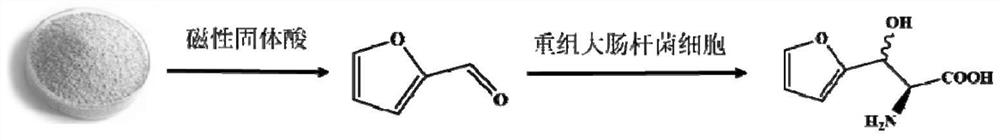

A kind of method that biomass chemical-enzymatic method prepares L-furanserine

A technology of furanserine and glycine, which is applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc., to achieve good biocompatibility, simple steps, economical and environmentally friendly processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

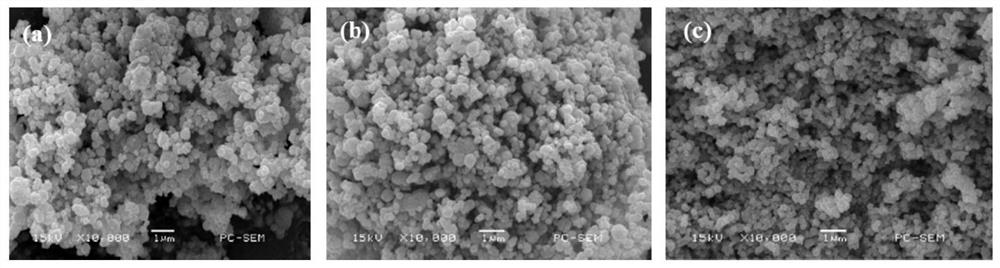

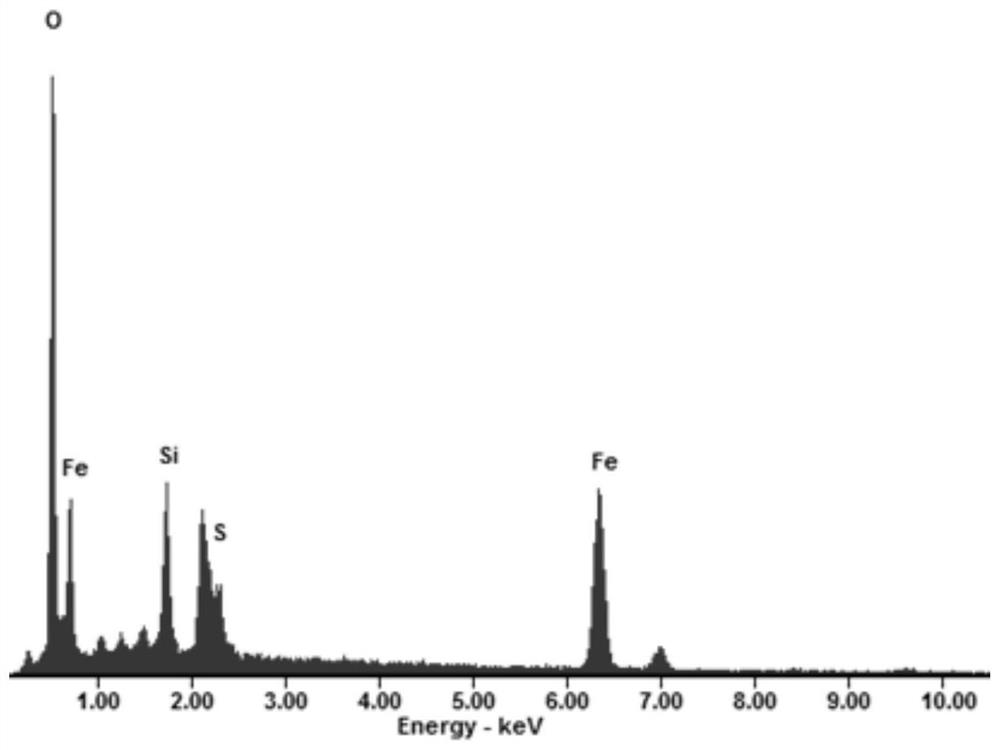

[0039] Example 1 Solid Acid Fe 3 O 4 @ MCM-41 / SO 4 2– Preparation

[0040] Magnetic solid acid Fe 3 O 4 @ MCM-41 / SO 4 2– Preparation as follows:

[0041] (1) Put FECL 3 · 6h 2 O and FECL 2 · 4h 2 O Dissolve in the stirred reactor, where Fe 3+ FE 2+ The molar ratio is 2.0: 1.1. Under nitrogen protection, heated to 85 ° C, stirring with NH at a high speed of 1000R / min. 3 · H 2 O Solution to the reaction liquid pH of 11, separating the deposited product by the magnetic field, ie gave Fe 3 O 4 Magnetic particles.

[0042] (2) mixing the fly ash material and mass fraction of 20% hydrochloric acid in mass ratio of 1:10, stirred at 80 ° C for 4 h, remove impurities such as iron, calcium, then filtered, washed, dried to obtain pretreatment powder coal ash. The sodium hydroxide is then uniformly mixed with the pre-treated fly as average of 1: 2, and heated at 550 ° C for 1 h. The resulting alkali flour coal ash was mixed with deionized water at a ratio of 1: 4, stirred at room temp...

Embodiment 2

[0046] Example 2 Solid acid Fe 3 O 4 @ MCM-41 / SO 4 2– Catalytic corn core prepared

[0047] 100 mL of deionized water, 10 g of corn core, and final concentration 22 g / l, for the magnetic solid acid Fe 3 O 4 @ MCM-41 / SO 4 2– The high pressure reactor was rapidly heated to 180 ° C and stirred for 40 min by electrical heating sleeve. After the reaction, the reactor was immediately soaked in an ice water bath to cool to room temperature.

[0048] After testing, the concentration of furfural after the reaction was 72 mm.

Embodiment 3

[0049] Example 3 Biomass furfural a pot method synthesized L-furan alkine

[0050] The recombinant L-threonine aldolase whole cells were prepared as follows: the engineering of L-threonine aldolase genes (the construction method of engineering bacteria) is as follows: gong, l., et al.applied Biochemistry andbiotechnology , 2020.DOI: ORG / 10.1007 / S12010-020-03447-Y) vaccinated to 50 μg · ml –1 The lb liquid medium of kanamycin was cultured at 37 ° C overnight. Then inoculate the amount of inoculated by 1% (volume concentration) to 50 μg · ml –1 In LB liquid medium of kanamycin, 37 ° C, 180 rpm culture to a bacterial concentration OD 600 In 0.6-1.0, IPTG of 0.2 mm was added, 25 ° C induced 10 h, 4 ° C, 8000 rpm centrifuge 10 min to collect wet bacteria, that is, recombinant L-threonine aldolase whole cells, and enzyme activity assay The whole cell enzyme is affected by 4000-80000U / g.

[0051] 100 ml of deionized water, 10g corn coincinal powder, 2 wt% magnetic solid acid Fe 3 O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com