Manufacturing method of modified graphite grounding body

A technology of graphite grounding body and manufacturing method, which is applied in the direction of contact manufacturing, connecting contact materials, etc., can solve problems such as resistance reduction and corrosion, and achieve the effects of improving flexibility, improving composite property, and improving low temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

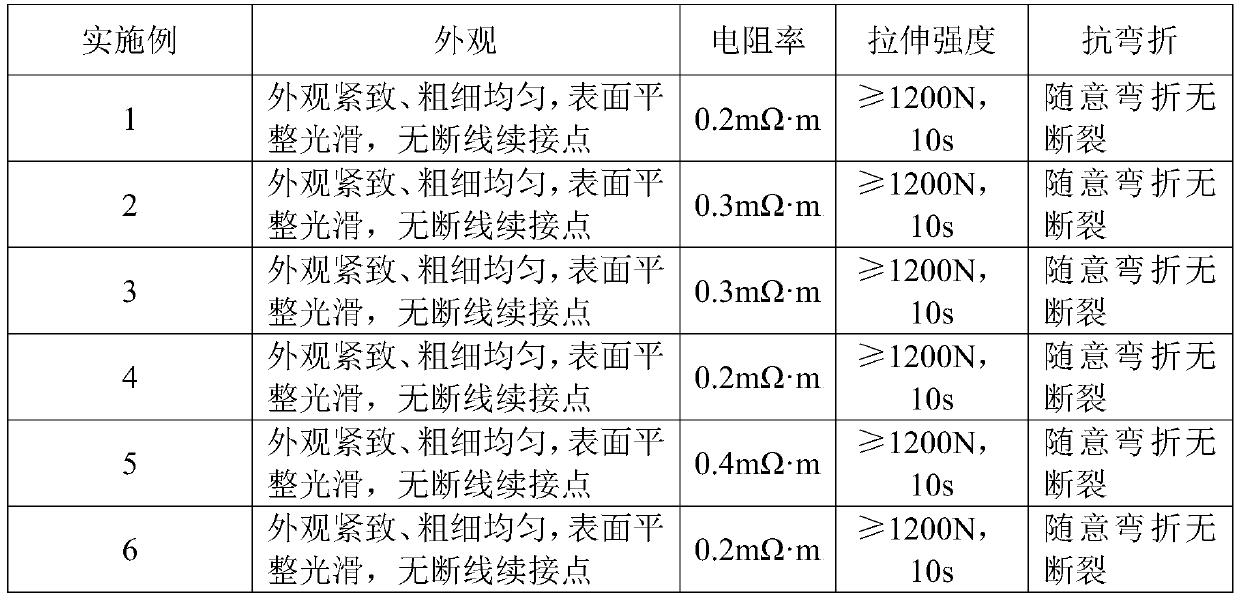

Embodiment 1

[0016] A kind of modified graphite provided by the present embodiment, its raw material comprises the following parts by mass of 28 parts of graphite with a carbon content≥95%, 5 parts of pitch, 8 parts of elastic resin, 8 parts of epoxy resin, 12 parts of carbon fiber and 2 parts of diacetone alcohol.

Embodiment 2

[0018] A kind of modified graphite provided by the present embodiment, its raw material comprises the following parts by mass of 20 parts of graphite with a carbon content≥95%, 4 parts of pitch, 7 parts of elastic resin, 8 parts of epoxy resin, 12 parts of carbon fiber and 3 parts of diacetone alcohol.

Embodiment 3

[0020] A kind of modified graphite provided by the present embodiment, its raw material comprises the following parts by mass of 25 parts of graphite with a carbon content≥95%, 6 parts of pitch, 8 parts of elastic resin, 7 parts of epoxy resin, 14 parts of carbon fiber and 4 parts of diacetone alcohol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com