Micron flaky silver grains and production method thereof

A manufacturing method and micron-level technology, applied in the direction of adhesive additives, electrical components, circuits, etc., can solve the problems of energy consumption, different specifications of micron-level flaky silver particles, high environmental load, etc., to improve complex, The effect of economical and environmentally friendly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] In this example, 10 g of silver nitrate was dissolved in 100 mL of pure water, and then 10 mL of 67 weight percent (wt %) concentrated nitric acid was added to form an acidic (pH<2) silver nitrate aqueous solution. Next, 3 g of a polyethylene glycol (MW=20000) surfactant solution was added to the acidic silver nitrate solution, and the mixture was appropriately stirred to disperse it uniformly to prepare a mixed solution (A).

[0031] In addition, 10 g of ascorbic acid or its derivatives (eg, its salts) were dissolved in 50 mL of deionized water to prepare a reducing agent solution (B).

[0032] Next, after adjusting the temperature of the above-mentioned two solutions to 30° C. with a heating device, the reducing agent solution (B) was poured into the mixed solution (A) and reacted for about 10 minutes. After that, the upper layer liquid was removed to separate the micron-sized flake silver particles. Then, the micron-sized flake silver particles are washed several ti...

Embodiment 2 to 8

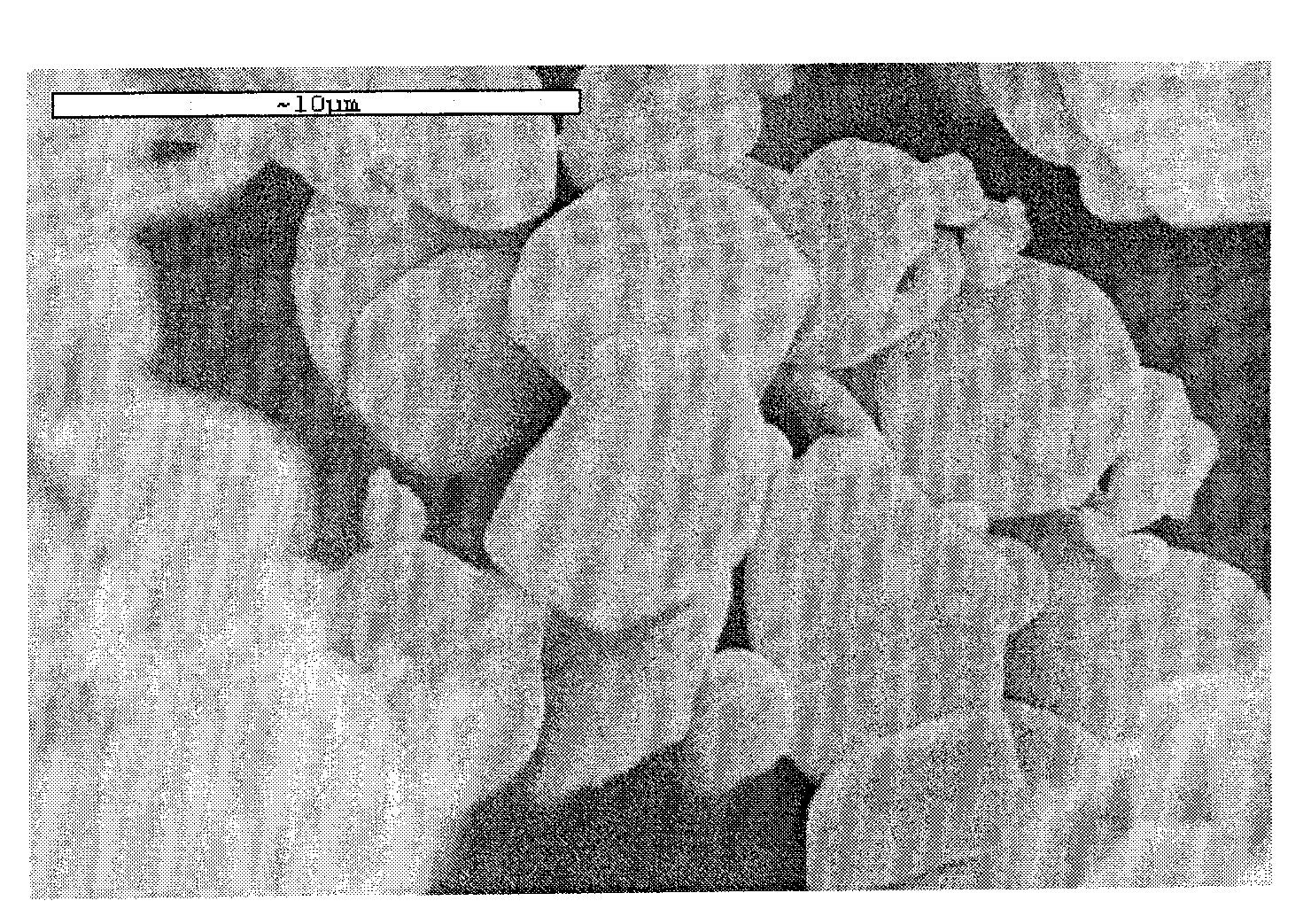

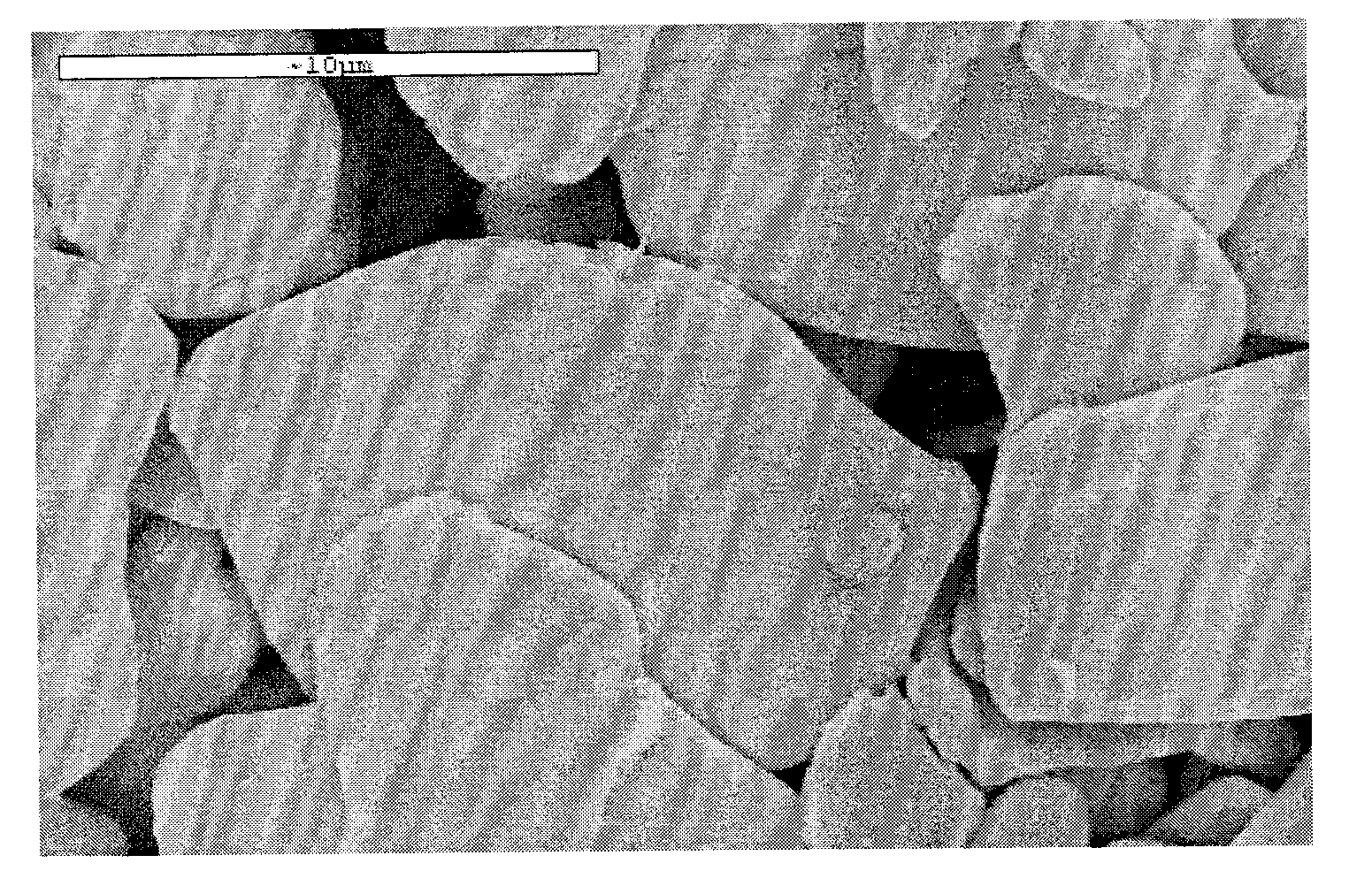

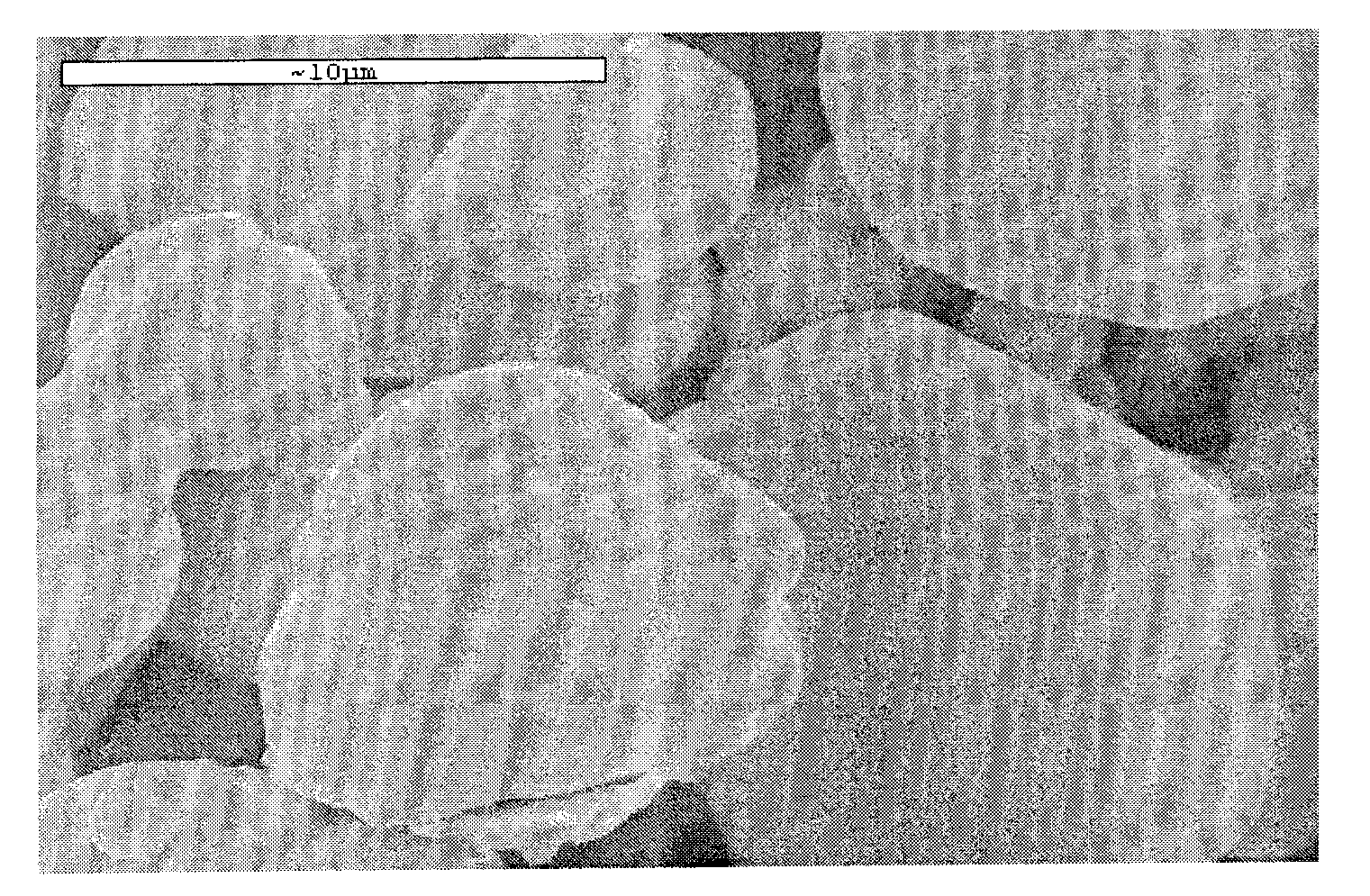

[0034] With the manufacture method of the micron-level flaky silver grains of embodiment 1, difference is that embodiment 2 to 8 change the kind, usage amount and liquid phase reduction reaction temperature of composition, and its formula and detection result are such as table 1 and Figure 2 to Figure 8 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com