Patents

Literature

46results about How to "Process economy and environmental protection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for comprehensively recovering metallic cobalt, ruthenium and aluminum from Fischer-Tropsch synthesis dead catalyst Co-Ru/Al2O3

ActiveCN102796873AHigh purityOperational securityProductsAluminium compoundsDistillationAluminium hydroxide

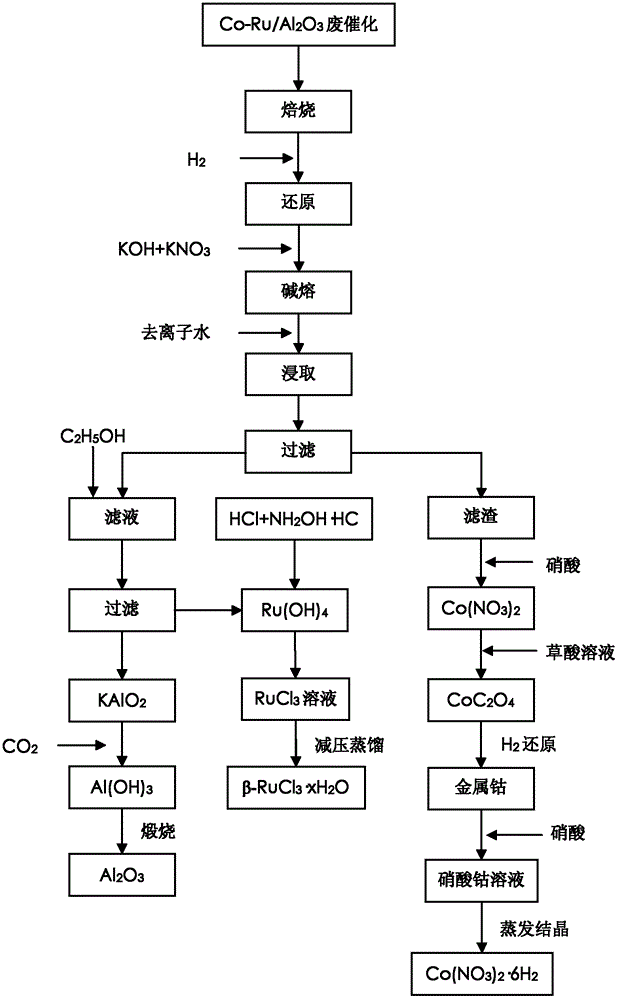

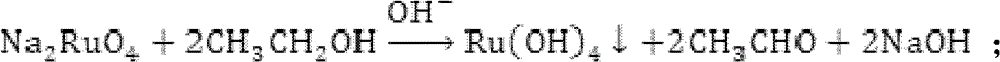

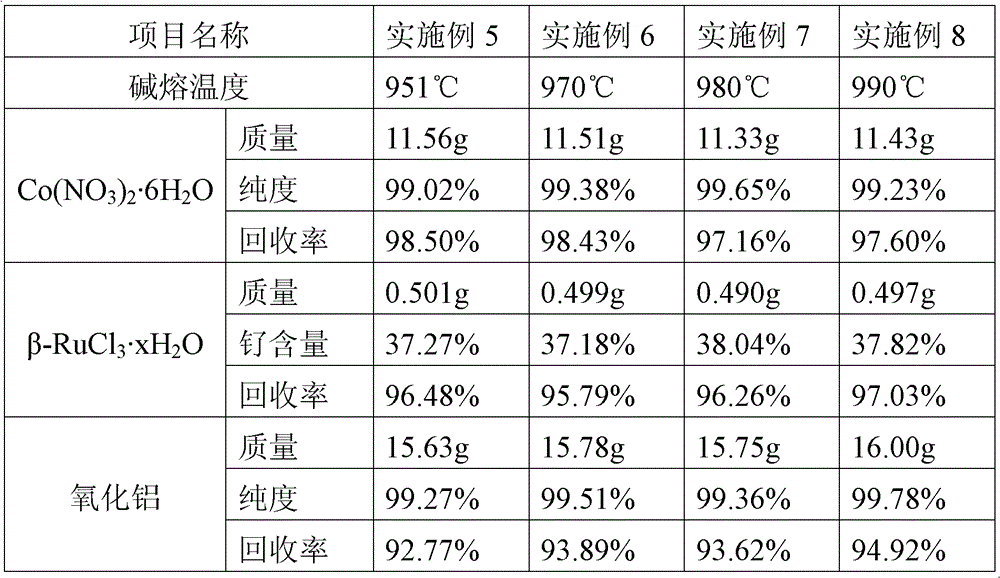

The invention discloses a method for comprehensively recovering metallic cobalt, ruthenium and aluminum from a Fischer-Tropsch synthesis dead catalyst Co-Ru / Al2O3, and the method can be used for effectively separating and comprehensively recovering valuable metallic cobalt, ruthenium and aluminum from the Fischer-Tropsch synthesis dead catalyst Co-Ru / Al2O3. The method comprises the steps of: firstly carrying out hydrocarbon removal and reductive treatment on the dead catalyst; effectively separating cobalt slag in an alkali fusion step; and carrying out acid leaching on the cobalt slag, oxalate or oxalate deposited cobalt, reducing cobalt oxalate, dissolving the metallic cobalt via nitric acid and the like to obtain Co(NO3)2.6H2O. Ruthenate is obtained by the steps of alkali fusion and deionized water leaching; and steps of ethanol reduction, concentrated hydrochloric acid dissolution, reduced pressure distillation and the like are carried out on the ruthenate to obtain a beta-RuCl1.xH2O product which is high in purity. By using a CO2 carbon dioxide decomposition method, the parameters such as reaction temperature, CO2 flow velocity, pH value of reaction destination and the like are controlled and aluminum hydroxide is prepared from meta-aluminate solution; high-temperature calcination is carried out to obtain aluminum oxide; and the product quality meets the quality requirement of first-level aluminum oxide of national standard and the process is economic and environment-friendly. According to the invention, the metallic recovery rate is high, wherein the recovery rate of cobalt is greater than or equal to 97%, the recovery rate of ruthenium is greater than or equal to 95% and the recovery rate of aluminum is greater than or equal to 92%.

Owner:SUNSHINE KAIDI NEW ENERGY GROUP CO LTD

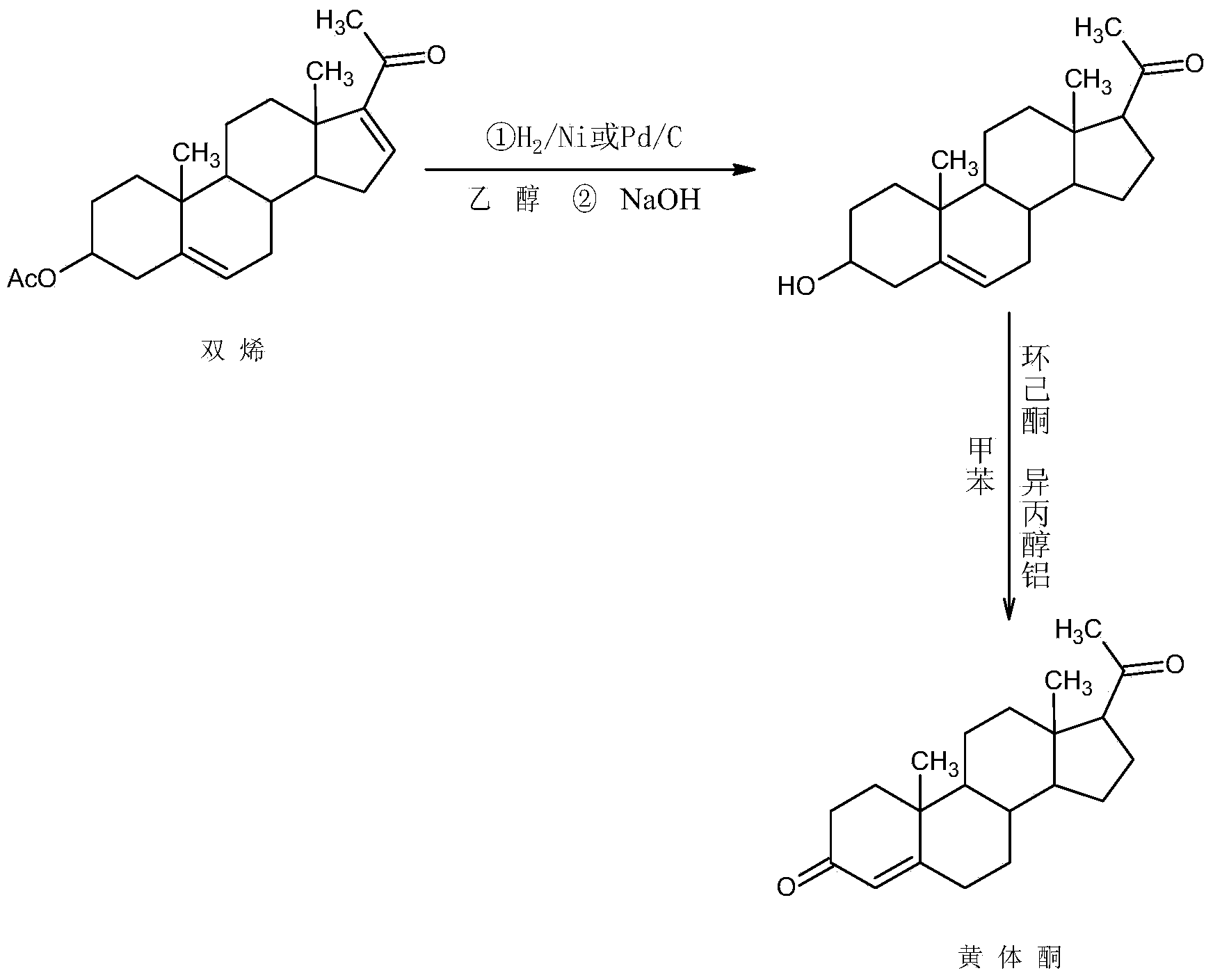

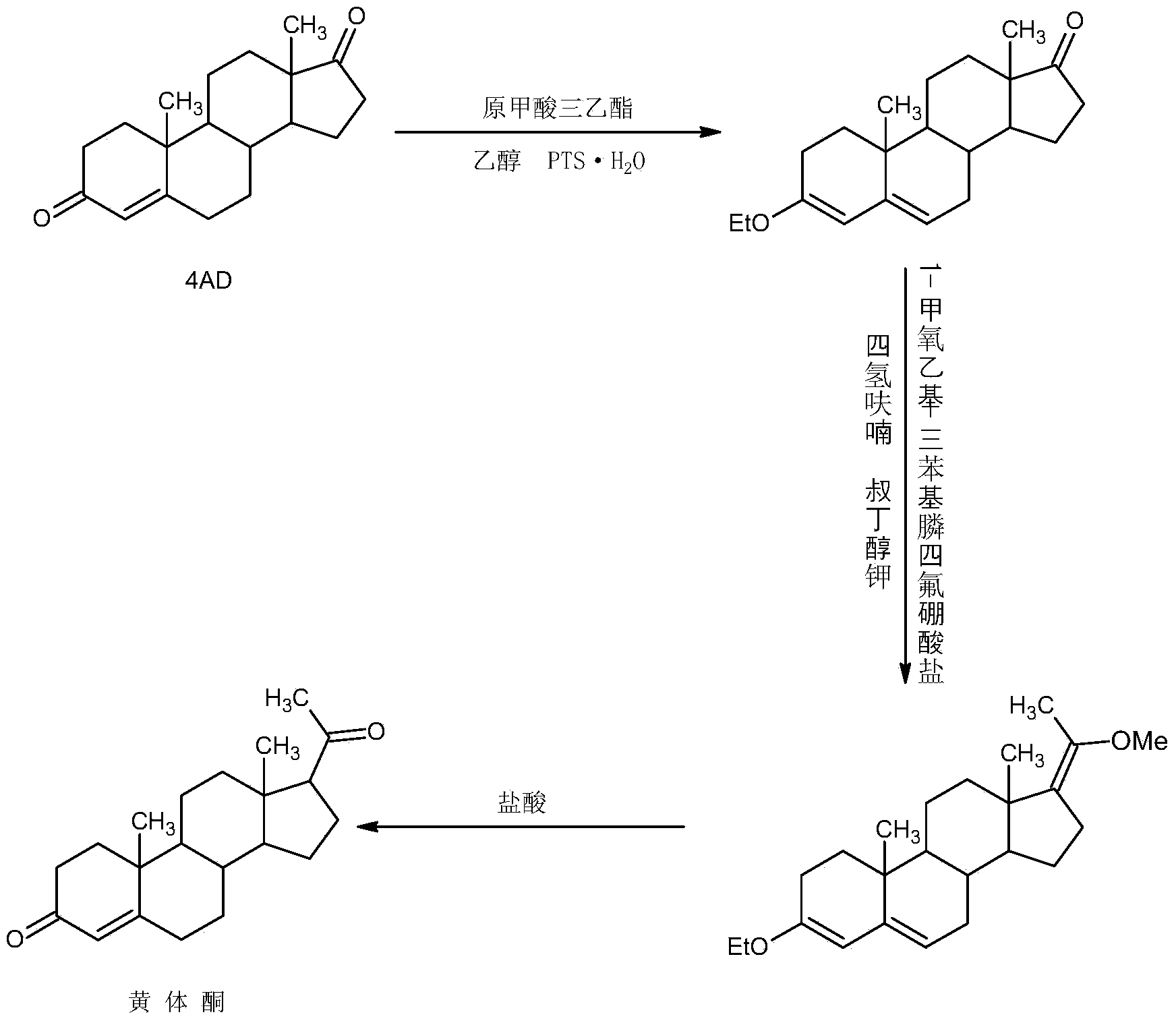

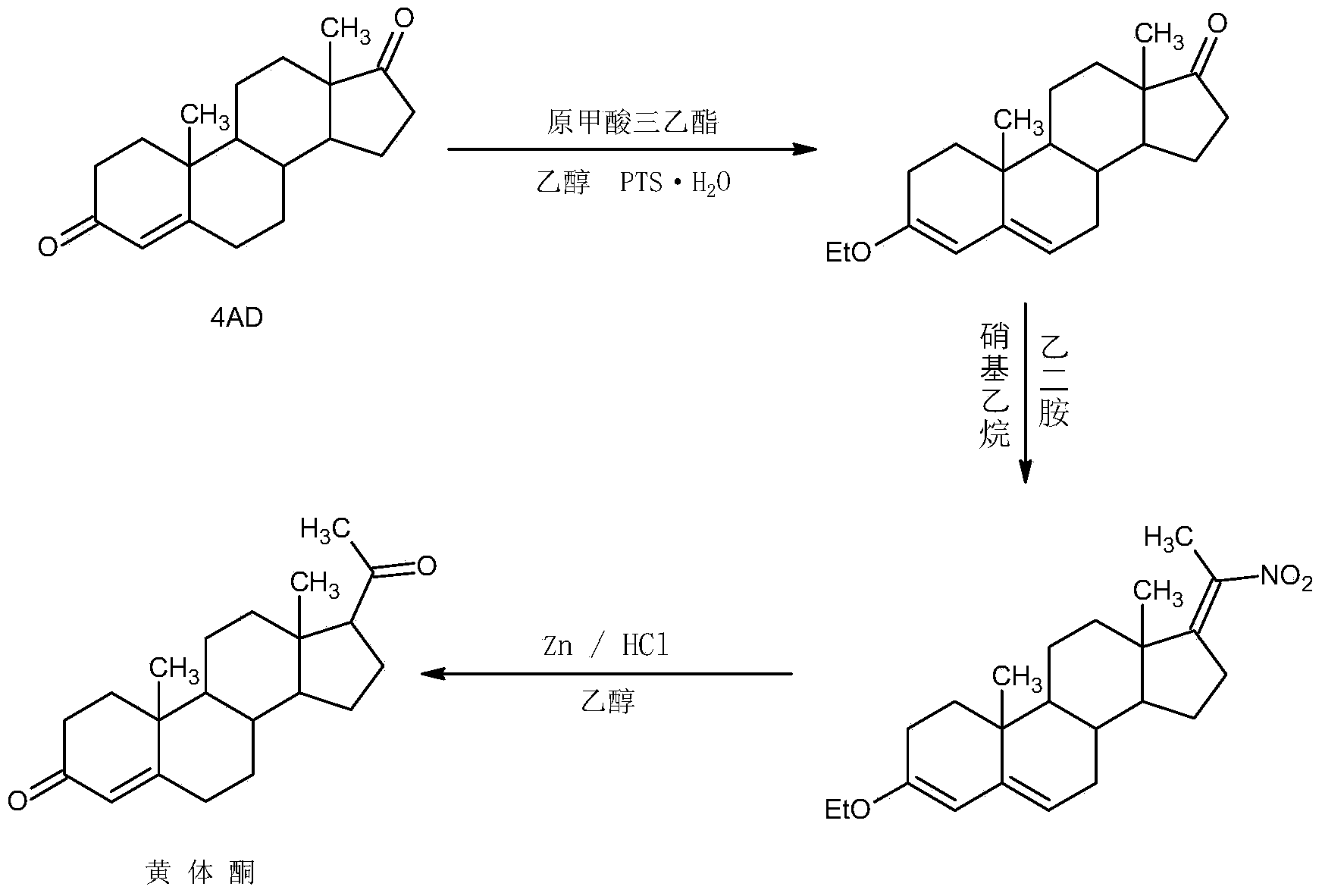

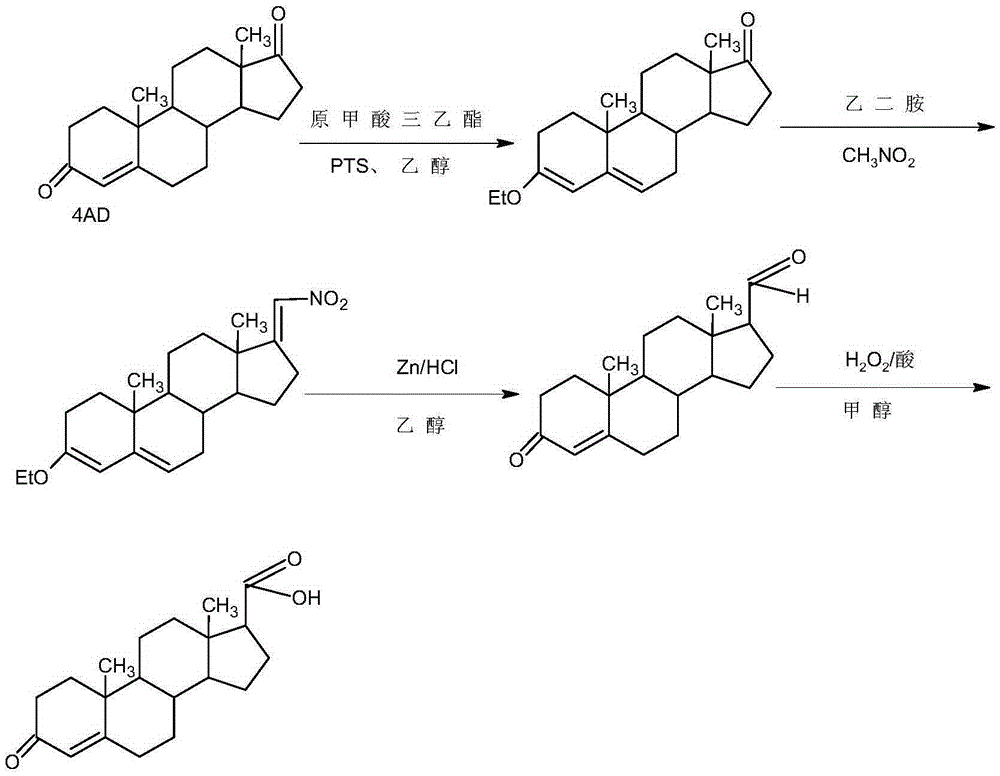

Preparation method for progestin

ActiveCN104262442AWide variety of sourcesProcess economy and environmental protectionSteroidsEthylenediamineKetone

The invention relates to a preparation method for progestin. 4-androstenedione is used as a raw material. The preparation method comprises the following steps: A, etherate is synthetized, wherein the 4-androstenedione and triethyl orthoformate perform an acid catalyzed reaction in organic solvents of dichloromethane, low-carbon alcohol and the like to obtain the etherate 3-ethoxy-androstane-3, 5-diolefin-17-ketone; B, a nitro substance is synthetized, wherein the etherate in the organic solvents and nitroethane perform 17-bit addition under the catalysis of ethylenediamine to obtain the nitro substance 3-ethoxy-20-nitro-pregnane-3, 5, 17 (20)-triene; and C, the progestin is synthetized, wherein the nitro substance is reduced by zinc powder in organic solvents of acetic acids, low-carbon alcohol and the like, acid hydrolysis is performed, so that semi-finished products of the progestin are obtained, the semi-finished products of the progestin are decolored and refined by alcohol and activated carbon to obtain the progestin, the content of HPLC is more than 99.5%, the melting point is 128-131 DEG C, and the total yield of synthetized weight is 83-87%. When the method disclosed by the invention is used for producing the progestin, the yield is high, the degree of purity is good, the quality is stable, the solvent recovering rate is high, and the method is economic and environment-friendly.

Owner:HUNAN KEREY BIOTECH

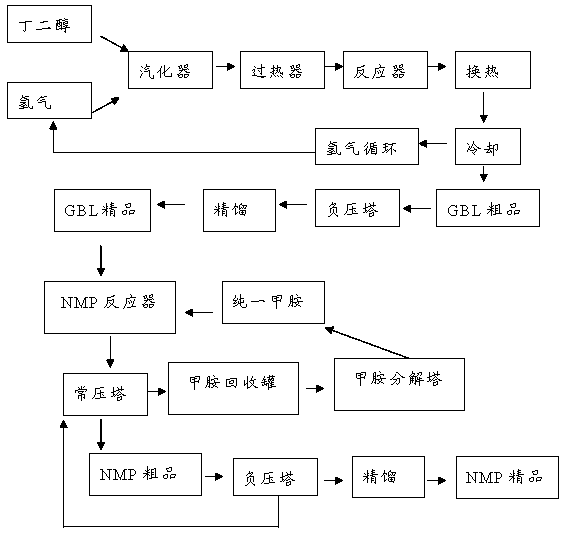

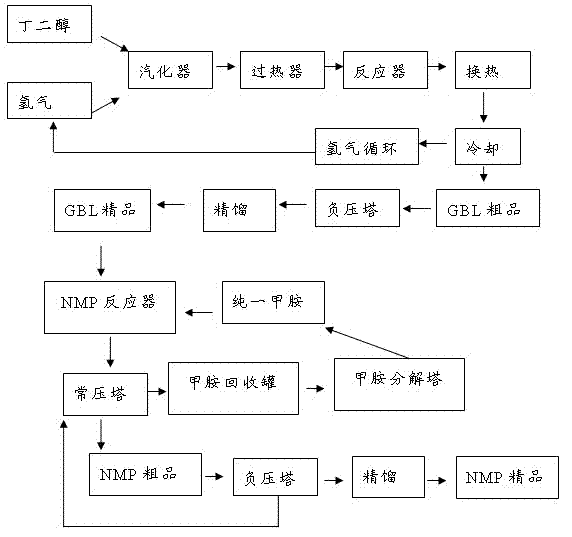

Continuous energy-saving NMP (N-methyl pyrrolidone) production method

ActiveCN103351321AHigh degree of automationReduce the ratioOrganic chemistryChemical industryAlkanePyrrolidinones

The invention belongs to the field of N-methyl pyrrolidone (NMP) production and preparation technologies, particularly relates to a continuous energy-saving production method for preparing GBL (Gamma-Butyrolactone) / NMP from butanediol and specifically relates to a continuous energy-saving NMP production method. According to the production method, an adopted process only has a lactone work section and an alkane ketone work section, and qualified materials in a negative pressure tower are directly transferred to a rectification tower from the negative pressure tower through pressure difference between the negative pressure tower and the rectification tower, so that the working procedure is efficient and energy-saving, the staff ratio of the whole process is low, the degree of automation is high, the unit consumption is low, the product quality is good, and the yield is high.

