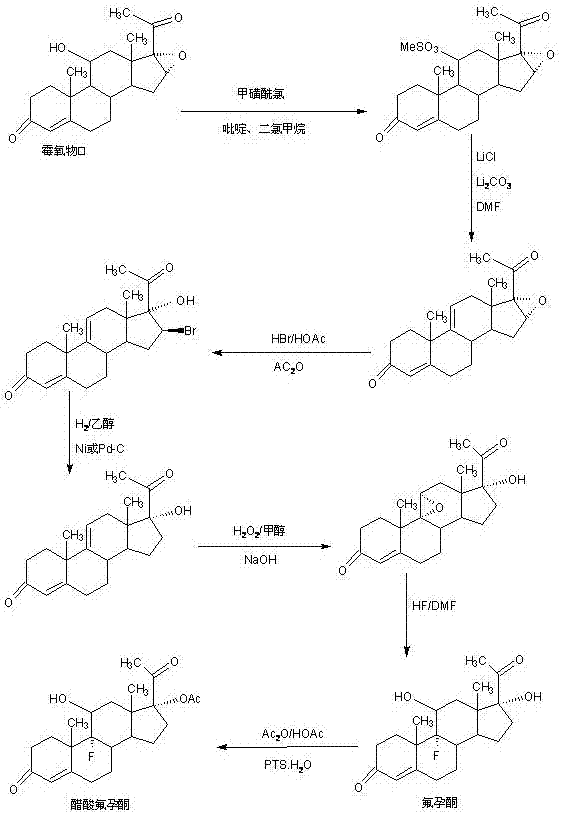

Preparation method of flurogestone acetate

InactiveCN107365341AWide variety of sourcesShort synthetic routeSteroidsAcetic anhydrideSodium iodide

The invention discloses a preparation method of flurogestone acetate. The preparation method comprises the following steps: using 9a-cortisone bifluoride as a raw material, dissolving 9a-cortisone bifluoride into an organic solvent, and reacting with acyl chloride under the existence of an acid-binding agent to obtain a 9a-cortisone bifluoride-21-O-ester; then reacting the ester with sodium iodide and a sulfur-containing reducing agent in the organic solvent for deesterification, and synthesizing flugestone; and finally reacting the flugestone with acetylchloride or acetic anhydride in the organic solvent, and synthesizing flurogestone acetate. According to the preparation method, 9a-cortisone bifluoride is used as the raw material, flurogestone acetate is synthesized through three-step reaction of 21-site esterification, then reduction and de-esterification and finally 17-site ethyl esterification, and compared with a traditional synthetic method for using a mold removal object acquired through diosgenin processing as a raw material, the preparation method has the advantages such as wide raw material source, short synthetic route, simple, convenient and environmentally-friendly process, few invested equipment and high product yield, and the production cost in the method is reduced by 25% to 30% as compared with a traditional method; and a solvent used in the production can be recycled and circularly used, and is easy for industrial production.

