Continuous purification process and device for detonation synthesized diamond

A synthetic diamond, continuous technology, applied in the field of continuous purification process and its device, can solve the problems of increasing harmful gas emissions, high energy consumption in the heating stage, low utilization rate of oxidants, etc. Effect of Reaction Efficiency and Perchloric Acid Utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

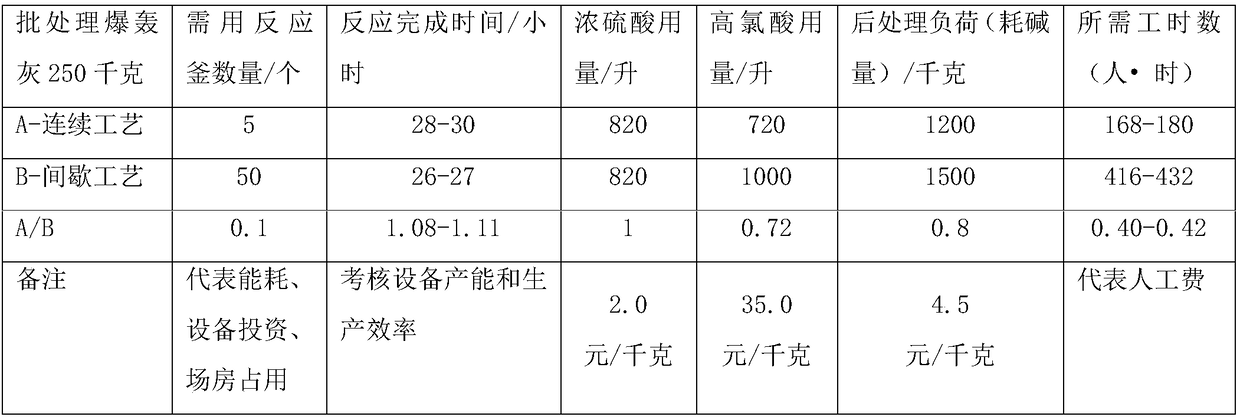

Embodiment 1

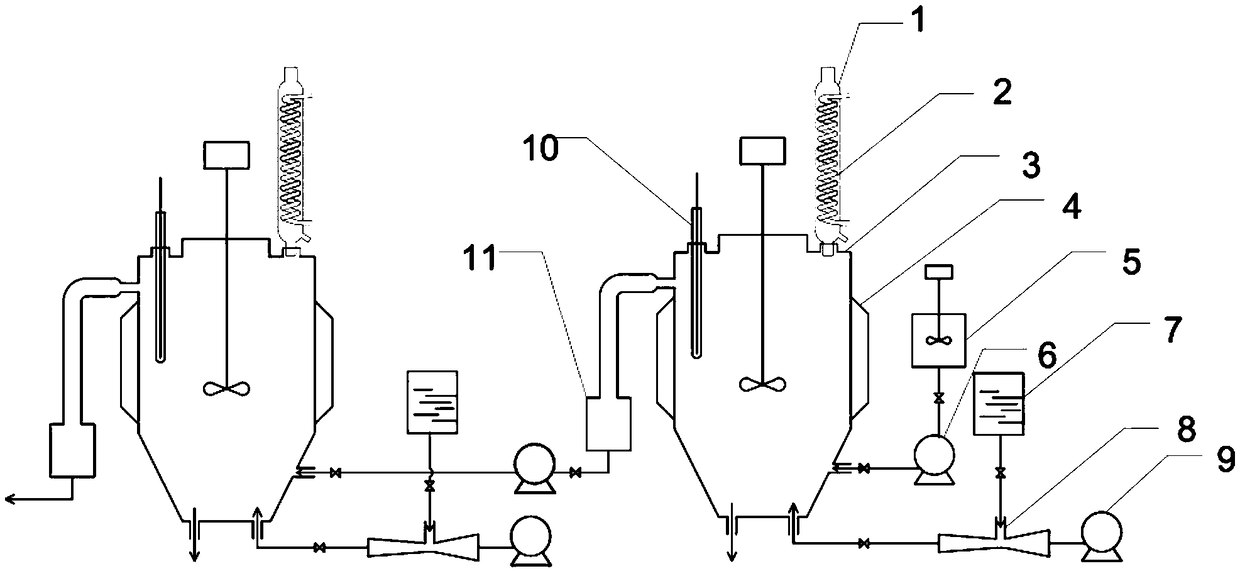

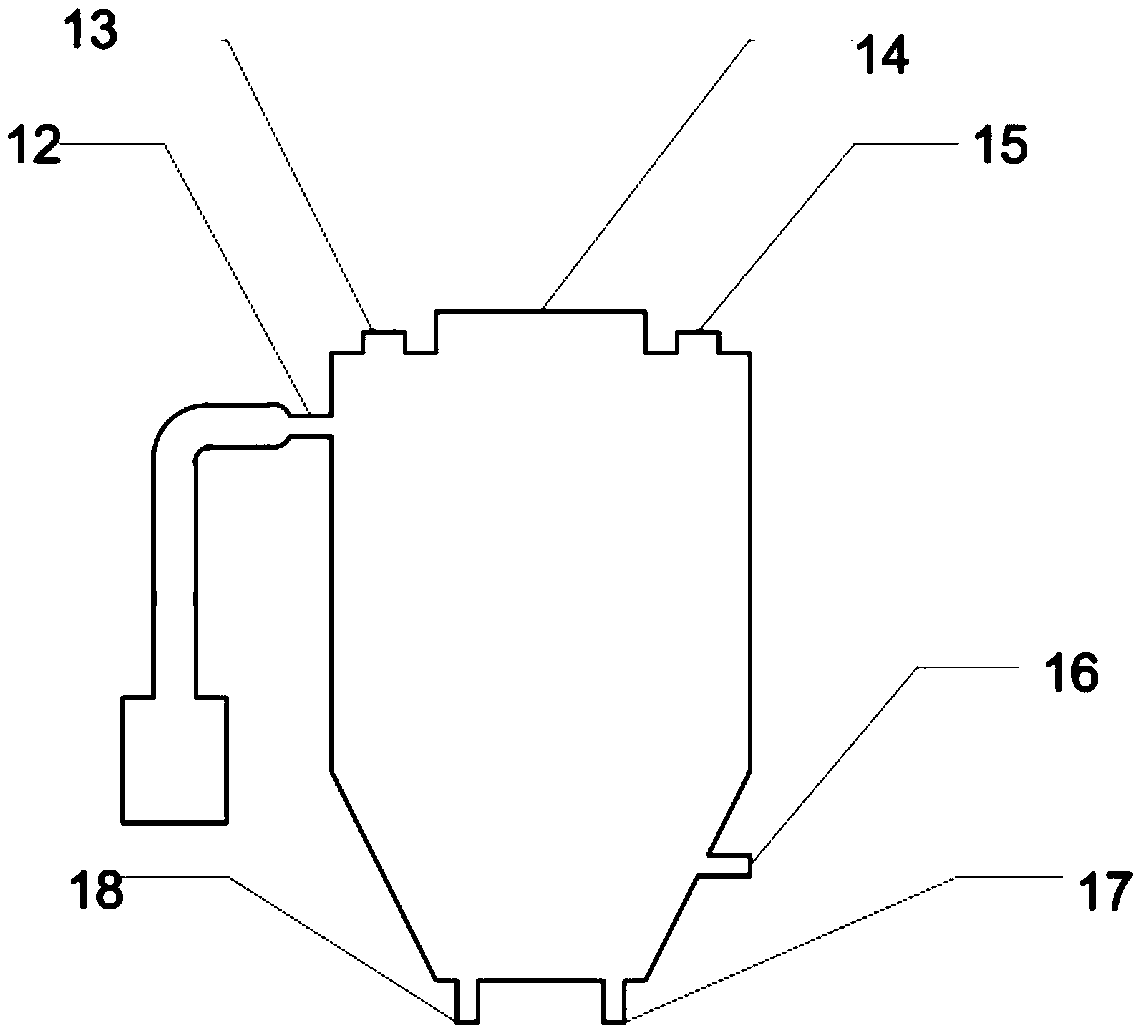

[0038] refer to figure 1 , figure 2 :

[0039] (1) with reaction solution:

[0040] Materials and specifications: detonation ash - dry powder; concentrated sulfuric acid - 95-98% chemically pure or industrial product; perchloric acid - 70-72% chemically pure.

[0041] (2) Feeding reaction:

[0042] Mix the detonation ash and concentrated sulfuric acid in the acid slurry storage tank 5 according to the ratio to form a slurry, and use the diaphragm pump 6 to pump the raw material inlet 16 into the kettle body 3 according to a certain flow rate, and the flow rate is controlled according to the processing capacity of the material And the capacity setting of reactor; Perchloric acid utilizes Venturi tube 8 to inject from perchloric acid feed port 17 at the bottom of reactor by perchloric acid storage tank 7 according to material ratio, is connected to stirring device interface 14 by dispersion stirring The device 1 stirs the mixture evenly to fully generate the oxidation reactio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com