Continuous energy-saving NMP (N-methyl pyrrolidone) production method

A production method, monomethylamine technology, applied in the field of continuous energy-saving production of NMP (N-methylpyrrolidone), can solve the problems of low flash point of pure monomethylamine, unrecoverable waste water, low safety, etc. High efficiency, energy saving, high degree of automation, and continuous effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

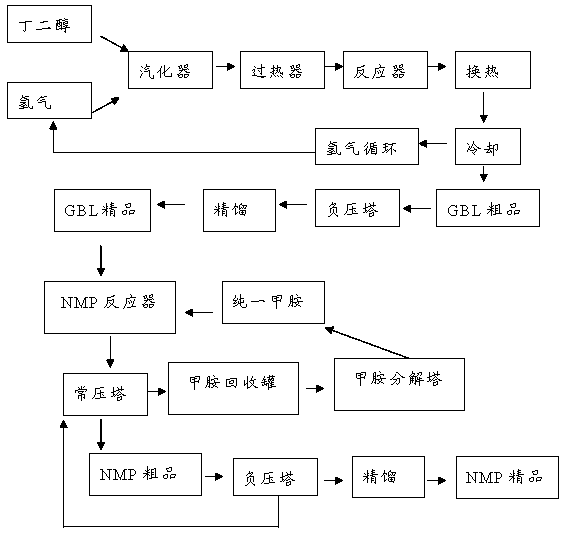

Image

Examples

Embodiment 1

[0035] Controlled by DCS, including the lactone section and the alkanone section, the detailed steps are,

[0036] The lactone section: firstly, the butanediol is preheated by the tail gas of the preheating coil, heated to 80°C, and the hydrogen gas is heated from normal temperature to 160°C by using the gas phase material from the reactor through the hydrogen preheater, and then the gas phase The material passes through the butanediol heat exchanger and uses the gas phase material from the reactor to reheat the butanediol to 130°C; then enters the vaporizer in the same direction, the molar ratio of hydrogen to alcohol is 10:1, the vaporization temperature: 190°C, and the pressure: 0.06Mpa ;After the butanediol is completely vaporized, it enters the superheater and is heated by heat transfer oil. The temperature of the superheater is 210°C and the pressure is 0.06Mpa; 2 o3 ) in the presence of the reaction, the temperature of the reactor is 220 ° C, the pressure: 0.06Mpa; the ...

Embodiment 2

[0039] Controlled by DCS, including the lactone section and the alkanone section, the detailed steps are,

[0040] The lactone section: first preheat the butanediol with exhaust gas from the preheating coil and heat it to 90°C, then heat the hydrogen gas from normal temperature to 180°C with the gas phase material from the reactor through the hydrogen preheater, and then the gas phase The material passes through the butanediol heat exchanger and uses the gas phase material from the reactor to reheat the butanediol to 130°C; then enters the vaporizer in the same direction, the molar ratio of hydrogen to alcohol is 5:1, the vaporization temperature: 210°C, and the pressure: 0.09Mpa ; After the butanediol is completely vaporized, it enters the superheater and is heated by heat transfer oil. The temperature of the superheater is 230°C and the pressure is 0.09Mpa; 2 o 3 ) in the presence of the reaction, the temperature of the reactor is 250 ° C, the pressure: 0.09Mpa; the mixture...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com