Owner:HUNAN KEREY BIOTECH

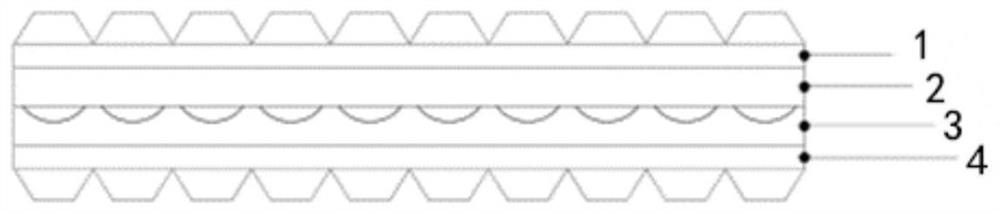

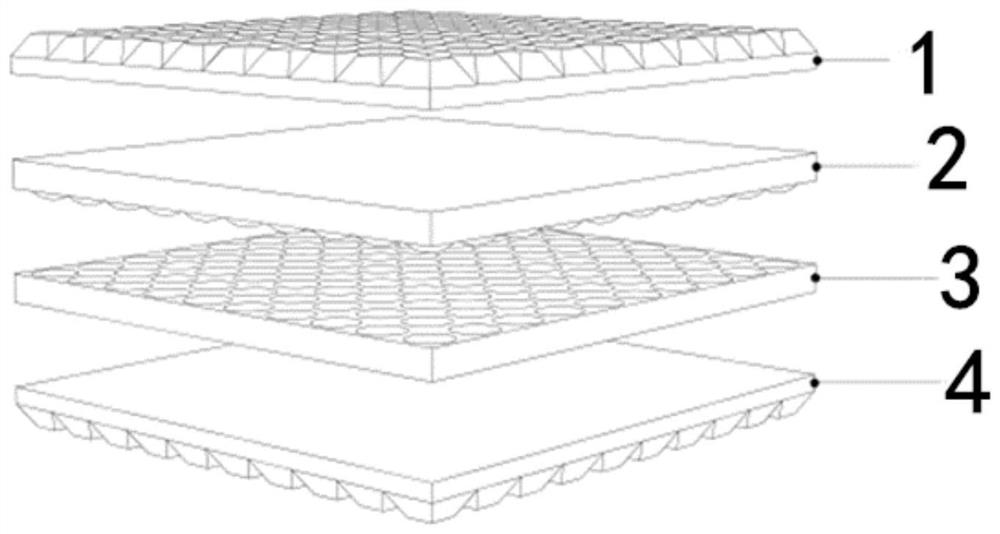

High-strength hydrophobic high-reliability packaging adhesive film and preparation method thereof

PendingCN113372831AImprove water resistanceImprove adhesionNon-macromolecular adhesive additivesFilm/foil adhesivesPolymer sciencePolyolefin

The invention relates to the technical field of packaging materials for photovoltaic modules, and provides a high-strength hydrophobic high-reliability packaging adhesive film. The high-strength hydrophobic high-reliability packaging adhesive film comprises an EVA adhesive film layer, a high-strength hydrophobic layer, a water absorption bonding layer and a polyolefin adhesive film layer which are sequentially arranged from top to bottom. Transverse and longitudinal grooves are formed in the upper surface of the EVA adhesive film layer and the lower surface of the polyolefin adhesive film layer and form #-shaped pattern surfaces; a plurality of regular first arc structures are arranged on the lower surface of the high-strength hydrophobic layer; and a second arc structure matched with the first arc structure is arranged on the upper surface of the water absorption bonding layer. The invention further provides a preparation method of the high-strength hydrophobic high-reliability packaging adhesive film. The front surfaces of the composite high-strength hydrophobic layer and the water absorption bonding layer functional film are compounded with the transparent EVA adhesive film, the back surfaces are compounded with a transparent polyolefin film, and then the upper surface and the lower surface are subjected to #-shaped embossing and rolling. The packaging adhesive film is good in water blocking effect and high in tensile strength, the mechanical performance of a packaging assembly can be effectively improved, and the lightweight design of the packaging assembly is promoted.