Owner:BINZHOU YUNENG CHEM

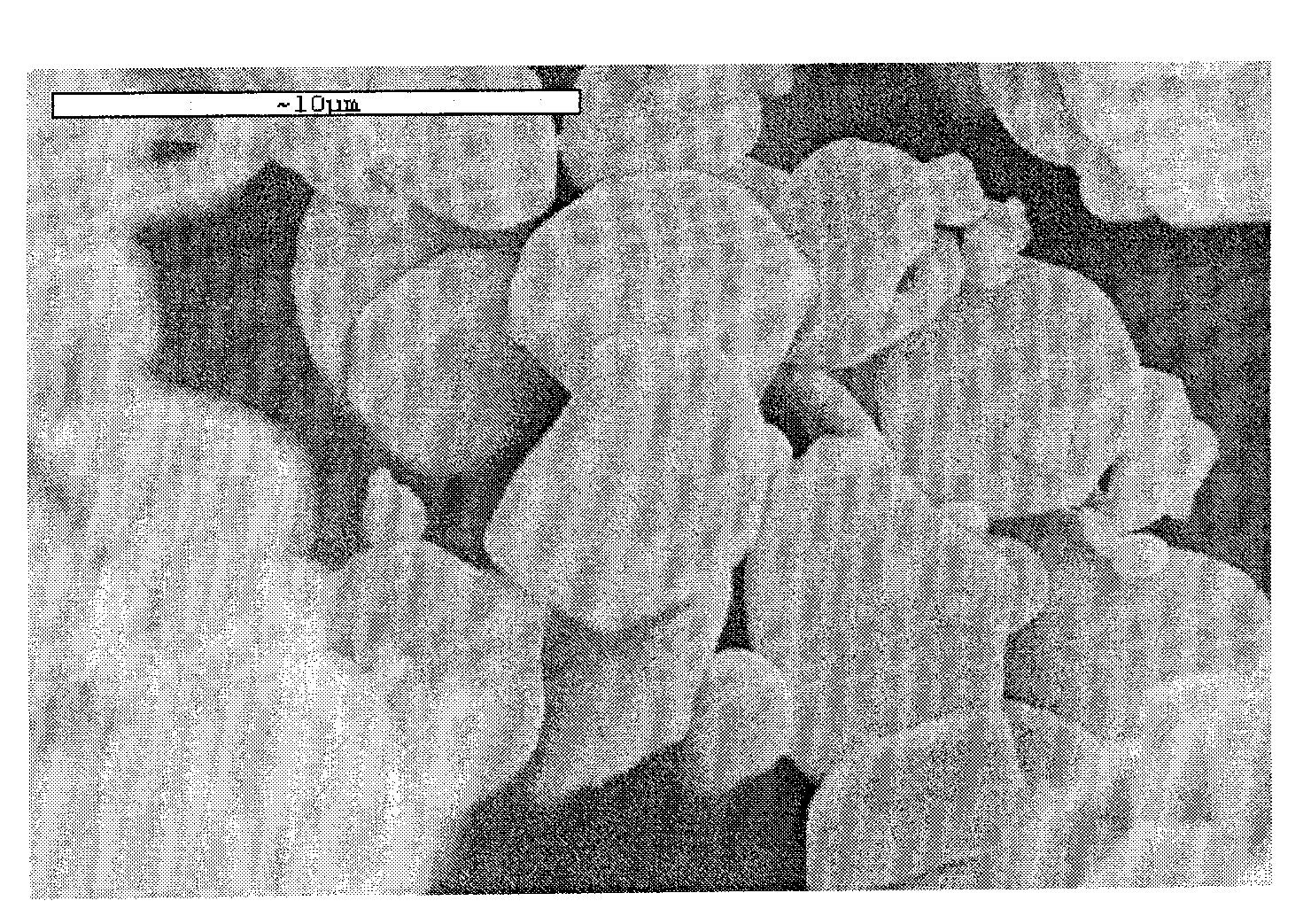

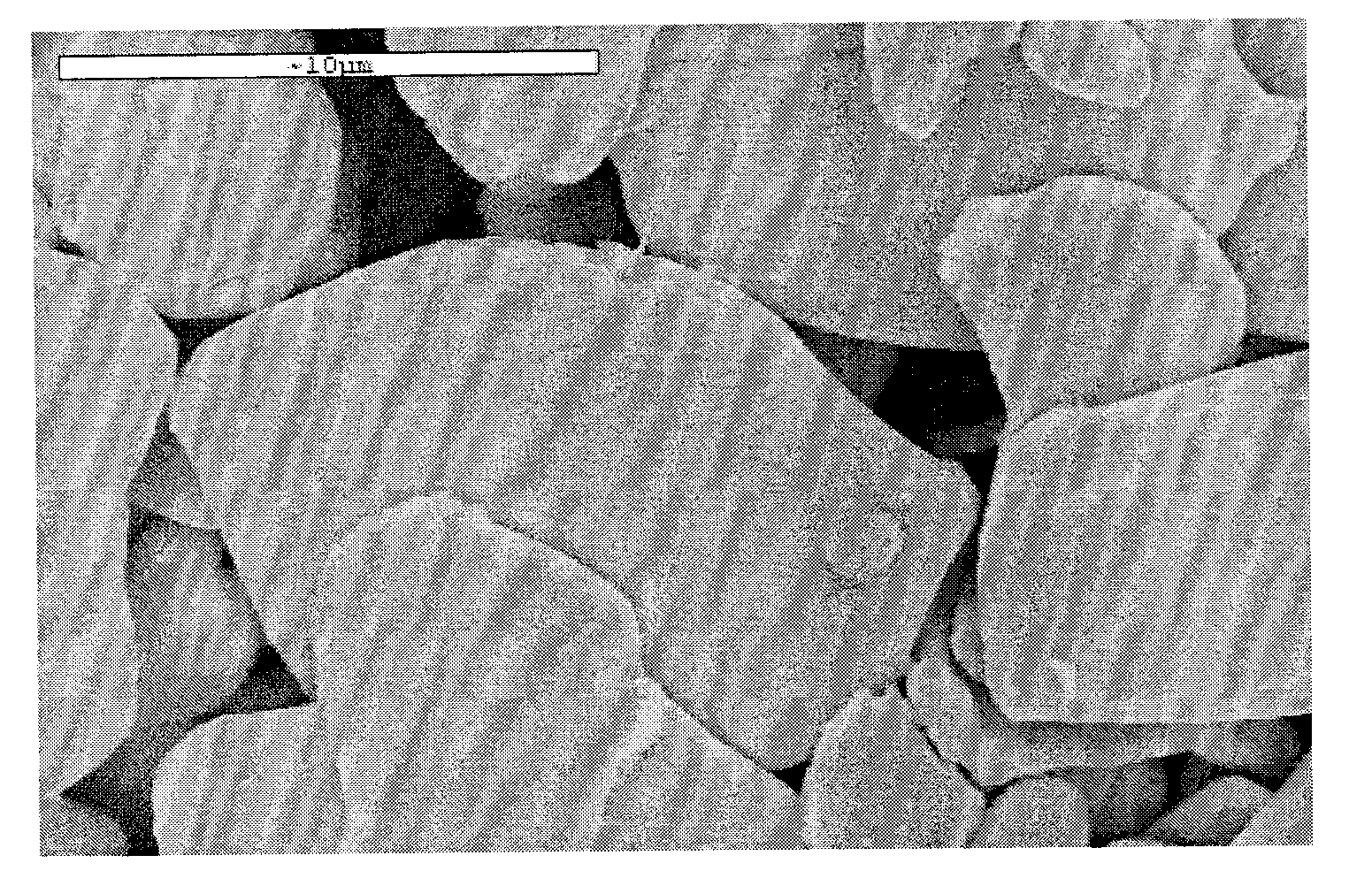

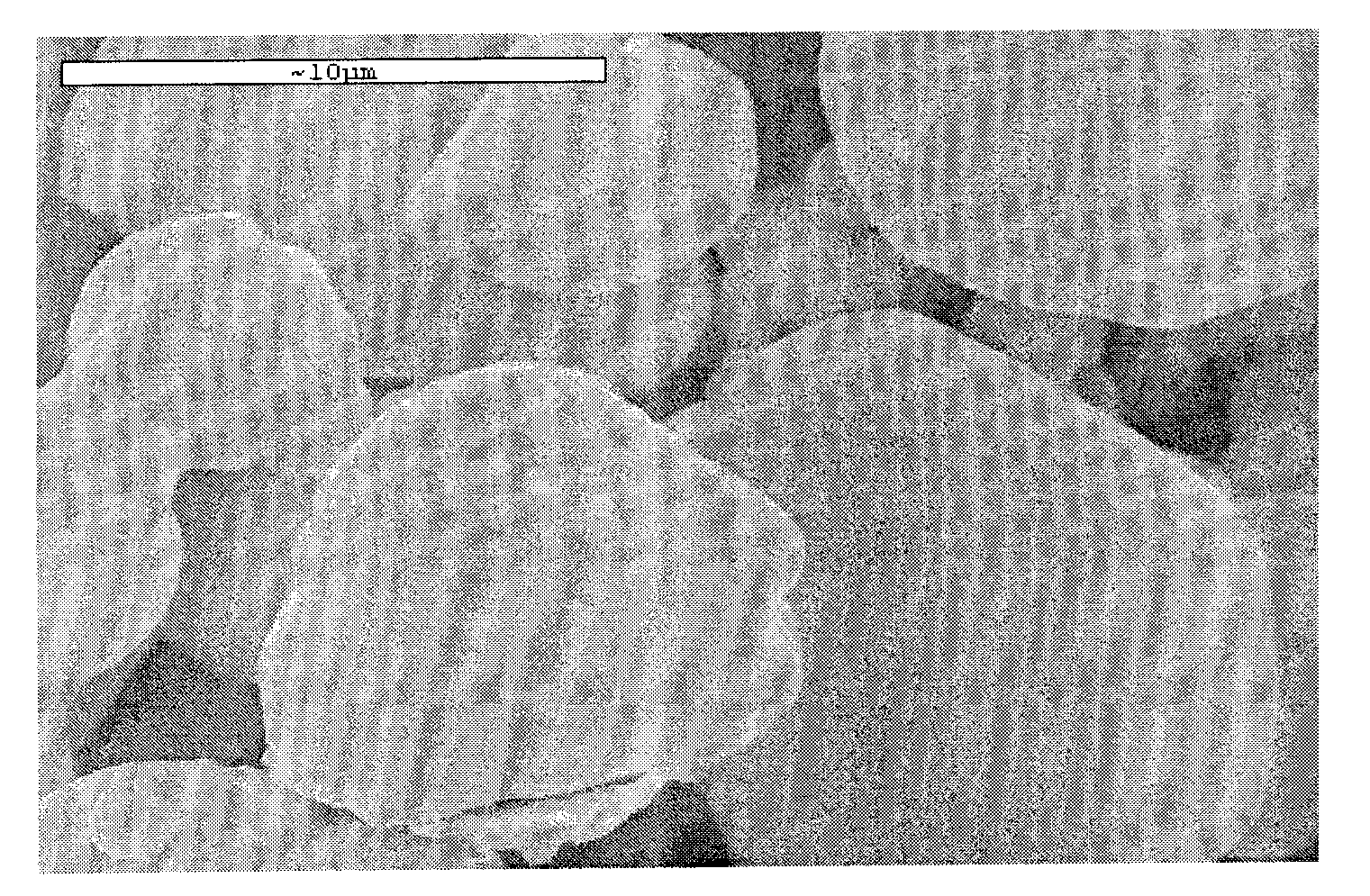

Micron flaky silver grains and production method thereof

InactiveCN103008677AEconomical and environmentally friendly processImprove complexNon-macromolecular adhesive additivesSemiconductor devicesHigh weightAdhesive

The invention relates to micron flaky silver grains and a production method thereof; and nitric acid / silver nitrate with low weight ratio and silver nitrate / reductant with high weight ratio have reduction reaction in liquid phase under the action of surfactant to produce uniform and dispersed micron flaky silver grains with preset specifications. The obtained micron flaky silver grains can be added into conductive adhesive so as to form a back-side electrode of a solar cell base material.

Owner:CHINA STEEL

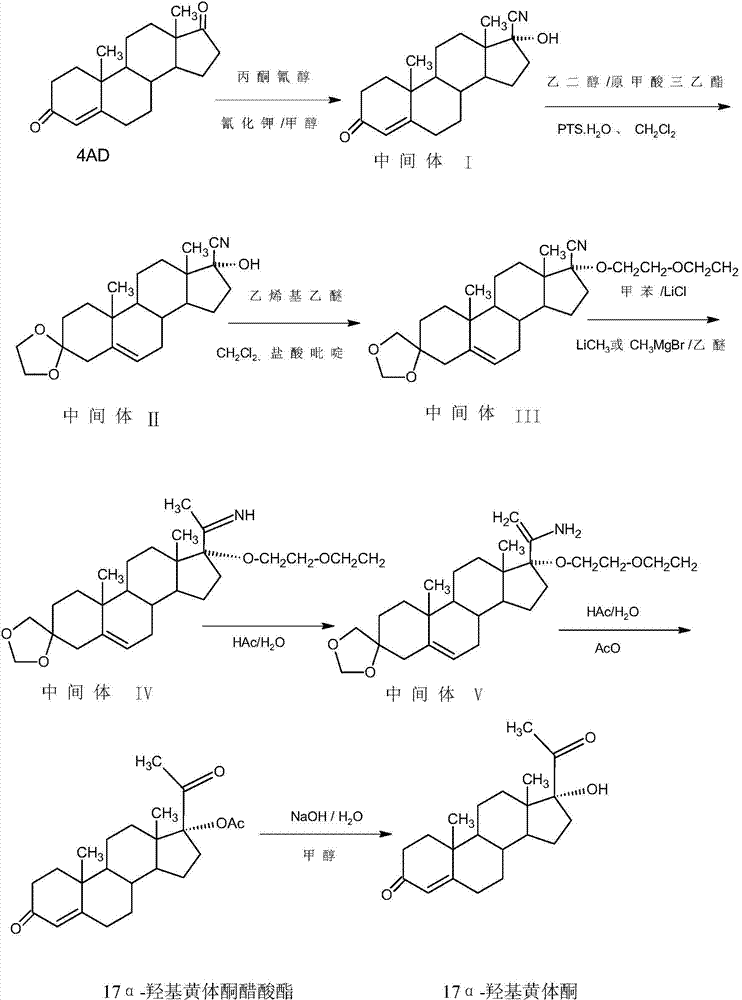

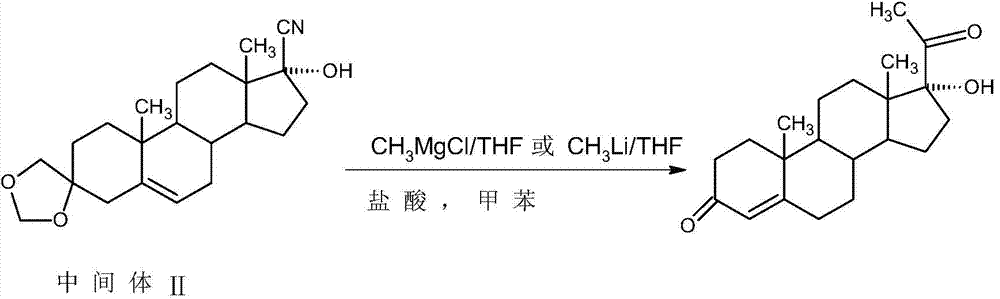

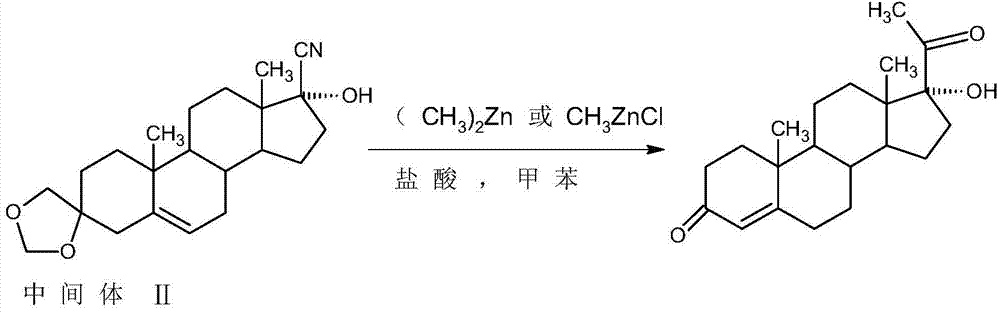

Method for preparing 17alpha-hydroxyprogesteron

The invention relates to a method for preparing 17alpha-hydroxyprogesterone. The17alpha-hydroxyprogesterone is prepared by taking 17beta- cyano-5-androstene-17-ol-3,3-diethylene ketal (referred as an intermediate II) as a raw material and dimethylzinc or methylzinc chloride as a reagent; the content of the 17alpha-hydroxyprogesterone by HPLC is above 99.5% and the weight yield is 83-87%. The method comprises the following steps of dissolving the intermediate II in an organic solvent, adding lithium chloride as a catalyst, stirring, raising the temperature to 40-80 DEG C, dropwise adding a toluene solution of dimethylzinc or methylzinc chloride of which the concentration is 2M, and continuing to complete the reaction; and then adding an ammonium chloride solution of which the concentration is 25% to destruct an organic zinc reagent, separating the aqueous layer out and extracting, merging the organic layer and the extract and concentrating the solvent to near dryness, and then adding lower alcohol, stirring, raising the temperature to 40-60 DEG C, adding the acid of which the concentration is 2M, hydrolyzing, adjusting the pH value with a weak base after the reaction is completed, evaporating 90% of the solvent out, adding tap water, cooling and crystallizing to obtain a crude 17alpha-hydroxyprogesterone product; and then carrying out reflux decolorizing on the crude product with activated carbon by virtue of alcohol, and refining to obtain the commercial grade 17alpha-hydroxyprogesterone. The 17alpha-hydroxyprogesterone produced by the method disclosed by the invention has the advantages of good purity and high yield and is economic and environment-friendly, and the solvent can be recycled.

Owner:HUNAN KEREY BIOTECH

Polymeric thin-film material ozone treatment graft modification chemical copper plating method

ActiveCN102776493AFast copper plating rateIncrease roughnessLiquid/solution decomposition chemical coatingAmmonium ferrous sulfateCopper plating

The invention discloses a polymeric thin-film material ozone treatment graft modification chemical copper plating method. The method comprises the steps of (1), washing; (2), performing ozone treatment; (3) performing chemical grafting and placing processed polymeric thin films into a water solution of acrylamide CH2=CHCONH2, ceric ammonium nitrate Fe(NH4)2(NO3)6 and ammonium ferrous sulfate Fe(NH4)2(SO4)2.6H2O; (4), performing activation and placing the grafted polymeric thin films into a solution of 0.1-1g / L of silver nitrate AgNO3 and 10-15mL / L37% of ammonia water BH3.H2O and immersing for 10-60s; and performing chemical copper plating, placing the activated thin films into chemical copper plating liquid and subjecting the thin films and the solution to reaction for 10-20min. The polymeric thin-film material ozone treatment graft modification chemical copper plating method has the advantages that the method is simple, practical, economical and environment-friendly, chemical copper plating can be performed on a polyethylene terephthalate (PET) thin film, the copper plating liquid is not required to be heated, and the method can be conducted at a normal temperature, and the like.

Owner:HUIZHOU KING BROTHER CIRCUIT TECH +1

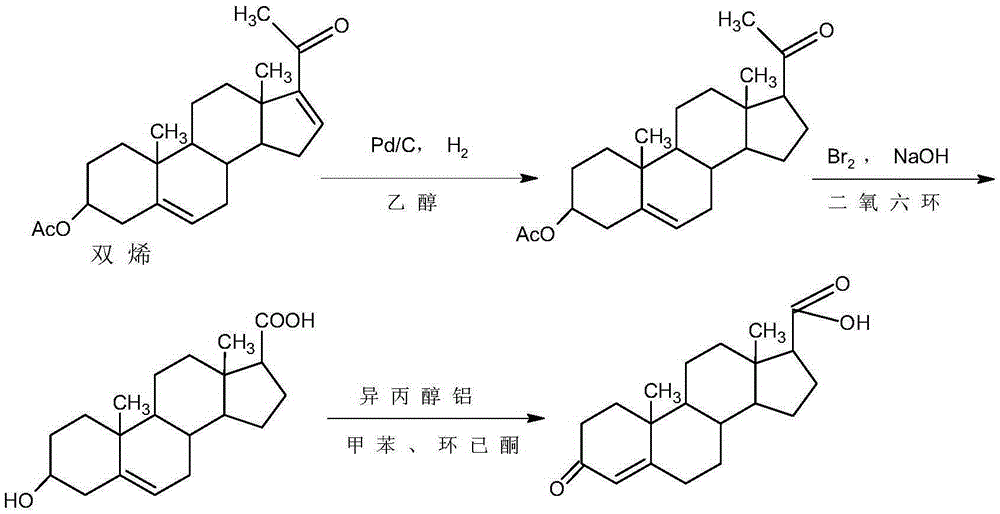

Preparation method of 17beta-androst-4-ene-3-one-17-carboxylic acid

InactiveCN105294798AWide variety of sourcesReduce manufacturing costSteroidsNitro compoundOrganosolv

The invention discloses a preparation method of 17beta-androst-4-ene-3-one-17-carboxylic acid. The preparation method comprises the following specific operation steps of performing acid catalyzed reaction on 4AD (Androstenedione) and triethyl orthoformate in low-carbon alcohol organic solvent to obtain etherate 3-ethyoxyl-androst-3,5-diene-17-one; performing 17-situ addition on the obtained etherate and nitromethane in the organic solvent under the catalysis of ethanediamine to obtain a nitro compound; reducing the obtained nitro compound in the organic solvent with zinc powder, and hydrolyzing with acid to obtain 17beta-androst-4-ene-3-one-17-formaldehyde; oxidizing an intermediate obtained by hydrolyzing in the organic solvent with hydrogen peroxide to obtain a 17beta-androst-4-ene-3-one-17-formic acid crude product; recrystallizing the crude product through methyl alcohol to obtain a finished product. According to the preparation method, total yield of synthesis weight is 70 to 72 percent, and the content of HPLC (High Performance Liquid Chromatography) is 99.0 percent or over 99.0 percent. The method disclosed by the invention has the advantages of high production yield, low cost, good purity, stable quality, high recovery rate of solvent, economy and environment friendliness.

