High-toughness polylactic acid in-situ maleic anhydride grafted thermoplastic elastomer composite material

A thermoplastic elastomer, maleic anhydride technology, applied in the field of polylactic acid, maleic anhydride grafted thermoplastic elastomer composite material, can solve the problems of high cost, complex modification method and production process, and achieve the effect of good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

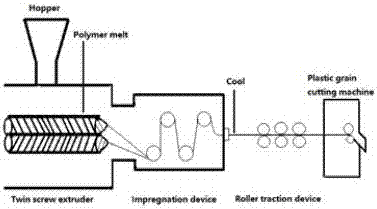

[0033] Embodiment 1, a kind of high-toughness polylactic acid in-situ maleic anhydride grafted thermoplastic elastomer composite material, its preparation method is as follows:

[0034] (1) Drying of raw materials: drying polylactic acid and maleic anhydride grafted thermoplastic elastomer with a molecular weight of 21700 in an oven at 70° C. for 24 hours, so that the water content by weight is less than 0.01%;

[0035] (2) Melt blending and extrusion: mix the obtained polylactic acid and maleic acid grafted thermoplastic elastomer in a ratio of 85:15, then shake for simple physical mixing, make it fully mixed, and mix at a speed of 250g / min Feed at high speed, melt and extrude through twin-screw extruder at a screw speed of 300 rpm, and at the same time draw at a speed of 300 rpm, and quickly cool and solidify in cooling water below 20°C, and finally extrude The strips are fully cooled in cold water and sent to the pelletizer for pelletizing; during melt blending and extrusio...

Embodiment 2

[0037] Embodiment 2, a kind of high-toughness polylactic acid in-situ maleic anhydride grafted thermoplastic elastomer composite material, its preparation method is as follows:

[0038] (1) Drying of raw materials: drying polylactic acid and maleic anhydride grafted thermoplastic elastomer with a molecular weight of 21700 in an oven at 70° C. for 24 hours, so that the water content by weight is less than 0.01%;

[0039](2) Melt blending and extrusion: mix the obtained polylactic acid and maleic acid grafted thermoplastic elastomer in a ratio of 80:20, shake for simple physical mixing, make it fully mixed, and mix at a speed of 200g / min Feed at high speed, melt and extrude through twin-screw extruder at a screw speed of 200 rpm, and at the same time draw at a speed of 200 rpm, and quickly cool and solidify in cooling water below 20°C, and finally extrude The strips are fully cooled in cold water and sent to the pelletizer for pelletizing; during melt blending and extrusion, the...

Embodiment 3

[0041] Embodiment 3, a kind of high-toughness polylactic acid in-situ maleic anhydride grafted thermoplastic elastomer composite material, its preparation method is as follows:

[0042] (1) Drying of raw materials: drying polylactic acid and maleic anhydride grafted thermoplastic elastomer with a molecular weight of 21700 in an oven at 70° C. for 24 hours, so that the water content by weight is less than 0.01%;

[0043] (2) Melt blending and extrusion: mix the obtained polylactic acid and maleic acid grafted thermoplastic elastomer in a ratio of 100:0, then shake for simple physical mixing, make it fully mixed, and mix at a speed of 300g / min Feed at high speed, melt and extrude through twin-screw extruder at a screw speed of 400 rpm, and at the same time draw at a speed of 400 rpm, and quickly cool and solidify in cooling water below 20°C, and finally extrude The strips are fully cooled in cold water and sent to the pelletizer for pelletizing; during melt blending and extrusio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com