Owner:CHANGZHOU SVECK PHOTOVOLTAIC NEW MATERIAL

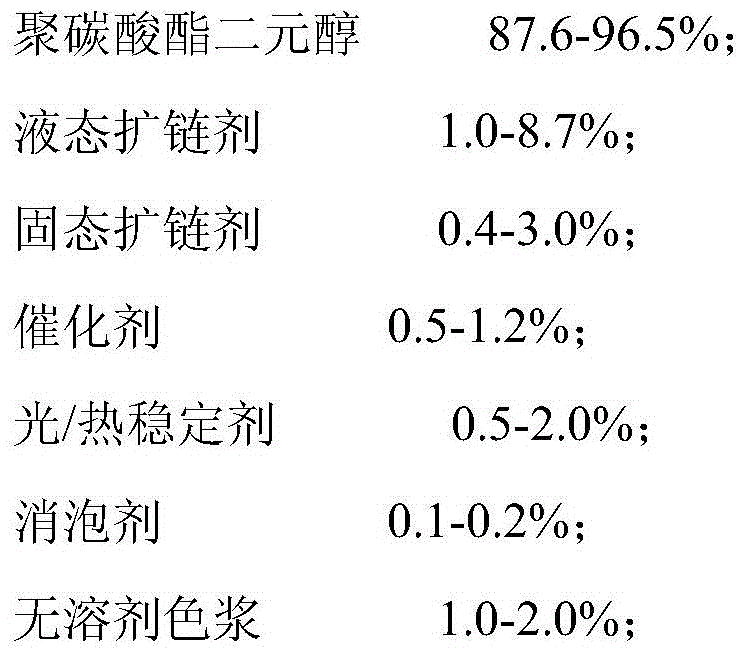

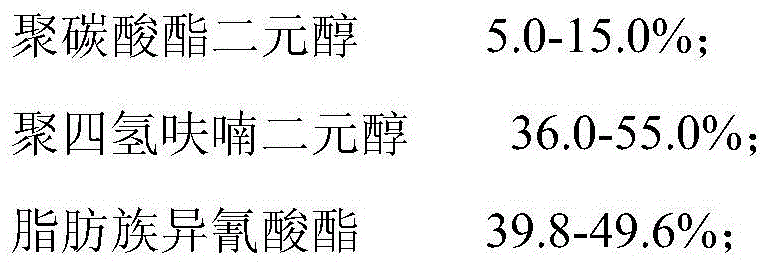

A kind of preparation method of solvent-free environment-friendly polyurethane automobile leather

ActiveCN104088161BEliminate pollutionSmall investmentLamination ancillary operationsLaminationProduction lineSurface layer

The invention provides a preparation method of solvent-free environment-friendly polyurethane automobile leather. The automobile leather comprises a surface layer and a foaming layer, wherein both the surface layer and the foaming layer are made of double-component solvent-free polyurethane; each of solvent-free environment-friendly polyurethane surface layer rein and solvent-free environment-friendly polyurethane foaming layer resin respectively used in the surface layer and the foaming layer is composed of a solvent hydroxyl mixture component A and an isocyanate component B. The specific preparation method of the automobile leather comprises the following steps: blade coating a shell fabric, drying the shell fabric, blade coating the foaming layer resin, adhering base cloth when the foaming layer resin is half-dry, curing and rolling. The automobile leather is prepared from the solvent-free environment-friendly polyurethane resin by one-step molding on a dry-method production line; the preparation method gets rid of a wet-method process flow in the traditional production process of polyurethane automobile leather and the production procedure is shortened for one half; no organic solvent is discharged, and the production process and finished products are friendly to the environment.

Owner:XUCHUAN CHEM SUZHOU

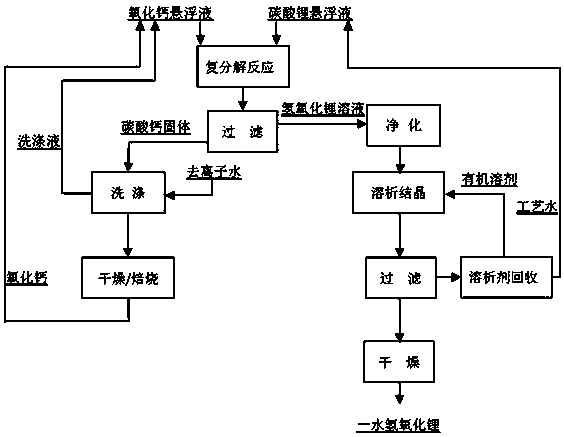

A kind of method utilizing lithium carbonate to prepare lithium hydroxide monohydrate

ActiveCN108821313BLow raw material requirementEasy to implement industrial productionLithium oxides/hydroxidesPhysical chemistryOrganosolv

The invention relates to a method for preparing lithium hydroxide monohydrate by using lithium carbonate. The method comprises the steps: adopting industrial grade lithium carbonate as a raw material,performing a reaction on suspension of the lithium carbonate, calcium oxide and water under the conditions of heating, pressurizing and stirring for 90-110 min, and performing filtration, purification, elution crystallization, drying and the like so as to obtain lithium hydroxide monohydrate. The method has the advantages that industrialization can be realized easily through adoption of industrial grade lithium carbonate to prepare the lithium hydroxide monohydrate, and improvement of the reaction speed and shortening of the reaction time are achieved by adopting a pressurized mode to increase the reaction temperature, so that the conversion rate of lithium carbonate is achieved; by adopting the elution crystallization method, the problems that a previously adopted evaporative crystallization method has large energy consumption and a high temperature, and lithium hydroxide is easily converted into lithium carbonate during evaporation are solved, and conversion, caused by water loss, of lithium hydroxide monohydrate into anhydrous lithium hydroxide can be prevented during evaporation; the product has stable quality and high purity, and organic solvents used during the elution crystallization can be recycled, so that discharge without solid and liquid waste is achieved.