Owner:HUNAN KEREY BIOTECH

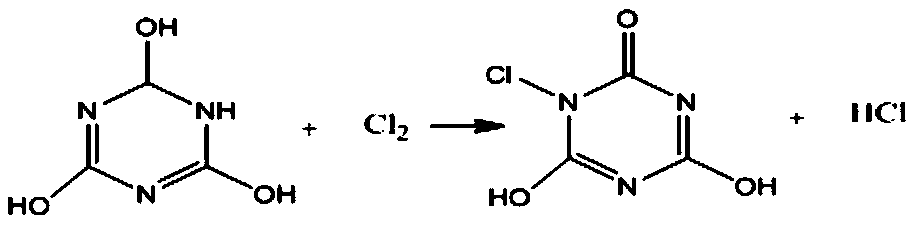

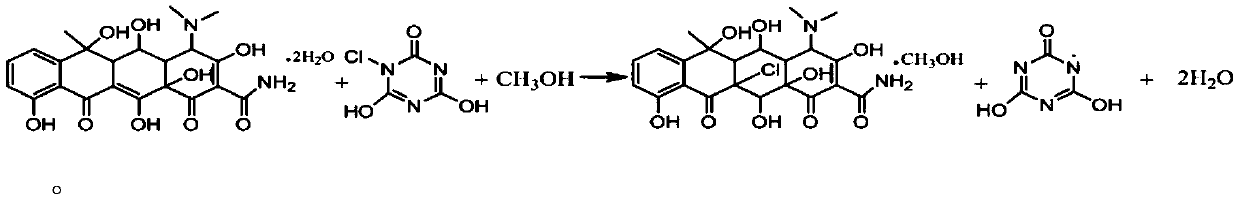

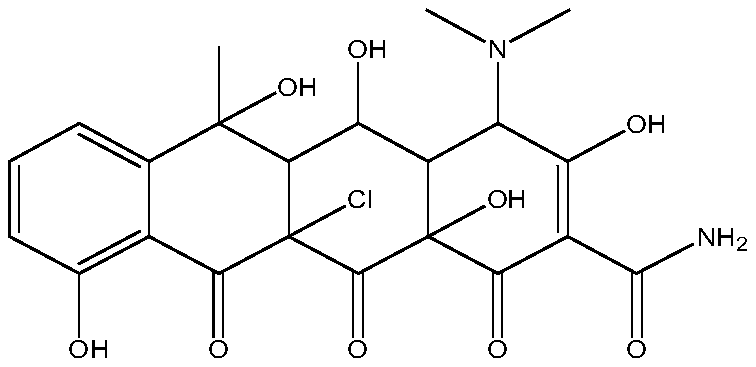

Preparation method of chlorinated oxytetracycline

ActiveCN111393319AHigh purityEasy to operateOrganic compound preparationCarboxylic acid amides preparationChemical reactionBiochemical engineering

The invention relates to a preparation method of chlorinated oxytetracycline. The preparation method can be widely applied to the technical field of veterinary drugs and solves the technical problemsof large toxic and side effects, large environmental harm, high waste liquid treatment cost and poor intermediate product stability in the existing preparation method of chlorinated oxytetracycline. The reaction equations are as follows: a first-step chemical reaction equation; and a second-step chemical reaction equation.

Owner:SHANDONG GUOBANG PHARMA +1

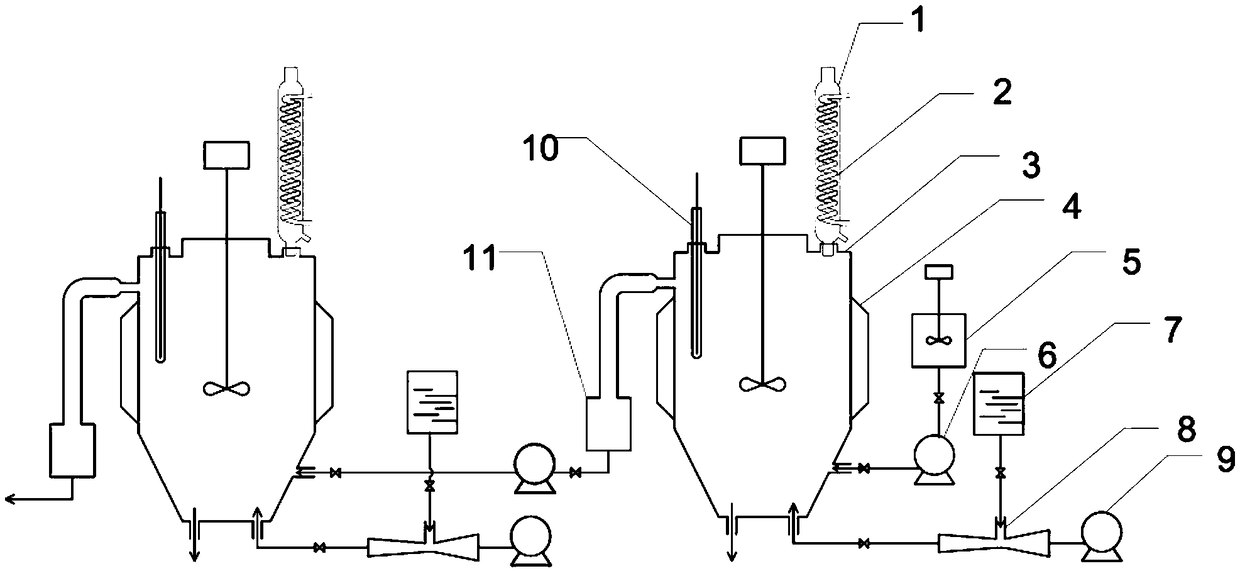

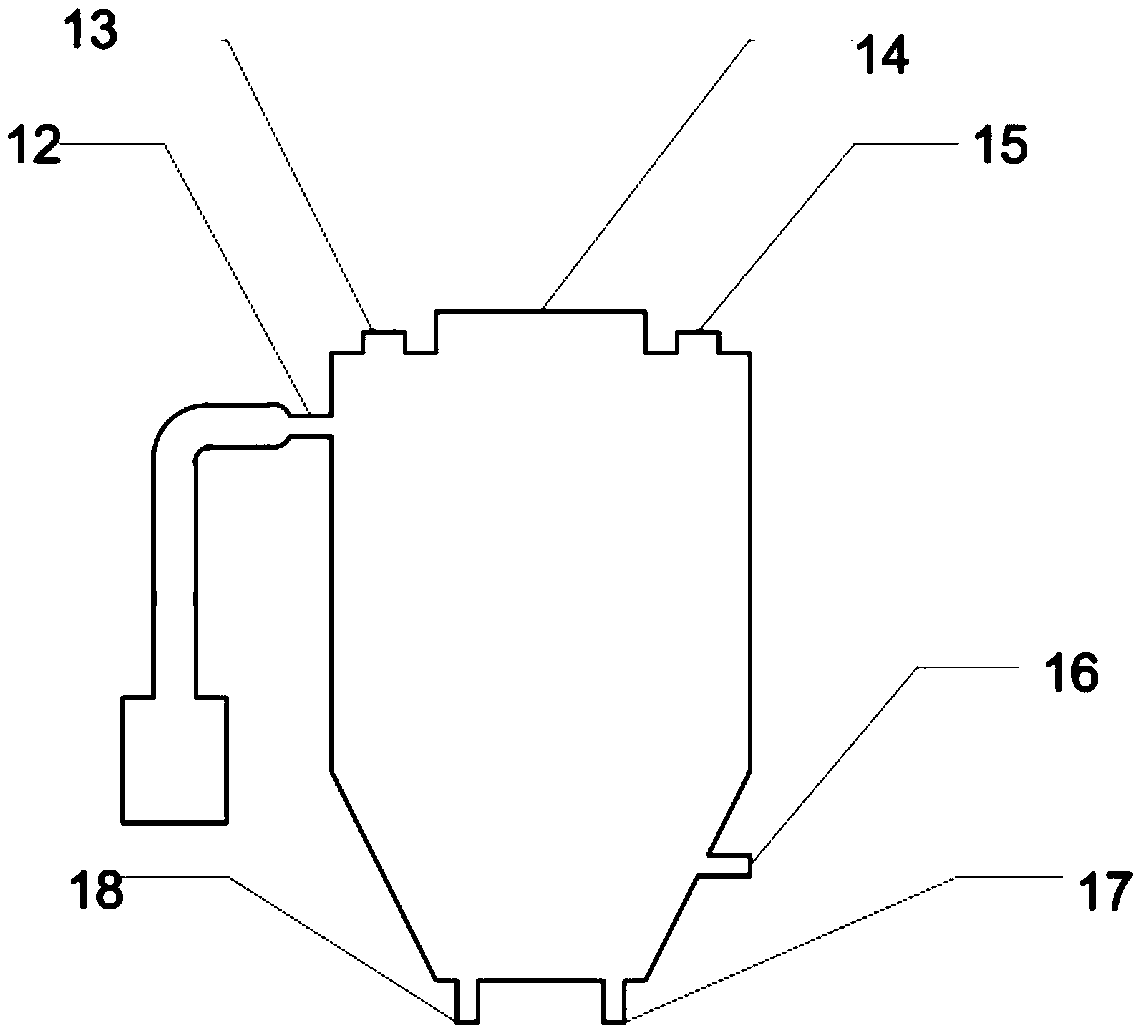

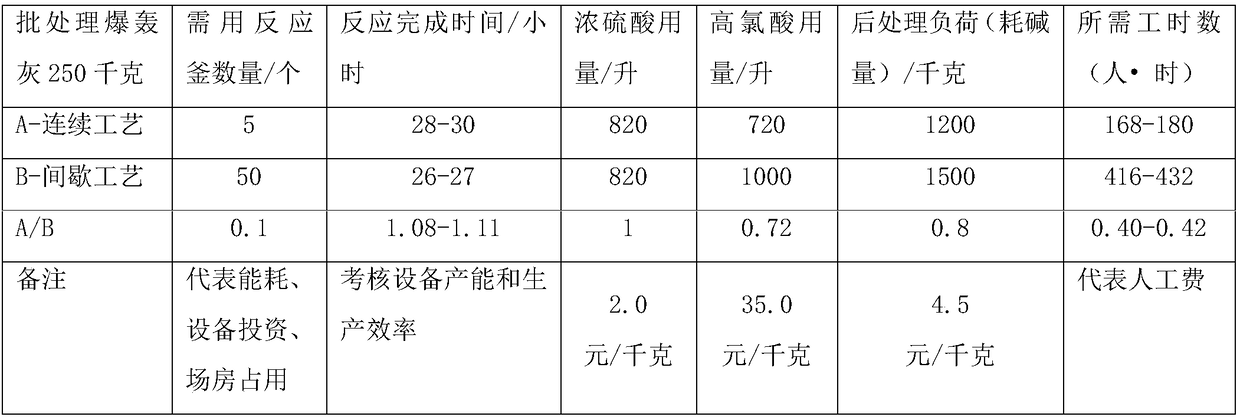

Continuous purification process and device for detonation synthesized diamond

The invention relates to a continuous purification process and a device for a detonation synthesized diamond. The continuous purification process for the detonation synthesized diamond comprises the following steps: mixing detonation ash with concentrated sulfuric acid having the purity of 95-98% to obtain a raw material slurry, injecting the raw material slurry into a reaction kettle from the bottom or the lower part according to a certain flow rate, injecting 50-60% perchloric acid into the reaction kettle from the bottom of the reaction kettle according to a material treatment amount, and carrying out mixing and stirring to fully generate an oxidation reaction; introducing reactants to a next-stage reaction kettle from the bottom or the lower part according to the feed quantity and thecapacity of the reaction kettle, and supplementing perchloric acid from the bottom of the next-stage reaction kettle; carrying out continuous fractional purification until the material color changes from black to gray. As a method of continuous purification is adopted by the process provided by the invention, the purified finished product of diamond dry powder has high purity and uniform quality,and as perchloric acid is added less in each stage of purification than in an intermittent purification method, the process is safe, reliable, economical and environmentally friendly, the utilizationrate of perchloric acid is high, and the total consumption is reduced.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

