A method for recovering rare earth and aluminum from the leaching solution of weathering crust elution type rare earth ore to remove impurities

A weathering crust leaching type and leachate technology, which is applied in the field of hydrometallurgy, can solve the problems of rare earth loss and other problems, achieve the effects of less impurity content, low production cost, and avoid waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

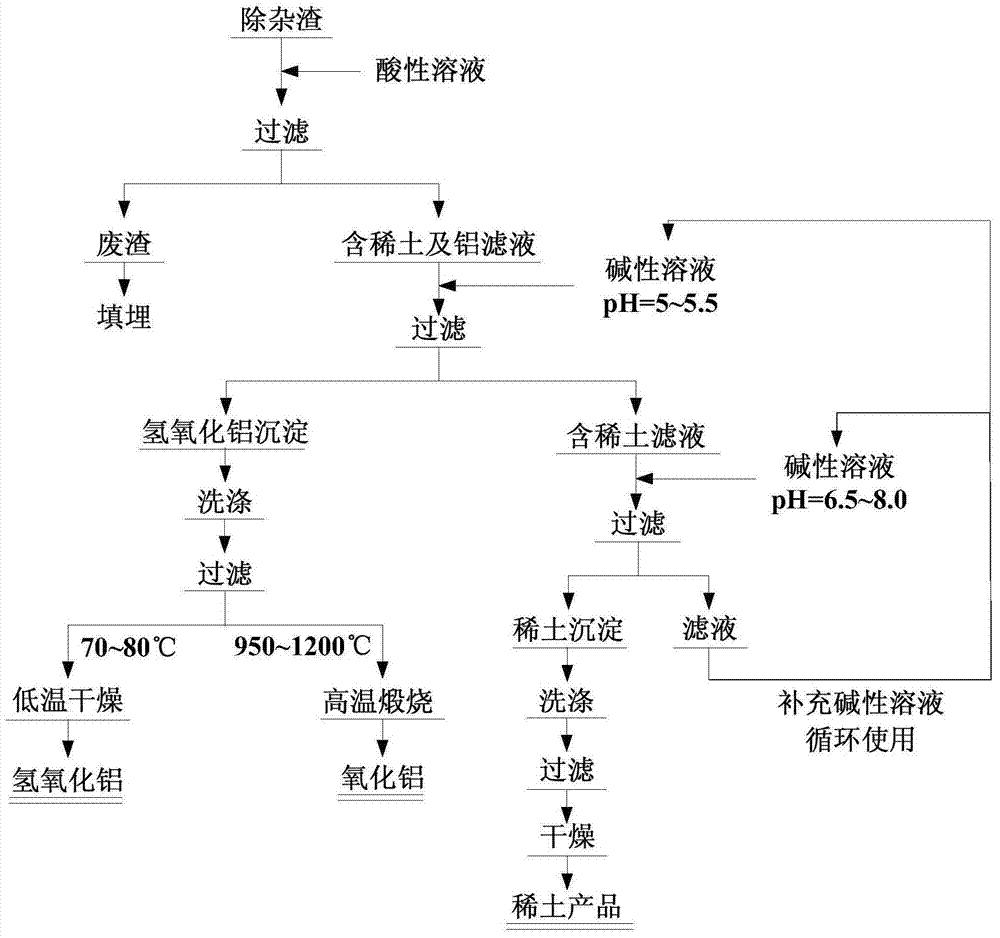

Image

Examples

Embodiment 1

[0030] A weathering crust leaching type rare earth mine in Guangdong, the rare earth composition is medium yttrium rich in europium, and the average grade of rare earth is RE 2 o 3 0.078%, the in-situ leaching process is adopted, and ammonium sulfate is used as the leaching agent to extract rare earths. After the collected rare earth leaching solution was removed by saturated ammonium bicarbonate solution, the rare earth and aluminum accounted for 4wt% respectively in the generated impurity removal residue (RE 2 o 3 ) and 50wt% (Al 2 o 3 ). Take 500g of this impurity-removing residue, slowly add 1000mL of sulfuric acid solution with a concentration of 10wt% at a liquid-solid ratio of 2mL / g, control the temperature at 30°C and keep stirring, and filter when the precipitate no longer decreases (about 4h). Landfill the filter residue, and slowly add saturated ammonium bicarbonate solution to the obtained filtrate, control the pH value to 5.0, and filter when the white floccu...

Embodiment 2

[0032] A weathering crust leaching type rare earth mine in Guangdong, the rare earth composition is medium yttrium rich in europium, and the average grade of rare earth is RE 2 o 3 0.085%, the heap leaching process is adopted, and ammonium sulfate is used as the leaching agent to extract the rare earth. After the collected rare earth leaching solution is removed by saturated ammonium bicarbonate solution, the rare earth and aluminum account for 2wt% respectively in the generated impurity removal residue (RE 2 o 3 ) and 32wt% (Al 2 o 3 ). Take 500g of this impurity removal residue, slowly add 750mL of nitric acid solution with a concentration of 1wt% at a liquid-solid ratio of 1.5mL / g, control the temperature at 20°C and keep stirring, and filter when the precipitate no longer decreases (about 6h) , the filter residue is landfilled, and the obtained filtrate is slowly added to it with ammonia solution (mass concentration is 25-28%), the pH is controlled at about 5.2, and w...

Embodiment 3

[0034] A weathering crust leaching-type rare earth ore in Jiangxi, the rare earth composition is yttrium-rich type, and the average grade of rare earth is RE2 o 3 0.093%, the in-situ leaching process is adopted, and ammonium sulfate is used as the leaching agent to extract rare earths. After the collected rare earth leaching solution was removed by saturated ammonium bicarbonate solution, the rare earth and aluminum accounted for 5wt% respectively in the generated impurity removal residue (RE 2 o 3 ) and 20wt% (Al 2 o 3 ). Take 500g of this impurity-removing residue, slowly add 250mL of hydrochloric acid solution with a concentration of 8wt% to it at a liquid-solid ratio of 0.5mL / g, control the temperature at 70°C and keep stirring, and filter when the precipitate no longer decreases (about 8h) , landfill the filter residue, and slowly add saturated sodium hydroxide solution to the obtained filtrate, control the pH at about 5.5, filter when the white flocculent precipitate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com