Owner:QINGHAI UNIVERSITY

Preparation method of finished 16alpha,21-diacetoxy prednisolone

ActiveCN109081860AAvoid many difficulties such as difficult purificationEasy to operateSteroidsAcetic acidAlcohol

The invention provides a preparation method of finished 16alpha,21-diacetoxy prednisolone product, comprising: subjecting 17alpha-deshydroxy prednisolone acetate as an initial material to 16,17-epoxidation with an organic peroxy acid in a first organic solvent to obtain an epoxide; subjecting the epoxide, in a second organic solvent, to ring-opening reaction with glacial acetic acid under the catalysis of an acid catalyst to obtain the target product, 16alpha,21-diacetoxy prednisolone; subjecting the crude 16alpha,21-diacetoxy prednisolone to heating reflux discoloration and crystallization with a lower carbon alcohol of C4 and below so as to obtain the finished 16alpha,21-diacetoxy prednisolone. The intermediate, 16alpha,21-diacetoxy prednisolone, to 16alpha-hydroxy prednisolone is prepared herein via the method that is efficient, environmentally friendly and fair in cost.

Owner:HUNAN KEREY BIOTECH

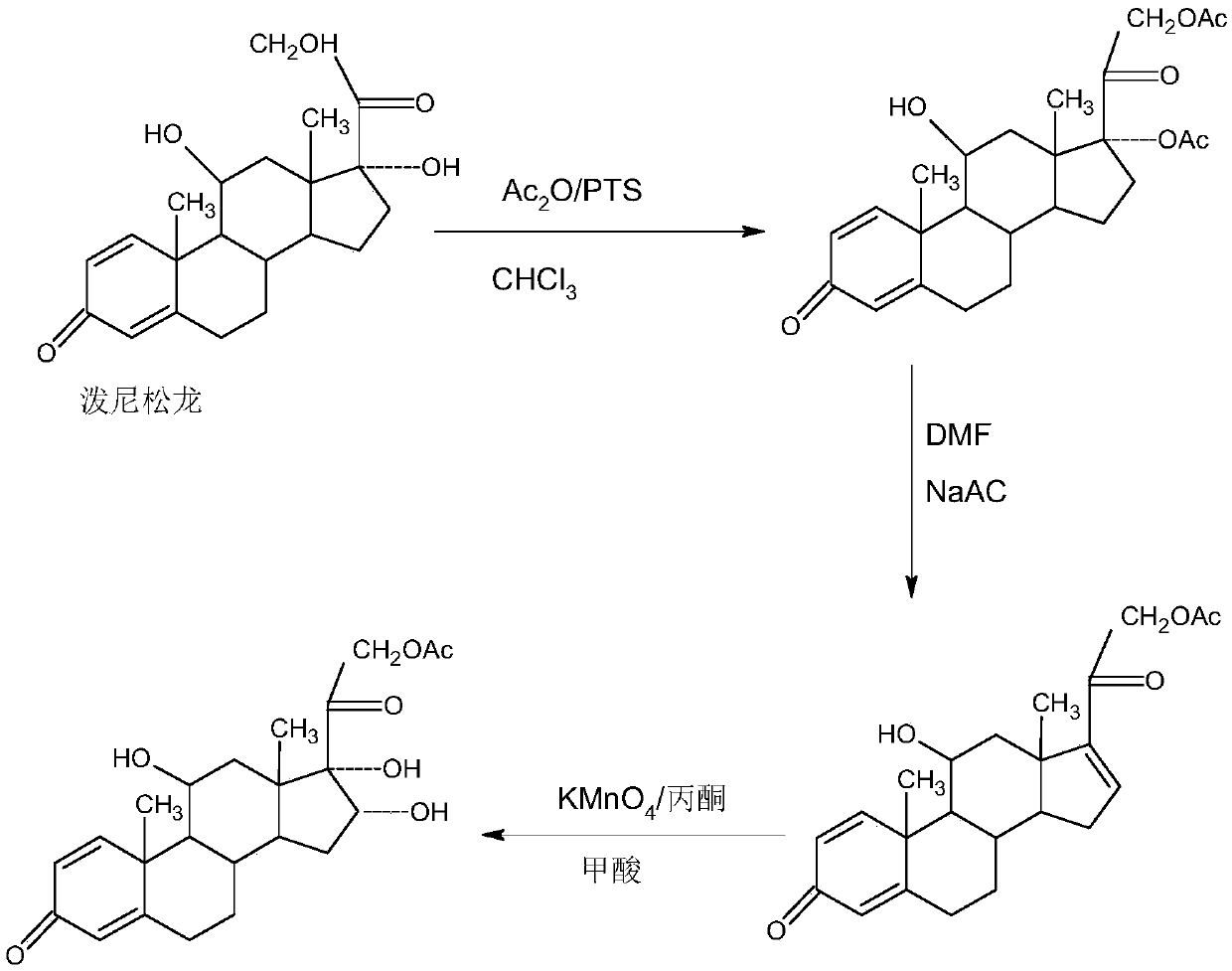

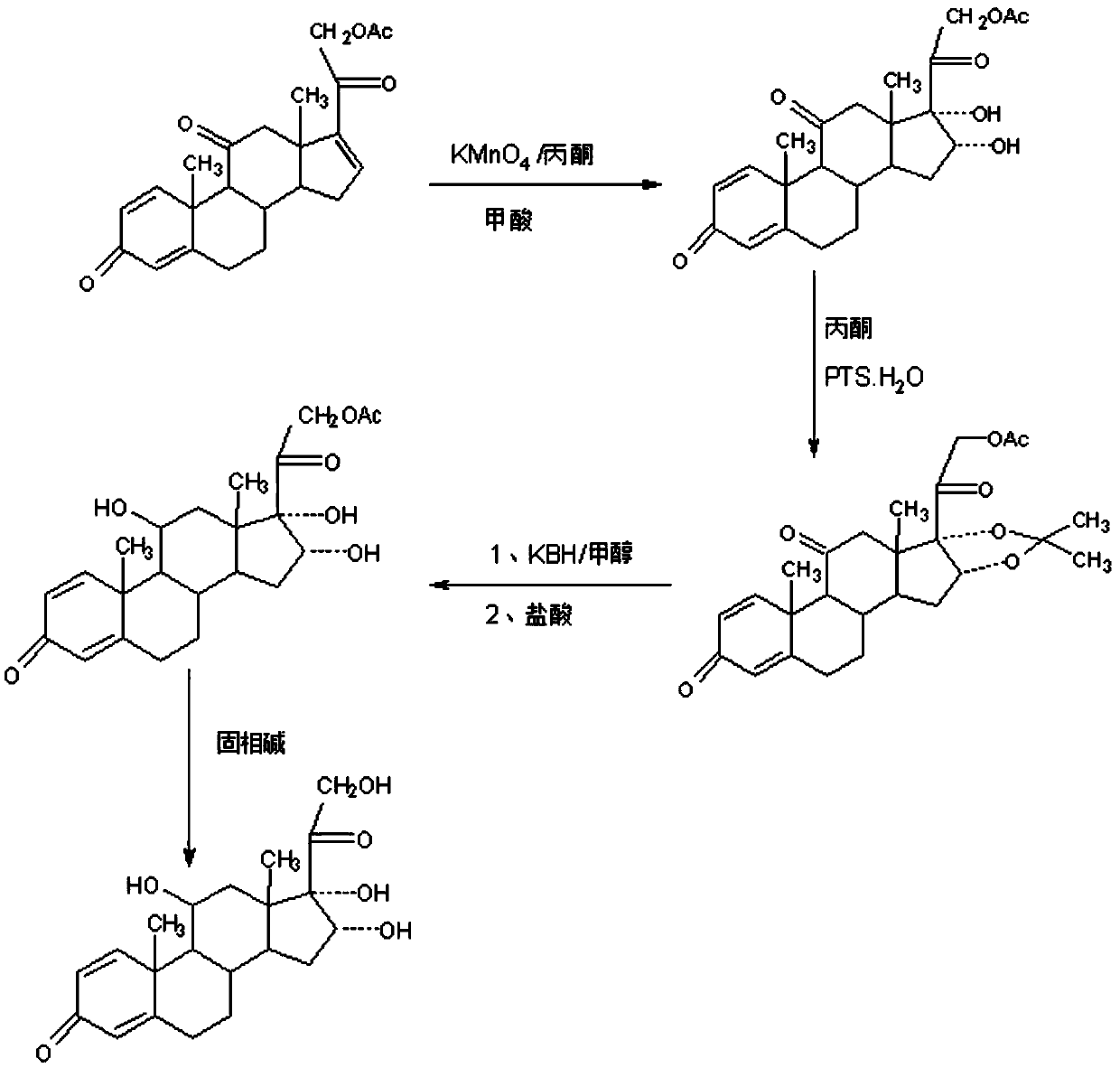

Novel preparation method of 16 alpha-hydroxyprednisolone

A novel preparation method of 16 alpha-hydroxyprednisolone comprises the following steps: dissolving 17-prednisone dehydroxyacetate as a raw material in an organic solvent, oxidizing a 16-position double bond and a 17-position double bond with potassium permanganate under acid catalysis to obtain an oxide, dissolving the obtained oxide in the organic solvent, adding acetone, and carrying out acidcatalysis reaction to obtain a protective substance; then dissolving the protective substance in an organic solvent, adding a reducing agent to reduce the 11-position ketone, and directly adding an acid aqueous solution to perform hydrolysis and deprotection after the reduction reaction to obtain the 16 alpha-hydroxyprednisolone, and dissolving 16 alpha -hydroxyacetate in an organic solvent, hydrolyzing 21-position