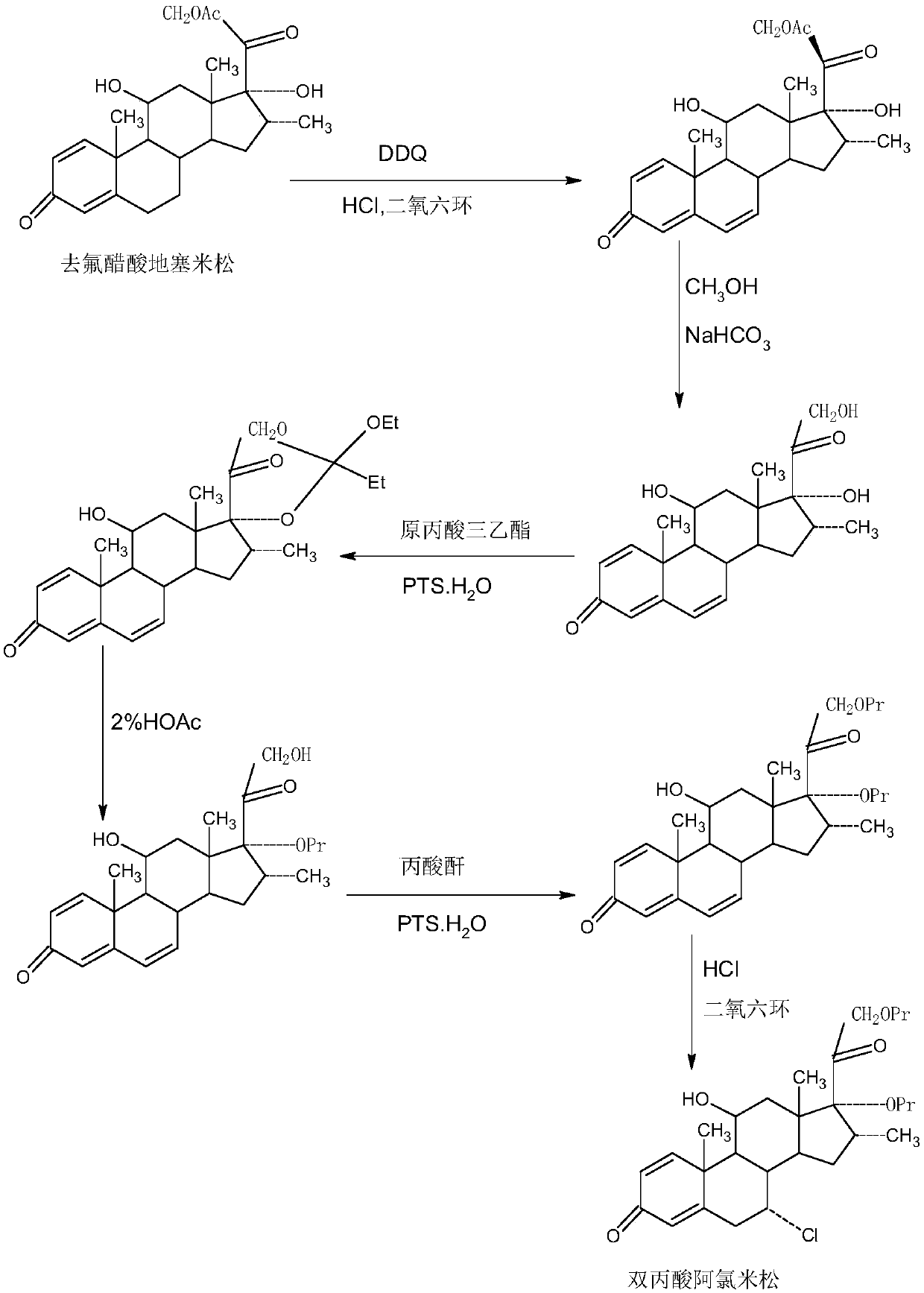

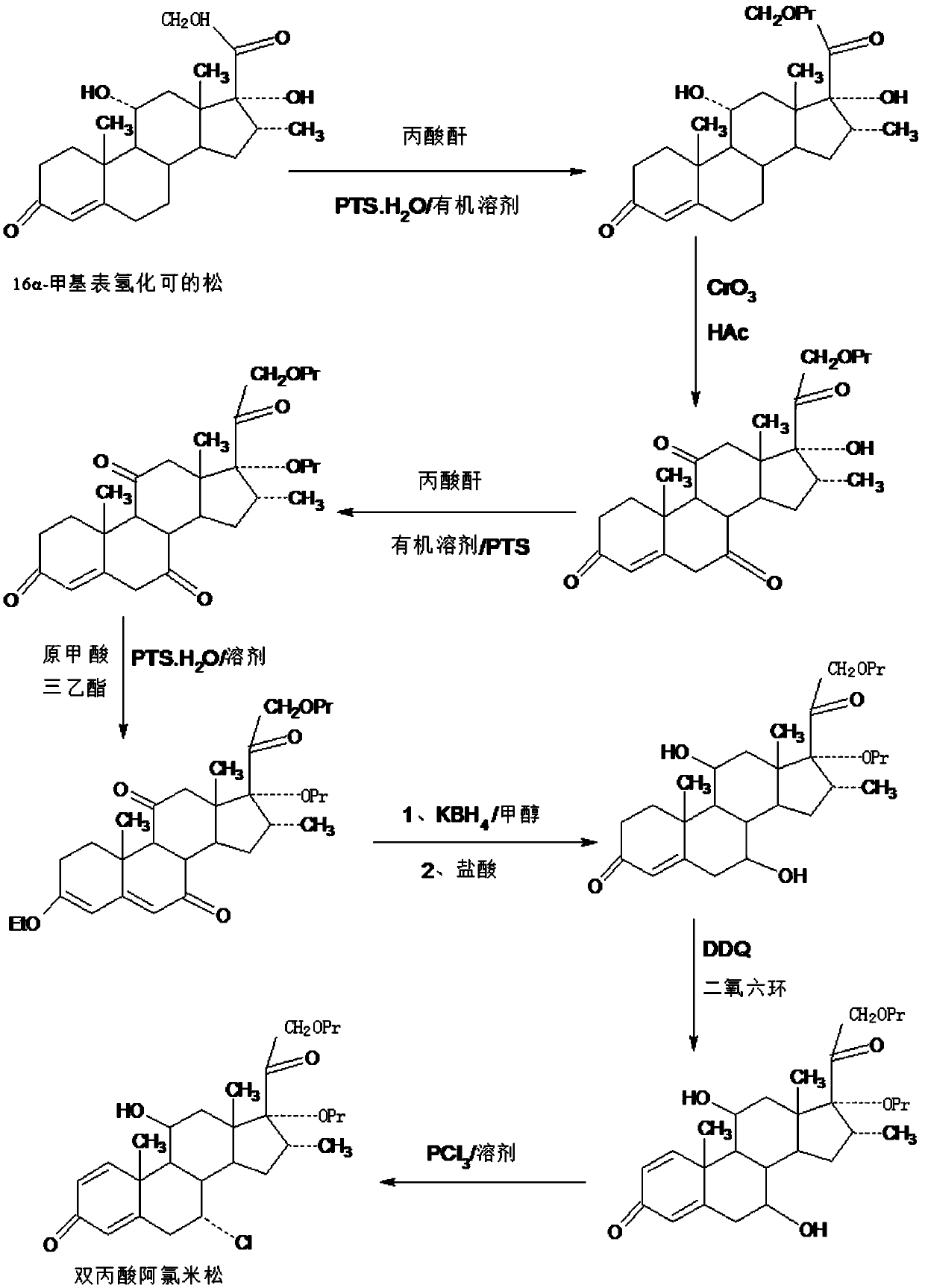

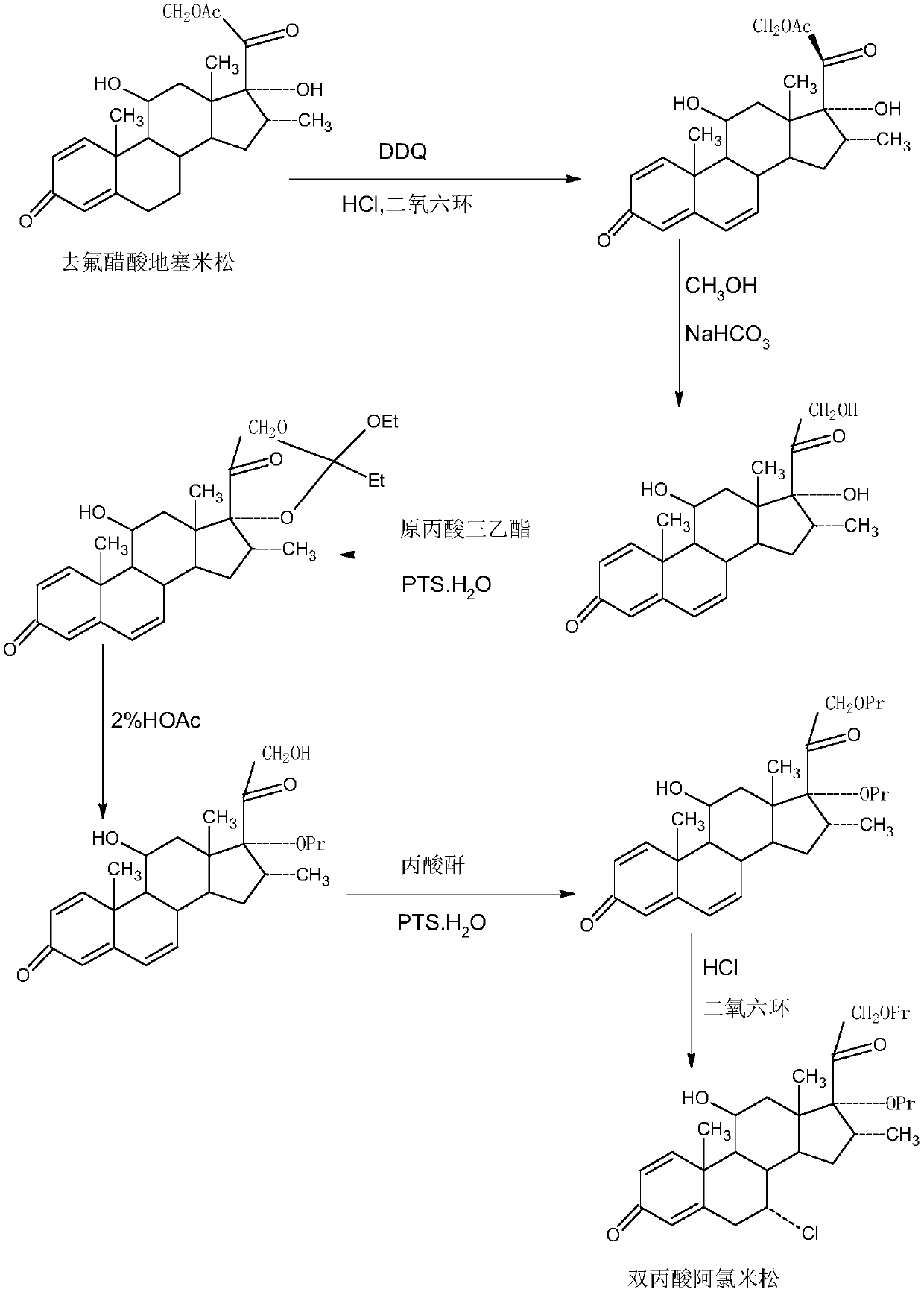

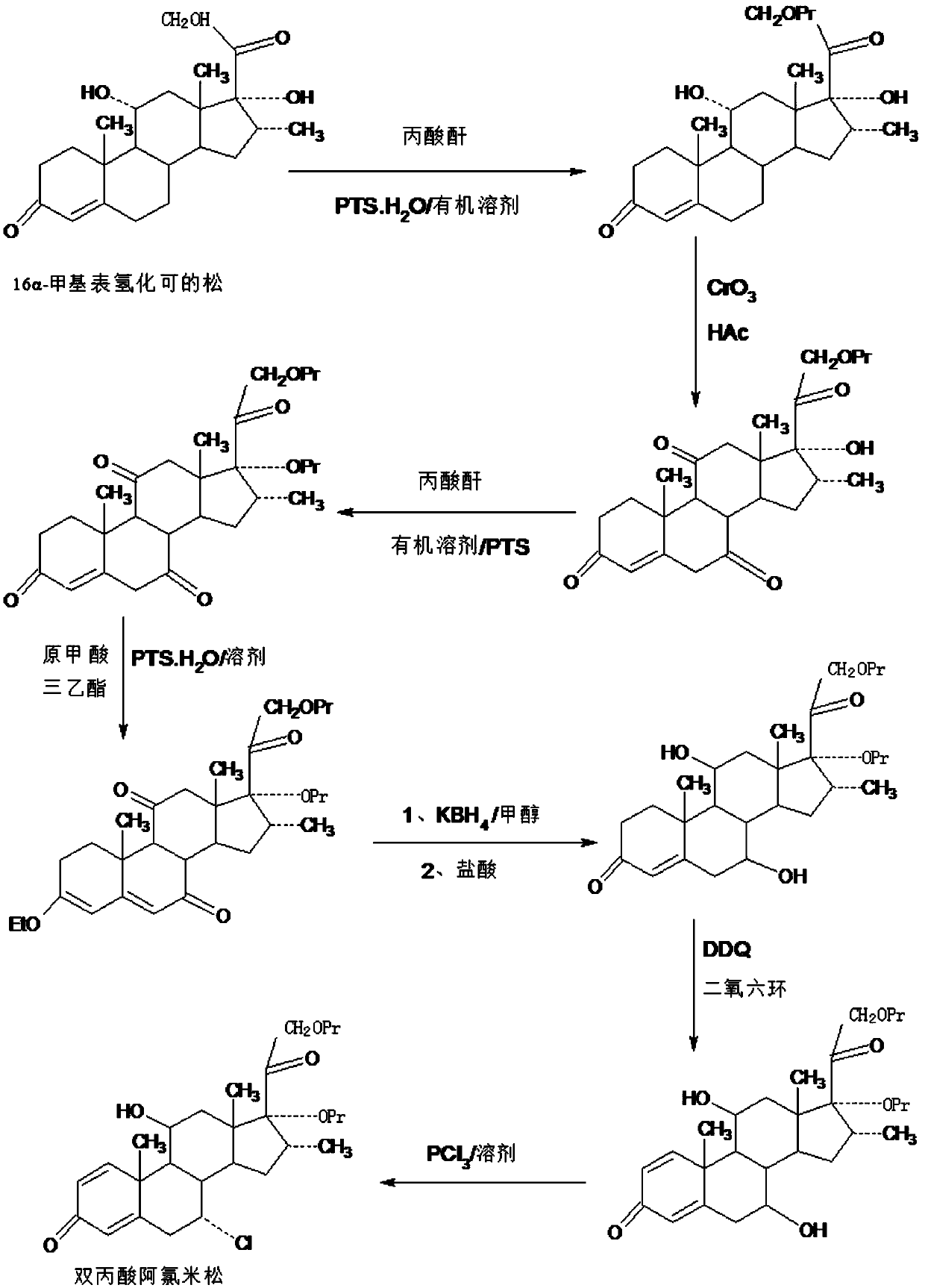

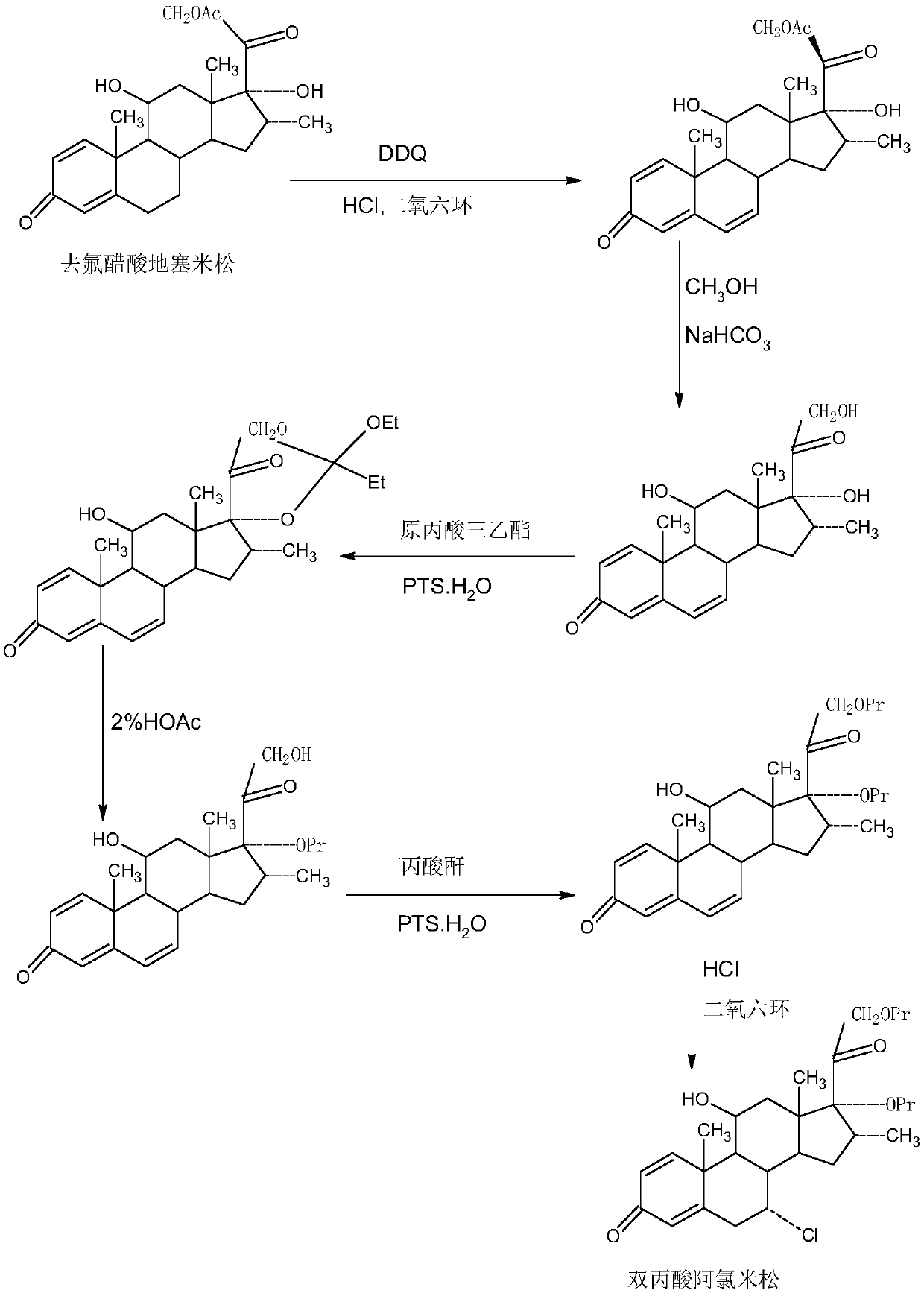

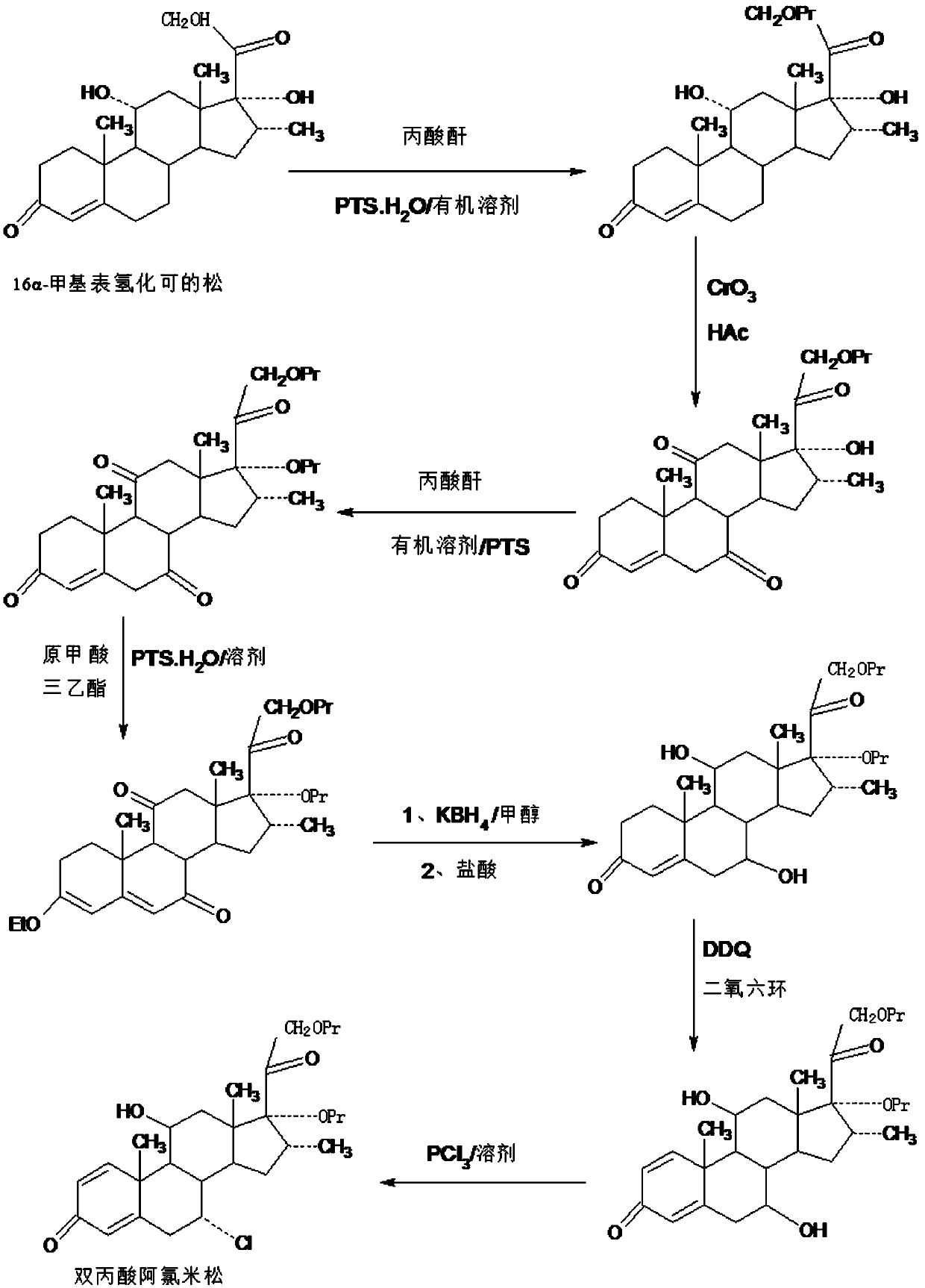

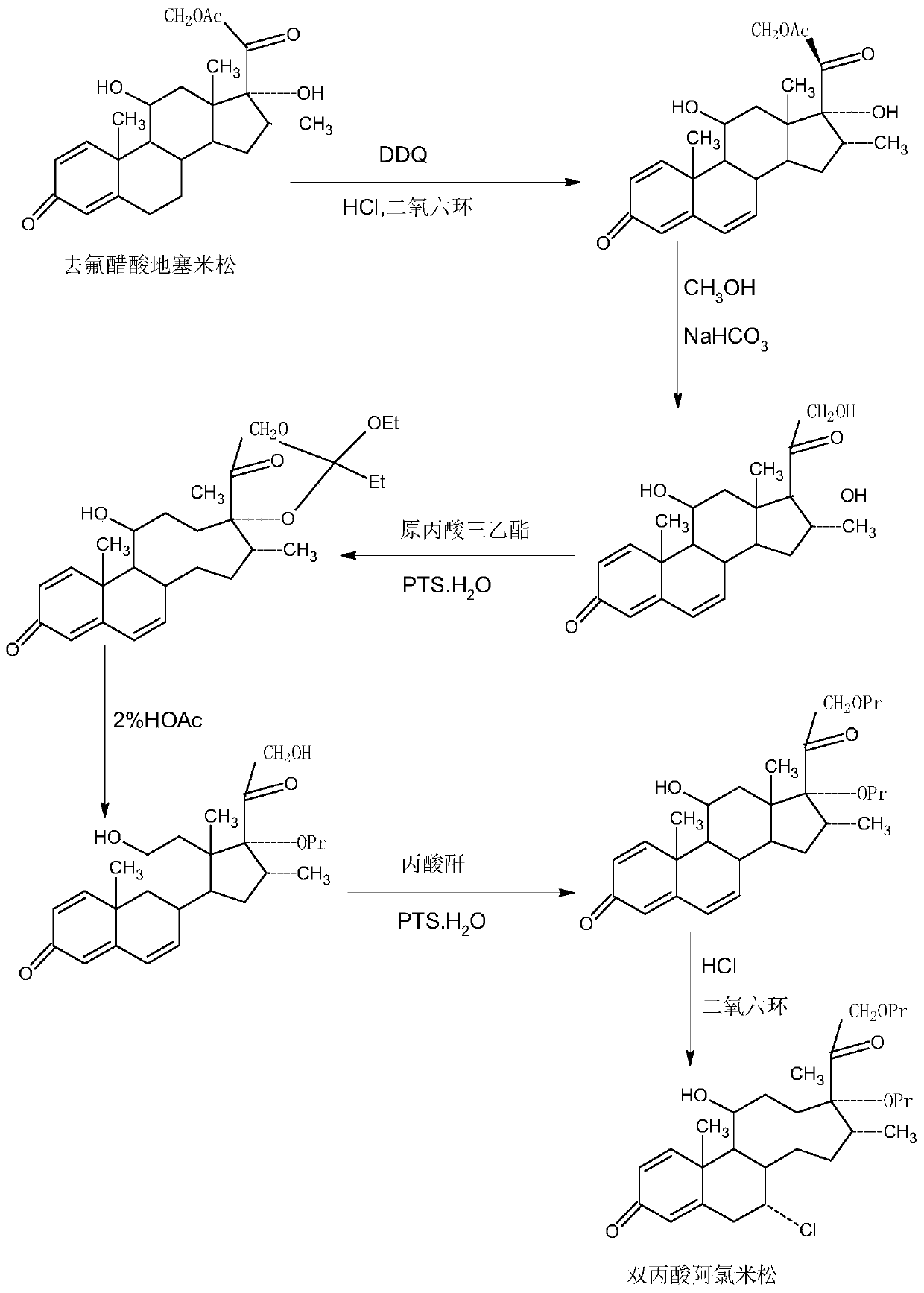

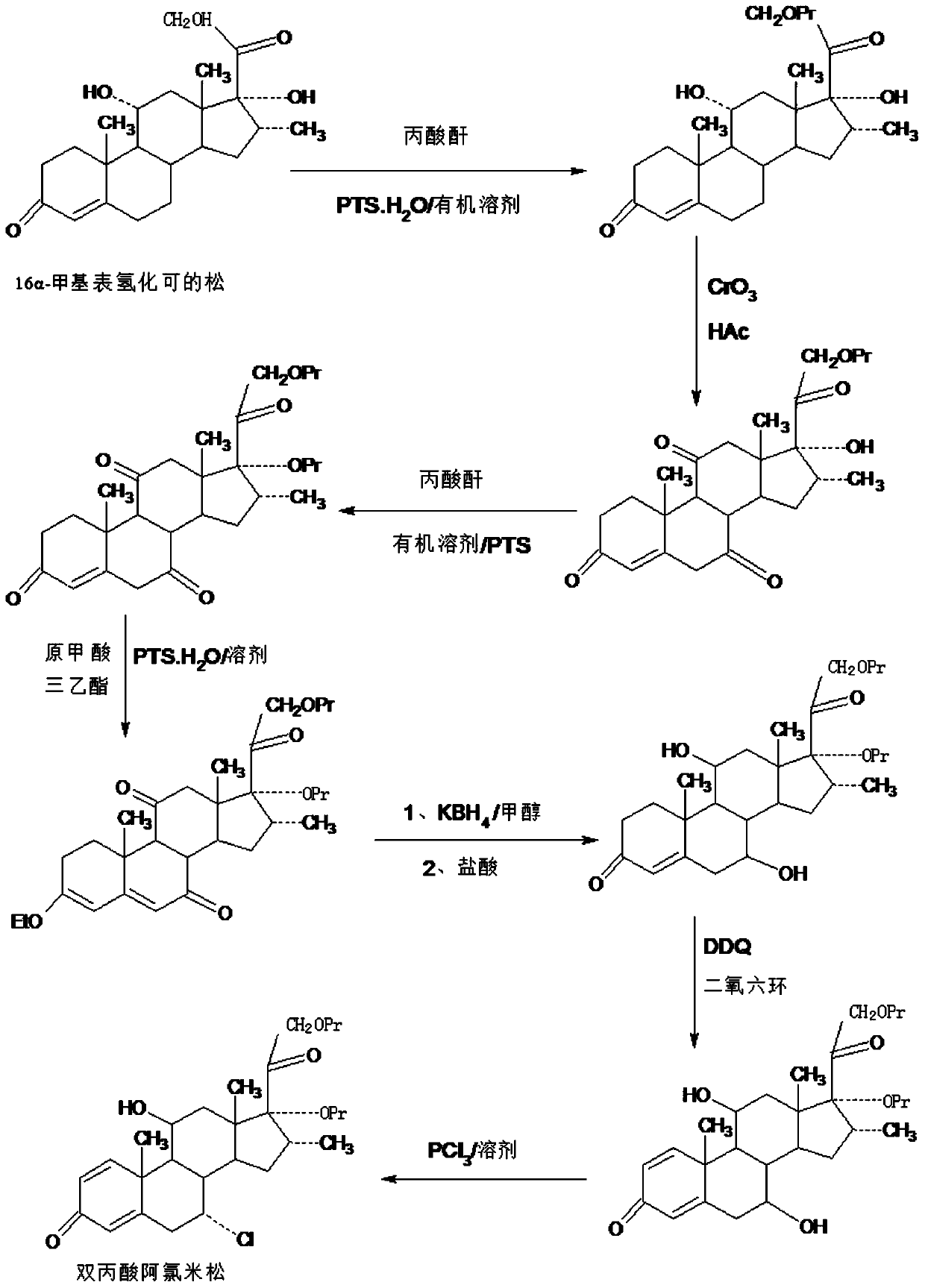

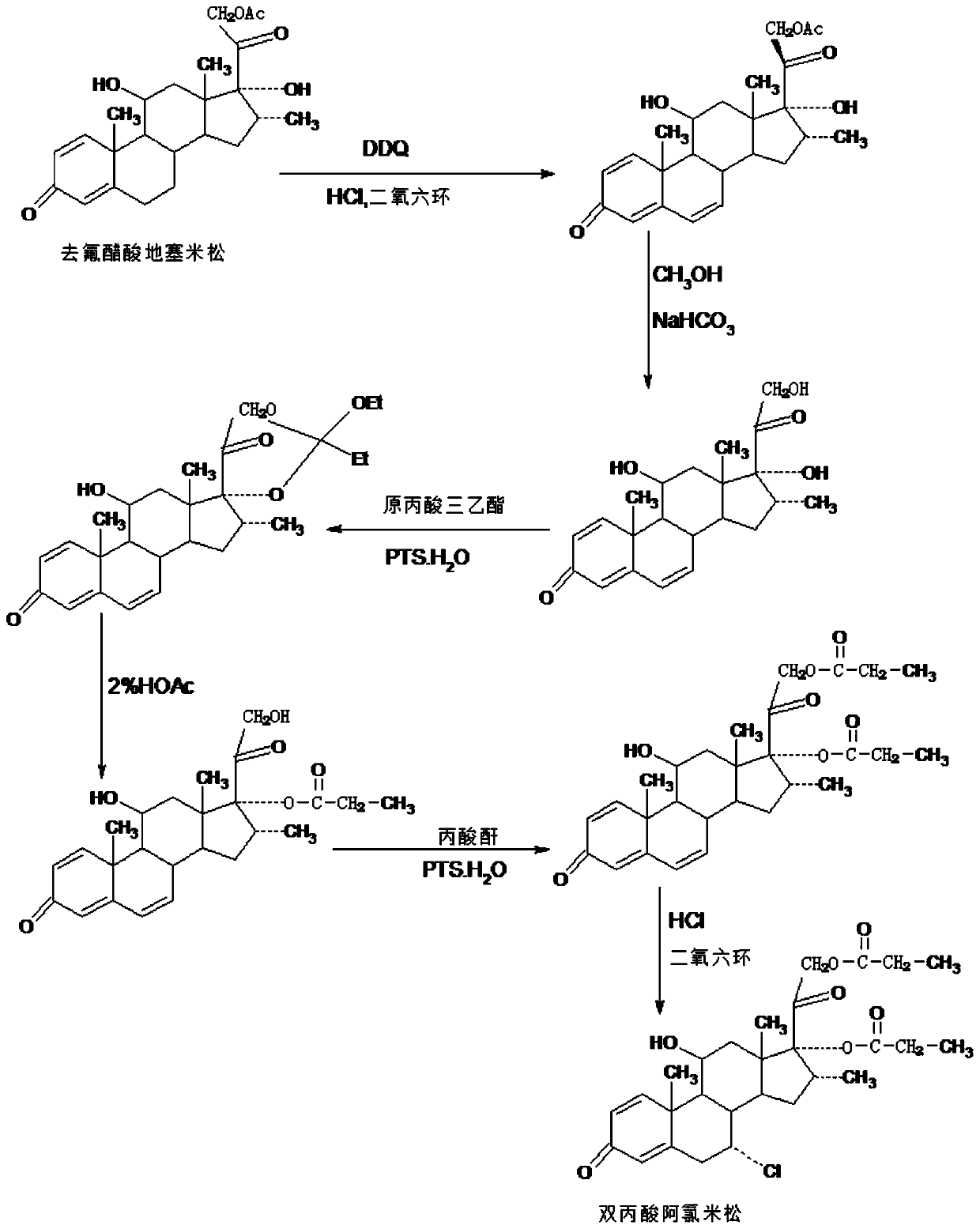

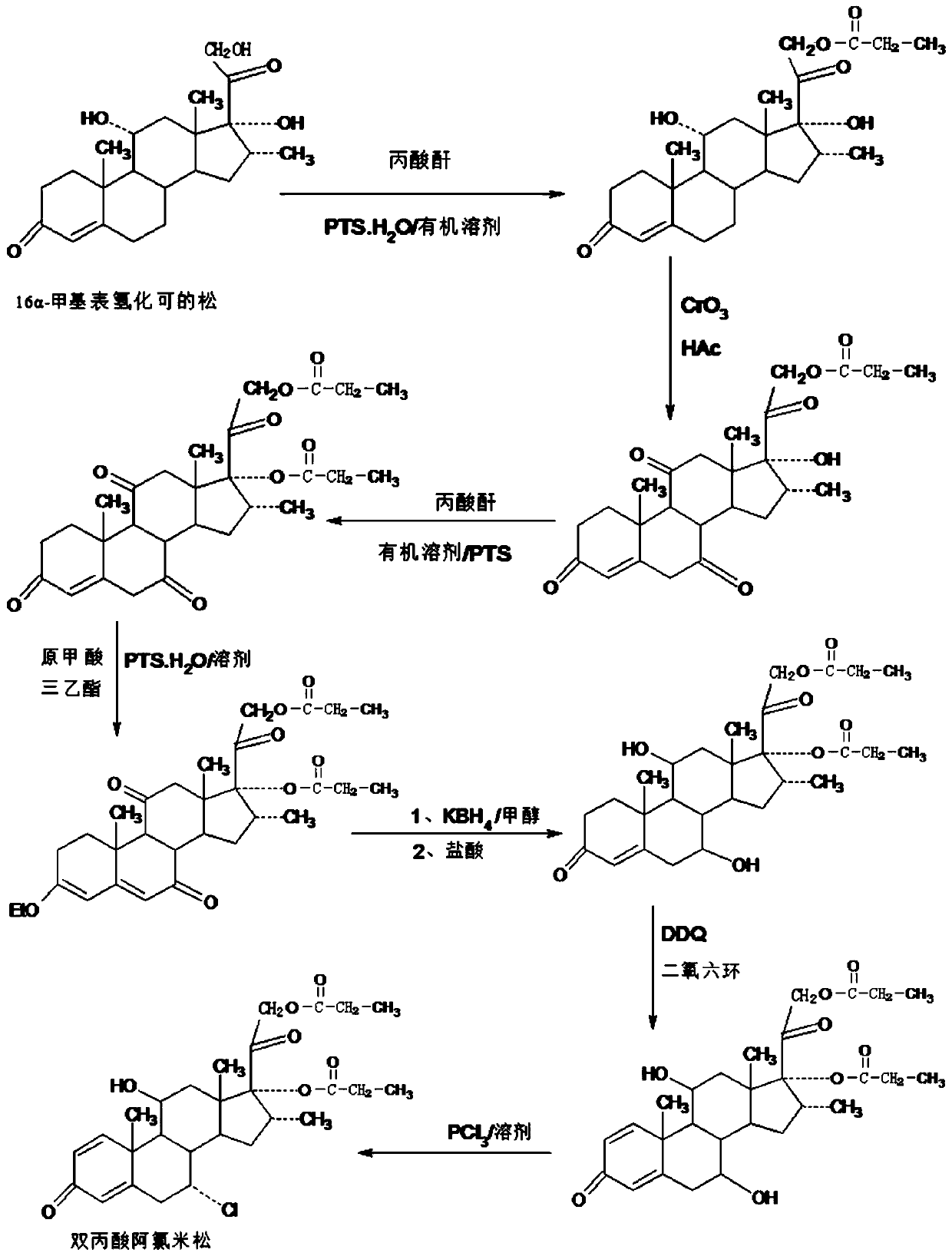

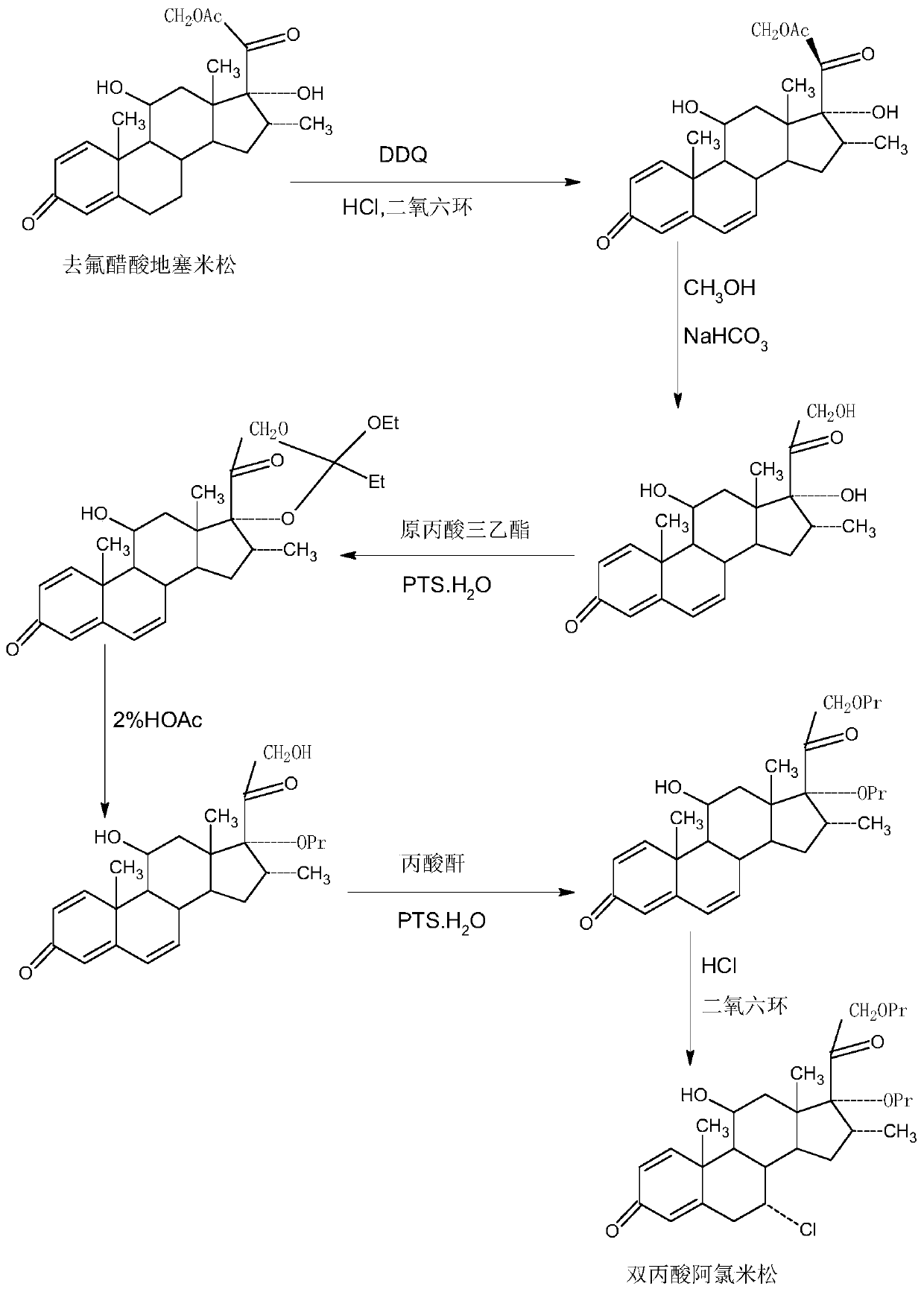

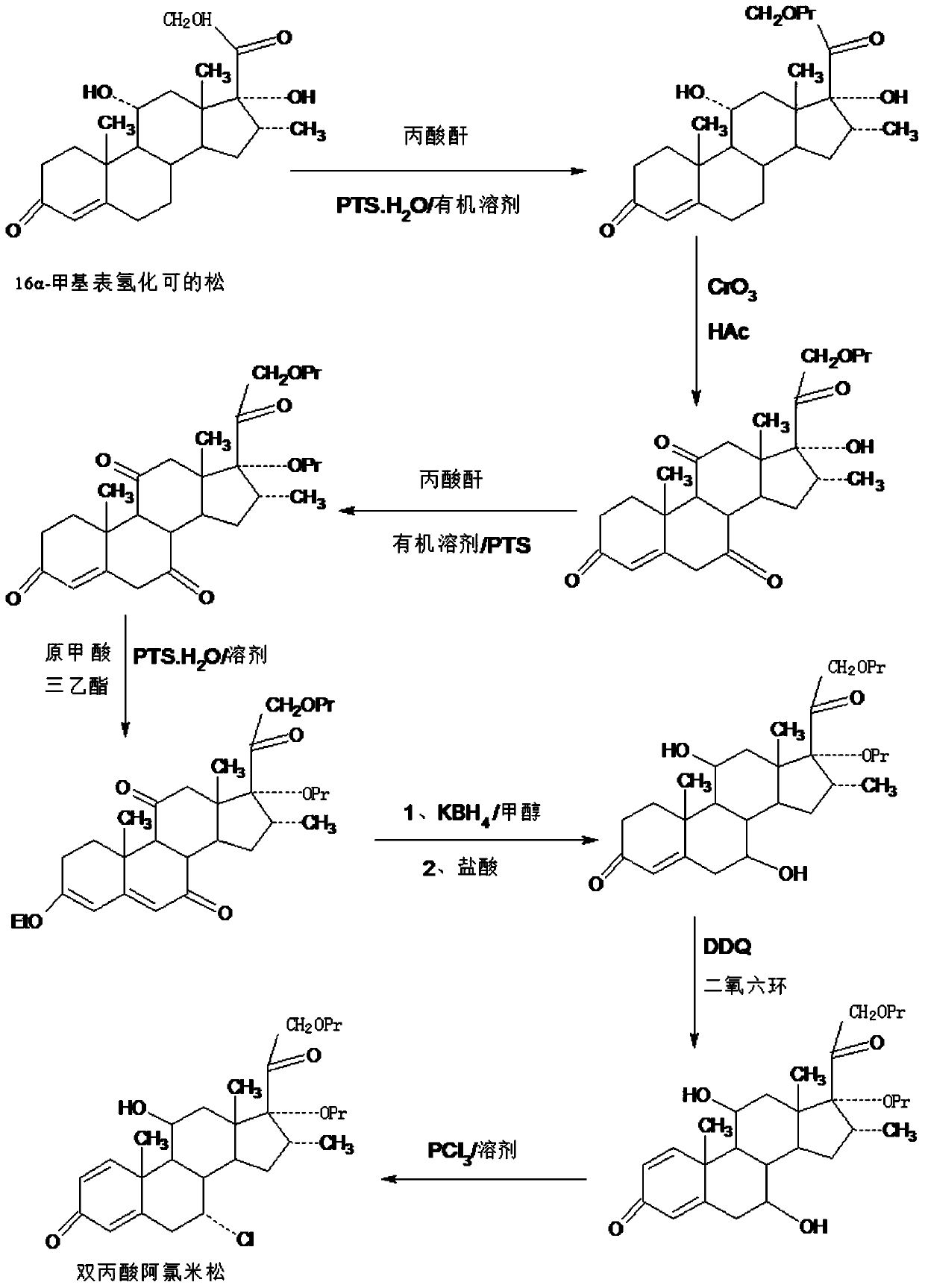

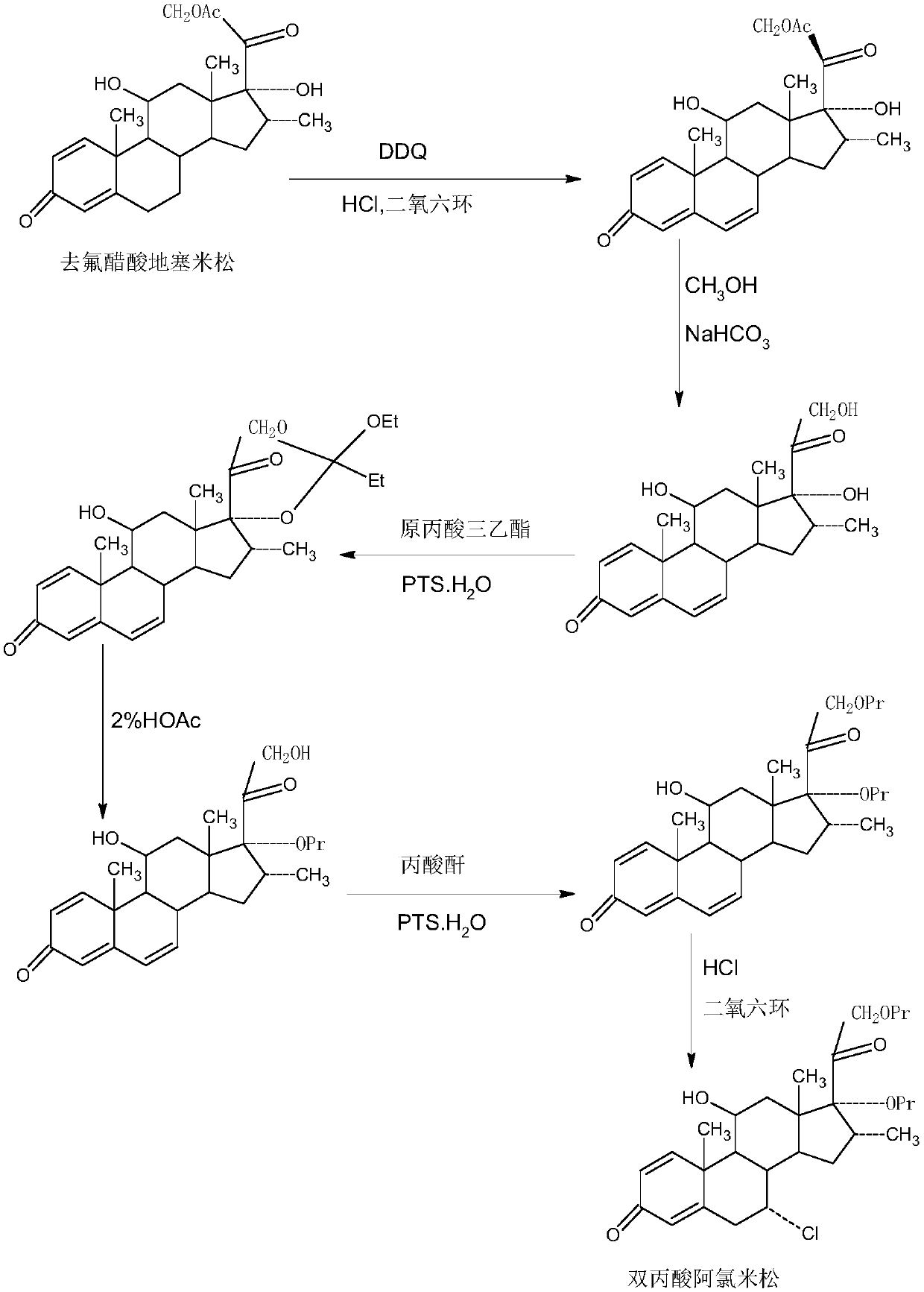

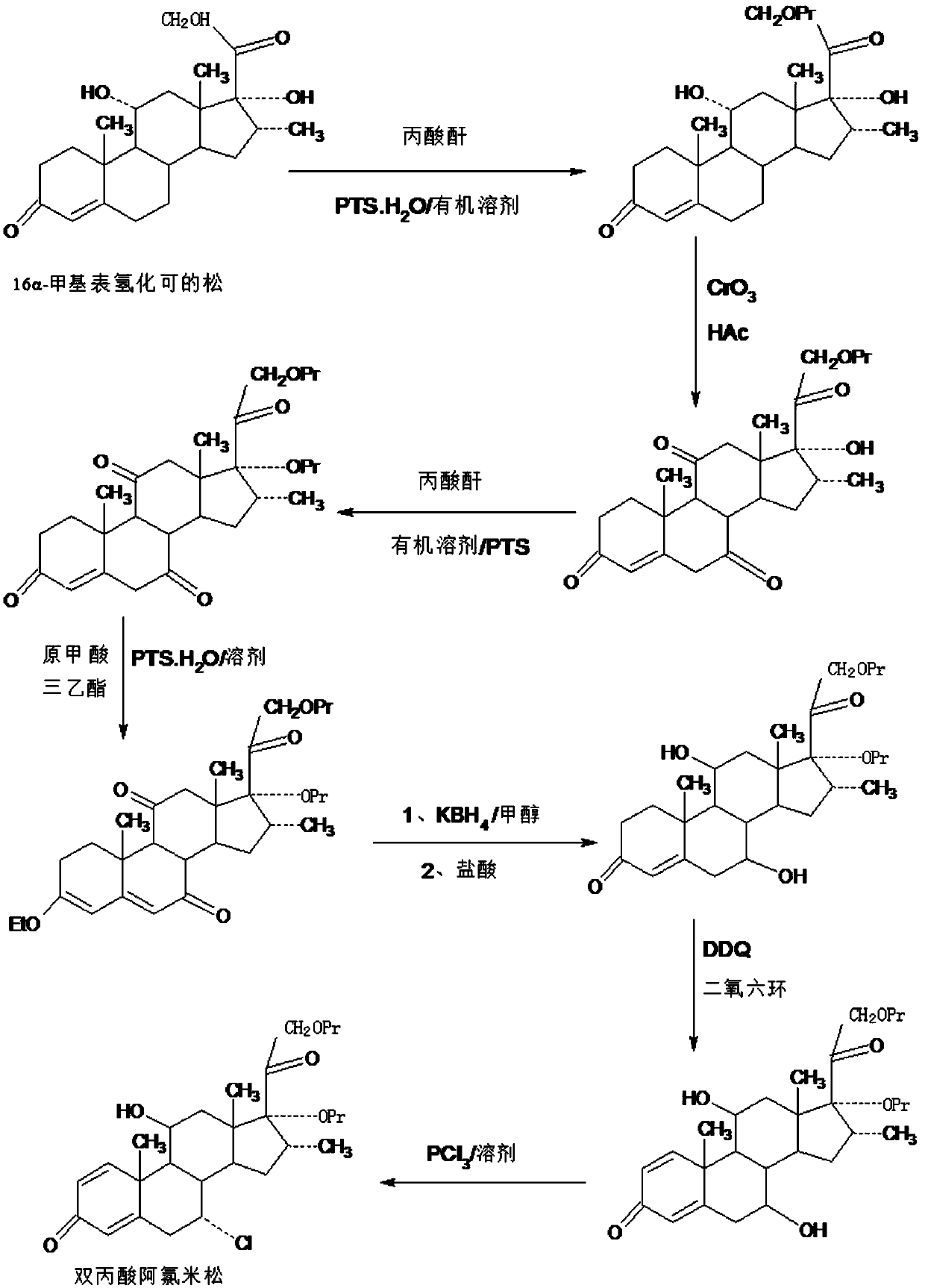

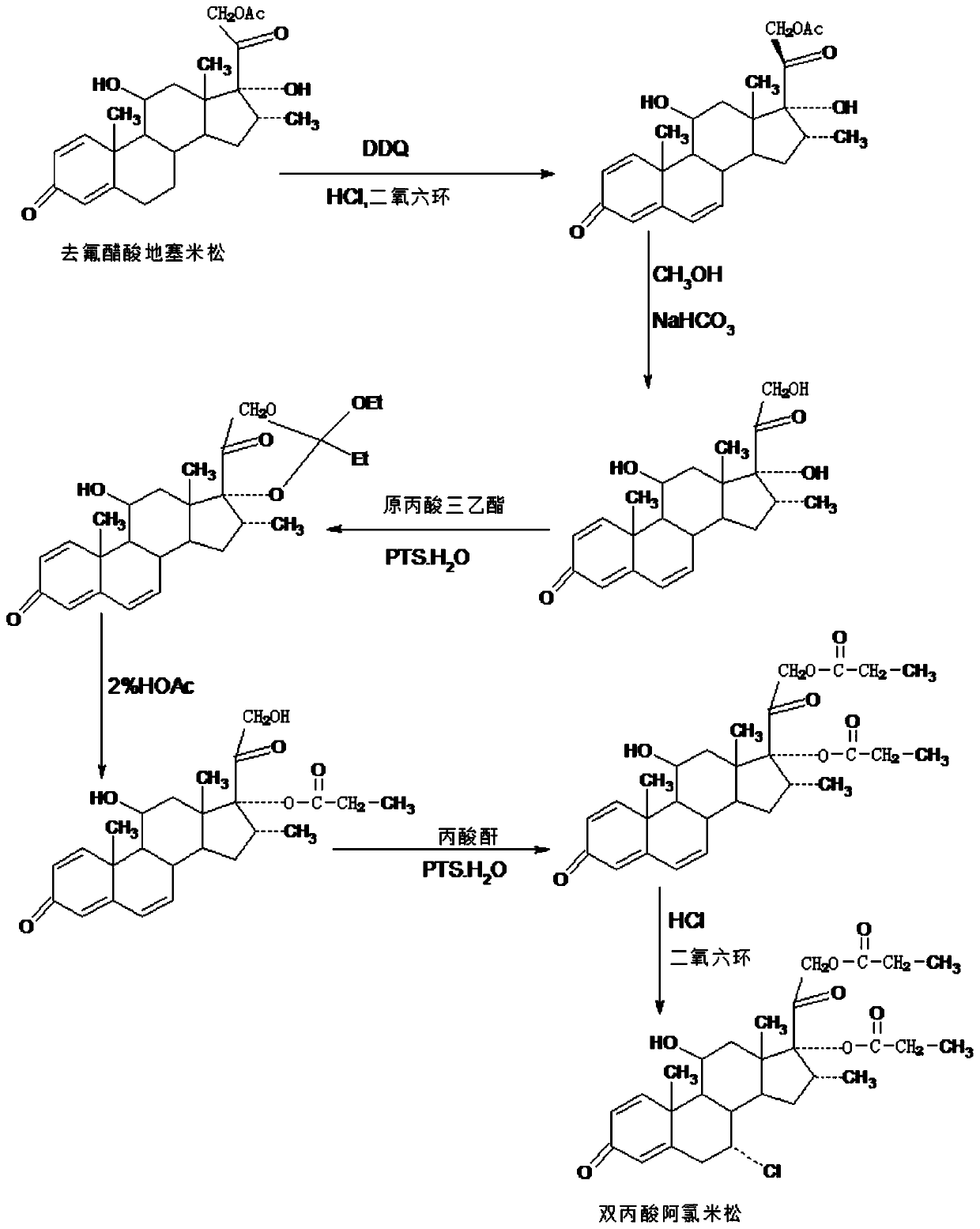

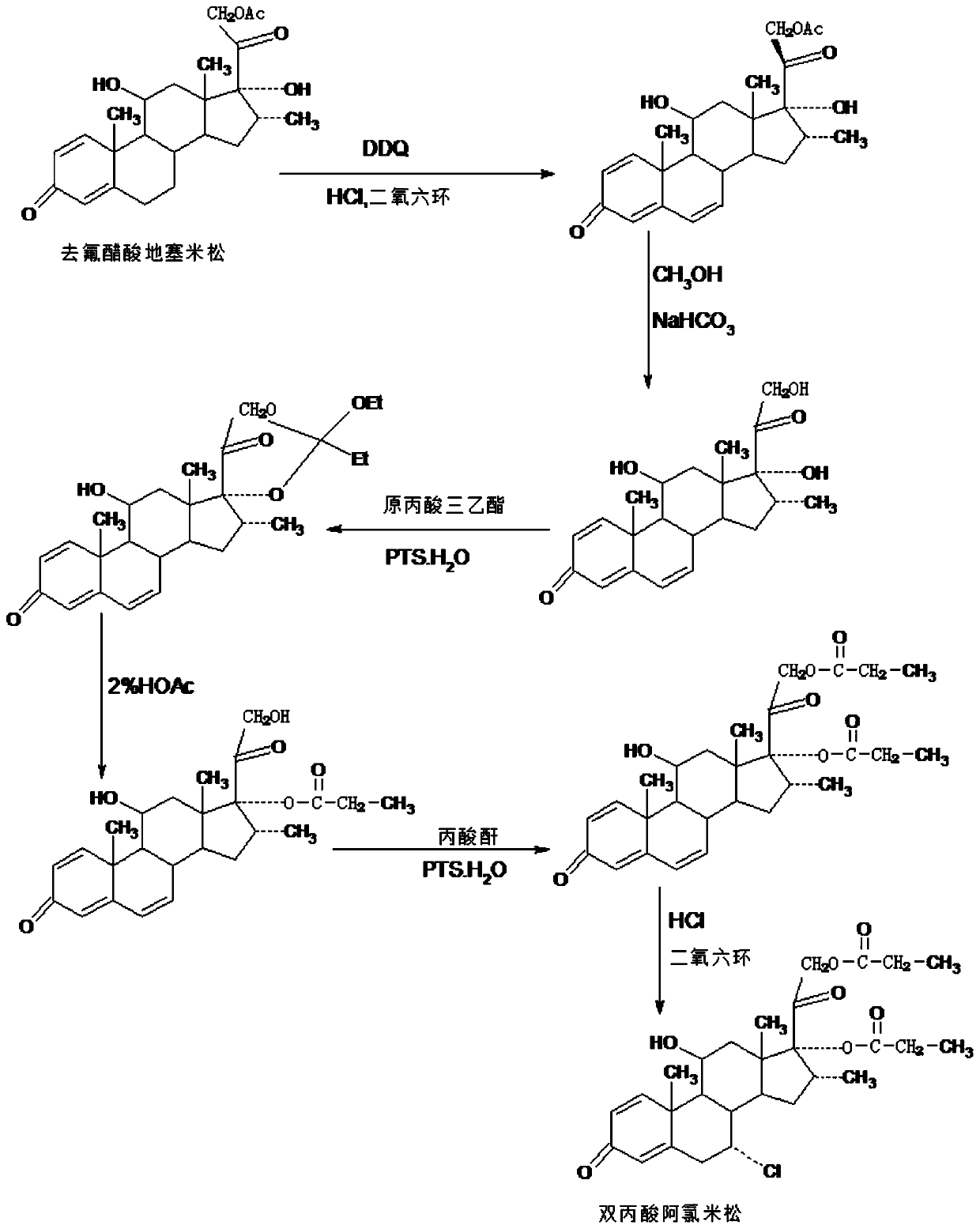

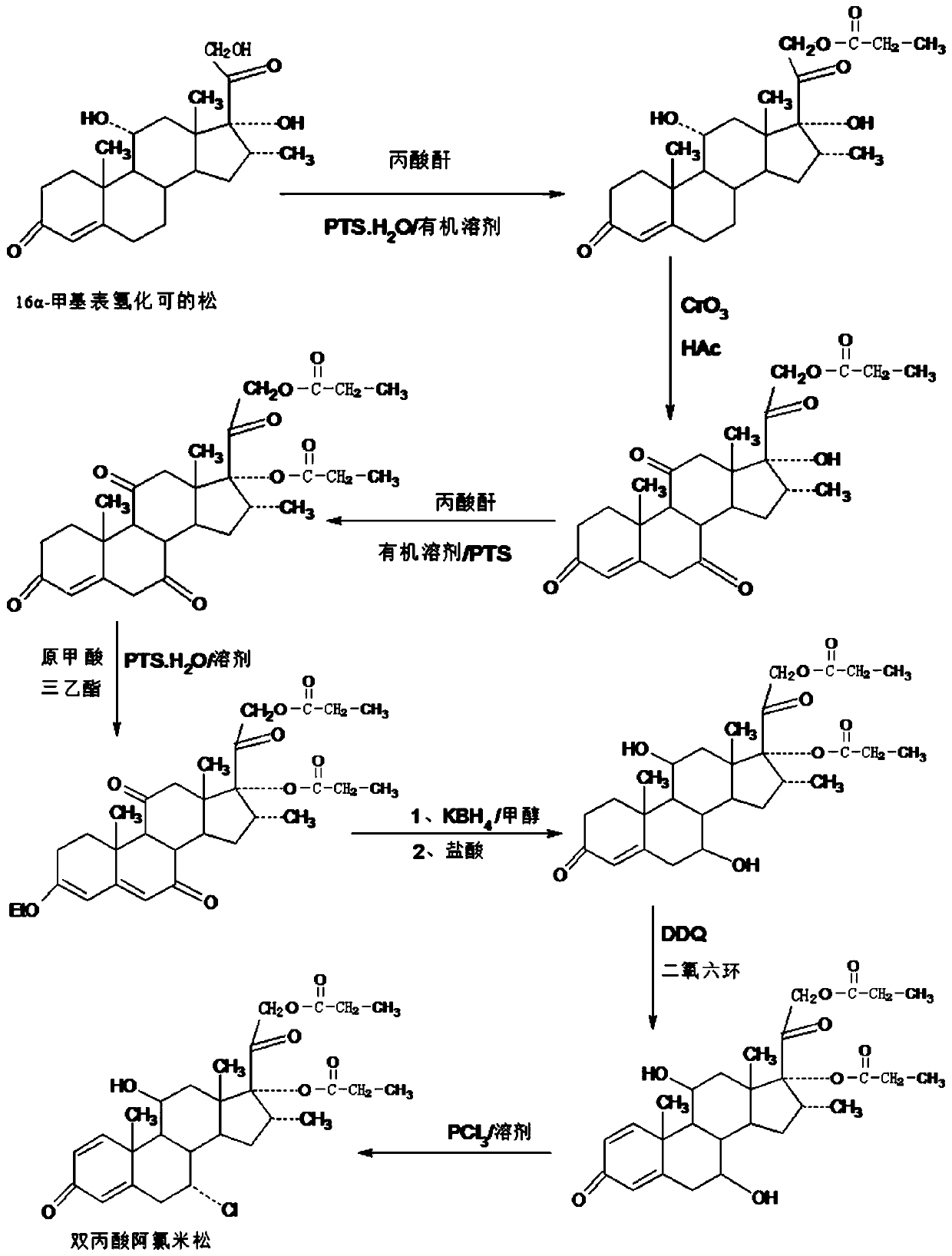

Method for preparing alclometasone dipropionate

ActiveCN109678920AShort synthetic routeProcess economy and environmental protectionSteroidsDexamethasonePropanoic acid

The invention provides a method for preparing alclometasone dipropionate. According to the method, alclometasone dipropionate is synthesized by the following seven reaction steps: esterification of 16a-methyl epihydrocortisone as a raw material with propionic acid at position 21; double-oxidization at positions 7 and 11 to obtain diketone; esterification with propionic acid at position 17; enolization and etherification protection at position 3; reduction and acid hydrolysis for deprotection with diketone at positions 7 and 11; dehydrogenation with DDQ (Dichlorodicyanobenzoquinone) at position1; and chlorine substitution at position 7. According to the method for preparing alclometasone dipropionate, the alclometasone dipropionate is synthesized by taking 16a-methyl epihydrocortisone as the raw material through seven steps; compared with a convention method with dexamethasone fluoroacetate as the raw material, the process has the advantages of short synthetic route and economy and environmental protection, simple production and operation, high product yield and the like; in the alclometasone dipropionate produced with the method, the total synthetic yield is increased from original 2.678% to 32-35%, the production cost is less than 20% of that of the traditional method; the solvent used in production can be recycled and reused; the industrial production is easy to implement.

Owner:HUNAN KEREY BIOTECH

A continuous production method of nmp

ActiveCN103351321BHigh degree of automationReduce the ratioOrganic chemistryChemical industryAlkanePyrrolidinones

The invention belongs to the field of N-methyl pyrrolidone (NMP) production and preparation technologies, particularly relates to a continuous energy-saving production method for preparing GBL (Gamma-Butyrolactone) / NMP from butanediol and specifically relates to a continuous energy-saving NMP production method. According to the production method, an adopted process only has a lactone work section and an alkane ketone work section, and qualified materials in a negative pressure tower are directly transferred to a rectification tower from the negative pressure tower through pressure difference between the negative pressure tower and the rectification tower, so that the working procedure is efficient and energy-saving, the staff ratio of the whole process is low, the degree of automation is high, the unit consumption is low, the product quality is good, and the yield is high.