acetic ester under the catalysis of solid-phase base to obtain 16 alpha -hydroxyprednisolone. Although two steps of the protection reaction and deprotection reaction are added, thereaction yield of each step unit is high, and the operation is simple and convenient, and the process is economical and environment-friendly, and the total synthesis yield is greatly improved; and compared with the traditional production method, the preparation cost of the method is reduced by 20-25%.

Owner:HUNAN KEREY BIOTECH

Method for preparing dehydrogenated intermediate product for aclomethasone dipropionate

ActiveCN109651477AShort synthetic routeProcess economy and environmental protectionSteroidsPropanoic acidAcid hydrolysis

Disclosed is a method for preparing a dehydrogenated intermediate product for aclomethasone dipropionate. The method comprises the steps that with 16a-methyl pihydrocortisone as a raw material, a crude dehydrogenated intermediate product for aclomethasone dipropionate is synthesized through a six-step reaction of 21-site propionic acid esterification, 7,11-site double-oxidation into diketone, 17-site propionic acid esterification, 3-site enolization etherification protection, 7,11-site diketone reduction and acid hydrolysis deprotection and 1-site DDQ dehydrogenation, then the dehydrogenated intermediate product for aclomethasone dipropionate is obtained through refining. By means of the method, with 16a-methyl pihydrocortisone as the raw material, the dehydrogenated intermediate product for aclomethasone dipropionate is synthesized through the six-step reaction; the process has the advantages of being short in synthesis route, economical, environmentally friendly, simple in productionoperation, high in product yield and the like; a solvent used in production can be recycled and applied, and industrial production is easy to implement.

Owner:HUNAN KEREY BIOTECH

Sulfonation preparation method of sulfur trioxide halogenated hydrocarbon solution of Ecabet

InactiveCN107628972AFast sulfonationThe conversion rate of sulfonation is completeSulfonic acid preparationChemistryStrong acids