Owner:BINZHOU YUNENG CHEM

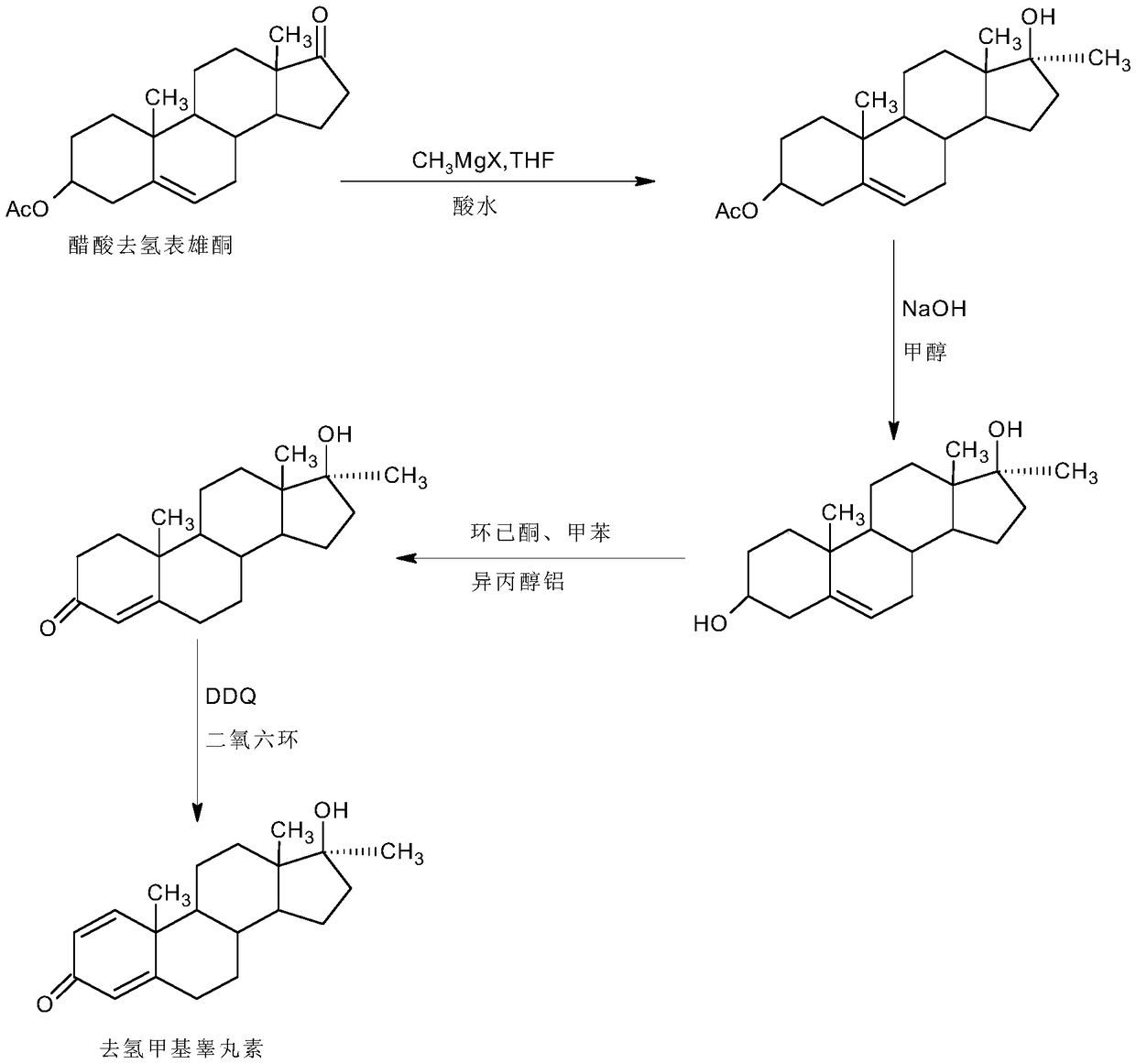

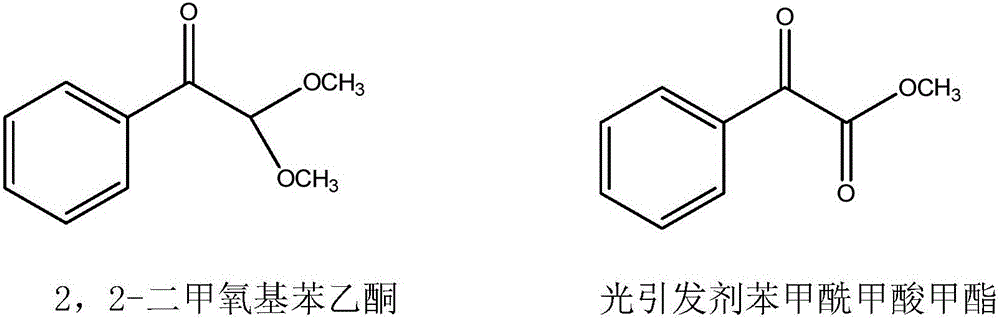

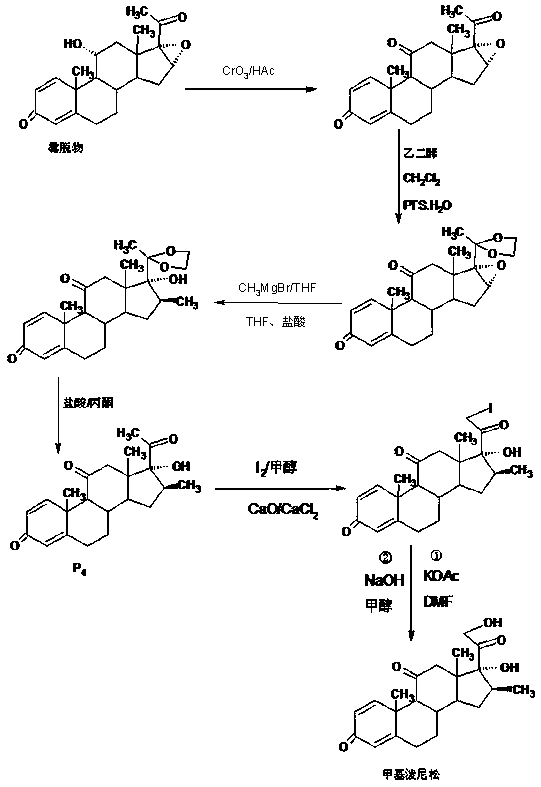

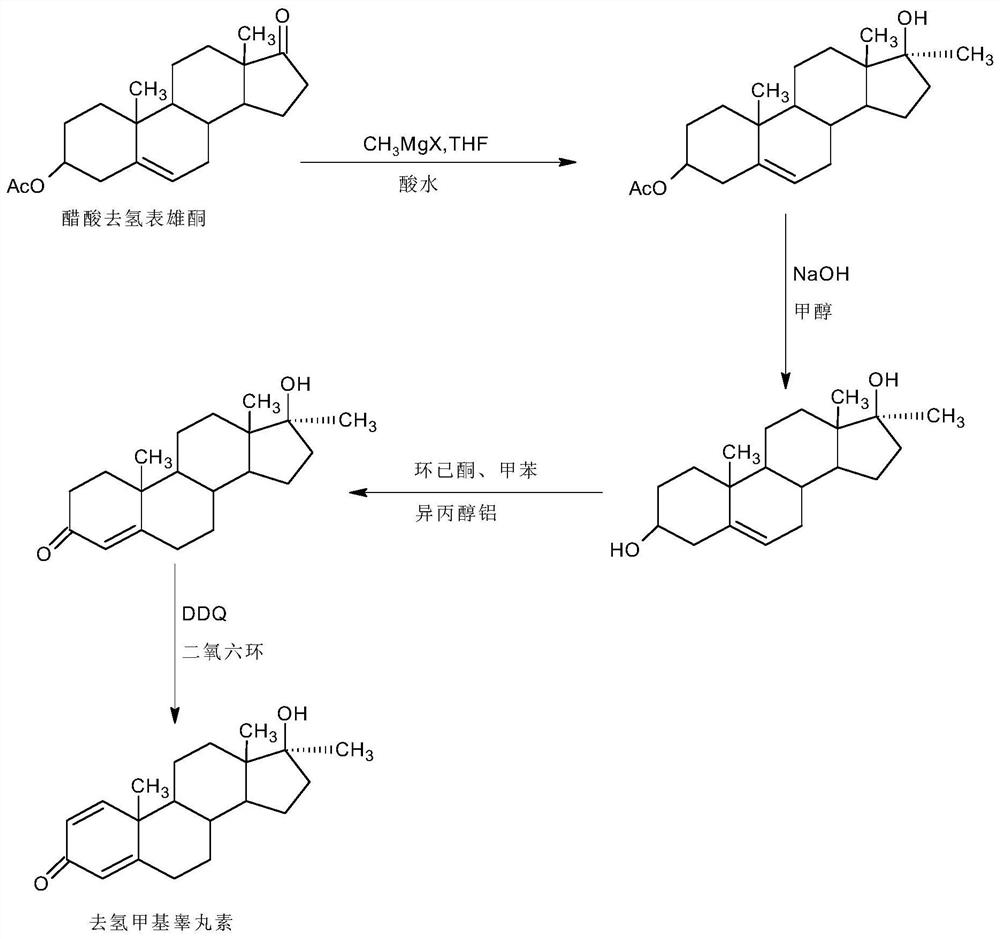

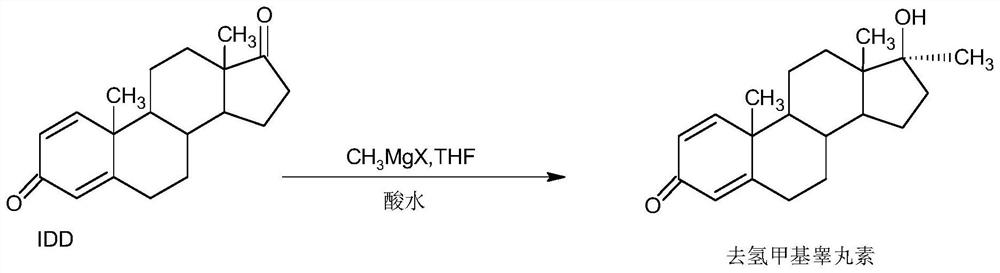

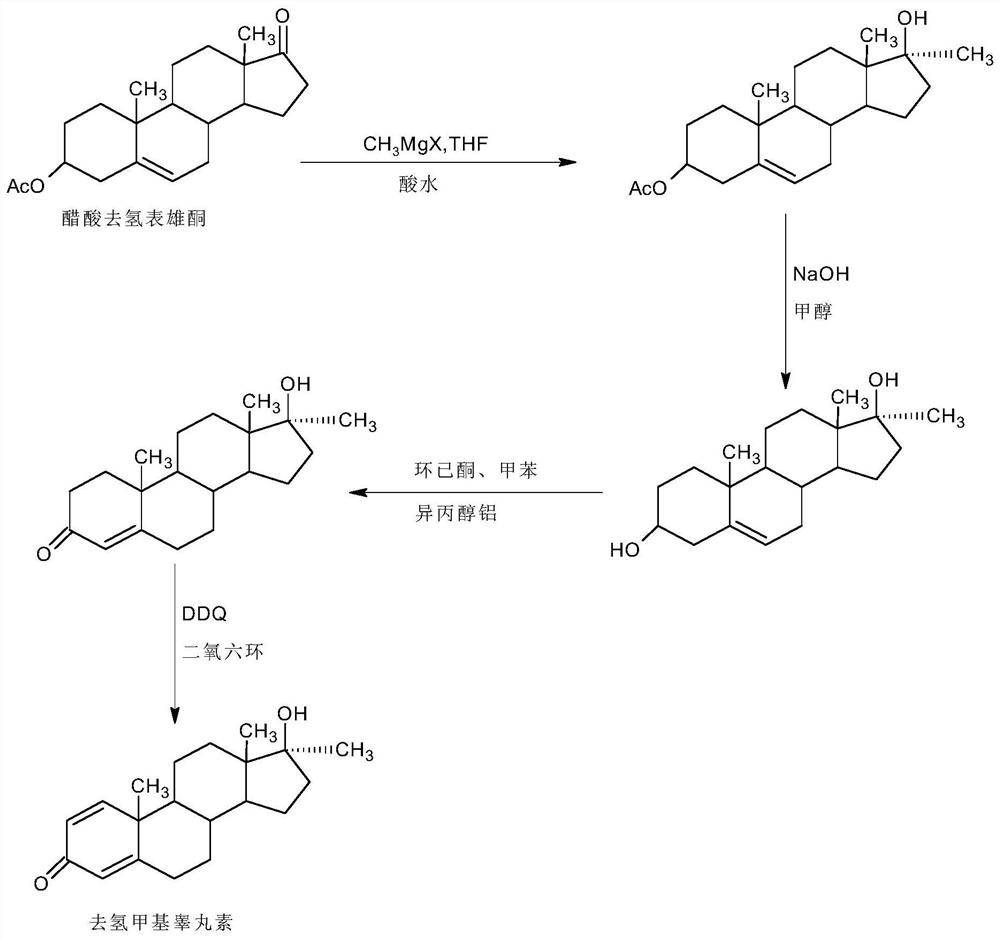

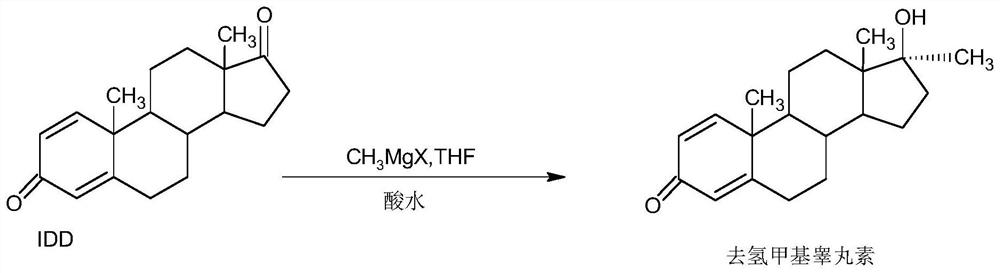

Method for preparing metandienone

ActiveCN109369760AWide variety of sourcesProcess economy and environmental protectionSteroidsFermentationPhytosterol

The invention provides a method for preparing metandienone, the method comprises firstly using a nutrient medium and one or more microbial strains, performing microbial fermentation on phytosterol toprepare 1,4-androstenedione, namely IDD, then using the IDD as the raw material, introducing alpha-CH3 and beta-OH into a 17 site with the existence of methyl magnesium halide, an organic solvent andan acid, and preparing the metandienone. The method uses the IDD as the raw material to prepare the metandienone, compared with the traditional method taking diosgenin as the raw material, the sourceof the raw material is wide, the process is economical and environmentally friendly, and the production cost is greatly reduced. Compared with the traditional production method, the synthesis route isshort, the process is simple, convenient and environmentally friendly, the yield of a product is high, the quality is high, and the cost of the raw material for production is reduced by 40-45% according to the current price of the raw material.