The invention discloses a sulfonation preparation method of a sulfur trioxide halogenated hydrocarbon solution of Ecabet. The method is characterized in that dehydroabietic acid (represented by a formula II) is taken as a starting raw material and is sulfonated with the sulfur trioxide halogenated hydrocarbon solution so as to generate Ecabet (represented by a formula I). According to the sulfonation preparation method, the deficiencies of the prior art are overcome; the sulfonation preparation method has the advantages that the sulfonation yield is high, the use amount of sulfur trioxide approximates to a theoretical amount, water is not generated, and a large number of strong-acid waste acid is not generated; and the sulfonation preparation method is simple in operation, safe, environment-friendly and suitable for industrial production.

Owner:CHONGQING KANGLE PHARMA +1

Method for preparing 16a, 21-diacetoxyprednisolone product

ActiveCN109180764AEasy to operateThe production process is economical and environmentally friendlySteroidsOrganic solventAlcohol

The invention provides a method for preparing a 16a, 21-diacetoxyprednisolone product. The method comprises that 17a-dehydroxyprednisolone as a raw material and an organic peroxyacid undergo an epoxidation reaction at the 16th and 17th in a first organic solvent to produce an epoxy, the epoxy and glacial acetic acid undergo a ring opening reaction in a second organic solvent in the presence of anacid catalyst to produce a desired product 16a, 21-diacetoxyprednisolone, and the crude 16a, 21-diacetoxyprednisolone is subjected to heating reflux in C1-4 lower alcohol so that the 16a, 21-diacetoxyprednisolone is decolorized and recrystallized and a 16a, 21-diacetoxyprednisolone product is obtained. The method is efficient and environmentally friendly, realizes a low cost and can prepare the 16a-hydroxyprednisolone intermediate 16a, 21-diacetoxyprednisolone.

Owner:HUNAN KEREY BIOTECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com