Owner:HUNAN KEREY BIOTECH

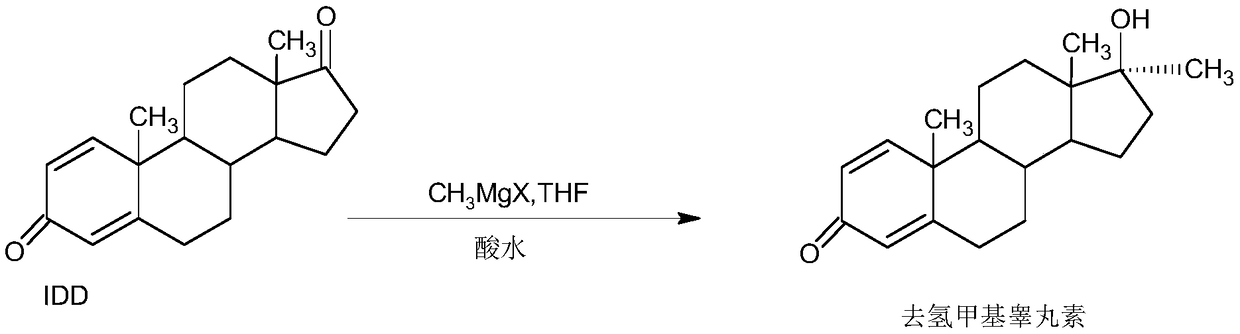

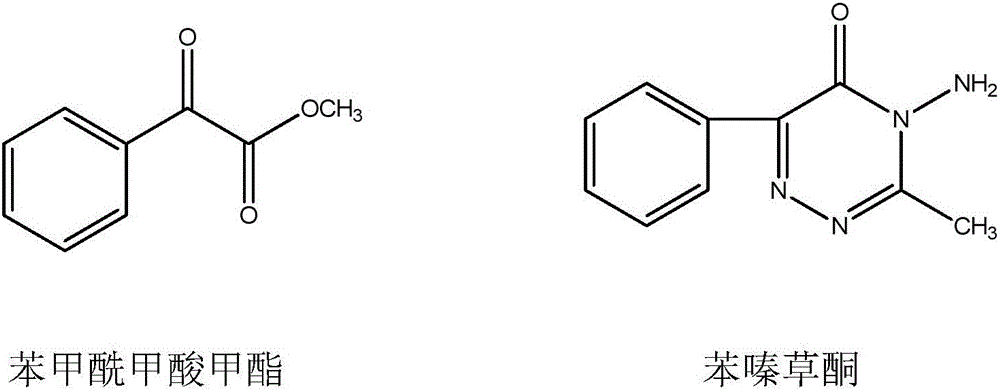

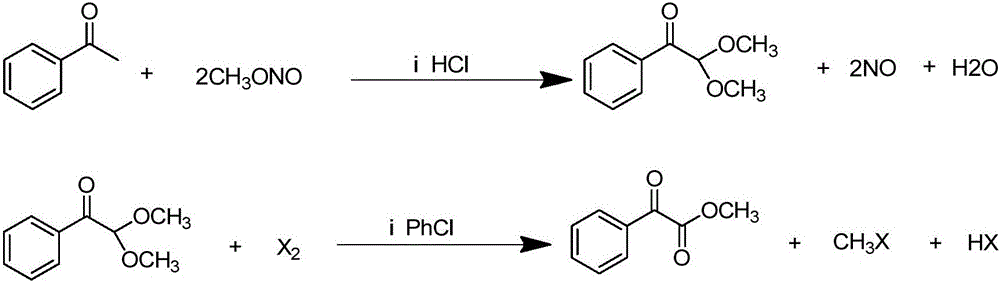

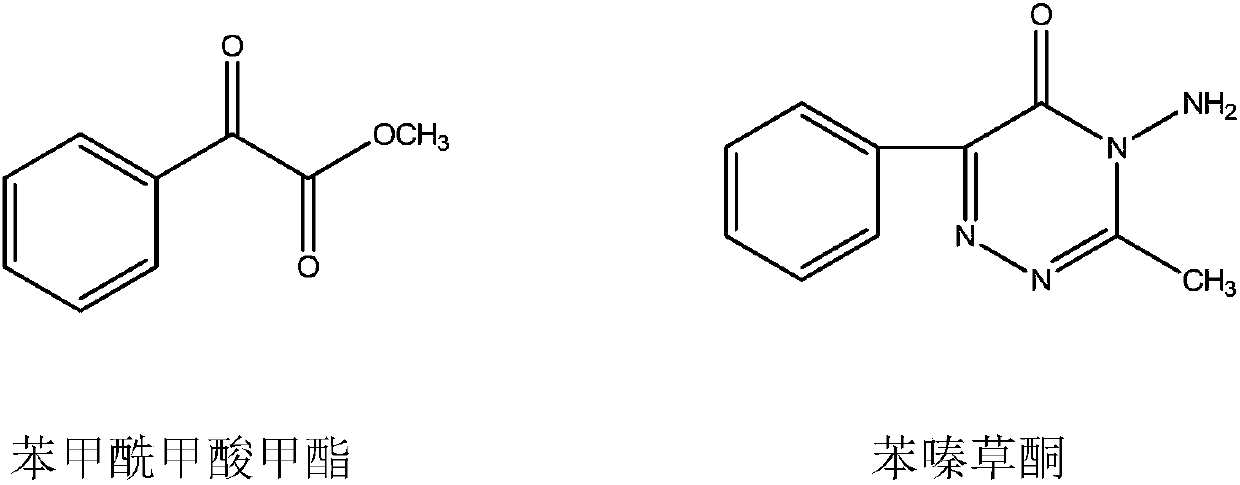

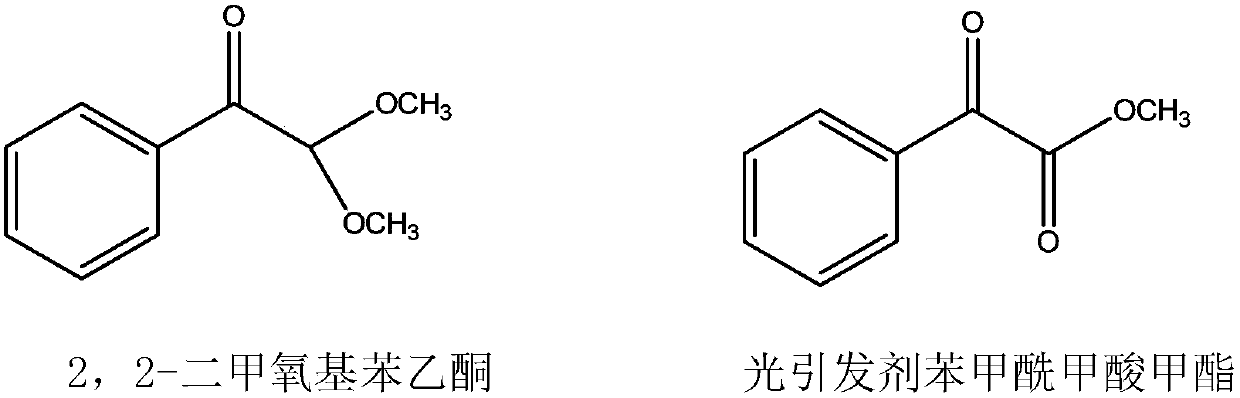

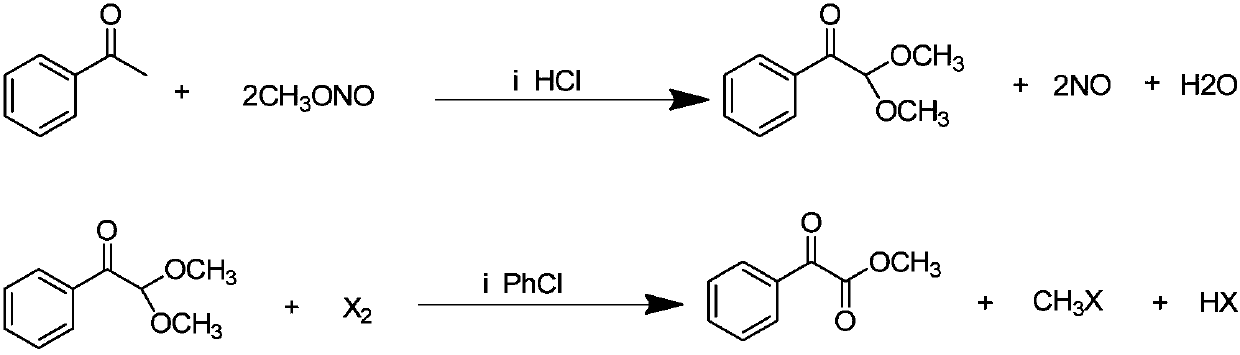

New synthesis technology of methyl benzoylformate

ActiveCN106242967ALow priceNo pollution in the processOrganic compound preparationCarboxylic acid esters preparationPhotoinitiatorHydrogen chloride

The invention relates to a brand new synthesis technology of a photoinitiator and herbicide metamitron intermediate methyl benzoylformate. The technology has not been reported in literatures. The technology comprises the following steps: acetophenone used as an initial raw material reacts with methyl nitrite under the action of hydrogen chloride to obtain 2,2-dimethoxyacetophenone, 2,2-dimethoxyacetophenone undergoes chlorine chlorination (or bromine bromination) under the catalysis action of a catalyst 4-methyl-2,6-di-tert-butyl phenol, and a molecule of haloalkane is removed from the chlorinated or brominated 2,2-dimethoxyacetophenone to obtain methyl benzoylformate. Influences of hydrogen chloride on the production of 2,2-dimethoxyacetophenone in the reaction and influences of the catalyst 4-methyl-2,6-di-tert-butyl phenol on the production of methyl benzoylformate are researched to determine the optimal conditions of the production of methyl benzoylformate. The new technology provided by the invention is simple to operate, and is economical.

Owner:HUAIHUA JINXIN NEW MATERIAL CO LTD

Method for preparing dehydrogenated intermediate product for aclomethasone dipropionate

ActiveCN109651477AShort synthetic routeProcess economy and environmental protectionSteroidsPropanoic acidAcid hydrolysis

Disclosed is a method for preparing a dehydrogenated intermediate product for aclomethasone dipropionate. The method comprises the steps that with 16a-methyl pihydrocortisone as a raw material, a crude dehydrogenated intermediate product for aclomethasone dipropionate is synthesized through a six-step reaction of 21-site propionic acid esterification, 7,11-site double-oxidation into diketone, 17-site propionic acid esterification, 3-site enolization etherification protection, 7,11-site diketone reduction and acid hydrolysis deprotection and 1-site DDQ dehydrogenation, then the dehydrogenated intermediate product for aclomethasone dipropionate is obtained through refining. By means of the method, with 16a-methyl pihydrocortisone as the raw material, the dehydrogenated intermediate product for aclomethasone dipropionate is synthesized through the six-step reaction; the process has the advantages of being short in synthesis route, economical, environmentally friendly, simple in productionoperation, high in product yield and the like; a solvent used in production can be recycled and applied, and industrial production is easy to implement.

Owner:HUNAN KEREY BIOTECH

Method for preparing beclomethasone dipropionate product

ActiveCN109666054AShort synthetic routeProcess economy and environmental protectionSteroidsPropanoic acidAcid hydrolysis

The invention discloses a method for preparing a beclomethasone dipropionate product. The method includes taking 16a-methylepihydrocortisone as a raw material, preforming a seven-step reaction to synthesize a crude product through esterification of 21-position propionic acid, double oxidation of 7-position and 11-position diketones, esterification of 17-position propionic acid, etherification protection of 3-position enolization, reduction of 7-position and 11-position diketones and acid hydrolysis deprotection, dehydrogenation of 1-position DDQ and substitution of 7-position chlorine; and refining to obtain the beclomethasone dipropionate product. According to the method, 16a-methylepihydrocortisone is taken as a raw material, and beclomethasone dipropionate is synthesized through the seven-step reaction, compared with the traditional method, the process has the advantages of short synthesis route, economical and environment-friendly process, simple and convenient production operation, high product yield and the like; when the method is used for producing beclomethasone dipropionate, the total synthesis yield is increased to 32-35% from the original 2.678%, and the production costis lower than 20% of the traditional method; and solvents used in production can be recycled and reused, and industrial production is easy to implement.

Owner:HUNAN KEREY BIOTECH

Method for preparing alclometasone dipropionate by using etherified intermediate

ActiveCN109796514AShort synthetic routeProcess economy and environmental protectionSteroidsDexamethasone acetateDehydrogenation

The invention provides a method for preparing alclometasone dipropionate by using an etherified intermediate. According to the method, the etherified intermediate 3-vinyl alcohol ether-16a-methyl-17a,21-bipropionyloxy-pregna-3,5-diene-7,11,20-triketone serves as the raw material and is reduced with 7-site and 11-site diketone and subjected to three reactions including acid hydrolysis deprotection,1-site DDQ dehydrogenation and 7-site chlorine substitution, and then alclometasone dipropionate is synthesized. According to the method, the etherified intermediate 3-vinyl alcohol ether-16a-methyl-17a,21-bipropionyloxy-pregna-3,5-diene-7,11,20-triketone serves as the raw material, alclometasone dipropionate is synthesized through three steps of reactions, compared with a traditional method using de-fluorated dexamethasone acetate as the raw material, the technology has the advantages that a synthetic route is short, the process is economical and environmentally friendly, the production operation is simple and convenient and the product yield is high; solvents used during production can be recycled, and industrial production is easy to implement.

Owner:HUNAN KEREY BIOTECH

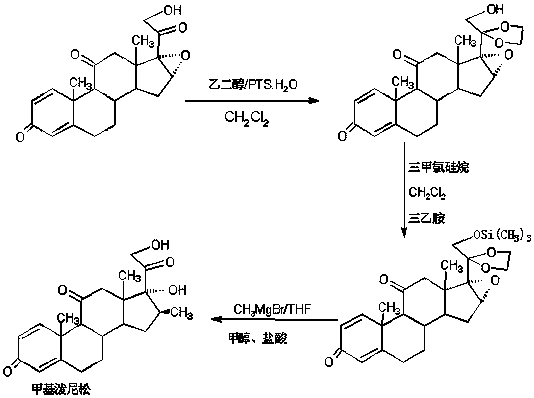

The preparation method of methylprednisone

ActiveCN106518944BWide variety of sourcesProcess economy and environmental protectionSteroidsGrignard reagentStrong acids

The invention relates to a preparation method of methylprednisone. The method comprises the following steps: carrying out acid catalyzed reaction on 16(17)a-epoxy prednisone prepared from 4-androstenedione (4AD for short) and ethanediol in an organic solvent at 10-50 DEG C to obtain a ketal substance 20-ketal-16(17)a-epoxy prednisone; carrying out alkali catalyzed reaction on the ketal substance and trimethylchlorosilane in an organic solvent to obtain a silyl ether substance 21-methylsilyl-ether-20-ketal-16(17)a-epoxy prednisone; and carrying out Grignard reaction on the silyl ether substance and a 2M methyl grignard reagent in an organic solvent, hydrolyzing the Grignard substance in strong acid to obtain the methylprednisone. The detection indicates that the HPLC (high performance liquid chromatography) content is 99.0% or above, the melting point is 228-237 DEG C, and the synthetic weight total yield is 80-85%. When being used for producing methylprednisone, the method has the advantages of wide raw material sources, economical and environment-friendly technique, simple production operation, short synthesis route, high synthesis yield and lower production cost (than the traditional method by 30-40%). The method is convenient for industrial production.

Owner:HUNAN KEREY BIOTECH

A kind of method for preparing the etherified intermediate used for aclomethasone dipropionate

ActiveCN109776643BShort synthetic routeProcess economy and environmental protectionSteroidsPropanoic acidBiochemical engineering

The invention provides a method for preparing an etherified intermediate for alclometasone dipropionate. 16a-methylhydrocortisone used as a raw material undergoes a four-step reaction comprising propionation at the 21-position, double oxidation at 7- and 11-positions into double ketones, propionation at the 17-position and enolification and etherification protection at the 3-position to synthesizethe etherified intermediate for alclometasone dipropionate. The method for preparing the etherified intermediate for alclometasone dipropionate from the 16a-methylhydrocortisone through the four-stepreaction has the advantages of short synthesis route, economical and environmentally-friendly process, simplicity in production operation, and high product yield; and the solvent used in production can be recovered and recycled, and so the method achieves easy industrial production.

Owner:HUNAN KEREY BIOTECH

Method of reduced intermediate used for alclometasone-17,21-dipropionate

ActiveCN109796515AShort synthetic routeProcess economy and environmental protectionSteroidsDiketoneAcid hydrolysis

The invention provides a method of a reduced intermediate used for alclometasone-17,21-dipropionate. The method comprises the steps that 16alpha-methlhydrocortisone as a raw material is subjected to 21-position propionic esterification, 7- and 11-position double oxidation to form diketone, 17-position propionic esterification, 3-position enolization etherification protection and 7- and 11-positiondiketone reduction and acid hydrolysis deprotection, and then the reduced intermediate used for the alclometasone-17,21-dipropionate is synthesized. In the method, the 16alpha-methlhydrocortisone serves as the raw material and is subjected to reactions in five steps to form the reduced intermediate used for the alclometasone-17,21-dipropionate, the technology has the advantages of being short insynthesis route, economical, environmentally friendly, simple in production operation and high in product yield; the solvent used in the production process can be recycled, and industrial production is easily implemented.

Owner:HUNAN KEREY BIOTECH

A kind of preparation method of dehydromethyl testosterone product

ActiveCN109456379BWide variety of sourcesProcess economy and environmental protectionSteroidsMethylmagnesium chlorideOrganosolv

The invention provides a preparation method of a metandienone product. The preparation method comprises the following steps that 1,4-androstenedione, namely IDD, is adopted as a raw material, in the presence of methylmagnesium chloride, an organic solvent and acid, alpha-CH3 and beta-OH are introduced at the 17 position, and metandienone is prepared; and then the obtained metandienone is heated byactivated carbon in acetone or lower alcohol below C4 for reflow discoloration and is recrystallized, and the metandienone product is obtained. According to the preparation method, the IDD serves asthe raw material to prepare the metandienone, compared with a traditional method adopting diosgenin as a raw material, the raw material source is wide, a process is economic and environmentally friendly, and the production cost is significantly lowered. Compared with a traditional production method, according to the preparation method, a synthesis route is short, the process is easy, convenient and environmentally friendly, the product yield is high, the quality is good, and the production raw material cost is lowered by 40-45% by calculating through the current raw material price.

Owner:HUNAN KEREY BIOTECH

Method for preparing reduced intermediate product for aclomethasone dipropionate

ActiveCN109651476AShort synthetic routeProcess economy and environmental protectionSteroidsDiketonePropanoic acid

The invention provides a method for preparing a reduced intermediate product for aclomethasone dipropionate. The method comprises the steps that with 16a-methyl pihydrocortisone as a raw material, a crude reduced intermediate product for aclomethasone dipropionate is synthesized through a five-step reaction of 21-site propionic acid esterification, 7,11-site double-oxidation into diketone, 17-sitepropionic acid esterification, 3-site enolization etherification protection and 7,11-site diketone reduction and acid hydrolysis deprotection, then the reduced intermediate product for aclomethasonedipropionate is obtained through refining. By means of the method, with 16a-methyl pihydrocortisone as the raw material, the reduced intermediate product for aclomethasone dipropionate is synthesizedthrough the five-step reaction; the process has the advantages of being short in synthesis route, economical, environmentally friendly, simple in production operation, high in product yield and the like; a solvent used in production can be recycled and applied, and industrial production is easy to implement.

Owner:HUNAN KEREY BIOTECH

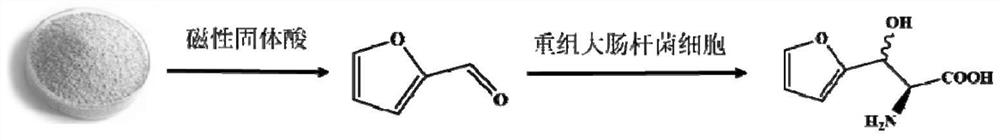

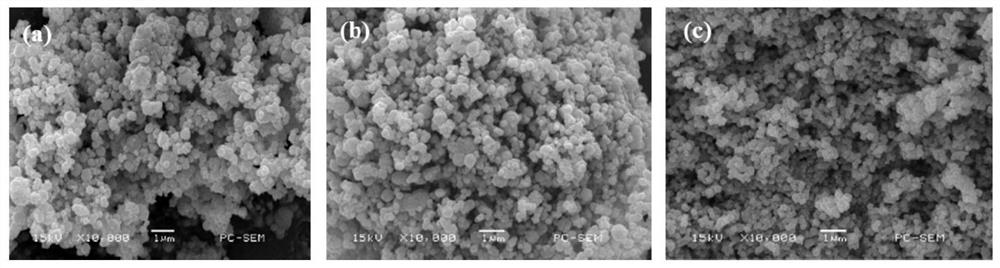

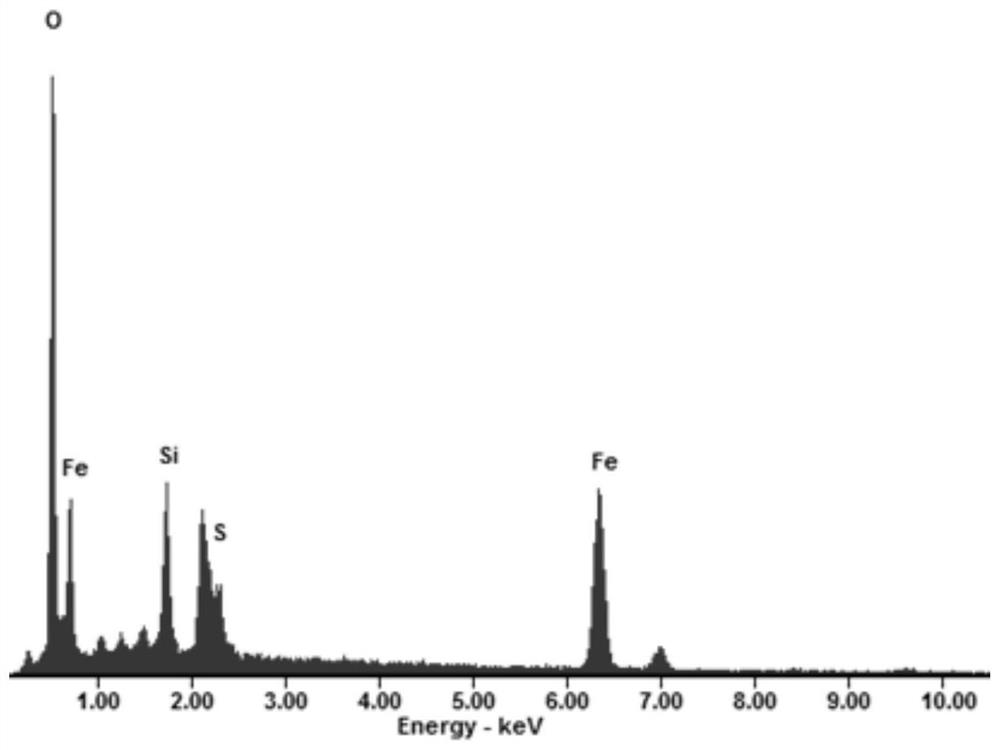

A kind of method that biomass chemical-enzymatic method prepares L-furanserine

ActiveCN112387299BEasy to separateGood biocompatibilityOrganic chemistryMolecular sieve catalystsBiochemical engineeringChemo enzymatic

The invention discloses a method for preparing L-furanserine by a biomass chemical-enzymatic method, which belongs to the field of biochemical industry. The invention provides a Fe with optimized preparation process 3 o 4 @MCM‑41 / SO 4 2– , and use it in the process of biochemical-enzymatic production of L-furanserine. The production method of L-furanserine of the present invention saves the separation process of intermediates, has good biocompatibility, simple steps, economical and environment-friendly process, and can make the yield of L-furanserine reach 73.6%, which is β-hydroxy- Green and sustainable manufacturing of α‑amino acids provides a reference.

Owner:JIANGNAN UNIV

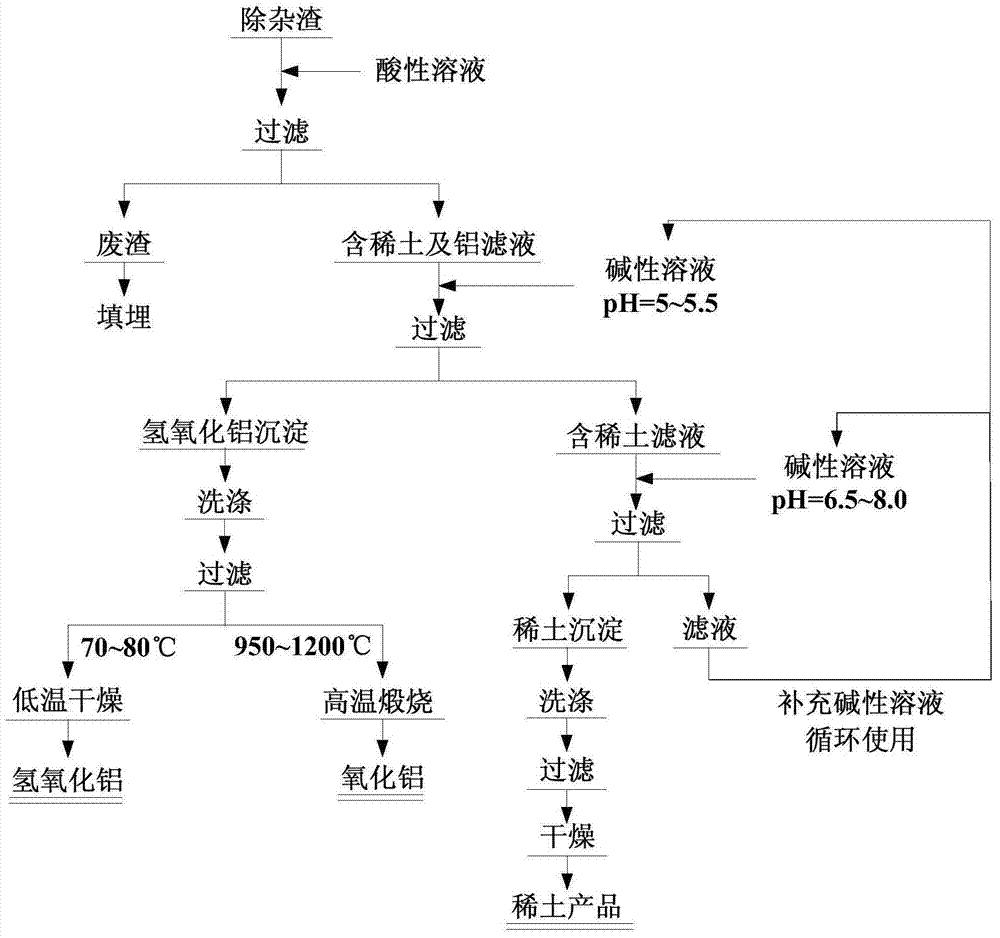

A method for recovering rare earth and aluminum from the leaching solution of weathering crust elution type rare earth ore to remove impurities

The invention relates to a method for recovering rare earth and aluminum from weathered crust ion-adsorption type rare earth ore lixivium impurity-removal slags, which comprises the following steps: (1) adding an acid solution into the impurity-removal slags, continuously stirring for 4-8h under the condition that the temperature is controlled at 10-70 DEG C, and filtering the obtained object so as to obtain rare earth and aluminum containing filtrate and waste residues; (2) adding an alkaline solution into the rare earth and aluminum containing filtrate until the pH value of the obtained mixture is 5.0-5.5, so that an aluminum hydroxide precipitate is generated in the filtrate, and filtering the filtrate so as to obtain the aluminum hydroxide precipitate and rare earth containing filtrate; (3) washing the aluminum hydroxide precipitate by using clean water, filtering the obtained object, and carrying out low-temperature drying on the aluminum hydroxide precipitate so as to obtain aluminum hydroxide or carrying out high-temperature calcining on the aluminum hydroxide precipitate so as to obtain an alumina product; and (4) adding an alkaline solution into the rare earth containing filtrate, adjusting the pH value of the filtrate to 6.5-6.5, aging for 6-24h, and filtering the obtained product, so that a rare earth precipitate and filtrate are obtained, and washing, filtering and drying the rare earth precipitate so as to obtain a rare earth product. The method disclosed by the invention is simple in process, rare earth and aluminum are recovered from weathered crust ion-adsorption type rare earth ore lixivium impurity-removal slags by using a cheap and easily-obtained reagent, the recovery rate is high, and the purity of recovered aluminum and rare earth products is high, therefore, the method has good economic benefits.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

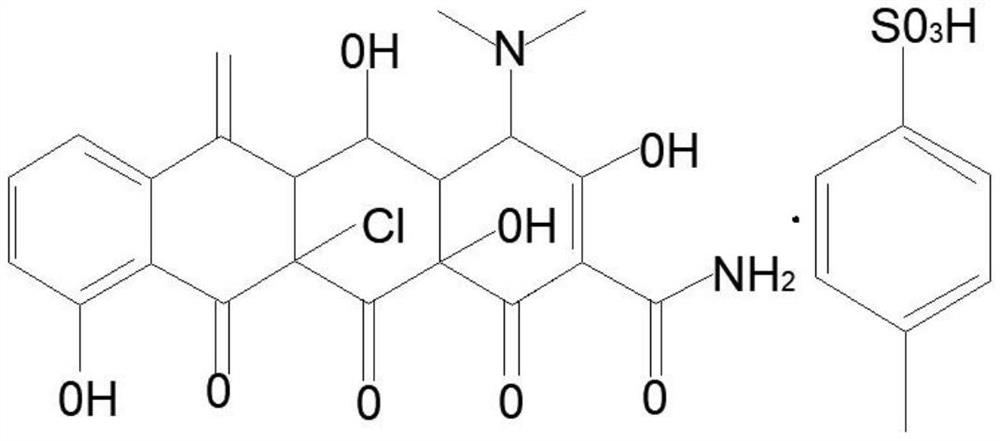

A kind of synthetic method of 11α-chloromethyloxytetracycline p-toluenesulfonate

ActiveCN113149855BHigh yieldImprove securityOrganic compound preparationSulfonic acids salts preparationBiochemical engineeringVeterinary Drugs

The invention discloses a method for synthesizing 11α-chloromethyoxytetracycline-p-toluenesulfonate, which solves the problems of unreasonable preparation method, high toxicity of raw materials, complicated operation, high cost, large output of three wastes and high yield. The technical problem of low and unsuitable for industrialized production, the present invention takes chloroxytetracycline as raw material, takes supercritical carbon dioxide as reaction solvent, takes anhydrous p-toluenesulfonic acid as dehydrating agent, and generates 11α-chloromethane through dehydration reaction Oxytetracycline, and then take absolute ethanol as a reaction solvent to generate a salt-forming reaction to obtain 11α-chloromethyoxytetracycline p-toluenesulfonate. The invention can be widely used in the technical field of veterinary medicine.

Owner:SHANDONG GUOBANG PHARMA +1

Natural beta-carotene fermentation production process

PendingCN112961897AIncrease productivityGuaranteed purityFungiMicroorganism based processesBiotechnologyBeta-Carotene

The invention discloses a natural beta-carotene fermentation production process. The fermentation production process comprises the following steps of 1, preparing a certain amount of blakeslea trispora and a fermentation culture medium; and 2, activating blakeslea trispora, inoculating the blakeslea trispora into the fermentation culture medium, and controlling culture conditions to obtain fermentation liquor. The production process has the beneficial effects that by reasonably controlling the fermentation conditions of the blakeslea trispora and the extraction process of the beta carotene, the production efficiency of the beta carotene is effectively improved, and in addition, the purity of the beta carotene is ensured, so that the beta carotene is higher in nutritional value and better in effect; and by strictly controlling the extraction process after fermentation of beta carotene, the discharge of production wastewater is effectively avoided, and in addition, the reutilization of slag liquid after extraction is realized, and the process is more economical and environment-friendly.

Owner:衢州市锦润化工有限公司

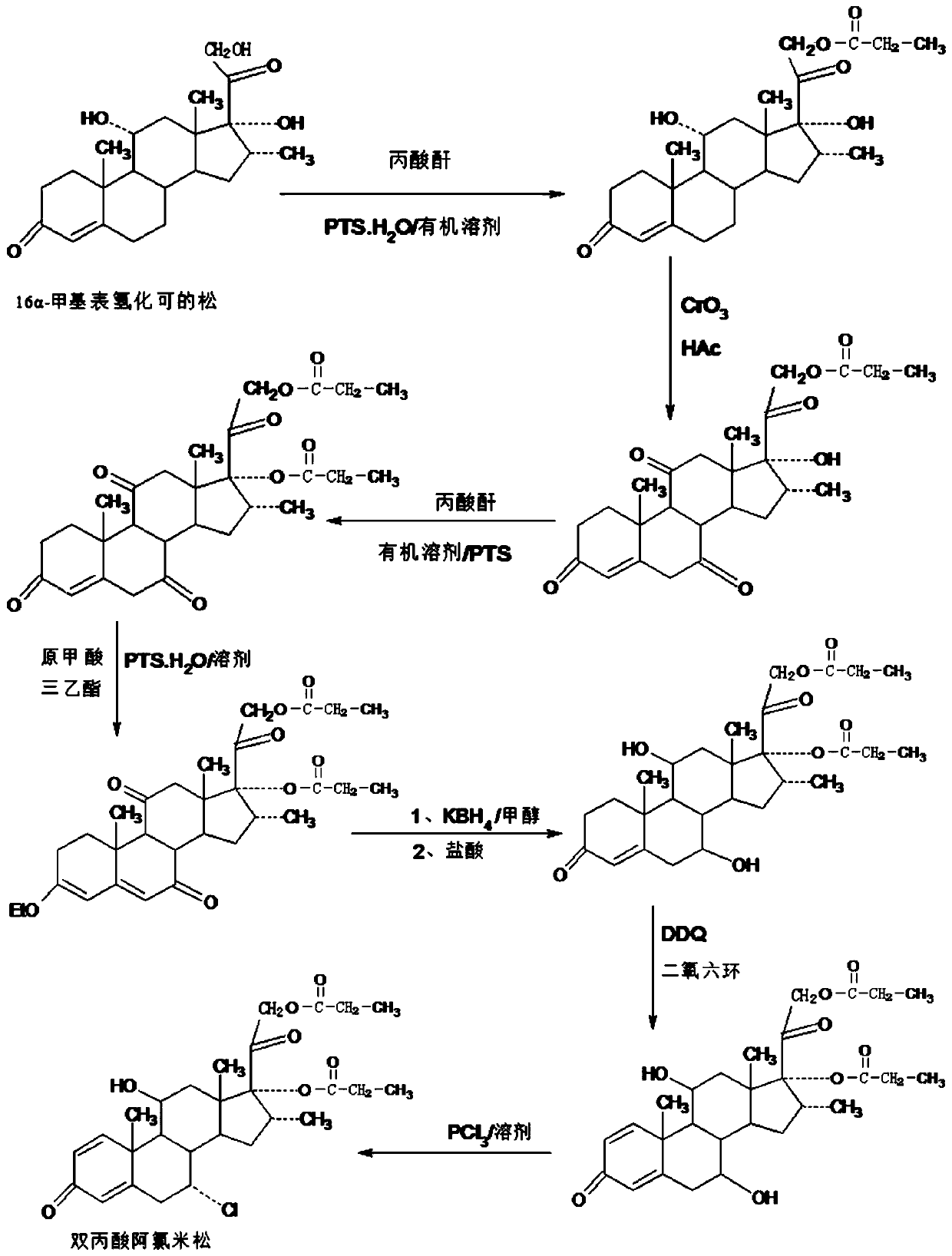

A kind of method for preparing aclomethasone dipropionate

ActiveCN109678920BShort synthetic routeProcess economy and environmental protectionSteroidsPropanoic acidHydrocortisone

The invention provides a method for preparing alclometasone dipropionate. According to the method, alclometasone dipropionate is synthesized by the following seven reaction steps: esterification of 16a-methyl epihydrocortisone as a raw material with propionic acid at position 21; double-oxidization at positions 7 and 11 to obtain diketone; esterification with propionic acid at position 17; enolization and etherification protection at position 3; reduction and acid hydrolysis for deprotection with diketone at positions 7 and 11; dehydrogenation with DDQ (Dichlorodicyanobenzoquinone) at position1; and chlorine substitution at position 7. According to the method for preparing alclometasone dipropionate, the alclometasone dipropionate is synthesized by taking 16a-methyl epihydrocortisone as the raw material through seven steps; compared with a convention method with dexamethasone fluoroacetate as the raw material, the process has the advantages of short synthetic route and economy and environmental protection, simple production and operation, high product yield and the like; in the alclometasone dipropionate produced with the method, the total synthetic yield is increased from original 2.678% to 32-35%, the production cost is less than 20% of that of the traditional method; the solvent used in production can be recycled and reused; the industrial production is easy to implement.

Owner:HUNAN KEREY BIOTECH

A new process for the synthesis of methyl benzoylformate

ActiveCN106242967BLow priceNo pollution in the processOrganic compound preparationCarboxylic acid esters preparationTert butyl phenolBenzoylformic acid

The invention relates to a brand new synthesis technology of a photoinitiator and herbicide metamitron intermediate methyl benzoylformate. The technology has not been reported in literatures. The technology comprises the following steps: acetophenone used as an initial raw material reacts with methyl nitrite under the action of hydrogen chloride to obtain 2,2-dimethoxyacetophenone, 2,2-dimethoxyacetophenone undergoes chlorine chlorination (or bromine bromination) under the catalysis action of a catalyst 4-methyl-2,6-di-tert-butyl phenol, and a molecule of haloalkane is removed from the chlorinated or brominated 2,2-dimethoxyacetophenone to obtain methyl benzoylformate. Influences of hydrogen chloride on the production of 2,2-dimethoxyacetophenone in the reaction and influences of the catalyst 4-methyl-2,6-di-tert-butyl phenol on the production of methyl benzoylformate are researched to determine the optimal conditions of the production of methyl benzoylformate. The new technology provided by the invention is simple to operate, and is economical.

Owner:HUAIHUA JINXIN NEW MATERIAL CO LTD

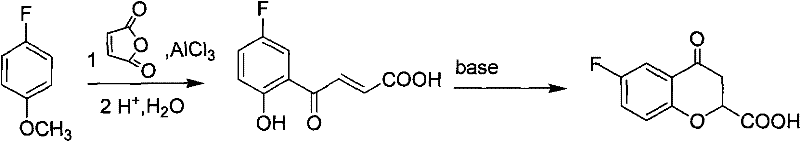

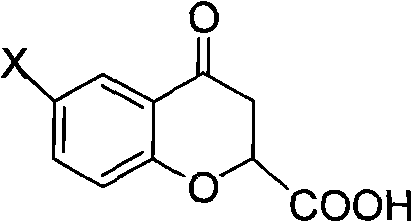

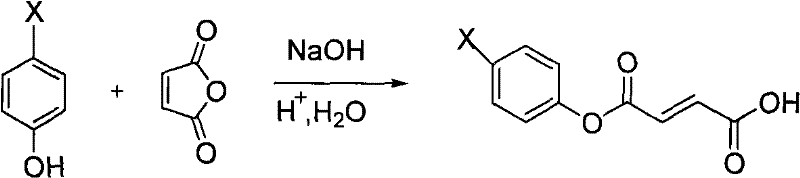

Preparation of 6-substituted-4-chromanone-2-carboxylic acid

InactiveCN101475551BReduce usageIncreased toxicityOrganic chemistrySodium bicarbonateCarboxylic acid

The invention discloses a method for preparing a 6-substituted-4-chromanone-2-methanoic acid. The method uses phenol or derivatives thereof, and maleic anhydride as raw materials. The method comprises the following steps: 1) phenol esterification, in which, the phenol or the derivatives thereof react with the maleic anhydride under base catalysis; 2) carboxyl esterification, in which, 3-(4-substituted phenyl)-3-keto-2-crotonic acid is dissolved in an organic solvent I, and an esterification catalyst and ethanol are added to the mixed solvent to react; 3) Fries recomposition, in which, the 3-(4-substituted phenyl)-3-keto-2-crotonic acid and aluminum trichloride are mixed to react; and 4) Michael addition, in which, the 3-(4-substituted phenyl)-3-keto-2-crotonic acid reacts with a sodium bicarbonate solution. The method for preparing the 6-substituted-4-chromanone-2-methanoic acid has the characteristics of simple and safe operation and low production cost.

Owner:ZHEJIANG NORMAL UNIVERSITY

A kind of method for preparing alclomethasone dipropionate by intermediate after etherification

ActiveCN109796514BShort synthetic routeProcess economy and environmental protectionSteroidsDexamethasone acetatePropanoic acid

The invention provides a method for preparing alclometasone dipropionate by using an etherified intermediate. According to the method, the etherified intermediate 3-vinyl alcohol ether-16a-methyl-17a,21-bipropionyloxy-pregna-3,5-diene-7,11,20-triketone serves as the raw material and is reduced with 7-site and 11-site diketone and subjected to three reactions including acid hydrolysis deprotection,1-site DDQ dehydrogenation and 7-site chlorine substitution, and then alclometasone dipropionate is synthesized. According to the method, the etherified intermediate 3-vinyl alcohol ether-16a-methyl-17a,21-bipropionyloxy-pregna-3,5-diene-7,11,20-triketone serves as the raw material, alclometasone dipropionate is synthesized through three steps of reactions, compared with a traditional method using de-fluorated dexamethasone acetate as the raw material, the technology has the advantages that a synthetic route is short, the process is economical and environmentally friendly, the production operation is simple and convenient and the product yield is high; solvents used during production can be recycled, and industrial production is easy to implement.

Owner:HUNAN KEREY BIOTECH

A kind of method for preparing dehydromethyltestosterone product

ActiveCN109456378BWide variety of sourcesProcess economy and environmental protectionSteroidsBiotechnologyPlant sterol

Owner:HUNAN KEREY BIOTECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com